Inventory control plays a crucial role in the success of manufacturing operations. Efficient management of inventory ensures that the right products are available at the right time, minimizing stockouts, optimizing production, and improving customer satisfaction.

However, traditional inventory control methods often suffer from limitations and inefficiencies that hinder operational performance.

Fortunately, the rise of automation is revolutionizing manufacturing operations and transforming the way inventory control is approached. By integrating automation technologies, such as robotics, IoT devices, and advanced analytics, manufacturers can streamline processes, improve accuracy, enhance efficiency, and achieve cost savings.

This article explores how automation is reshaping inventory control in manufacturing operations, delving into the key technologies driving automation, the advantages it offers, and the challenges and considerations that come with its implementation.

Furthermore, real-world case studies and success stories provide valuable insights and best practices for organizations looking to leverage automation in their inventory control strategies. As we look to the future, emerging trends and predictions shed light on the transformative impact that automation will have on the manufacturing landscape, paving the way for more agile, optimized, and customer-centric operations.

Let’s take a look at the table of content below:

- Significance of Inventory Control in Manufacturing Operations

- Automation as a game-changer in revolutionizing manufacturing operations

- Traditional Inventory Control Methods

- The Rise of Automation in Manufacturing Operations

- Key Applications of Automation in Inventory Control

- Advantages of Automation in Manufacturing Operations

- Challenges and Considerations in Implementing Automated Inventory Control

- Case Studies and Success Stories

- Future Trends and Predictions

- Frequently Asked Questions (FAQs) on Automation in Manufacturing Operations and Inventory Control

- Wrapping Up

- How Deskera Can Assist You?

Significance of Inventory Control in Manufacturing Operations

Inventory control plays a crucial role in the success and efficiency of manufacturing operations. It encompasses the processes and strategies employed to manage and track raw materials, work-in-progress (WIP), and finished goods within a manufacturing environment.

Effective inventory control ensures that the right materials are available at the right time, minimizes stockouts and overstocks, and optimizes production and distribution processes.

The ability to maintain accurate inventory levels is vital for meeting customer demand, reducing costs, improving profitability, and achieving a competitive edge in the market.

Current Challenges Faced in Traditional Inventory Control Methods

Traditional inventory control methods often rely on manual processes, including manual data entry, spreadsheet tracking, and physical counts. However, these methods are prone to human error, time-consuming, and lack real-time visibility into inventory levels. Some of the common challenges faced in traditional inventory control include:

- Inaccurate forecasting: Without sophisticated tools and data analytics, accurately predicting customer demand and inventory needs becomes difficult, leading to stockouts or excessive inventory.

- Poor inventory visibility: Manual tracking methods make it challenging to have real-time visibility into inventory levels across multiple locations, making it harder to manage stock efficiently.

- Inefficient replenishment processes: Manual order processing and reordering systems are slow and prone to errors, leading to delays in restocking critical inventory items.

- Increased carrying costs: Inaccurate inventory control can result in overstocking, leading to increased storage and holding costs, as well as the risk of obsolescence and waste.

- Lack of scalability: Traditional inventory control methods may struggle to keep pace with the growing complexity and scale of modern manufacturing operations, limiting scalability and adaptability.

Automation as a game-changer in revolutionizing manufacturing operations

Automation has emerged as a transformative solution to overcome the limitations of traditional inventory control methods in manufacturing operations.

By leveraging advanced technologies and software systems, automation streamlines and optimizes inventory control processes, leading to improved accuracy, efficiency, and cost-effectiveness.

Automation enables real-time data collection, analysis, and decision-making, enhancing inventory visibility, demand forecasting, order processing, and supply chain optimization. By automating inventory control and implementing an IoT development team, manufacturers can achieve higher productivity, reduce waste, lower costs, and improve overall operational performance.

In the following sections, we will delve deeper into the key applications and advantages of automation in inventory control, discuss the challenges in implementing automated systems, highlight successful case studies, explore future trends, and emphasize the importance of embracing automation for sustainable and competitive manufacturing operations.

Traditional Inventory Control Methods

Following, we've thoroughly discussed traditional inventory control methods. Let's learn:

A. Description of manual inventory management systems:

Manual inventory management systems rely on human effort and physical documentation to track and manage inventory. These systems typically involve manual data entry, paper-based records, and periodic physical counts of inventory items. Key components of manual inventory management systems include:

Spreadsheets: Inventory data is often recorded and tracked using spreadsheet software such as Microsoft Excel. Data entry is done manually, and formulas are used to calculate inventory quantities, reorder points, and other relevant metrics.

Paper-based records: Physical documents, such as purchase orders, receiving reports, and stock cards, are used to record inventory transactions. These records are manually updated whenever inventory is received, issued, or transferred.

Periodic physical counts: Inventory accuracy is determined by periodically conducting physical counts of all inventory items. These counts involve manually counting each item and comparing the results to the recorded quantities.

B. Limitations and drawbacks of traditional inventory control methods:

Traditional inventory control methods suffer from several limitations and drawbacks, including:

Time-consuming processes: Manual data entry, paperwork, and physical counts require significant time and effort, leading to delays and inefficiencies in inventory management.

Human error: Relying on manual processes increases the risk of human error, such as data entry mistakes, misplaced or lost documents, and inaccurate counts, resulting in incorrect inventory records.

Lack of real-time visibility: Manual inventory control systems often lack real-time visibility into inventory levels, making it difficult to promptly identify stockouts, overstocks, or discrepancies.

Inefficient forecasting: Without advanced analytical tools, manual systems struggle to accurately forecast demand, leading to stockouts or excessive inventory.

Poor decision-making: Manual systems provide limited data analysis capabilities, hindering effective decision-making regarding inventory replenishment, production planning, and optimizing supply chain operations.

C. Examples of common issues and inefficiencies experienced in traditional inventory control:

Stockouts and overstocks: Inaccurate inventory tracking can result in stockouts, leading to lost sales and dissatisfied customers. Conversely, overstocking ties up capital, incurs storage costs, and increases the risk of obsolescence.

Inefficient order processing: Manual order processing and reordering can be time-consuming and prone to errors, leading to delays in fulfilling customer orders and replenishing inventory.

Lack of coordination: In multi-location or multi-channel operations, manual inventory control systems may struggle to maintain coordination and visibility across different sites, warehouses, or sales channels.

Increased carrying costs: Inaccurate inventory control can lead to unnecessary carrying costs, including storage, insurance, and handling expenses, reducing profitability.

Ineffective demand forecasting: Manual systems often rely on historical data and intuition for demand forecasting, resulting in inaccurate predictions and inefficient inventory management.

Limited scalability: Traditional inventory control methods may lack the scalability to accommodate the growth and complexity of modern manufacturing operations, hindering expansion and adaptability.

Addressing these challenges and inefficiencies through automation is crucial to driving efficiency, accuracy, and competitiveness in manufacturing operations.

The Rise of Automation in Manufacturing Operations

Following, check the rise of automation in manufacturing operations. Let's check:

A. Explanation of automation and its integration into inventory control:

Automation refers to the use of technology and systems to perform tasks and processes with minimal human intervention. In the context of inventory control, automation involves the integration of various technologies and software systems to streamline and optimize inventory management processes. Automation can encompass a range of functions, such as data collection, analysis, decision-making, and execution of inventory-related tasks.

Automated inventory control systems leverage technologies like sensors, barcode scanning, data analytics, artificial intelligence (AI), machine learning (ML), and robotic process automation (RPA) to improve efficiency and accuracy. These systems integrate with other enterprise resource planning (ERP) and manufacturing execution systems (MES) to ensure seamless coordination between inventory management and production processes.

B. Overview of the key technologies driving automation in manufacturing operations:

Several key technologies drive automation in manufacturing operations and play a significant role in revolutionizing inventory control:

Internet of Things (IoT): IoT enables the connection of physical devices and sensors to the internet, allowing real-time tracking and monitoring of inventory. IoT devices can collect data on inventory levels, location, and condition, providing valuable insights for effective inventory control.

Barcode and RFID technology: Barcodes and radio frequency identification (RFID) tags enable automated identification and tracking of inventory items. Scanning barcodes or RFID tags with handheld or fixed scanners allows for quick and accurate data capture, reducing manual data entry errors.

Data analytics and AI/ML: Advanced analytics techniques and AI/ML algorithms can analyze large volumes of data, including historical sales data, supplier information, and market trends, to generate accurate demand forecasts, optimize inventory levels, and detect patterns for better decision-making.

Warehouse management systems (WMS): WMS software automates and optimizes warehouse operations, including inventory receiving, put-away, picking, and shipping. These systems improve inventory accuracy, enhance order fulfillment processes, and enable efficient warehouse layout and space utilization.

Robotic process automation (RPA): RPA involves the use of software robots or bots to automate repetitive and rule-based tasks. In inventory control, RPA can automate data entry, reconciliation, report generation, and other administrative processes, reducing manual effort and improving accuracy.

C. Benefits of implementing automated inventory control systems:

Implementing automated inventory control systems offers several benefits for manufacturing operations:

Improved accuracy and reduced human error: Automation minimizes human intervention, reducing the chances of errors in data entry, tracking, and inventory counts. This leads to more accurate inventory records and better decision-making.

Enhanced efficiency and productivity: Automation streamlines inventory management processes, such as data collection, order processing, and replenishment. This improves operational efficiency, reduces lead times, and increases overall productivity.

Cost savings and waste reduction: Automated inventory control systems optimize inventory levels, minimizing stockouts and overstocks. This reduces carrying costs, eliminates waste, and improves cash flow by aligning inventory with actual demand.

Increased visibility and transparency in inventory management: Automation provides real-time visibility into inventory levels, locations, and movement across multiple warehouses or sales channels. This enables proactive decision-making, improved demand planning, and better coordination across the supply chain.

Scalability and adaptability: Automated systems are scalable and flexible, capable of handling increased inventory volumes and adapting to changing business needs. They can accommodate the growth and complexity of manufacturing operations without significant manual effort.

By harnessing the power of automation, manufacturers can optimize inventory control processes, achieve operational excellence, and gain a competitive edge in the market. Automated inventory control systems enable manufacturers to meet customer demand efficiently, reduce costs, minimize risks, and drive sustainable growth.

Key Applications of Automation in Inventory Control

Check the important applications of automation in inventory control. Let's learn:

A. Automated data collection and tracking:

Automation enables the automated collection of data related to inventory, such as item details, quantities, locations, and movements. This is achieved through technologies like barcode scanning, RFID tagging, and IoT sensors.

By automating data collection, manufacturers can eliminate manual data entry errors, improve data accuracy, and save time. Automated data collection also facilitates real-time updates to inventory records, ensuring accurate and up-to-date information for decision-making.

B. Real-time inventory monitoring and management:

Automation allows for real-time monitoring and management of inventory levels. By integrating sensors and IoT devices, manufacturers can have instant visibility into inventory across multiple locations and warehouses.

This real-time information enables timely decision-making, such as initiating reorders, transferring inventory between locations, or adjusting production schedules based on stock availability. Real-time inventory monitoring also helps prevent stockouts, reduce excess inventory, and improve overall inventory accuracy.

C. Demand forecasting and predictive analytics:

Automation, coupled with advanced analytics and AI/ML algorithms, enables accurate demand forecasting and predictive analytics for inventory control. By analyzing historical sales data, market trends, customer behavior, and other relevant factors, automated systems can generate accurate demand forecasts.

This further helps manufacturers optimize inventory levels, align production capacity, and minimize stockouts or overstocks. Predictive analytics also assists in identifying patterns, trends, and anomalies, allowing proactive decision-making and efficient resource allocation.

D. Automated order processing and replenishment:

Automation streamlines the order processing and replenishment processes. When integrated with sales channels and ERP systems, automated inventory control systems can automatically process incoming orders, check inventory availability, and initiate replenishment based on predefined rules and thresholds.

This further reduces manual effort, minimizes order fulfillment delays, and ensures timely replenishment of inventory. Automated order processing also improves accuracy by eliminating human errors in order entry and ensures efficient coordination between sales and inventory management teams.

E. Optimization of supply chain and logistics:

Automation plays a crucial role in optimizing supply chain and logistics operations for inventory control. Automated systems can analyze inventory data, supplier performance, lead times, and transportation logistics to optimize sourcing decisions, supplier relationships, and delivery routes.

By automating inventory replenishment, production planning, and distribution processes, manufacturers can achieve cost-effective supply chain management. Automation also enables better coordination and visibility among suppliers, manufacturers, and distributors, leading to improved supply chain efficiency, reduced stockouts, and optimized inventory carrying costs.

By leveraging automation in these key applications, manufacturers can achieve higher accuracy, efficiency, and productivity in inventory control. Automation streamlines processes, enables real-time decision-making, and optimizes inventory levels, leading to improved customer satisfaction, cost savings, and competitive advantage in the market.

Advantages of Automation in Manufacturing Operations

Following, we've discussed the advantages of automation in manufacturing operations. Let's learn:

A. Improved accuracy and reduced human error:

Automation significantly reduces the reliance on manual data entry and manual processes, minimizing the chances of human error in inventory control. Automated systems capture data electronically, eliminating transcription errors and ensuring accurate and consistent data.

By reducing errors in tasks such as data entry, order processing, and inventory tracking, automation improves the overall accuracy of inventory records, leading to more reliable decision-making and minimizing costly mistakes.

B. Enhanced efficiency and productivity:

Automation streamlines and accelerates inventory control processes, leading to enhanced operational efficiency and increased productivity. With automation, tasks that were previously time-consuming and labor-intensive, such as data entry, physical inventory counts, and order processing, can be performed more quickly and accurately.

This further allows employees to focus on more value-added activities, such as analyzing data, making strategic decisions, and improving overall operational efficiency. By eliminating manual bottlenecks, automation optimizes workflows, reduces lead times, and improves throughput.

C. Cost savings and waste reduction:

Automated inventory control systems contribute to significant cost savings and waste reduction in manufacturing operations. By optimizing inventory levels, manufacturers can minimize overstocking and stockouts, reducing carrying costs and obsolescence risks. Automation enables accurate demand forecasting, helping manufacturers avoid excess inventory and associated costs.

Additionally, automated systems improve procurement processes, allowing manufacturers to negotiate better pricing and terms with suppliers. By reducing waste, optimizing inventory, and minimizing costs, automation enhances profitability and strengthens the financial health of manufacturing operations.

D. Increased visibility and transparency in inventory management:

Automation provides real-time visibility and transparency into inventory management. Through connected devices, sensors, and software systems, manufacturers gain instant access to accurate and up-to-date information about inventory levels, locations, and movements.

This visibility further allows for proactive decision-making, quick identification of potential issues, and efficient coordination across the supply chain. Real-time visibility also helps manufacturers respond promptly to changes in demand, optimize production schedules, and improve customer service by ensuring the availability of the right products at the right time.

By leveraging the advantages of automation in manufacturing operations, companies can achieve higher accuracy, efficiency, cost savings, and transparency in inventory control. Automation improves overall operational performance, enables faster and better decision-making, and enhances the competitiveness and profitability of manufacturing businesses.

Challenges and Considerations in Implementing Automated Inventory Control

Following, we've discussed the challenges and considerations associated with implementing automated inventory control. Let's learn:

A. Initial setup costs and integration challenges:

Implementing automated inventory control systems often requires significant upfront investment in hardware, software, and infrastructure. This includes purchasing or upgrading technology, such as barcode scanners, RFID readers, IoT devices, and inventory management software.

Additionally, integrating these systems with existing enterprise resource planning (ERP) or manufacturing execution systems (MES) can be complex and time-consuming. Organizations need to carefully evaluate the costs and benefits associated with implementing automation and ensure proper planning and budgeting to address the initial setup costs and integration challenges.

B. Workforce training and skill requirements:

Introducing automation in inventory control necessitates training employees on new technologies, software systems, and processes. Workforce training is essential to ensure that employees can effectively operate, maintain, and utilize the automated inventory control systems.

This may require additional investment in training programs or hiring personnel with the required skill set. Organizations need to assess the skill requirements, develop training plans, and provide ongoing support to enable employees to adapt to the new automated systems and fully leverage their capabilities.

C. Data security and privacy concerns:

Automation involves the collection, storage, and transmission of sensitive inventory data. Organizations must address data security and privacy concerns associated with automated inventory control systems.

This includes implementing robust cybersecurity measures, such as encryption, access controls, and regular system audits, to protect inventory data from unauthorized access, breaches, or theft. Compliance with data protection regulations, like the General Data Protection Regulation (GDPR) or industry-specific standards, is crucial to ensure the privacy and integrity of inventory data.

D. Maintaining flexibility and adaptability in automated systems:

While automation brings efficiency, organizations need to ensure that their automated inventory control systems remain flexible and adaptable to changing business needs. This includes the ability to accommodate fluctuations in demand, changes in product lines, introduction of new inventory items, and evolving supply chain dynamics.

Maintaining flexibility may require regular system updates, scalability considerations, and the ability to integrate with other technologies and systems. Organizations should carefully evaluate the flexibility and adaptability of the chosen automation solutions to ensure long-term viability and mitigate the risk of technology obsolescence.

By addressing these challenges and considerations, organizations can successfully implement automated inventory control systems. Proper planning, investment, training, and attention to data security and flexibility are crucial for a smooth transition to automated systems. The benefits of improved accuracy, efficiency, and visibility in inventory control outweigh the challenges, enabling organizations to achieve better inventory management and drive operational excellence in manufacturing operations.

Case Studies and Success Stories

Following, we've discussed case studies and success stories. Let's learn:

A. Examples of manufacturing companies successfully implementing automation in inventory control:

Tesla:

Tesla, the electric vehicle manufacturer, implemented automated inventory control systems to manage its complex supply chain and production operations. They leveraged automation technologies such as RFID tagging, barcode scanning, and real-time data analytics to track inventory, optimize order fulfillment, and improve supply chain visibility. By automating inventory management processes, Tesla reduced stockouts, improved production efficiency, and enhanced overall operational performance.

Amazon:

As a leading e-commerce and logistics company, Amazon has heavily relied on automation in its inventory control operations. Their fulfillment centers use a combination of robotics, IoT sensors, and advanced algorithms to automate inventory tracking, order processing, and fulfillment. Automation has allowed Amazon to handle large volumes of inventory efficiently, minimize errors, and offer fast delivery times. The company's success in automating inventory control has contributed to its reputation as a global leader in the e-commerce industry

B. Description of the outcomes and benefits achieved through automation:

Check the outcomes and benefits achieved through automation:

Improved accuracy and reduced errors:

By implementing automated inventory control systems, companies experience higher accuracy in inventory data and reduced errors compared to manual processes. Accurate inventory records enable better decision-making, minimize stockouts, and eliminate costly mistakes, leading to improved customer satisfaction and operational efficiency.

Enhanced efficiency and productivity:

Automation streamlines inventory management processes, resulting in improved efficiency and productivity. With automated data collection, real-time monitoring, and streamlined workflows, companies can optimize inventory replenishment, reduce manual effort, and allocate resources more effectively. This leads to higher throughput, faster order fulfillment, and increased overall productivity

Cost savings and waste reduction:

Automated inventory control systems contribute to cost savings and waste reduction. By optimizing inventory levels based on accurate demand forecasts, companies can reduce carrying costs associated with excess inventory. Automation also minimizes the risk of stockouts, ensuring that customers' orders are fulfilled on time and reducing the need for expedited shipping or lost sales.

Enhanced visibility and decision-making:

Automation provides real-time visibility into inventory levels, locations, and movements. This visibility enables companies to make data-driven decisions, respond quickly to changes in demand, and optimize supply chain operations. With automation, companies can better align inventory with customer demand, improve demand forecasting accuracy, and enhance coordination across the supply chain.

C. Lessons learned and best practices from real-world applications:

Check the important lessons learned and top practices from the real-world applications:

Thoroughly evaluate and plan for automation implementation:

Before implementing automation in inventory control, companies should conduct a comprehensive evaluation of their existing processes, identify pain points, and define clear objectives. This evaluation helps in selecting the most suitable automation technologies and systems for their specific needs. A well-planned implementation strategy ensures smoother integration, minimizes disruptions, and maximizes the benefits of automation.

Invest in workforce training and change management:

Automation requires employees to adapt to new technologies and processes. Providing comprehensive training programs and change management initiatives is crucial to ensure the successful adoption of automation. Training employees on how to operate the automated systems, interpret data insights, and utilize the new tools effectively helps maximize the value of automation.

Start with pilot projects and iterate:

Instead of attempting to automate all inventory control processes at once, starting with pilot projects can help companies validate the effectiveness of automation solutions. Piloting automation in specific areas allows for testing and fine-tuning before scaling up. Iterating and continuously improving the automated systems based on real-world feedback and insights ensure optimal performance and alignment with business goals.

Prioritize data security and privacy:

Automation involves the collection and management of sensitive inventory data. It is crucial for companies to prioritize data security and privacy. Implementing robust cybersecurity measures, ensuring compliance with relevant regulations, and regularly assessing and updating security protocols help safeguard inventory data and maintain customer trust.

By studying these case studies, understanding the outcomes achieved through automation, and adopting the lessons learned and best practices, companies can successfully implement automated inventory control systems and reap the benefits of improved accuracy, efficiency, and decision-making in their manufacturing operations.

Future Trends and Predictions

Following, we've discussed important future trends and predictions. Let's learn:

A. Emerging technologies shaping the future of inventory control automation:

Several emerging technologies are poised to shape the future of inventory control automation. These include:

Internet of Things (IoT): IoT devices and sensors will continue to play a crucial role in inventory control by providing real-time data on inventory levels, conditions, and locations. IoT-enabled devices can automate data collection and enable proactive decision-making based on real-time insights.

Blockchain: Blockchain technology has the potential to enhance transparency, traceability, and trust in supply chain management. By leveraging blockchain, manufacturers can securely track inventory movements, verify authenticity, and streamline transactions between stakeholders.

Robotics and Automation: The use of robotics and automation will expand in inventory control, particularly in warehouses and distribution centers. Robotic systems can handle repetitive tasks such as picking, packing, and sorting, improving speed and accuracy in inventory management.

Predictive Analytics and Big Data: Advanced analytics and big data capabilities will enable more accurate demand forecasting, inventory optimization, and proactive decision-making. Predictive analytics algorithms can analyze historical data, market trends, and customer behavior to forecast demand patterns and optimize inventory levels.

B. Integration of artificial intelligence and machine learning in inventory management systems:

Artificial intelligence (AI) and machine learning (ML) will increasingly be integrated into inventory management systems, enabling more intelligent and automated decision-making. AI-powered algorithms can analyze large volumes of data, identify patterns and anomalies, and provide recommendations for inventory optimization. ML models can learn from historical data and continuously improve accuracy in demand forecasting, inventory planning, and order fulfillment.

By leveraging AI and ML, inventory management systems can dynamically adjust reorder points, optimize safety stock levels, and predict potential supply chain disruptions. These technologies also enable predictive maintenance of automated systems, ensuring smooth operations and minimizing downtime.

C. Predicted impact of automation on future manufacturing operations:

The impact of automation on future manufacturing operations is expected to be significant. Some key predictions include:

Increased efficiency and productivity: Automation will streamline inventory control processes, leading to increased efficiency and productivity. By automating routine tasks, manufacturers can free up human resources to focus on more strategic activities, improving overall operational efficiency.

Enhanced supply chain visibility: Automation will provide real-time visibility into inventory levels, supply chain performance, and demand trends. This enhanced visibility will enable better coordination, faster response to changes, and improved collaboration among stakeholders in the supply chain.

Optimized inventory levels and reduced waste: Automation, coupled with advanced analytics, will enable accurate demand forecasting and optimization of inventory levels. Manufacturers will be able to minimize stockouts, reduce excess inventory, and optimize carrying costs, resulting in reduced waste and improved profitability.

Seamless integration with other systems: Automated inventory control systems will seamlessly integrate with other systems, such as ERP, MES, and sales platforms, creating a unified and interconnected ecosystem. This integration will enable streamlined data flow, efficient order processing, and improved synchronization of inventory management with production planning and customer demands.

Customization and personalization: Automation will enable manufacturers to offer greater customization and personalization options to customers. By efficiently managing inventory and production processes, manufacturers can respond quickly to customer demands and deliver tailored products, leading to increased customer satisfaction and loyalty.

It's important to note that while automation offers significant benefits, its implementation should be accompanied by careful planning, continuous monitoring, and adaptability to ensure successful integration and mitigate any potential challenges or risks.

Frequently Asked Questions (FAQs) on Automation in Manufacturing Operations and Inventory Control

Following, we’ve discussed some common frequently asked questions (FAQs) associated with automation manufacturing operations and inventory control. Let’s learn:

Q1: What is automation in manufacturing operations?

A1: Automation in manufacturing operations refers to the use of technology, such as robotics, sensors, and software systems, to automate and streamline various tasks and processes involved in production, including inventory control. It aims to improve efficiency, accuracy, and productivity while reducing human effort and errors.

Q2: What are the benefits of implementing automated inventory control systems?

A2: Implementing automated inventory control systems offers several benefits, including improved accuracy and reduced human error, enhanced efficiency and productivity, cost savings and waste reduction, and increased visibility and transparency in inventory management. These benefits contribute to better decision-making, optimized inventory levels, and improved customer service.

Q3: How does automation improve accuracy and reduce human error in inventory control?

A3: Automation reduces the reliance on manual data entry and manual processes, minimizing the chances of human error. Automated systems capture data electronically, eliminating transcription errors and ensuring accurate and consistent data. By reducing errors in tasks such as data entry, order processing, and inventory tracking, automation improves the overall accuracy of inventory records and minimizes costly mistakes.

Q4: Can automation in inventory control lead to cost savings and waste reduction?

A4: Yes, automation in inventory control can lead to cost savings and waste reduction. By optimizing inventory levels based on accurate demand forecasts, manufacturers can minimize carrying costs associated with excess inventory. Automation also helps to reduce the risk of stockouts, ensuring that customer orders are fulfilled on time and reducing the need for expedited shipping or lost sales. By minimizing waste, optimizing inventory, and reducing costs, automation contributes to improved profitability.

Q5: How does automation enhance visibility and transparency in inventory management?

A5: Automation provides real-time visibility and transparency into inventory management. Through connected devices, sensors, and software systems, manufacturers gain instant access to accurate and up-to-date information about inventory levels, locations, and movements. This visibility allows for proactive decision-making, quick identification of potential issues, and efficient coordination across the supply chain. Real-time visibility helps manufacturers respond promptly to changes in demand, optimize production schedules, and improve customer service by ensuring the availability of the right products at the right time.

Q6: What are the key technologies driving automation in manufacturing operations?

A6: The key technologies driving automation in manufacturing operations include Internet of Things (IoT) devices and sensors, robotics and automation systems, advanced analytics and big data, artificial intelligence (AI), machine learning (ML), and blockchain. These technologies enable automated data collection, real-time monitoring, predictive analytics, intelligent decision-making, and secure data exchange, revolutionizing inventory control and overall manufacturing operations.

Q7: What are some real-world examples of companies successfully implementing automation in inventory control?

A7: Tesla and Amazon are two notable examples of companies successfully implementing automation in inventory control. Tesla utilizes automation technologies such as RFID tagging, barcode scanning, and real-time data analytics to track inventory and optimize supply chain operations. Amazon leverages robotics, IoT sensors, and advanced algorithms in its fulfillment centers to automate inventory tracking, order processing, and fulfillment. These companies have achieved improved accuracy, efficiency, and customer service through automation.

Q8: What are some best practices for implementing automation in inventory control?

A8: Some best practices for implementing automation in inventory control include thoroughly evaluating and planning for automation, investing in workforce training and change management, prioritizing data security and privacy, and maintaining flexibility and adaptability in automated systems. Starting with pilot projects, iterating based on feedback, and ensuring integration with other systems are also important best practices for successful implementation.

Q9: How will automation impact future manufacturing operations?

A9: Automation is predicted to have a significant impact on future manufacturing operations. It will lead to increased efficiency and productivity, enhanced supply chain visibility, optimized inventory levels, reduced waste, and seamless integration with other systems. Automation will enable manufacturers to respond quickly to customer demands, offer customization and personalization options, and create more agile and competitive operations.

Q10: What are the challenges in implementing automated inventory control?

A10: Some challenges in implementing automated inventory control include initial setup costs and integration challenges, workforce training and skill requirements, data security and privacy concerns, and maintaining flexibility and adaptability in automated systems. Overcoming these challenges requires careful planning, selecting the right technologies, providing adequate training, ensuring cybersecurity measures, and continually evaluating and adjusting automated systems to meet evolving needs.

Please note that the answers provided are for informational purposes only and may vary depending on the specific circumstances and technologies involved in each situation.

Wrapping Up

Automation is revolutionizing inventory control in manufacturing operations, bringing about significant improvements in accuracy, efficiency, and overall performance.

By leveraging technologies such as robotics, IoT devices, advanced analytics, and AI, manufacturers can optimize inventory management processes, enhance supply chain visibility, and make data-driven decisions.

The benefits of automation are far-reaching, including improved accuracy and reduced human error, enhanced efficiency and productivity, cost savings, and increased visibility in inventory management. Real-world case studies and success stories demonstrate the tangible outcomes achieved through automation, ranging from streamlined workflows and improved customer service to reduced waste and increased profitability.

However, implementing automation in inventory control also poses challenges that organizations must address. Considerations such as initial setup costs, workforce training, data security, and maintaining flexibility require careful planning and strategic approaches. By adopting best practices and lessons learned from successful implementations, manufacturers can navigate these challenges and maximize the potential of automation in inventory control.

Looking ahead, emerging technologies, such as IoT, AI, and blockchain, will continue to shape the future of inventory control automation. Predictions suggest increased efficiency, seamless integration with other systems, and greater customization and personalization options for customers.

The future of manufacturing operations lies in the intelligent and interconnected automation of inventory control, empowering organizations to optimize their supply chains, respond swiftly to changing demands, and deliver superior products and experiences.

In conclusion, the integration of automation in inventory control is revolutionizing manufacturing operations, unlocking new levels of efficiency, accuracy, and competitiveness. As companies embrace automation, they position themselves for success in the rapidly evolving manufacturing landscape, where agility, optimization, and customer-centricity are paramount.

By embracing automation, manufacturers can pave the way for a future of streamlined processes, optimized inventory, and superior operational performance.

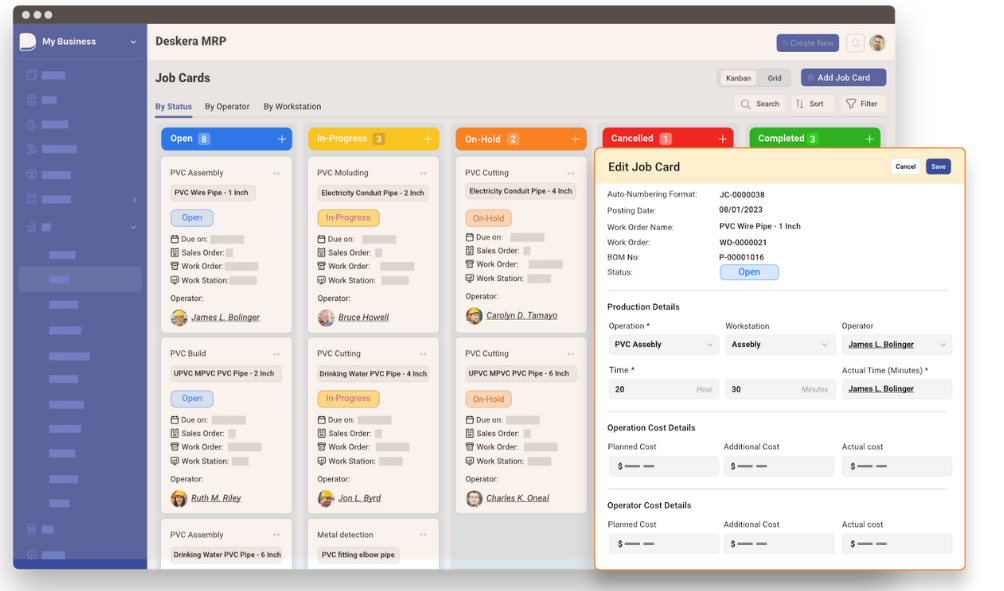

How Deskera Can Assist You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's key features of demand forecasting with Deskera include as follows:

- Establish Demand Forecasting Process

- Automate Data Collection

- Monitor Market Trends

- Analyze Historical Data

- Estimate Future Demand

- Adjust Production Levels

- Manage Supply Chain...and much more!

- Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

- Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

- Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

- Deskera People is a straightforward tool for centralizing your human resource management functions.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Inventory control plays a crucial role in the success and efficiency of manufacturing operations. It encompasses the processes and strategies employed to manage and track raw materials, work-in-progress (WIP), and finished goods within a manufacturing environment.

- Automation refers to the use of technology and systems to perform tasks and processes with minimal human intervention. In the context of inventory control, automation involves the integration of various technologies and software systems to streamline and optimize inventory management processes.

- Barcodes and radio frequency identification (RFID) tags enable automated identification and tracking of inventory items. Scanning barcodes or RFID tags with handheld or fixed scanners allows for quick and accurate data capture, reducing manual data entry errors.

- Automation enables the automated collection of data related to inventory, such as item details, quantities, locations, and movements. This is achieved through technologies like barcode scanning, RFID tagging, and IoT sensors. By automating data collection, manufacturers can eliminate manual data entry errors, improve data accuracy, and save time.

- Integrating these systems with existing enterprise resource planning (ERP) or manufacturing execution systems (MES) can be complex and time-consuming. Organizations need to carefully evaluate the costs and benefits associated with implementing automation and ensure proper planning and budgeting to address the initial setup costs and integration challenges.

- Automation involves the collection, storage, and transmission of sensitive inventory data. Organizations must address data security and privacy concerns associated with automated inventory control systems. This includes implementing robust cybersecurity measures, such as encryption, access controls, and regular system audits, to protect inventory data from unauthorized access, breaches, or theft.

Related Articles