The very essence of any business is to cater to customer needs by providing services and goods and, in the process, create value for customers and solve their problems. This can be easily achieved through production management. Let’s learn about production management and why it’s important for your business.

This article covers the following:

- What are the basics of production management?

- What is strategic planning in production management?

- What is the role of technology in production management?

- What is the importance of quality control in production management?

- How to analyze and improve production efficiency?

- What are the benefits of production management?

- What are the best practices in production management?

- What are the managing resources in production management?

- How can Deskera assist you?

What are the Basics of Production Management?

Production management is a broad term that encompasses the process of overseeing the production of goods or services. It is a critical element of the business process, as it helps to ensure that the highest quality standards are met while efficiently managing the resources and costs involved in the production process.

The basics of production management involve planning, organizing, controlling, and directing all of the activities related to the production of goods and services. It is essential to have a detailed plan in place before the production process begins so that the end goal is achievable.

This plan should include a timeline, budget, and materials needed for the production process. Organizing the production process is key to efficient operations. This involves creating an organizational structure, assigning roles and responsibilities, and setting up a system for tracking and monitoring production processes.

It is also important to have an effective communications strategy in place to ensure that all team members are on the same page. Controlling the production process involves monitoring and adjusting the production process to ensure that it is running smoothly and according to plan.

This may include evaluating the performance of employees, making adjustments to processes and procedures to improve efficiency, and setting goals for the team. Quality Control is also essential here, as it helps to ensure that the finished product meets the highest standards.

Finally, directing the production process involves motivating and inspiring the team to reach the desired outcome. This includes providing feedback and guidance, setting clear objectives and expectations, and creating an environment that encourages collaboration and innovation.

Production management is a complex process that requires careful planning and execution. With the right systems and processes in place, production processes can be streamlined, and costs can be minimized. By following these basic steps, businesses can ensure that their production processes are running smoothly and efficiently.

What is Strategic Planning in Production Management?

Strategic planning is an important part of production management. It involves setting objectives, developing strategies to achieve these objectives, and monitoring progress. Strategic planning is the process of establishing long-term goals and objectives and a plan for achieving them.

The purpose of strategic planning is to ensure that the organization is working towards its goals and objectives and that it has the resources necessary to do so. The first step in strategic planning is to determine the organization’s mission and vision. The mission statement should be a clear and concise statement of the organization’s purpose and the values that guide it.

The vision statement should outline the goals and objectives that the organization hopes to achieve. Once the mission and vision are established, the next step is to develop a strategic plan. This plan should include a detailed analysis of the organization’s current situation and the external environment.

This analysis should include a review of the organization’s strengths and weaknesses, as well as an assessment of potential opportunities and threats. The strategic plan should also identify the organization’s objectives and strategies. For each of these objectives, the plan should outline how they will be achieved and the resources required to do so. It should also include a timeline for achieving the objectives.

Once the strategic plan is developed, it is important to monitor progress. This includes assessing the results of the plan and making adjustments as necessary. It is also important to evaluate the effectiveness of the strategies and objectives.

Regular reviews should be conducted to ensure that the plan is on track and that it is achieving the desired results. Strategic planning is a critical component of production management. It is a process of setting long-term goals and objectives and developing a plan to achieve them.

The plan should include a detailed analysis of the external environment and an assessment of the organization’s strengths and weaknesses. It should also include objectives and strategies to achieve these objectives, as well as a timeline for achieving them. Finally, the plan should be monitored and evaluated regularly to ensure that it is on track and achieving the desired results.

What is the Role of Technology in Production Management?

Production management is the process of coordinating and optimizing the production process of a business to ensure that it meets customer needs while also ensuring that it is cost-effective and efficient.

Technology is a critical component of production management, as it can help businesses optimize their processes and improve efficiency. Technology can be used to automate production processes and increase the speed of production.

Automation can be used to reduce the labor costs associated with production and increase efficiency. Automated systems can also reduce the amount of human error associated with manual production processes.

Automated systems can be used to monitor and control functions such as temperature, speed, and pressure, as well as to alert personnel when something needs to be adjusted or inspected.

Technology can also be used to improve the quality of products. Quality control systems can be used to ensure that products meet pre-determined quality standards. Quality assurance systems can be used to ensure that products meet customer requirements and are up to industry standards.

Quality management systems can also be used to track and analyze production data to identify problems and suggest solutions. Technology can also be used to improve the accuracy of production planning.

Production planning software can help businesses plan production schedules and adjust production processes in real time. This can help businesses reduce costs associated with overproduction and wasted materials.

Production planning software can also be used to track and analyze inventory data to ensure that there is enough raw material and supplies available to meet customer demands. Technology can also be used to improve communication between various departments within a business.

Communication systems can be used to quickly and accurately share information between departments. This can help ensure that production processes are coordinated and that all departments are working together to meet customer needs.

Technology can also be used to improve the safety of production processes. Safety systems can be used to monitor production processes and alert personnel when there is a potential safety risk. This can help ensure that the production process is safe and that the products being produced are of high quality.

Technology has revolutionized production management and is an important tool for businesses that want to optimize their processes and improve efficiency. Automation, quality control, production planning, communication, and safety systems are just a few of the ways that technology can be used to improve production management processes. By leveraging the right technology, businesses can make sure that their production processes are efficient, cost-effective, and up to industry standards.

What is the Importance of Quality Control in Production Management?

Quality control is an important part of production management. It is the process of ensuring that all products meet the required standards of quality and are free from defects.

Quality control is necessary in order to ensure that the products produced are consistent and meet customer expectations. It is a critical part of the production process that helps to reduce costs and improve customer satisfaction. The first step in quality control is to set clear standards and objectives.

This involves defining the quality criteria for the products, such as the materials that are to be used, the type of design, and the level of performance that is expected. Once these standards have been established, it is important to ensure that they are consistently met.

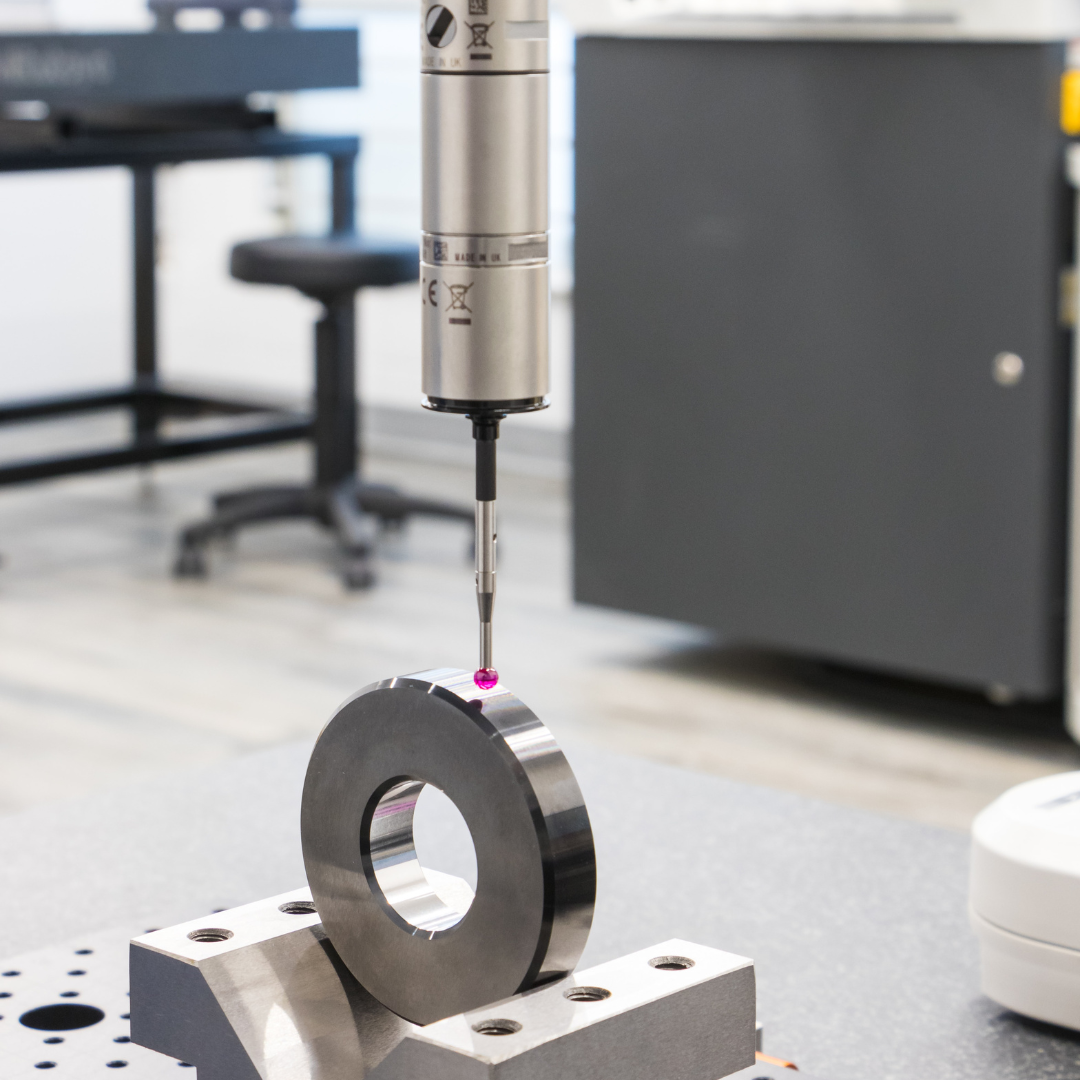

This can be done by creating a plan that outlines the steps that need to be taken to ensure quality control. The next step is to choose the right tools and techniques to be used in the production process. This includes selecting the right machinery and equipment, as well as choosing the right materials and processes to be used.

It is also important to ensure that the production process is monitored to ensure that all the quality control objectives are met. This includes setting up quality assurance systems, such as inspections and tests, that are used to check the quality of products. Once the production process is in place, it is important to monitor the quality control process.

This includes conducting regular audits and inspections to ensure that all the quality control objectives are met. These audits should be conducted regularly to ensure that the quality control process is working as intended. It is also important to document the results of these audits and review them periodically to ensure that changes are made if needed.

Finally, it is important to provide feedback to the production team. This includes providing feedback on the quality control process, as well as any feedback from customers.

Feedback can help to ensure that the quality control process is working as intended and that any changes are made if needed. Quality control is an important part of production management.

It is the process of ensuring that all products meet the required standards of quality and are free from defects. Quality control is necessary in order to ensure that the products produced are consistent and meet customer expectations.

It is a critical part of the production process that helps to reduce costs and improve customer satisfaction. Quality control involves setting clear standards and objectives, choosing the right tools and techniques, monitoring the production process, conducting regular audits and inspections, and providing feedback to the production team. By implementing these steps, companies can ensure that their production processes are producing quality products that meet the expectations of their customers.

How to Analyze and Improve Production Efficiency?

Analyzing and improving production efficiency is essential for any business that wants to remain competitive and profitable. Production efficiency involves optimizing the production process to maximize output while minimizing waste, cost, and time.

It requires careful analysis of the production process to identify areas where improvements can be made. In this blog, we will discuss the various methods for analyzing and improving production efficiency.

Analyzing Production Efficiency

The first step in improving production efficiency is to analyze the current production process. This can include examining the production process from end to end, identifying any inefficiencies or bottlenecks, and understanding the causes of these inefficiencies.

It can also involve reviewing production data to identify areas where efficiency can be improved. This analysis should give an understanding of the current production process, identify areas for improvement, and provide the basis for developing a plan for improving efficiency.

Identifying Bottlenecks

Once the production process has been analyzed, the next step is to identify any bottlenecks or inefficiencies that could be hindering production efficiency. Bottlenecks can occur at any stage of the production process, from raw materials to finished products, and can be caused by a variety of factors, such as inadequate resources, inefficient methods, or outdated equipment. Identifying and addressing these bottlenecks can help improve production efficiency and reduce costs.

Implementing Lean Manufacturing

Lean manufacturing is an approach to production efficiency that focuses on eliminating waste in the production process. It involves streamlining the production process by eliminating unnecessary steps and activities, reducing the time needed to complete tasks, and improving the flow of materials and information. By implementing lean manufacturing strategies, production can be made more efficient and cost-effective.

Streamlining Processes

Another way to improve production efficiency is to streamline processes. This can involve simplifying processes, eliminating redundant steps, and automating tasks where possible. Streamlining processes can help reduce errors, reduce costs, and increase production speed.

Improving Equipment and Facilities

Finally, production efficiency can be improved by investing in better equipment and facilities. This could involve purchasing more efficient machinery and tools, upgrading existing equipment, or improving the layout of the production facility.

Investing in better equipment and facilities can help increase production output, reduce waste, and reduce costs. These are just some of the methods for analyzing and improving production efficiency.

By understanding the production process, identifying inefficiencies, and implementing the strategies discussed, businesses can improve their production efficiency and remain competitive in the market.

What are the Benefits of Production Management?

Production management is the science of planning, organizing, and controlling the process of transforming raw materials into finished products. It is the basis of modern business because it helps companies take complex projects and break them down into small, manageable steps.

By understanding how to efficiently manage production, businesses can streamline their operations, reduce costs, and increase profits. The benefits of production management are numerous and can help companies reach their full potential. Here are the top five benefits of production management.

Streamlined Operations

Production management helps companies develop efficient processes that save time and money. By understanding the flow of materials and tasks, managers can identify areas of waste and inefficiency. This allows them to develop strategies to reduce costs and increase productivity.

Improved Quality

Production management helps companies maintain consistent product quality. By understanding the process of production, managers can identify any flaws or defects that could affect the quality of the final product. This allows them to quickly address any issues and ensure that all products meet the highest standards.

Increased Productivity

Production management helps companies maximize the use of resources and reduce waste. By understanding the production process, managers can develop strategies to reduce the amount of time, energy, and money spent to produce a single unit. This increases productivity and reduces costs.

Reduced Costs

Production management helps companies reduce costs by streamlining operations and increasing efficiency. By understanding the production process, managers can identify areas of waste and develop strategies to reduce costs. This allows them to produce products at a lower cost and increase profits.

Increased Profits

Production management helps companies maximize profits by reducing costs and increasing productivity. By understanding the production process, managers can identify areas of waste and develop strategies to reduce costs. This allows them to produce products at a lower cost, while still maintaining high-quality standards.

Production management is essential for modern businesses because it helps companies streamline operations, reduce costs, and increase profits. By understanding the production process, managers can identify areas of waste and develop strategies to reduce costs.

This allows them to produce products at a lower cost while still maintaining high-quality standards. With the right production management strategies, companies can maximize profits and reach their full potential.

What are the Best Practices of Production Management?

Production management is an essential part of any business, as it involves the oversight of the entire production process from start to finish. It encompasses all the activities from product design and development to inventory management and customer service.

Production management is responsible for ensuring that the production process runs smoothly and that the end product meets customer expectations. As such, it is important to understand and implement the best practices of production management in order to ensure that the production process is efficient and effective.

Effective Communication

The first best practice of production management is effective communication. It is important to ensure that all members of the production team are aware of the goals and objectives of the production process.

The production manager should be able to effectively communicate the details of the production process to all involved, from the highest level of management to the line workers. This will help to ensure that everyone is on the same page and that there are no misunderstandings that could hamper the production process.

Careful Planning

The second best practice of production management, is careful planning. Before beginning any production process, the production manager should develop a detailed plan for the production run.

This should include a timeline for the production process, as well as a budget for the project. The plan should also include any necessary materials, resources, and personnel that will be required to complete the production process.

Planning is essential for the success of the production process, as it helps to minimize delays and ensure that the end product meets customer expectations. The third best practice of production management is the use of quality control measures. Quality control measures are designed to ensure that the final product meets the standards set by the customer.

Quality control measures can include inspections, testing, and audits. These measures should be used throughout the entire production process to ensure that all products are of the highest quality.

Use of Technology

The fourth best practice of production management is the use of technology. Technology can be used to streamline the production process, as well as to improve quality control measures. Automation can be used to reduce the amount of time and effort required to complete a production run, as well as to reduce errors.

Technology can also be used to monitor the production process, allowing for greater visibility into the process and faster response times in the event of any problems.

Use Data-Driven Decision-Making

The fifth best practice of production management is the use of data-driven decision-making. Data-driven decision-making involves the use of data to inform decisions about the production process.

This can include the use of analytics to determine the most efficient production process or to identify areas of improvement. Data-driven decision-making can help to ensure that the production process is as efficient and effective as possible.

By implementing these best practices of production management, businesses can ensure that their production process is efficient and effective and that the end product meets customer expectations.

These practices can also help to reduce costs and improve quality control measures, leading to an improved bottom line. Ultimately, these practices can help to ensure that businesses are able to produce high-quality products that meet customer needs in a timely and cost-effective manner.

What are the Managing Resources in Production Management?

Production management is a process that involves the efficient use of resources, such as human resources, materials, machines, and equipment, to achieve the desired level of production.

It is a complex process that requires close coordination between different departments and personnel in order to ensure that production runs smoothly. This article will provide an overview of the managing resources of production management.

Human Resources

Human resources are one of the most important resources in production management. They are responsible for the planning, organizing, directing, and controlling of the production process.

They are also responsible for ensuring that the appropriate personnel is available to carry out the tasks required in the production process. They must also ensure that the person has the necessary skills and knowledge to complete their tasks.

Materials

Materials are another important resource in production management. This includes raw materials, components, and finished products. It is important to ensure that the right materials are used for the production process.

This includes selecting the appropriate materials for the job, purchasing the materials, storing the materials, and disposing of them when they are no longer needed.

Machines and Equipment

Machines and equipment are essential for the production process. They are used to produce the product, assemble parts, and test the product. It is important to select the right machines and equipment for the production process. This includes considering the size and complexity of the product, the cost of the machine, and the maintenance and repair costs.

Quality Control

Quality control is an important part of production management. It involves ensuring that the product meets the required standards of quality. It also involves detecting and correcting any defects in the production process. This includes using quality assurance techniques such as testing, inspection, and analysis.

Information Technology

Information technology is an important resource in production management. It is used to manage the production process, track progress, and store information. It is also used to communicate information between different departments and personnel.

These are some of the resources used in production management. It is important to ensure that the right resources are used in the right way to ensure a successful production process.

It is also important to ensure that the resources are used efficiently and in an organized manner. By doing this, production management can be more productive and efficient.

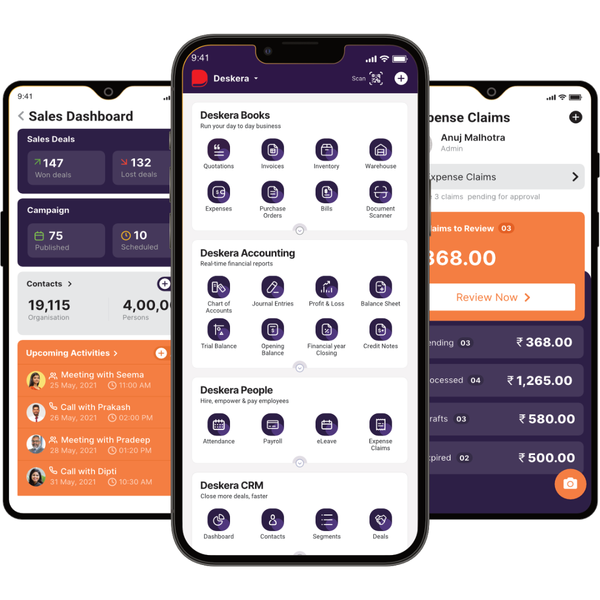

How Can Deskera Assist You?

Remember discussing best-in-class inventory software? There is no way you can find anything as well-equipped as the Deskera inventory software. Deskera inventory software allows you to closely monitor the manufacturing process.

Key Takeaways:

- Production management is a broad term that encompasses the process of overseeing the production of goods or services.

- The basics of production management involve planning, organizing, controlling, and directing all of the activities related to the production of goods and services.

- Strategic planning is an important part of production management. It involves setting objectives, developing strategies to achieve these objectives, and monitoring progress.

- Technology is a critical component of production management, as it can help businesses optimize their processes and improve efficiency.

- Quality control is necessary in order to ensure that products produced are consistent and meet customer expectations.

- Analyzing and improving production efficiency is essential for any business that wants to remain competitive and profitable.

Related Articles: