Manufacturing businesses face many challenges, but ensuring rapid order fulfillment ranks among the most critical. Delivering goods on time and in the right quantity is essential to maintaining customer satisfaction and retaining customers. If an order is not fulfilled quickly and correctly, it can lead to quality issues, wasted resources, and lost sales.

Rapid order fulfillment is essential for manufacturing organizations to keep up with the competition. However, it is also a challenging task that requires close coordination between different departments. In this article, we will discuss some of the best practices that can help you achieve rapid order fulfillment.

In today’s guide, we’ll thoroughly learn important tips for executives of manufacturing organizations to help them ensure rapid order fulfillment. Let’s take a look at the table of content below:

- What is Rapid Order Fulfillment?

- Why is Rapid Order Fulfillment Important for Manufacturing Organizations?

- Streamline Production Processes

- Enhance Supply Chain Management

- Improve Order Processing and Fulfillment

- Enhance Collaboration and Communication

- Improve Communication with Customers

- What are the Benefits of Rapid Order Fulfillment for Manufacturing Organizations?

- How can Lean Manufacturing Principles Contribute to Rapid Order Fulfillment?

- What Role Does Technology Play in Achieving Rapid Order Fulfillment?

- How Can Supply Chain Management Contribute to Rapid Order Fulfillment?

- How Can an Integrated Order Management System Improve Order Fulfillment?

- What Steps Can Be Taken to Improve Warehouse Operations for Better Order Fulfillment?

- How can Collaboration and Communication Enhance Order Fulfillment Speed?

- How Long Does it Take to Implement the Suggested Tips for Rapid Order Fulfillment?

- What are Some Potential Challenges in Achieving Rapid Order Fulfillment?

- How Can Executives Measure the Success of Their Efforts in Achieving Rapid Order Fulfillment?

- What Role Does Customer Demand Forecasting Play in Rapid Order Fulfillment?

- What are the Risks Associated with Rapid Order Fulfillment & Solutions?

- How Can Continuous Improvement Initiatives Contribute to Achieving Rapid Order Fulfillment?

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

What is Rapid Order Fulfillment?

Rapid order fulfillment refers to the efficient and timely processing, production, and delivery of customer orders within short turnaround times.

Furthermore, it involves the entire order fulfillment cycle, from the moment an order is received to the point of delivery to the customer's doorstep. Rapid order fulfillment aims to minimize the time it takes for a customer's order to be processed, manufactured (if applicable), and shipped, ensuring that the products reach the customers within the expected timeframe.

The concept of rapid order fulfillment has gained significant importance in recent years due to changing customer expectations and the competitive landscape. Customers now expect fast and reliable service, and organizations that can fulfill orders quickly gain a competitive advantage. Rapid order fulfillment encompasses various stages and processes, each contributing to the overall speed and efficiency of the fulfillment cycle:

Order Processing: Rapid order fulfillment begins with the efficient processing of customer orders. This involves capturing and verifying order details, such as product specifications, quantities, and customer information. Streamlining order processing through automated systems, well-defined workflows, and clear communication channels helps reduce processing time and minimize errors.

Production Planning: If the products are manufactured or assembled based on customer orders, efficient production planning becomes crucial. Rapid order fulfillment requires effective coordination between production teams, ensuring that the necessary materials, resources, and capacity are available to meet production deadlines. Adopting lean manufacturing principles and advanced production technologies can help optimize production processes for faster turnaround times.

Inventory Management: Effective inventory management plays a vital role in rapid order fulfillment. Organizations need to maintain optimal inventory levels to avoid stockouts while minimizing carrying costs. Implementing just-in-time (JIT) inventory management techniques, accurate demand forecasting, and leveraging supplier-managed inventory (SMI) programs can optimize inventory levels and improve order fulfillment speed.

Warehouse Operations: Efficient warehouse operations are essential for rapid order fulfillment. This includes warehouse layout optimization, well-defined picking and packing processes, inventory tracking systems (such as barcodes or RFID), and trained staff to handle order fulfillment tasks accurately and quickly. By minimizing errors, reducing handling time, and optimizing storage, organizations can expedite the fulfillment process.

Logistics and Shipping: Coordinating logistics and shipping operations is crucial for delivering products to customers promptly. This involves selecting reliable shipping carriers, optimizing transportation routes, and leveraging technology for real-time tracking and visibility. Streamlining these processes helps reduce transit times and ensures timely delivery.

Communication and Customer Service: Effective communication with customers is a vital aspect of rapid order fulfillment. Proactively updating customers on order status, providing tracking information, and promptly addressing any inquiries or concerns contribute to a positive customer experience. Clear communication channels and self-service options empower customers to track their orders and obtain necessary information without additional delays.

Implementing strategies and technologies to accelerate each stage of the order fulfillment process leads to rapid order fulfillment. By minimizing lead times, optimizing internal processes, leveraging automation and technology, and prioritizing customer satisfaction, organizations can ensure that orders are fulfilled swiftly and reliably. Rapid order fulfillment not only enhances customer satisfaction and loyalty but also provides a competitive edge in the market by meeting the growing demand for fast and efficient service.

Why is Rapid Order Fulfillment Important for Manufacturing Organizations?

Rapid order fulfillment is of paramount importance for manufacturing organizations due to several significant reasons. In today's competitive business landscape, customer expectations have evolved, and timely delivery of products has become a crucial factor in maintaining customer satisfaction and loyalty. Here are the key reasons why rapid order fulfillment holds immense significance for manufacturing organizations:

Meeting Customer Expectations: In a fast-paced consumer market, customers have grown accustomed to quick and efficient service. They expect their orders to be fulfilled promptly, and any delays can lead to dissatisfaction, negative reviews, and even loss of business. Rapid order fulfillment allows manufacturing organizations to meet these heightened customer expectations and deliver products within the expected timeframes.

Enhanced Customer Satisfaction: Timely order fulfillment contributes significantly to customer satisfaction. When customers receive their orders promptly, they experience a sense of reliability and trust in the manufacturing organization. This positive experience can lead to repeat purchases, customer loyalty, and positive word-of-mouth referrals, all of which are essential for business growth.

Competitive Advantage: In highly competitive markets, rapid order fulfillment can be a key differentiator. When manufacturing organizations can consistently fulfill orders faster than their competitors, they gain a competitive edge. Customers are more likely to choose a company that can deliver their products quickly, especially when faced with similar offerings from other companies.

Reduced Risk of Lost Sales: Delayed order fulfillment increases the risk of lost sales. Customers who experience delays may cancel their orders or turn to alternative suppliers who can fulfill their needs more rapidly. By ensuring rapid order fulfillment, manufacturing organizations minimize the risk of losing potential sales and revenue.

Improved Brand Reputation: The reputation of a manufacturing organization is closely tied to its ability to fulfill orders quickly and efficiently. A reputation for reliable and timely order fulfillment builds trust among customers and positions the organization as a dependable supplier. A positive brand reputation leads to increased market share and opportunities for growth.

Supply Chain Optimization: Rapid order fulfillment necessitates streamlined supply chain processes. To fulfill orders quickly, manufacturing organizations must optimize their supply chain management, including efficient procurement, inventory management, and logistics. This optimization not only benefits order fulfillment but also leads to overall supply chain efficiency and cost reduction.

Operational Efficiency: Rapid order fulfillment requires manufacturing organizations to evaluate and optimize their internal processes. Inefficiencies and bottlenecks are identified and addressed, leading to streamlined production, reduced lead times, minimized errors, and improved overall operational efficiency. This, in turn, reduces costs, enhances productivity, and enables better resource utilization.

Adapting to Changing Market Demands: Customer demands and market trends can change rapidly. Manufacturing organizations that can fulfill orders quickly are better positioned to adapt to changing demands. Rapid order fulfillment allows companies to capitalize on market opportunities, respond swiftly to customer requirements, and stay ahead of competitors.

In summary, rapid order fulfillment is essential for manufacturing organizations as it helps meet customer expectations, enhances customer satisfaction, provides a competitive advantage, reduces the risk of lost sales, improves brand reputation, optimizes the supply chain, enhances operational efficiency, and enables adaptability in a dynamic market. By prioritizing rapid order fulfillment, manufacturing organizations can achieve sustainable growth and success in a highly competitive business environment.

Streamline Production Processes

Following, we've discussed thoroughly about streamlining the production process. Let's learn:

A. Implement Lean Manufacturing Principles:

Identify and eliminate waste in production processes:

One of the key tenets of lean manufacturing is the identification and elimination of waste. Waste, or "muda" in lean terminology, refers to any activity or process that does not add value to the final product. By conducting a thorough analysis of production processes, organizations can identify various forms of waste, such as overproduction, waiting time, excess inventory, unnecessary transportation, defects, and inefficient use of resources.

Once the waste is identified, lean principles provide tools and methodologies to eliminate or minimize it. For example, implementing just-in-time (JIT) production helps reduce excess inventory and overproduction. Value stream mapping allows organizations to visualize and analyze the flow of materials and information, identifying areas of waste and opportunities for improvement. By actively eliminating waste, organizations can streamline production processes, reduce lead times, and enhance order fulfillment speed.

Optimize workflows and minimize non-value-added activities:

Lean manufacturing emphasizes the importance of optimizing workflows to minimize non-value-added activities. This involves evaluating the sequence of operations, eliminating unnecessary steps, and rearranging processes to reduce movement and improve efficiency.

By adopting principles such as cellular manufacturing or work cells, where workstations are arranged in a logical and efficient layout, organizations can reduce transportation time and optimize the flow of materials. Standardized work procedures ensure consistency and reduce variation, leading to increased productivity and faster order fulfillment.

Applying lean principles also involves implementing visual management techniques. Visual cues and indicators, such as kanban boards or Andon systems, help teams quickly understand the status of work, identify bottlenecks, and take immediate action. This visual transparency enables timely decision-making, problem-solving, and course correction, leading to improved workflow efficiency.

Implement a continuous improvement culture to drive efficiency:

A core principle of lean manufacturing is the establishment of a culture of continuous improvement, often referred to as Kaizen. This involves engaging employees at all levels to contribute ideas, identify opportunities for improvement, and drive efficiency gains.

By fostering a culture of continuous improvement, organizations encourage employees to proactively seek out inefficiencies and suggest innovative solutions. Regular improvement events, such as Kaizen workshops or daily stand-up meetings, provide platforms for employees to collaborate, share knowledge, and implement changes to streamline production processes.

Continuous improvement also involves measuring and analyzing key performance indicators (KPIs) to monitor progress and identify areas for further optimization. Organizations can use techniques like root cause analysis, 5 Whys, or Pareto charts to identify underlying causes of inefficiencies and take targeted action to address them.

By implementing lean manufacturing principles, organizations can streamline production processes, reduce waste, and drive efficiency. This leads to improved order fulfillment speed, as operations become more optimized, predictable, and capable of meeting customer demands rapidly. The continuous improvement mindset ensures that the organization is constantly striving for greater efficiency, allowing for sustained improvements in production and order fulfillment over time.

B. Embracing Automation and Technology

Following, we’ve discussed embracing or adapting automation and technology in detail. Let’s learn:

Invest in advanced manufacturing technologies, such as robotics and AI:

Investing in advanced manufacturing technologies can significantly enhance order fulfillment speed and efficiency. Robotics and AI can be utilized to automate various tasks in the production process, from material handling to assembly and packaging.

Furthermore, robots can work continuously and with precision, reducing production lead times and improving overall quality. AI-powered systems can analyze data, predict demand patterns, and optimize production schedules, leading to better resource utilization and faster order processing.

Implementing such technologies may require an initial capital investment, but the long-term benefits are substantial. By reducing labor-intensive processes and streamlining operations, manufacturing organizations can achieve higher production rates and meet customer demands more rapidly.

Automate repetitive tasks to reduce human error and increase productivity:

Repetitive tasks in the manufacturing process are often prone to human error, which can lead to delays and defects. By automating these tasks, organizations can eliminate errors and improve overall productivity. Automation allows for consistent and accurate execution of tasks, reducing the need for rework and ensuring that products meet quality standards.

For example, automated picking and packing systems in warehouses can significantly speed up order fulfillment. Automated quality control systems can quickly detect defects and deviations from specifications, allowing for immediate corrective action. By deploying automation strategically, organizations can accelerate the order fulfillment process while maintaining product quality and consistency.

Utilize real-time data analytics to monitor production performance and identify bottlenecks:

Real-time data analytics provide valuable insights into production performance and supply chain operations. By monitoring key performance indicators (KPIs) in real time, manufacturing organizations can identify bottlenecks and inefficiencies as they arise. This proactive approach enables swift problem-solving and process adjustments, reducing lead times and enhancing order fulfillment speed.

For instance, data analytics can reveal production line downtimes, enabling quick response and minimizing disruptions. By analyzing customer demand patterns, organizations can align production schedules to meet anticipated orders, ensuring products are ready for shipment in advance.

Additionally, real-time data analytics can aid in inventory management, helping organizations maintain optimal stock levels and avoid stockouts. This ensures that products are readily available for fulfillment, further contributing to faster order processing and delivery.

In conclusion, embracing automation and technology is a fundamental aspect of ensuring rapid order fulfillment for manufacturing organizations. Investing in advanced manufacturing technologies like robotics and AI, automating repetitive tasks, and utilizing real-time data analytics empower organizations to streamline operations, reduce lead times, minimize errors, and meet customer demands swiftly. By leveraging these technological advancements, manufacturing organizations can achieve a competitive advantage, enhance customer satisfaction, and position themselves as leaders in their industry.

Enhance Supply Chain Management

Following, we’ve discussed thoroughly enhancing supply chain management. Let’s learn:

A. Develop Strong Supplier Relationships:

1. Collaborate closely with suppliers to ensure timely delivery of raw materials and components:

Establishing a collaborative relationship with suppliers is vital for rapid order fulfillment. By working closely with suppliers, manufacturing organizations can ensure timely delivery of raw materials and components, reducing the risk of production delays. Open lines of communication allow for effective coordination, enabling suppliers to understand production requirements and align their deliveries accordingly.

Regular communication with suppliers helps in anticipating potential supply chain disruptions and resolving issues promptly. By sharing production forecasts and customer demand patterns, manufacturers can provide suppliers with the necessary visibility to plan their production and manage their inventory levels. This collaboration leads to smoother supply chain operations and faster order fulfillment.

2. Establish long-term contracts and maintain open communication channels:

Long-term contracts with suppliers provide stability and foster stronger relationships. They offer mutual benefits such as preferential pricing, priority access to resources, and commitment to ongoing collaboration. Long-term contracts also enable suppliers to better align their operations with the manufacturing organization's needs, resulting in more reliable and timely deliveries.

Open communication channels are essential for effective supplier collaboration. Regular meetings, joint planning sessions, and shared performance metrics facilitate transparency and enable both parties to address issues and make adjustments proactively. This level of communication ensures that suppliers understand the manufacturing organization's order fulfillment priorities and can align their processes accordingly.

3. Consider dual sourcing strategies to mitigate supply chain risks:

Relying on a single supplier can pose risks to order fulfillment if disruptions occur in their operations. Adopting a dual-sourcing strategy, where possible, involves working with multiple suppliers for critical materials or components. This approach diversifies the supply chain and reduces the impact of disruptions caused by a single supplier's issues.

Maintaining relationships with alternative suppliers allows for flexibility and quick response in case of unforeseen circumstances. It enables manufacturers to switch suppliers swiftly if one is unable to meet the required timelines. However, it is crucial to assess the capabilities and reliability of alternative suppliers before implementing a dual-sourcing strategy.

By developing strong supplier relationships, manufacturing organizations can enhance supply chain management and contribute to rapid order fulfillment. Collaborating closely with suppliers ensures timely deliveries, establishes long-term contracts, and maintains open communication channels. Additionally, implementing dual-sourcing strategies mitigates risks and improves the organization's ability to respond to supply chain disruptions. These practices help create a more resilient and efficient supply chain, enabling manufacturing organizations to fulfill orders rapidly and meet customer expectations.

B. Implement Just-in-Time (JIT) Inventory Management:

1. Optimize inventory levels to reduce carrying costs and minimize stockouts:

Just-in-Time (JIT) inventory management focuses on maintaining optimal inventory levels to meet customer demand without carrying excessive inventory. By optimizing inventory levels, organizations can reduce carrying costs associated with storage, obsolescence, and depreciation. This frees up capital that can be invested in other areas of the business.

With JIT, inventory is replenished based on actual customer demand, minimizing the risk of stockouts. By closely monitoring customer orders, organizations can determine the appropriate reorder points and quantities to ensure that inventory is replenished precisely when needed. This helps prevent delays in order fulfillment and improves customer satisfaction.

2. Implement demand forecasting techniques to better align inventory levels with customer demand:

Accurate demand forecasting is a critical component of JIT inventory management. By using historical data, market trends, and other relevant factors, organizations can forecast customer demand with greater accuracy. This enables them to align inventory levels more effectively, avoiding both excess inventory and stockouts.

Sophisticated forecasting techniques, such as statistical models, predictive analytics, and machine learning algorithms, can help organizations improve the accuracy of their demand forecasts. By continuously monitoring and refining forecasts, organizations can better anticipate customer demand patterns, adjust production and procurement plans accordingly, and ensure that inventory levels are optimized for rapid order fulfillment.

3. Leverage supplier-managed inventory (SMI) programs for improved efficiency:

Supplier-managed inventory (SMI) programs involve close collaboration between manufacturers and suppliers to streamline inventory management. In an SMI arrangement, suppliers take responsibility for managing and replenishing inventory at the manufacturing organization's facilities. This eliminates the need for the manufacturer to hold excess inventory, as the supplier can respond directly to changes in demand.

SMI programs offer several benefits. First, they enable organizations to reduce lead times by having suppliers located closer to their facilities or implementing vendor-managed inventory (VMI) arrangements. Second, suppliers gain greater visibility into the manufacturer's inventory levels and demand patterns, allowing them to proactively replenish stock and avoid stockouts. Third, SMI programs can improve overall supply chain coordination and collaboration, leading to faster response times and increased order fulfillment speed.

Implementing JIT inventory management, coupled with effective demand forecasting and supplier collaboration through SMI programs, enables organizations to optimize inventory levels, reduce carrying costs, and minimize stockouts. By maintaining the right amount of inventory at the right time, organizations can achieve rapid order fulfillment while maximizing efficiency and customer satisfaction.

Improve Order Processing and Fulfillment:

Following, we’ve discussed thoroughly improving order processing and fulfillment. Let’s learn:

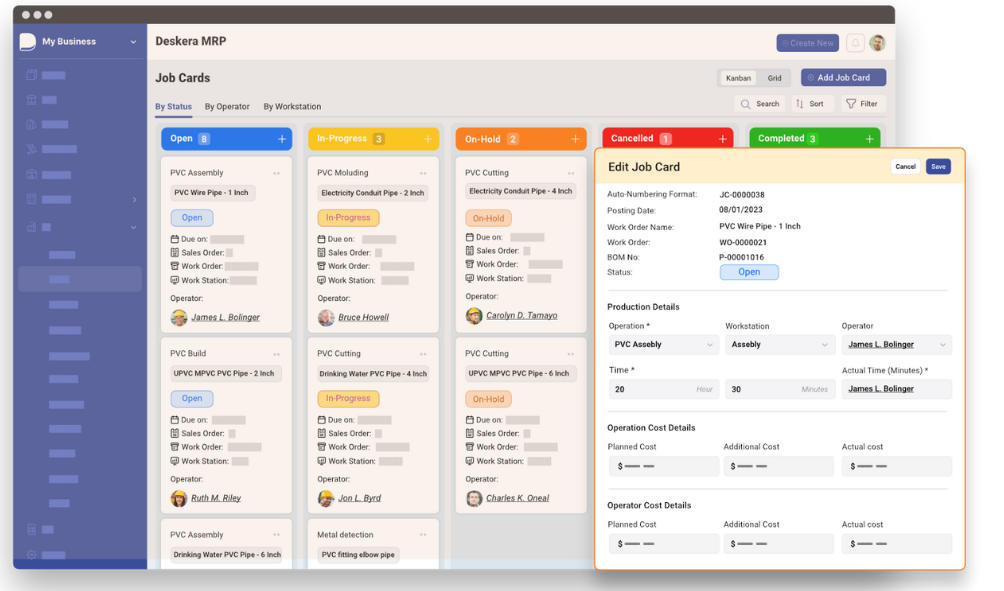

A. Implement an Integrated Order Management System:

1. Adopt a robust order management software to streamline the order processing workflow:

Implementing comprehensive order management software is essential for streamlining the order processing workflow. This software enables organizations to automate and standardize various order-related tasks, such as order entry, order validation, order tracking, and invoicing. It eliminates manual processes, reduces errors, and improves overall efficiency.

A robust order management software should provide features like order capture from multiple channels (e.g., online platforms, sales representatives), automated order routing, and order validation against inventory availability. It should also have capabilities for order modifications, cancellations, and returns, ensuring that changes can be easily accommodated.

2. Centralize order information and enable real-time visibility across departments:

Centralizing order information within the order management system is crucial for improving order processing and fulfillment. This central repository ensures that all relevant order details, including customer information, product details, pricing, and shipping instructions, are readily accessible.

Real-time visibility across departments, such as sales, customer service, inventory, and fulfillment, allows for seamless collaboration and communication. All stakeholders can access the latest order status and make informed decisions. This visibility helps identify bottlenecks, address issues promptly, and maintain a smooth order fulfillment process.

3. Integrate the system with customer relationship management (CRM) and enterprise resource planning (ERP) systems for seamless data flow:

Integration of the order management system with CRM and ERP systems is essential to ensure seamless data flow and optimize order processing. Integration with CRM systems allows for a holistic view of customer interactions, preferences, and order history. This information helps in providing personalized customer experiences, accurate order capture, and efficient order fulfillment.

Integration with ERP systems enables the synchronization of inventory data, production planning, and fulfillment processes. This integration ensures that order fulfillment is aligned with inventory availability and production capacity, avoiding stockouts and production delays. It also facilitates accurate tracking of order progress, from processing to shipping.

When implementing an integrated order management system, it is crucial to select a solution that aligns with the organization's specific needs and integrates effectively with existing systems. The software should provide scalability, security, and flexibility to adapt to evolving business requirements.

By adopting an integrated order management system, organizations can streamline the order processing workflow, improve accuracy, and enhance order fulfillment speed. The centralization of the order information and real-time visibility across departments promote collaboration and efficient decision-making. Integration with CRM and ERP systems ensures seamless data flow, optimized inventory management, and synchronized production and fulfillment processes. These factors collectively contribute to improved order processing and fulfillment efficiency, ultimately enhancing customer satisfaction.

B. Optimize Warehouse Operations:

Following, we’ve discussed in detail optimizing warehouse operations:

1. Utilize efficient warehouse layout and organization methods:

Efficient warehouse layout and organization are crucial for maximizing productivity and minimizing order fulfillment time. Organizations can achieve this by:

- Analyzing and optimizing the warehouse layout to minimize unnecessary travel distances and improve the flow of goods. This includes considering factors such as product demand, storage requirements, and order-picking processes.

- Implementing zone-based storage strategies to group similar products together. This allows for easier inventory management, faster order picking, and reduced search time.

- Utilizing vertical space by implementing mezzanine floors, tall storage racks, or automated vertical lift modules. This increases storage capacity without expanding the warehouse footprint.

- Implementing clear signage and labeling systems to facilitate easy navigation and identification of products and locations within the warehouse.

- Regularly reviewing and updating the warehouse layout and organization based on changing business needs and customer demands.

By optimizing the warehouse layout and organization, organizations can reduce the time it takes to locate and retrieve products, leading to faster order fulfillment and improved operational efficiency.

2. Implement barcode or RFID tracking systems for accurate inventory management:

Implementing barcode or radio-frequency identification (RFID) tracking systems can greatly enhance inventory management accuracy and efficiency. These technologies enable real-time visibility of inventory levels and streamline the tracking of goods throughout the warehouse. Benefits include:

- Accurate and efficient inventory counts: Barcode or RFID scanners enable faster and more accurate inventory counts, reducing discrepancies and minimizing stockouts or overstock situations.

- Real-time inventory visibility: By scanning barcodes or RFID tags, warehouse staff can instantly update the system with accurate information on product location and quantity. This improves inventory accuracy and allows for better planning and decision-making.

- Automated data capture: Barcode or RFID systems automate the data capture process, reducing manual data entry errors and saving time. This streamlines warehouse operations and order processing.

- Efficient order picking: Barcode or RFID systems can be integrated with order management systems, guiding warehouse staff to the correct locations for picking and validating the accuracy of picked items.

- Implementing barcode or RFID tracking systems significantly improves inventory management accuracy, reduces errors, and speeds up order fulfillment processes.

3. Train warehouse staff on best practices to minimize picking errors and improve order accuracy:

Properly trained warehouse staff are essential for efficient warehouse operations. Organizations should invest in comprehensive training programs that focus on:

- Proper order picking techniques: Warehouse staff should be trained on efficient picking methods, such as batch picking, zone picking, or wave picking. This ensures that the right products are selected quickly and accurately.

- Accurate inventory tracking: Warehouse staff should understand the importance of accurate inventory tracking and be trained on how to use barcode scanners or RFID devices correctly.

- Quality control procedures: Training should cover quality control processes to minimize picking errors and ensure order accuracy. This includes checking for damaged products, correct quantities, and adherence to specific customer requirements.

- Safety protocols: Warehouse staff should be trained on proper lifting techniques, handling hazardous materials (if applicable), and general safety guidelines to maintain a safe working environment.

Regular training sessions and refresher courses should be provided to ensure that warehouse staff are up to date with the latest best practices and technologies. Well-trained staff contributes to improved order accuracy, reduced errors, and increased productivity in warehouse operations.

By optimizing warehouse operations through efficient layout and organization, implementing barcode or RFID tracking systems, and providing comprehensive training to warehouse staff, organizations can significantly enhance order fulfillment speed, accuracy, and overall operational efficiency. These improvements contribute to higher customer satisfaction and a competitive advantage in the market.

Enhance Collaboration and Communication

Following, we’ve discussed thoroughly enhancing collaboration and communication. Let’s learn:

A. Foster Cross-Functional Collaboration:

1. Encourage collaboration between production, sales, and customer service teams:

Cross-functional collaboration is essential for rapid order fulfillment as it ensures that different departments work together seamlessly towards a common goal. To foster collaboration:

- Encourage open communication and a shared sense of purpose among teams. Emphasize the importance of collaboration in achieving rapid order fulfillment and meeting customer expectations.

- Facilitate regular interactions between production, sales, and customer service teams, whether through in-person meetings, virtual collaboration platforms, or cross-departmental projects. This allows for the exchange of insights, challenges, and ideas.

- Foster a culture of mutual respect and understanding, where teams recognize the value each department brings to the order fulfillment process. Encourage teams to view themselves as part of a unified effort rather than siloed functions.

By encouraging collaboration between production, sales, and customer service teams, organizations can ensure alignment and effective coordination throughout the order fulfillment process.

2. Implement regular meetings to align goals, share insights, and address issues:

Regular meetings provide an opportunity for cross-functional teams to align their goals, share insights, and address any issues or challenges that may arise. Consider the following practices:

- Hold regular team meetings or stand-ups to discuss order fulfillment status, share updates, and identify any bottlenecks or issues that need attention.

- Conduct joint planning sessions to align production capabilities with sales forecasts, ensuring that capacity and demand are in sync.

- Use these meetings as a platform for brainstorming solutions, sharing best practices, and improving collaboration and communication.

- Regular meetings not only enhance collaboration but also foster a sense of accountability and shared responsibility among team members.

3. Utilize collaborative project management tools for enhanced communication:

Collaborative project management tools provide a centralized platform for teams to communicate, share information, and track progress. Consider the following:

- Implement a project management tool that allows teams to create and assign tasks, set deadlines, and track progress in real-time. This enhances transparency and ensures that everyone is on the same page regarding project timelines and deliverables.

- Utilize communication features within the project management tool, such as discussion boards, chat functionalities, or comment sections. This enables teams to communicate and collaborate effectively without relying solely on email or in-person meetings.

- Leverage document sharing and version control features to facilitate the sharing of important documents, such as production schedules, sales forecasts, or customer requirements. This ensures that teams have access to the most up-to-date information.

By utilizing collaborative project management tools, organizations can streamline communication, improve information sharing, and enhance collaboration across teams involved in the order fulfillment process.

Enhancing collaboration and communication between production, sales, and customer service teams is crucial for rapid order fulfillment. Encouraging collaboration, implementing regular meetings, and utilizing collaborative project management tools foster a culture of teamwork, coordination, and shared responsibility. This leads to improved efficiency, faster problem resolution, and ultimately, enhanced order fulfillment speed and customer satisfaction.

Improve Communication with Customers

Following, we’ve discussed thoroughly improving communication with customers. Let’s learn:

A. Establish clear channels for customer inquiries and order updates:

Clear and accessible communication channels are essential for improving customer satisfaction and providing a positive order fulfillment experience. Consider the following practices:

- Provide multiple channels for customers to inquire about their orders or seek assistance, such as phone, email, live chat, or online contact forms. Ensure that these channels are clearly communicated on your website, order confirmation emails, and other customer touchpoints.

- Assign dedicated customer service representatives or teams to handle inquiries and provide prompt responses. Train them to effectively address customer concerns, resolve issues, and provide order updates.

- Implement a robust customer relationship management (CRM) system to track and manage customer interactions. This allows for efficient handling of inquiries and ensures that customers receive consistent and accurate information.

By establishing clear communication channels, organizations can enhance customer satisfaction, build trust, and provide a positive customer experience throughout the order fulfillment process.

B. Provide self-service options, such as online order tracking portals:

Offering self-service options empowers customers to track their orders and access relevant information independently. Here's how to provide self-service options effectively:

- Develop an online order tracking portal where customers can log in to view the status of their orders, estimated delivery dates, and any updates or notifications.

- Ensure that the tracking portal is user-friendly, providing intuitive navigation and clear instructions on how to use the system.

- Regularly update the tracking portal with real-time information on order status and shipping details. This helps customers stay informed and eliminates the need for frequent inquiries.

- Self-service options not only reduce the workload on customer service teams but also give customers a sense of control and visibility over their orders, leading to improved satisfaction and a more streamlined order fulfillment process.

C. Proactively communicate any delays or issues and offer alternative solutions:

Timely and proactive communication with customers is crucial when there are delays or issues affecting order fulfillment. Here are some best practices:

- Monitor order progress closely and identify any potential delays or issues as early as possible.

- Proactively reach out to customers to inform them about any delays, changes, or unexpected issues that may impact their orders. Provide transparent and detailed explanations, and apologize for any inconvenience caused.

- Offer alternative solutions or options to mitigate the impact of delays, such as expedited shipping, partial shipments, or product substitutions. Ensure that customers are aware of these options and assist them in making informed decisions.

- Regularly update customers on the progress of their orders, especially if there are further delays or changes. Maintain open lines of communication and be responsive to their inquiries or concerns.

- Proactive communication demonstrates your commitment to customer satisfaction and helps manage expectations effectively. It also gives customers the opportunity to plan accordingly and maintain trust in your organization.

By improving communication with customers through clear channels, providing self-service options for order tracking, and proactively communicating any delays or issues, organizations can enhance the overall customer experience, build loyalty, and ensure a smooth order fulfillment process.

What are the Benefits of Rapid Order Fulfillment for Manufacturing Organizations?

Rapid order fulfillment offers several significant benefits for manufacturing organizations. Here are some key advantages:

Improved Customer Satisfaction: Rapid order fulfillment plays a crucial role in meeting customer expectations and enhancing their overall satisfaction. Customers today have come to expect fast and efficient order processing, quick delivery, and accurate fulfillment. By delivering orders promptly and consistently, manufacturing organizations can create positive customer experiences, build trust, and foster long-term customer relationships.

Competitive Advantage: In today's highly competitive market, rapid order fulfillment can provide a significant competitive edge. Organizations that can fulfill orders quickly and efficiently gain an advantage over competitors who have longer lead times or struggle with order delays. Being able to offer faster delivery times and meet tight deadlines can attract new customers, retain existing ones, and differentiate the organization in the marketplace.

Increased Operational Efficiency: Rapid order fulfillment requires streamlined and optimized operational processes. As manufacturing organizations focus on improving speed and efficiency, they often identify and eliminate inefficiencies, bottlenecks, and unnecessary steps in their workflows. This optimization leads to improved operational efficiency, reduced costs, and enhanced productivity.

Reduced Inventory Holding Costs: Rapid order fulfillment is closely tied to effective inventory management. By implementing strategies like just-in-time (JIT) inventory management, organizations can minimize inventory holding costs. Instead of maintaining excessive inventory levels, they can keep inventory levels optimized to meet immediate demand. This reduces the need for large warehouse spaces, lowers storage costs, and minimizes the risk of obsolete inventory.

Enhanced Supply Chain Visibility and Responsiveness: Rapid order fulfillment requires a well-coordinated supply chain. Organizations that focus on improving order fulfillment speed often enhance visibility across their supply chain, enabling real-time tracking and monitoring of inventory, production, and logistics. This increased visibility allows for better coordination, quicker decision-making, and improved responsiveness to changes in customer demand or supply chain disruptions.

Improved Cash Flow: Rapid order fulfillment can positively impact cash flow by reducing the time it takes to convert inventory into revenue. When orders are fulfilled quickly, invoices can be generated promptly, and payments can be received sooner. This reduces the cash conversion cycle and improves the organization's working capital position.

Positive Brand Reputation: Organizations that consistently deliver rapid order fulfillment gain a reputation for reliability, efficiency, and customer-centricity. Positive word-of-mouth and customer referrals can drive additional business and strengthen the brand's reputation in the market. A strong brand reputation can attract new customers and build loyalty among existing ones.

Operational Agility: Rapid order fulfillment requires organizations to be agile and adaptable. By implementing efficient processes, leveraging technology, and fostering a culture of continuous improvement, manufacturing organizations become more agile in responding to changing market conditions, customer demands, and competitive pressures. This agility enables them to seize new opportunities, quickly adjust production schedules, and meet evolving customer needs.

Overall, rapid order fulfillment offers numerous benefits that contribute to the success and growth of manufacturing organizations. By focusing on speed, efficiency, and customer satisfaction, organizations can stay ahead of the competition, optimize their operations, and build strong relationships with customers.

How can Lean Manufacturing Principles Contribute to Rapid Order Fulfillment?

Lean manufacturing principles play a crucial role in contributing to rapid order fulfillment for manufacturing organizations. By focusing on waste reduction, process optimization, and continuous improvement, lean principles help streamline operations and improve overall efficiency. Here's how lean manufacturing principles specifically contribute to rapid order fulfillment:

Waste Reduction: Lean manufacturing aims to identify and eliminate various forms of waste, such as overproduction, waiting time, excess inventory, unnecessary transportation, defects, and inefficient processes. By minimizing waste, organizations can free up resources, reduce lead times, and enhance the speed of order fulfillment.

Optimized Workflows: Lean principles emphasize the need for optimized workflows by eliminating non-value-added activities and streamlining processes. Through techniques like value stream mapping, organizations can identify bottlenecks, inefficiencies, and redundancies in their order fulfillment processes. By eliminating these bottlenecks and improving process flow, orders can move through the fulfillment cycle more rapidly.

Continuous Improvement: The concept of continuous improvement, often associated with Kaizen, is a core aspect of lean manufacturing. It encourages organizations to continually assess and enhance their processes, seeking opportunities for incremental improvements. By fostering a culture of continuous improvement, manufacturing organizations can identify and implement changes that contribute to faster order fulfillment.

Standardized Work: Lean manufacturing emphasizes the importance of standardized work processes and procedures. By establishing clear and standardized work instructions, organizations can ensure consistency and minimize variations in order fulfillment activities. This reduces the risk of errors, enhances efficiency, and enables faster processing and delivery of customer orders.

Visual Management: Visual management is a key lean practice that uses visual cues and indicators to communicate information, status, and progress. Visual management tools, such as kanban boards, Andon systems, and visual signals, help teams quickly understand the status of orders, identify bottlenecks, and take immediate action to resolve issues. This visual transparency enables faster decision-making and problem-solving, leading to improved order fulfillment speed.

Employee Empowerment: Lean manufacturing principles focus on empowering employees and involving them in the improvement process. By encouraging frontline workers to identify and address issues in their work areas, organizations can harness the knowledge and expertise of their employees to drive process improvements. This employee involvement enhances efficiency, reduces delays, and contributes to rapid order fulfillment.

Pull System Implementation: Lean manufacturing promotes the implementation of pull systems, such as kanban systems, where production is triggered based on actual customer demand. By aligning production with customer orders, organizations can avoid overproduction, reduce excess inventory, and respond quickly to changes in demand. This pull-based approach enhances agility and allows for faster order fulfillment.

Supplier Collaboration: Lean principles extend beyond internal operations and emphasize collaboration with suppliers. By fostering strong relationships with suppliers and implementing practices like just-in-time (JIT) delivery, organizations can ensure the timely availability of raw materials and components. This collaboration minimizes lead times, reduces dependency on excess inventory, and enables faster order fulfillment.

By embracing lean manufacturing principles, manufacturing organizations can optimize their processes, eliminate waste, improve efficiency, and ultimately achieve rapid order fulfillment. Lean principles provide a systematic framework for identifying areas of improvement, implementing changes, and continuously driving toward faster and more efficient order fulfillment.

What Role Does Technology Play in Achieving Rapid Order Fulfillment?

Technology plays a pivotal role in achieving rapid order fulfillment for manufacturing organizations. It enables automation, streamlines processes, improves visibility, and enhances efficiency throughout the order fulfillment cycle. Here's a detailed explanation of the role of technology:

Automation of Order Processing:

Technology enables the automation of various order processing tasks, reducing manual intervention and minimizing errors. Automated systems can handle tasks such as order entry, order validation, pricing calculations, and invoicing, leading to faster and more accurate order processing.

Efficient Inventory Management:

Technology facilitates real-time inventory tracking, allowing organizations to maintain optimal inventory levels and avoid stockouts or overstock situations. With technologies such as barcode scanning, radio-frequency identification (RFID), or warehouse management systems (WMS), organizations can track inventory movement, monitor stock levels, and automate replenishment processes. This improves inventory accuracy, streamlines picking processes, and ensures timely fulfillment.

Demand Forecasting and Planning:

Advanced technology tools and algorithms enable organizations to analyze historical data, market trends, and customer behavior to forecast demand accurately. Demand forecasting helps organizations align production and inventory levels with anticipated customer requirements, reducing lead times and enabling faster order fulfillment. By leveraging technology for demand planning, organizations can optimize their production schedules, resource allocation, and procurement processes.

Streamlined Production and Manufacturing:

Technology plays a crucial role in streamlining production processes. Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems enable efficient production planning, scheduling, and resource management. These systems provide real-time visibility into production progress, enable better coordination among teams, and facilitate timely order fulfillment.

Additionally, advanced manufacturing technologies, such as robotics, artificial intelligence (AI), and machine learning, automate repetitive tasks, improve operational efficiency, and enhance production speed. Robotic automation can accelerate assembly or packaging processes, while AI-driven algorithms optimize production flow and resource allocation. By integrating these technologies, organizations can achieve faster and more reliable production processes, leading to rapid order fulfillment.

Enhanced Communication and Collaboration:

Technology tools and platforms facilitate seamless communication and collaboration among different departments involved in order fulfillment, such as sales, production, inventory management, and logistics. Enterprise communication platforms, project management tools, and customer relationship management (CRM) systems enable efficient sharing of information, task assignments, real-time updates, and collaboration on order-related activities. This ensures smooth coordination, reduces delays, and enhances overall order fulfillment speed.

Improved Customer Experience:

Technology empowers customers with self-service options, such as online ordering, order tracking portals, and interactive customer support platforms. These tools allow customers to place orders, track shipment progress, and resolve queries independently, reducing the need for manual interventions. Moreover, customer relationship management (CRM) systems enable organizations to store and analyze customer data, providing personalized experiences and targeted marketing efforts.

Through technology, organizations can deliver faster response times, provide accurate and up-to-date information, and offer convenient self-service options, leading to improved customer satisfaction and loyalty.

In summary, technology plays a critical role in achieving rapid order fulfillment by automating order processing, improving inventory management, enabling accurate demand forecasting, streamlining production processes, enhancing communication and collaboration, and enhancing the overall customer experience. Embracing and leveraging technology in manufacturing organizations is essential for achieving efficiency, agility, and competitive advantage in the fast-paced world of order fulfillment.

How Can Supply Chain Management Contribute to Rapid Order Fulfillment?

Supply chain management plays a crucial role in achieving rapid order fulfillment for manufacturing organizations. It involves the coordination and optimization of all activities, processes, and stakeholders involved in delivering products or services to customers. Here's a detailed explanation of how supply chain management contributes to rapid order fulfillment:

Efficient Supplier Management:

Effective supply chain management begins with strong supplier relationships. By collaborating closely with suppliers, organizations can ensure the timely delivery of raw materials and components, which is essential for meeting production schedules and fulfilling customer orders on time. Key practices include:

- Establishing clear communication channels and maintaining open lines of dialogue with suppliers.

- Sharing production forecasts and demand information to facilitate better planning and coordination.

- Developing long-term partnerships and contracts to secure a reliable supply of materials.

- Implementing vendor-managed inventory (VMI) or supplier-managed inventory (SMI) programs, where suppliers take responsibility for maintaining optimal inventory levels.

Streamlined Logistics and Transportation:

Efficient logistics and transportation management are critical for rapid order fulfillment. Key considerations include:

- Optimizing transportation routes to minimize lead times and maximize efficiency.

- Leveraging technology, such as transportation management systems (TMS), to track and manage shipments in real-time.

- Collaborating with logistics providers to ensure seamless coordination and on-time delivery.

- Implementing efficient warehouse management practices, such as cross-docking or dynamic slotting, to reduce handling and transit times.

Effective Demand Planning and Forecasting:

Accurate demand planning and forecasting are vital for aligning production and inventory levels with customer demand. By understanding customer needs and market trends, organizations can optimize their supply chain operations. Key practices include:

- Utilizing historical sales data, market research, and customer insights to forecast demand.

- Collaborating with sales and marketing teams to incorporate their inputs and insights into demand planning.

- Implementing demand-driven replenishment strategies, such as Just-in-Time (JIT) or Vendor-Managed Inventory (VMI).

- Establishing effective communication channels with customers to gather real-time feedback and insights.

Inventory Optimization:

Optimizing inventory levels is crucial for rapid order fulfillment. Excess inventory can tie up working capital, while inadequate inventory can lead to stockouts and delayed order fulfillment. Key strategies include:

- Implementing inventory management systems to track and monitor stock levels in real-time.

- Utilizing inventory segmentation techniques to prioritize and manage different product categories based on demand patterns.

- Adopting Just-in-Time (JIT) or lean inventory principles to minimize carrying costs while ensuring availability.

- Collaborating with suppliers and implementing vendor-managed inventory (VMI) programs to improve inventory visibility and replenishment.

Supply Chain Visibility and Collaboration:

Visibility and collaboration across the supply chain are essential for rapid order fulfillment. This involves:

- Implementing supply chain visibility tools and technologies to track and monitor the movement of goods, inventory levels, and order statuses in real-time.

- Sharing relevant information, such as production schedules, forecasts, and customer requirements, with key stakeholders.

- Collaborating closely with internal teams, suppliers, logistics partners, and customers to identify bottlenecks, address issues, and streamline processes.

- Implementing advanced analytics and data-driven insights to identify opportunities for process improvement and optimization.

By effectively managing the supply chain, organizations can enhance efficiency, minimize lead times, reduce costs, and improve overall order fulfillment speed. This results in satisfied customers, increased competitiveness, and a stronger market position.

How Can an Integrated Order Management System Improve Order Fulfillment?

An integrated order management system plays a crucial role in improving order fulfillment for manufacturing organizations. It streamlines and automates various aspects of the order-processing workflow, leading to increased efficiency, accuracy, and customer satisfaction. Here's a detailed explanation of how an integrated order management system can improve order fulfillment:

Streamlined Order Processing:

An integrated order management system enables organizations to centralize and automate the entire order processing workflow. Key benefits include:

- Order Entry: The system allows for easy and efficient order entry, eliminating manual data entry errors and ensuring accurate order information.

- Order Validation: The system can validate orders in real-time, checking for data completeness, pricing accuracy, product availability, and other business rules. This helps prevent errors and delays caused by invalid or incomplete orders.

- Order Routing: The system can intelligently route orders to the appropriate departments or locations based on predefined rules, ensuring efficient order handling and minimizing processing time.

- Order Tracking: Organizations can track the status of orders in real-time, from entry to fulfillment, providing transparency and visibility throughout the process.

Centralized Order Information:

An integrated order management system centralizes order information, making it easily accessible to all relevant departments and stakeholders. This leads to better coordination and collaboration, as well as improved order fulfillment. Key benefits include:

- Customer Data: The system stores and organizes customer data, including contact information, order history, preferences, and special instructions. This allows for personalized service and efficient handling of customer inquiries or requests.

- Inventory Visibility: The system provides real-time inventory visibility, enabling accurate order promising and allocation based on available stock levels. It helps prevent overselling or stockouts, ensuring timely and accurate fulfillment.

- Order Documentation: All order-related documents, such as purchase orders, invoices, packing slips, and shipping labels, can be generated automatically within the system. This eliminates the need for manual document creation, reduces errors, and accelerates the order fulfillment process.

Seamless Integration with CRM and ERP Systems:

An integrated order management system seamlessly integrates with customer relationship management (CRM) and enterprise resource planning (ERP) systems, creating a unified data flow and enabling efficient end-to-end order fulfillment. Key benefits include:

- Customer Relationship Management: Integration with CRM systems allows organizations to access customer data, order history, and communication logs, providing a holistic view of customer interactions. This enables personalized service, better order management, and proactive communication with customers.

- Enterprise Resource Planning: Integration with ERP systems ensures that order information seamlessly flows into other business processes, such as production planning, inventory management, and financial accounting. This integration minimizes data duplication, improves accuracy, and enables efficient resource allocation.

Enhanced Customer Experience:

An integrated order management system significantly improves the customer experience throughout the order fulfillment process. Key benefits include:

- Faster Order Processing: By automating order entry, validation, and routing, the system reduces processing time, allowing for quicker order fulfillment and delivery.

- Accurate Order Promising: Real-time inventory visibility and order validation ensure accurate order promising, setting realistic delivery expectations for customers.

- Order Tracking and Communication: The system provides customers with access to order tracking information, allowing them to monitor the status and progress of their orders independently. Automated order updates and proactive communication regarding any delays or issues further enhance the customer experience.

- Efficient Issue Resolution: With centralized order information, customer service representatives can quickly access order details and resolve any issues or inquiries promptly, ensuring customer satisfaction.

By implementing an integrated order management system, organizations can streamline order processing, centralize order information, enhance coordination, and provide an exceptional customer experience. This leads to faster order fulfillment, improved efficiency, and a competitive advantage in the market.

What Steps Can Be Taken to Improve Warehouse Operations for Better Order Fulfillment?

Improving warehouse operations is crucial for better order fulfillment in manufacturing organizations. By optimizing warehouse processes, organizations can enhance efficiency, accuracy, and speed in picking, packing, and shipping orders. Here are several steps that can be taken to improve warehouse operations for better order fulfillment:

Efficient Warehouse Layout and Organization:

- Analyze the current warehouse layout and optimize it for streamlined operations. Designate specific areas for receiving, storage, picking, packing, and shipping.

- Implement efficient storage methods, such as bin locations, zone picking, or ABC analysis, to minimize travel time and increase picking efficiency.

- Arrange high-demand items closer to the shipping area to reduce picking distances and accelerate order fulfillment.

- Clearly label and mark storage locations to improve accuracy and ease of inventory retrieval.

Implement Barcode or RFID Tracking Systems:

- Introduce barcode or radio-frequency identification (RFID) tracking systems to improve inventory accuracy and streamline order fulfillment processes.

- Assign unique identifiers to each product or storage location and use handheld scanners or RFID readers to track inventory movement in real-time.

- Automate data entry by scanning barcodes or RFID tags, reducing manual errors and improving overall picking accuracy.

Optimize Order Picking Processes:

- Implement efficient picking strategies, such as batch picking or wave picking, to reduce travel time and increase productivity.

- Train warehouse staff on proper picking techniques and equip them with tools, such as pick lists, handheld devices, or pick-to-light systems, to expedite order picking.

- Utilize pick-to-cart or pick-to-conveyor systems to optimize picking routes and consolidate multiple orders for efficient fulfillment.

Streamline Packing and Shipping:

- Standardize packing processes to ensure consistency and minimize errors. Develop packing guidelines, use standardized packing materials, and implement quality control checks.

- Automate weighing, labeling, and documentation processes to expedite packing and shipping.

- Integrate shipping software with the warehouse management system (WMS) to generate shipping labels and streamline carrier selection and communication.

Continuous Training and Development:

- Provide regular training sessions to warehouse staff to enhance their skills and knowledge in warehouse operations.

- Train employees on the proper use of warehouse equipment, safety protocols, and best practices for order fulfillment.

- Foster a culture of continuous improvement, encouraging employees to provide suggestions for process optimization and efficiency gains.

Implement Technology and Automation:

- Explore warehouse automation technologies, such as conveyor systems, robotic picking systems, or automated guided vehicles (AGVs), to increase throughput and reduce labor-intensive tasks.

- Integrate the warehouse management system (WMS) with other business systems, such as enterprise resource planning (ERP) or order management systems, to enable seamless data flow and process synchronization.

Real-time Visibility and Analytics:

- Implement real-time visibility tools and dashboards to monitor warehouse performance metrics, such as order cycle time, picking accuracy, or inventory levels.

- Utilize data analytics to identify bottlenecks, optimize processes, and make data-driven decisions for warehouse improvement initiatives.

- Regularly review warehouse performance and adjust processes as needed to achieve continuous improvement.

By implementing these steps, organizations can optimize warehouse operations, streamline order fulfillment processes, reduce errors, and increase overall efficiency. This leads to faster order processing, improved customer satisfaction, and a competitive edge in the market.

How can Collaboration and Communication Enhance Order Fulfillment Speed?

Collaboration and communication play a critical role in enhancing order fulfillment speed for manufacturing organizations. By fostering effective collaboration and ensuring clear communication channels, organizations can streamline processes, address issues promptly, and achieve faster order fulfillment. Here's a detailed explanation of how collaboration and communication can enhance order fulfillment speed:

Cross-Functional Collaboration:

Encouraging collaboration among different teams involved in the order fulfillment process, such as production, sales, and customer service, can significantly improve speed and efficiency. Key benefits include:

- Demand Planning: Collaborating with sales and marketing teams allows for better understanding of customer demand, market trends, and upcoming promotions. This helps align production schedules and inventory levels with anticipated demand, reducing lead times.

- Production Coordination: Collaboration between production and sales teams enables timely production planning based on accurate demand forecasts. Close communication ensures that production schedules align with customer orders, reducing delays and bottlenecks.

- Timely Issue Resolution: Cross-functional collaboration ensures swift resolution of issues or inquiries related to orders. When teams work together and share information effectively, they can address problems promptly, preventing delays in order fulfillment.

Regular Meetings and Communication:

Establishing regular meetings and maintaining open communication channels across departments is essential for efficient order fulfillment. Key practices include:

- Order Status Updates: Regular meetings or status updates allow teams to share information on order progress, identify potential bottlenecks, and proactively address any issues. This ensures that orders move smoothly through the fulfillment process.

- Real-Time Communication: Utilize instant messaging platforms or collaboration tools to enable quick and seamless communication between teams. Instant access to information and the ability to resolve queries or make decisions in real-time accelerates order processing.

- Feedback and Insights Sharing: Encourage teams to provide feedback and share insights on process improvements. Regular communication allows for the identification of areas that can be optimized to enhance order fulfillment speed.

Collaborative Project Management Tools:

Leveraging collaborative project management tools can facilitate efficient communication and coordination among teams. Key benefits include:

- Task Assignment and Tracking: Collaborative project management tools enable the assignment of tasks to individuals or teams, with clear deadlines and priorities. This ensures accountability and visibility into task progress, preventing delays.

- Document Sharing and Version Control: Centralized document repositories or cloud-based platforms enable teams to access and share essential order-related documents, such as purchase orders, invoices, or product specifications. Version control features ensure everyone is working with the most up-to-date information, reducing errors and confusion.

- Workflow Visualization: Visualizing order fulfillment workflows using project management tools provides a clear overview of the entire process, highlighting dependencies and potential bottlenecks. This allows teams to identify areas for optimization and make informed decisions to speed up order fulfillment.

Collaboration with External Partners:

Collaboration with external partners, such as suppliers, logistics providers, or third-party vendors, is also crucial for fast order fulfillment. Key practices include:

Supplier Collaboration: Collaborating closely with suppliers enables better visibility into their production and delivery schedules. This helps ensure timely availability of raw materials or components, reducing lead times in the production process.

Logistics Coordination: Effective collaboration with logistics providers facilitates efficient transportation and delivery of orders. Sharing order information, shipment requirements, and delivery deadlines allows for accurate planning and reduces transit times.

Third-Party Integration: Integrating systems or sharing information with third-party vendors, such as fulfillment centers or drop-shipping partners, streamlines the fulfillment process and eliminates manual handoffs or delays.

By promoting collaboration and maintaining effective communication channels, organizations can accelerate order fulfillment speed. Teams can work together seamlessly, address issues promptly, and make informed decisions to optimize processes. This results in faster order processing, reduced lead times, improved customer satisfaction, and a competitive advantage in the market.

How Long Does it Take to Implement the Suggested Tips for Rapid Order Fulfillment?

The time required to implement the suggested tips for rapid order fulfillment can vary depending on several factors, including the complexity of the organization's existing processes, the scale of operations, the availability of resources, and the level of readiness for change. Here are some considerations that can affect the implementation timeline:

Evaluation and Planning Phase:

During this phase, it is important to assess the current order fulfillment processes, identify areas for improvement, and define the specific goals and objectives. The duration of this phase depends on the depth of analysis required and the level of complexity within the organization. It typically involves evaluating existing systems, conducting process mapping, and gathering input from key stakeholders. This phase can take anywhere from a few weeks to a couple of months, depending on the organization's size and complexity.

Technology Acquisition and Implementation:

If implementing new technologies or software solutions, the time required will depend on factors such as the complexity of the technology, the need for customization or integration with existing systems, and the availability of IT resources. It may involve vendor selection, software customization, data migration, and user training. The implementation of advanced manufacturing technologies, such as robotics or AI, may require additional time for installation, testing, and calibration. This phase can range from a few weeks to several months, depending on the scope and scale of the technology implementation.

Process Redesign and Optimization:

Implementing lean manufacturing principles, optimizing workflows, and eliminating waste requires a systematic approach. It involves analyzing current processes, identifying inefficiencies, redesigning workflows, and implementing changes. The duration of this phase depends on the complexity of the processes, the level of resistance to change, and the extent of process redesign required. It may involve piloting new processes, collecting feedback, and making iterative improvements. This phase can take several months to a year, depending on the organization's size and the magnitude of process changes.

Training and Skill Development:

Training employees on new processes, technologies, and best practices is crucial for successful implementation. The duration of training programs depends on the number of employees involved, the complexity of the changes, and the availability of training resources. It may involve classroom training, hands-on workshops, or online courses. The timeline can vary from a few weeks to a few months, depending on the training requirements and the availability of training resources.

Continuous Improvement and Monitoring:

Implementing rapid order fulfillment practices is an ongoing journey of continuous improvement. Organizations should establish mechanisms for monitoring key performance indicators (KPIs), collecting feedback, and making further optimizations. This requires regular review meetings, data analysis, and a commitment to a culture of continuous improvement. The duration of this phase is indefinite, as organizations should continuously refine their processes to adapt to changing market dynamics and customer demands.

It is important to note that the timeline provided here is a general estimation and can vary based on organizational factors. It is recommended to conduct a thorough assessment of the specific organizational context and develop a realistic implementation plan with a timeline tailored to the organization's needs and resources.

What are Some Potential Challenges in Achieving Rapid Order Fulfillment?

Achieving rapid order fulfillment can come with several challenges that organizations need to address to ensure smooth implementation. Here are some potential challenges that organizations may face:

Legacy Systems and Infrastructure:

Many organizations may have outdated or disparate systems and infrastructure that are not designed for rapid order fulfillment. Integrating new technologies or implementing changes can be challenging and time-consuming. Legacy systems may lack the necessary capabilities for real-time data sharing, process automation, or seamless integration with other systems. Upgrading or replacing systems may require significant investment and careful planning to ensure a smooth transition.

Resistance to Change:

Implementing changes in processes, technologies, or organizational culture can face resistance from employees and stakeholders. Resistance to change may stem from fear of job insecurity, lack of understanding about the benefits of the changes, or discomfort with new ways of working. Overcoming resistance requires effective change management strategies, clear communication, and involvement of employees in the process. It is crucial to address concerns, provide training and support, and emphasize the positive impact of rapid order fulfillment on employees and the organization.

Lack of Data Visibility and Analytics:

Inefficient data management and lack of real-time visibility into order fulfillment processes can hinder rapid order fulfillment. Organizations may struggle to collect, consolidate, and analyze data from various sources, leading to delays, errors, and ineffective decision-making. Implementing robust data management systems, integrating data from different departments, and utilizing analytics tools can help overcome this challenge. Organizations need to invest in technology and develop data-driven capabilities to monitor and optimize order fulfillment processes.

Supply Chain Complexity and Risks:

Supply chain complexities, such as multiple suppliers, global sourcing, or unpredictable demand fluctuations, can pose challenges to rapid order fulfillment. Lack of coordination and visibility across the supply chain can result in delays, stockouts, or poor quality control. Organizations need to develop strong supplier relationships, implement demand forecasting techniques, and adopt risk mitigation strategies. Collaborative planning, effective communication, and contingency planning can help address supply chain challenges and ensure timely order fulfillment.

Scalability and Capacity Constraints:

Rapid order fulfillment requires the ability to scale operations quickly to meet increased demand. Organizations may face challenges related to limited production capacity, warehouse space, or skilled labor. Scaling up operations may require capital investments, process redesign, and workforce planning. Organizations need to assess their capacity constraints, optimize resource allocation, and plan for scalability to ensure efficient order fulfillment during periods of high demand.

Customer Expectations and Variability:

Customer expectations for fast and accurate order fulfillment are constantly increasing. Meeting diverse customer demands, such as personalized products, shorter lead times, or flexible delivery options, can be challenging. Organizations need to understand customer requirements, invest in customer relationship management systems, and develop agile processes to accommodate variability. Balancing speed, customization, and quality requires effective coordination and communication with customers throughout the order fulfillment process.

Continuous Improvement and Adaptability: