Have you ever wondered why some manufacturing plants seem to run at full speed while others struggle to meet even basic demand? The answer often lies in how well a business understands and manages its production capacity. In simple terms, production capacity determines how much you can produce with the resources you already have. When companies fail to measure or optimize it, they face delays, rising costs, and dissatisfied customers—even when demand is high.

Production capacity has become a critical performance indicator in today’s competitive manufacturing landscape. With fluctuating market demand, global supply chain disruptions, and increasing pressure to deliver faster, manufacturers can no longer rely on guesswork. They need a clear understanding of how much output their machines, workforce, and processes can realistically support. When capacity is optimized, businesses experience smoother operations, shorter production cycles, and higher profitability.

However, improving capacity isn’t as straightforward as adding more machines or hiring additional workers. Many manufacturers struggle with bottlenecks, unpredictable downtime, inefficient planning, and material shortages that quietly restrict their capacity. Identifying the root cause of these limitations—and aligning resources accordingly—requires a strategic and data-driven approach. This is why capacity planning and optimization are no longer optional; they’re essential for staying competitive.

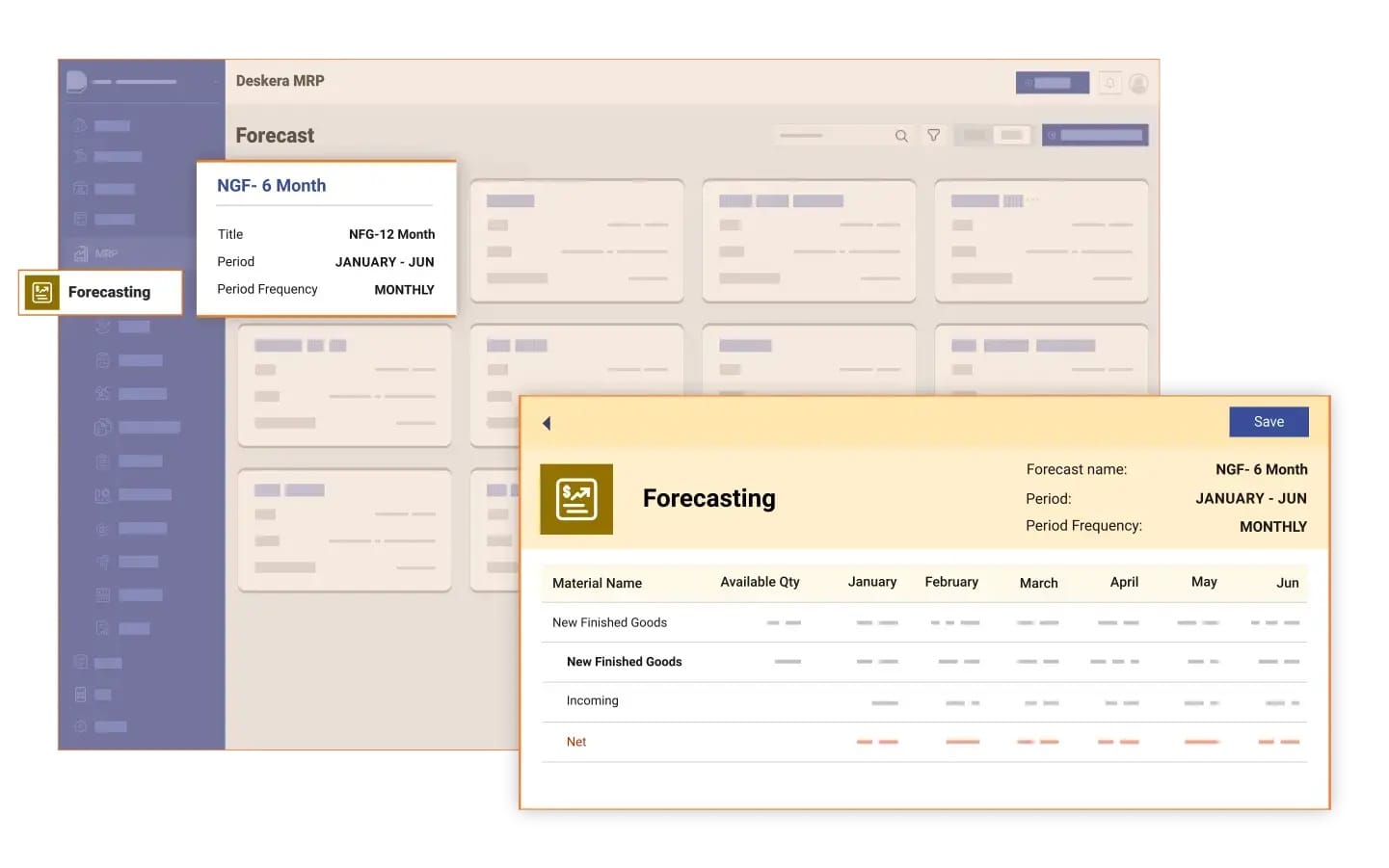

This is where Deskera MRP becomes a powerful enabler for modern manufacturers. Deskera’s system helps businesses streamline production planning, optimize work orders, and allocate resources more efficiently. With real-time visibility into machine capacity, labor availability, and material readiness, manufacturers can prevent bottlenecks before they occur. Its automated scheduling, smart demand forecasting, and intuitive dashboards empower teams to increase throughput without overextending resources—making it a valuable tool for improving overall production capacity.

What Is Production Capacity?

Production capacity refers to the maximum amount of goods a manufacturer can produce within a specific timeframe using its existing resources—including machines, labor, materials, and available working hours. It reflects the highest output a facility can achieve under normal operating conditions and serves as a crucial benchmark for understanding how efficiently the production system is performing.

At its core, production capacity helps manufacturers see the difference between what they are producing and what they could produce. This insight allows leaders to identify bottlenecks, evaluate resource utilization, and uncover hidden inefficiencies that may be causing unnecessary downtime or limiting throughput. Although every business aims to run at full capacity, real-world operations often experience constraints that reduce output, such as machine breakdowns, skill gaps, or material shortages.

This metric is also essential for making informed business decisions—both immediate and strategic. Whether it’s accepting a large customer order, planning labor shifts, evaluating machine upgrades, or forecasting future demand, understanding capacity ensures that manufacturers commit to what they can realistically deliver. It also prevents overburdening resources, which can lead to delays, quality issues, or cost overruns.

To further refine capacity analysis, manufacturers often break it down into different dimensions: design capacity (theoretical maximum output), effective capacity (output after accounting for planned downtime, maintenance, and changeovers), and actual capacity (true output after real-world disruptions). The gap between these levels highlights how well a plant is performing and where opportunities for optimization truly lie.

Types of Production Capacity

Understanding production capacity isn’t just about knowing the maximum output your factory can achieve—it’s about recognizing the different layers of capacity that shape real-world performance.

Manufacturers rarely operate at “perfect conditions,” so breaking capacity into distinct types helps identify gaps, hidden constraints, and areas where improvements can significantly boost throughput.

Below are the three major types of production capacity every manufacturer should measure.

Design Capacity

Design capacity represents the theoretical maximum output a production system can achieve if everything operates flawlessly. This assumes no machine downtime, no labor breaks, no changeovers, and no material delays—essentially a perfect production environment.

While no manufacturer consistently reaches this level, design capacity serves as an important benchmark for understanding the full potential of your equipment and processes.

Effective Capacity

Effective capacity reflects the realistic maximum output after accounting for planned downtime such as scheduled maintenance, cleaning, setup times, breaks, and expected workflow variations.

It provides a more accurate target for operations teams because it considers normal disruptions that naturally occur in manufacturing. This is the capacity level used for planning, scheduling, and forecasting.

Actual Capacity

Actual capacity refers to the true output achieved during production after including both planned and unplanned disruptions—such as machine breakdowns, quality issues, labor shortages, and material delays.

This metric shows how close the factory is to reaching its effective capacity. The gap between actual and effective capacity often highlights inefficiencies or bottlenecks that need attention.

Key Factors That Influence Production Capacity

Production capacity is shaped by a combination of operational, technological, and human factors. Even if a facility has advanced equipment, limitations in planning, materials, or workforce availability can still restrict output.

Understanding these influencing factors helps manufacturers pinpoint where productivity is being lost and what improvements can make the biggest impact.

Below are the key elements that determine how much a factory can truly produce.

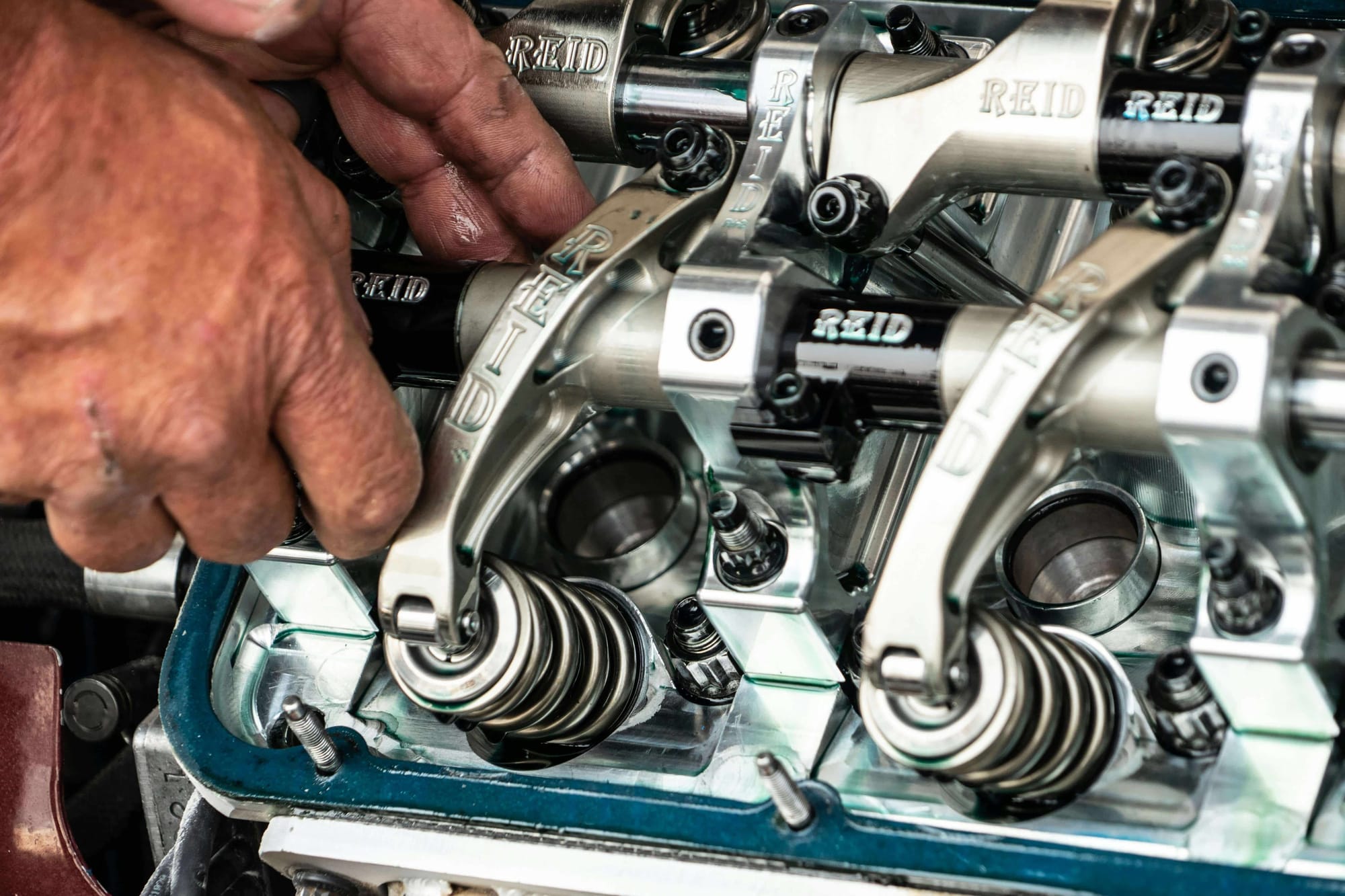

Equipment and Machine Efficiency

The performance, speed, and reliability of machinery directly affect production capacity. Aging equipment, frequent breakdowns, slow cycle times, and poor maintenance practices can significantly reduce output. Optimizing machine efficiency through upgrades, preventive maintenance, and monitoring tools helps manufacturers produce more without purchasing additional assets.

Labor Skills and Workforce Availability

A skilled and adequately staffed workforce is essential for maintaining high production levels. Capacity drops when workers lack training, when absenteeism rises, or when specialized skills are in short supply. Cross-training employees, improving shift planning, and enhancing skill development programs ensure that labor does not become a production bottleneck.

Production Planning and Scheduling

Even well-equipped factories can experience low capacity due to inefficient planning. Poor scheduling leads to idle time, uneven workload distribution, and longer lead times. Advanced planning tools, real-time scheduling, and accurate demand forecasting help align resources with actual production needs.

Material Availability and Inventory Levels

Capacity is heavily influenced by the timely availability of raw materials and components. Stockouts, long supplier lead times, or poor inventory management can halt production lines. Implementing better inventory control systems and improving supplier coordination ensures materials are available when needed.

Technology, Automation, and Digital Tools

Modern technologies—such as IoT sensors, automation, MRP/ERP systems, and AI-driven insights—play a pivotal role in boosting capacity. These tools improve visibility, streamline workflows, reduce manual errors, and enhance overall productivity. Manufacturers leveraging digital tools often achieve higher and more consistent output.

Layout, Workflow, and Space Utilization

Inefficient factory layouts and congested workflows slow down production. Poor material flow, long travel distances, and cluttered workstations reduce operational speed. Redesigning the layout, implementing 5S practices, and improving workflow ergonomics enable smoother, faster processes that increase capacity.

How to Calculate Production Capacity

Understanding how to calculate production capacity helps manufacturers forecast output, plan resources more accurately, and minimize costly inefficiencies. A precise capacity calculation improves scheduling, ensures better material planning, and reduces the risk of production bottlenecks. By evaluating technical, operational, and efficiency-related factors, manufacturers can gain a realistic view of how much they can produce within a given time frame.

1. Identify Total Available Machine or Labor Hours

Start by determining the total number of operational hours available. This includes:

- Number of machines or workers

- Shift length (in hours)

- Number of shifts per day

- Working days per month

- Planned maintenance shutdowns

Pro Tip: Deduct planned downtime, such as maintenance, cleaning, and inspection time, to get actual available hours.

2. Calculate Output per Hour (Cycle Time-Based)

Determine how many units a machine or line can produce per hour. This depends on:

- Standard cycle time per unit

- Level of automation

- Complexity of the product

- Material availability

Formula: Output per Hour = 60 / Cycle Time (in minutes)

This gives a more accurate measure than a general hourly estimate.

3. Incorporate Machine Utilization and Efficiency

No machine operates at 100%. Adjust for:

- Utilization: Percentage of time equipment is actually running

- Efficiency: How close actual performance is to ideal performance

Effective capacity = Available Hours × Output per Hour × Utilization × Efficiency

4. Consider Quality Yield (Good Units vs. Total Units)

Production capacity should reflect usable output. So, adjust for:

- Scrap rate

- Rework rate

- First-pass yield

Capacity after quality adjustment = Effective Capacity × Quality Yield %

Example: If 5% of units require rework, actual usable capacity drops.

5. Account for Bottlenecks

Your true production capacity is limited by the slowest machine, longest process, or most constrained workstation.

To calculate realistic capacity:

- Identify the bottleneck step

- Measure its maximum output

- Align all other processes to this limit

This is central to the Theory of Constraints (TOC).

6. Include Changeover and Setup Time

Multi-product environments require setup and tooling changes. This directly reduces available production time.

Consider:

- Number of changeovers

- Time per changeover

- Batch size planning

Reducing setup time increases capacity without new investments.

7. Evaluate Material Flow and Supply Availability

Production capacity is also influenced by:

- Raw material delivery speed

- Inbound quality consistency

- Warehouse or WIP movement speed

- Material handling constraints

If material flow is slow, capacity drops even if machines are fast.

8. Consider Workforce Productivity

Human-driven operations require factoring in:

- Skill levels

- Training time

- Fatigue and breaks

- Shift overlaps

Upskilling workers can directly improve line capacity.

9. Apply the Core Formula

Combining all variables:

Production Capacity = (Available Time − Downtime − Changeover Time) × Output per Hour × Utilization × Efficiency × Quality Yield

This gives the most accurate estimate.

10. Use a Capacity Cushion for Volatility

Manufacturers often keep a capacity cushion (usually 10–20%) to absorb:

- Sudden demand spikes

- Unexpected breakdowns

- Supply delays

This prevents overloading the system.

11. Adjust for Seasonal and Demand Variations

For manufacturers with fluctuating demand:

- Calculate monthly or quarterly capacity separately

- Maintain flexible shifts

- Plan inventory buffers

This keeps production aligned with market needs.

Common Challenges That Limit Production Capacity

Maximizing production capacity isn’t just about adding more machines or pushing workers harder—it starts with understanding what’s quietly restricting output. Many of these issues remain hidden until they begin affecting lead times, order fulfillment, or product quality.

Below are the most common challenges that prevent manufacturers from reaching their true production potential.

Bottlenecks and Unplanned Downtime

Every production line has a weakest link, and when that point slows down, the entire workflow suffers. A single machine running below standard speed, unexpected breakdowns, or imbalanced workstations can silently choke throughput.

The issue often isn’t noticed until performance metrics dip—by then, delays are already stacking up. Without real-time tracking, manufacturers end up reacting to problems instead of preventing them.

Workforce and Scheduling Constraints

Even the most advanced machines rely on skilled operators to run efficiently. Capacity drops when there are training gaps, staffing shortages, or rigid shift structures that don’t match production demand.

Seasonal spikes and last-minute order changes make scheduling even tougher—sometimes there aren’t enough hands on deck, while other times labor goes underutilized, raising operational costs.

Aging Equipment and Reactive Maintenance

Older machines can still get the job done, but they often come with slower speeds, recurring issues, and longer maintenance windows.

When maintenance is reactive instead of predictive, downtime becomes unpredictable and more expensive. Relying on manual logs or gut-based assessments makes it difficult to understand true asset performance, leading to underestimated capacity losses.

Demand Variability and Forecasting Challenges

Fluctuating customer demand makes capacity planning complex. A sudden surge of orders can overwhelm available resources, while unexpected drops lead to idle time and excess inventory.

Without flexible planning tools or accurate forecasting, manufacturers risk overcommitting to customers or tying up capital in products that don’t move.

Inefficient Inventory and Material Flow

A lack of timely materials, poor inventory visibility, or delays in procurement can stop production lines instantly. Even minor stockouts or late deliveries create cascading delays across batches.

Inefficient material movement within the facility—such as long travel distances, cluttered aisles, or disorganized storage—further slows down operations.

Poor Production Planning and Coordination

When planning is done manually or across disconnected systems, errors are common. Misaligned schedules, inaccurate BOMs, and last-minute changes create confusion on the shop floor. Without a unified view of resources, manufacturers end up with idle machines, delayed work orders, or overworked teams, directly reducing capacity.

Quality Issues and Rework

Defects, rework, and scrap consume both time and resources that could be used for new production. High defect rates point to deeper issues in processes, materials, or training. Over time, quality problems quietly eat into capacity, extending cycle times and reducing the number of usable units produced per shift.

Space Constraints and Inefficient Layouts

Congested aisles, poor workstation layout, and lack of clear material paths slow down movement and increase production time. As facilities scale, layouts often become outdated, leading to traffic jams and wasted space that restrict capacity.

Benefits of Increasing Production Capacity

Increasing production capacity is more than boosting output—it’s a strategic move that strengthens a manufacturer’s ability to compete, scale, and meet evolving market needs. When capacity improves, productivity rises, operations become more agile, and the entire value chain benefits.

Here are the key advantages of increasing production capacity.

1. Ensures Consistent Demand Fulfillment

Increasing production capacity directly improves your ability to meet customer demand without delays or shortages. When capacity aligns with market needs, manufacturers can deliver products on time, maintain reliability, and prevent backlogs. This consistency strengthens customer trust and protects long-term revenue streams.

2. Prevents Stockouts and Reduces Lost Sales

Higher capacity allows manufacturers and ecommerce businesses to keep sufficient inventory on hand, especially during seasonal spikes or unexpected demand surges. This reduces the risk of stockouts—one of the biggest contributors to lost sales and customer churn.

3. Streamlines Manufacturing Processes

Capacity improvements often go hand-in-hand with better resource allocation, optimized workflows, and reduced waste. Whether through lean methods, automation, or better scheduling, manufacturers achieve smoother operations and more predictable output. This leads to higher productivity with fewer operational disruptions.

4. Supports Better Resource and Workforce Allocation

A clear understanding of capacity allows businesses to distribute workloads evenly across teams, shifts, and equipment. This prevents overburdening a single machine or workforce group, reducing fatigue, errors, and burnout while maintaining morale and efficiency.

5. Enhances Operational Efficiency

Rising demand puts stress on existing systems. Increasing capacity—through better planning, skilled labor, or improved technology—helps preserve operational efficiency even as workloads grow. This reduces bottlenecks, minimizes error rates, and ensures smoother production flows.

6. Enables Scalability and Business Growth

A business cannot scale without scalable production. Increasing production capacity allows companies to enter new markets, accept larger contracts, or expand product lines. It positions the organization to handle future growth without requiring constant emergency adjustments.

7. Boosts Profitability and Reduces Cost Per Unit

Higher production levels mean more units sold—and when efficiency improves simultaneously, cost per unit decreases. Reduced wastage, optimized machine utilization, and better procurement all contribute to healthier margins. Ultimately, a more productive facility drives higher profitability.

8. Improves Market Competitiveness

In competitive markets, the ability to deliver faster and in larger quantities can set a company apart. Businesses with higher capacity respond quicker to demand spikes, fulfill orders consistently, and maintain service quality even during peak periods—strengthening their market position.

9. Helps Surpass Customer and Market Expectations

With improved capacity, manufacturers not only meet demand—they exceed expectations by offering shorter lead times, consistent quality, and reliable service. This can significantly enhance brand reputation and customer loyalty.

10. Fosters Continuous Improvement and Innovation

Increasing production capacity often requires evaluating bottlenecks, reviewing processes, and adopting new technologies. This naturally drives a culture of continuous improvement, enhanced problem-solving, and steady operational innovation.

11. Enables Faster Adaptation to Market Changes

When capacity is well-managed, manufacturers can adjust quickly to demand fluctuations, supply chain disruptions, or shifts in customer preferences. This adaptability is essential in dynamic markets where agility determines sustained success.

12. Strengthens Supply Chain Performance

Higher capacity supports better planning across procurement, production, and distribution. It reduces last-minute purchases, improves supplier coordination, and ensures smoother production scheduling, resulting in a more resilient supply chain.

13. Provides Clear Data for Measuring Operational Success

Production capacity serves as a strategic performance indicator. As it improves, manufacturers gain insights into workforce productivity, equipment efficiency, and the health of overall operations. Regular capacity assessments help identify areas for investment, optimization, and long-term planning.

14. Supports New Product Launches and Expansion Initiatives

A facility with stronger capacity can introduce new SKUs, test new product lines, or expand into new regions with confidence. This supports innovation and gives businesses room to experiment and grow without straining existing resources.

How to Improve Production Capacity in 2025

Improving production capacity in 2025 requires a mix of quick wins and long-term transformation. As manufacturers face rising demand variability, labor shortages, and growing pressure to optimize cost per unit, boosting capacity is no longer just about adding more machines.

Instead, it’s about using smarter methods, advanced technologies, and streamlined workflows to maximize what you already have—while preparing your operations for future growth.

Below are the most effective short-term and long-term strategies manufacturers can use to reliably increase capacity.

1. Add More Work Shifts or Offer Overtime

Running additional shifts is one of the fastest ways to increase output without buying new equipment. Manufacturers can:

- Add an evening or weekend shift

- Offer overtime pay to extend machine run-time

- Use temporary labor during peak demand seasons

This approach works best when equipment is available but labor capacity is the limiting factor.

2. Outsource Production for Short-Term Needs

When internal capacity is maxed out, outsourcing certain production steps to contract manufacturers provides flexibility. This helps businesses:

- Meet seasonal spikes

- Prevent order backlogs

- Maintain delivery timelines without heavy capital expenditure

Outsourcing is ideal when short-term demand exceeds long-term capacity requirements.

3. Optimize Current Equipment Utilization

Before investing in new assets, manufacturers should ensure current machines are running at their best. Focus on:

- Using underutilized machine capabilities

- Reducing setup times

- Improving changeover efficiency

- Increasing operator-machine coordination

Small improvements in utilization can unlock significant additional capacity.

4. Improve Equipment Effectiveness With Proactive Maintenance

Adopting proactive or predictive maintenance practices ensures equipment stays reliable and productive. Manufacturers should:

- Track OEE (Overall Equipment Effectiveness) at the machine level

- Schedule planned maintenance before breakdowns occur

- Reduce minor stoppages and performance losses

Higher OEE directly correlates with higher production capacity.

5. Reduce Machine Downtime With Total Productive Maintenance (TPM)

TPM empowers operators—not just maintenance teams—to take part in daily upkeep. When workers handle cleaning, basic inspections, lubrication, and early detection:

- Downtime drops

- Equipment life increases

- Breakdowns become rare

- Throughput improves consistently

TPM builds a culture of ownership and keeps production lines running at peak capacity.

6. Identify and Resolve Production Bottlenecks

Capacity is always determined by your slowest process. Use tools like:

- Value stream mapping

- Flowcharts

- Pareto charts

- Cause-and-effect diagrams

- Simulation modeling

This data helps you pinpoint where delays occur, why they happen, and how to remove them. Eliminating a single bottleneck can unlock exponential capacity growth.

7. Implement Lean Manufacturing Principles

Lean manufacturing eliminates waste and optimizes flow, making it an essential strategy for capacity improvement. Techniques include:

- 5S for workplace organization

- Just-in-Time (JIT) to reduce WIP and improve flow

- Kaizen for continuous improvement

- Standardized work to reduce variations

By targeting the eight wastes—defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra processing—operations become faster, cleaner, and more productive.

8. Optimize Your Production Layout

A poorly designed layout slows material movement and creates unnecessary delays. To improve flow:

- Reorganize stations around logical process sequences

- Reduce motion waste by placing materials closer to use points

- Label equipment and storage for easy access

- Involve shop-floor workers in layout improvement decisions

A streamlined layout ensures smoother operations and increased throughput.

9. Plan and Execute Tasks More Efficiently

A well-organized production schedule and coordinated workflow help prevent delays. Manufacturers should:

- Build realistic schedules

- Balance machine loading

- Ensure material availability before production begins

- Use visual management tools for real-time tracking

Reducing micro-delays prevents slowdowns from snowballing into expensive shutdowns.

10. Improve Workforce Skills Through Training

Skilled operators can:

- Run machines more efficiently

- Reduce setup time

- Identify issues before breakdowns

- Maintain higher product quality

Investing in training improves speed, accuracy, and reliability—boosting capacity without additional headcount or machinery.

11. Utilize Advanced Planning and Scheduling (APS) Software

Modern APS systems help manufacturers plan smarter by:

- Using real-time data to allocate resources

- Automatically adjusting schedules during disruptions

- Predicting load vs. capacity mismatches

- Providing full visibility across machines and shifts

APS tools eliminate guesswork, reduce idle time, and maximize production output.

12. Try New Technologies That Enhance Visibility and Control

Smart manufacturing technologies, such as IoT sensors, AI-driven monitoring tools, and automated data collection, help manufacturers:

- Track machine health

- Predict failures

- Measure true cycle times

- Monitor operator performance

- Improve OEE in real-time

Technology upgrades create sustained increases in capacity and efficiency.

13. Maximize Your Capacity Utilization Rate

Calculating and monitoring capacity utilization helps you understand how much potential output is being used.

Formula: Capacity Utilization = (Actual Output ÷ Potential Output) × 100

Improving utilization through better planning, fewer stoppages, and optimized scheduling increases the percentage of productive time, driving higher throughput.

14. Purchase New Machinery for Long-Term Capacity Expansion

When every optimization has been exhausted and demand keeps growing, it may be time to invest in:

- Faster machines

- More automated systems

- Additional production lines

Capital expenditure should align with long-term demand forecasts, not short-term spikes.

15. Improve Overall Business Processes

Capacity improvement is not limited to the shop floor. Manufacturers should evaluate:

- Material procurement

- Supplier reliability

- Inventory management

- Quality control

- Process documentation

Standardizing and optimizing these processes helps eliminate delays and ensures smoother, more predictable production cycles.

15 Metrics to Keep Tracking Production Capacity

Consistently monitoring the right metrics is essential for understanding how efficiently your factory is running—and where hidden capacity may be unlocked.

These KPIs reveal whether your equipment, labor, and processes are performing at their full potential, and they help you make data-backed decisions that improve production output over time.

Here are the most important metrics manufacturers should track to manage and optimize production capacity.

1. Overall Equipment Effectiveness (OEE)

OEE measures the three critical dimensions of equipment performance—availability, performance, and quality. It highlights how much productive time you're losing due to machine downtime, speed losses, or defects.

A high OEE score indicates strong utilization of equipment capacity, while a low score signals bottlenecks and hidden inefficiencies.

2. Total Effective Equipment Performance (TEEP)

TEEP takes OEE a step further by measuring total machine capability across 24 hours a day, 365 days a year.

Where OEE tells you how effective you are during scheduled production time, TEEP shows how much unused potential capacity exists overall. This is especially helpful when evaluating long-term expansion plans or deciding whether to add shifts.

3. Capacity Utilization Rate

This KPI measures how much of your potential output you’re actually producing.

Formula: Capacity Utilization = (Actual Output ÷ Maximum Possible Output) × 100

A lower rate means there is idle capacity that could be tapped through better planning, scheduling, or maintenance.

4. Machine Utilization

This percentage tracks how often a machine is in operation compared to how often it could be operating. It shows whether production time is being fully leveraged and helps identify idle machines, overused machines, or imbalanced workloads.

5. Throughput (Units per Hour)

Throughput measures how many units a production line delivers in a set period. Increasing throughput without adding new resources indicates improved productivity and better capacity management.

6. Cycle Time

Cycle time is the total time required to produce one unit from start to finish. By monitoring cycle time variations, manufacturers can detect:

- Operator inefficiencies

- Setup issues

- Equipment performance drops

- Bottlenecks in specific steps

Lower cycle times directly translate into higher production capacity.

7. Takt Time

Takt time defines the pace of production needed to meet customer demand. Comparing actual cycle time to takt time shows whether your factory is keeping up—or falling behind.

If cycle time > takt time → capacity shortages

If cycle time < takt time → available capacity exists

8. Planned vs. Actual Production

This KPI tracks the difference between scheduled output and actual output achieved. Frequent gaps indicate issues such as:

- Poor scheduling

- Material shortages

- Inefficiencies in worker allocation

- Unplanned downtime

A consistent gap also signals the need to revisit capacity assumptions.

9. Downtime Rate (Planned + Unplanned)

Downtime is one of the biggest capacity killers. Monitoring downtime by category—breakdowns, changeovers, material shortages, labor unavailability—reveals where capacity is being lost.

Reducing downtime is one of the fastest ways to boost output without investment.

10. First Pass Yield (FPY) or Quality Yield

FPY measures how many units pass through production without requiring rework. Poor FPY reduces available capacity because defective units consume machine hours, labor time, and materials.

High FPY = more output, less waste.

11. Changeover Time

Frequent or lengthy changeovers reduce available machine hours. Tracking this metric helps you:

- Standardize changeover procedures

- Adopt SMED (Single-Minute Exchange of Dies) techniques

- Reduce transition delays between product runs

- Recover lost capacity through better planning

12. Labor Productivity

Labor productivity measures output per worker or per labor hour. Monitoring this helps evaluate skill gaps, training needs, and the impact of workforce efficiency on overall capacity.

13. Work-in-Progress (WIP) Levels

High WIP often signals bottlenecks, poor workflow balance, or uneven pacing. Optimizing WIP helps free up space, reduce lead times, and improve throughput—all of which increase capacity.

14. Resource Loading & Line Balancing Metrics

These metrics help ensure every workstation has the right amount of work. Imbalances (one station overloaded, another idle) reduce the line’s total output.

15. Supplier Lead Time Performance

Production capacity is heavily affected by material availability. Long or inconsistent lead times create slowdowns that pull the capacity below its true potential. Monitoring supplier reliability helps prevent these disruptions.

How Can Deskera MRP Improve Production Capacity?

Deskera MRP plays a pivotal role in helping manufacturers boost their production capacity by optimizing planning, eliminating inefficiencies, and enabling smarter decision-making. With its AI-powered assistance, real-time visibility, and automated workflows, Deskera empowers teams to produce more with the same—or even fewer—resources. Here’s how it directly strengthens production capacity:

1. Accurate Demand Forecasting for Better Capacity Planning

Deskera MRP uses historical data, current market trends, and predictive analytics to forecast demand more accurately. This ensures you allocate the right resources at the right time, preventing overloading or underutilization of machines and labor. With clearer demand visibility, production capacity is planned proactively rather than reactively.

2. Automated Production Scheduling

Deskera’s drag-and-drop production scheduling tool automatically assigns jobs based on machine availability, workforce capacity, and material readiness. This reduces downtime, avoids scheduling conflicts, and ensures a consistent production flow—allowing you to execute more orders efficiently.

3. Real-Time Inventory Control

The system tracks raw materials, WIP, and finished goods in real time. By preventing stockouts and reducing excess inventory, Deskera ensures uninterrupted production cycles. Material availability directly influences production capacity, and Deskera helps maintain the optimal balance.

4. Bottleneck Identification and Workload Balancing

With real-time insights into machine performance, resource utilization, and workflow timings, Deskera MRP easily identifies bottlenecks. Managers can rebalance workloads, reroute tasks, or adjust schedules to avoid delays. This helps maximize throughput without overburdening teams.

5. Enhanced Shop Floor Efficiency

Deskera offers real-time shop floor updates so manufacturers can track job progress, lead times, and completion rates instantly. This helps detect inefficiencies early, enabling faster corrective action. Improved shop-floor visibility leads to better capacity utilization and higher output.

6. AI Assistant (David) for Faster Decision-Making

Deskera’s AI assistant, David, provides instant insights, generates reports, predicts delays, and recommends improvements. When decision-making is faster and data-driven, manufacturers can adjust capacity planning on the fly and respond quickly to changes in demand.

7. Reduced Downtime Through Preventive Maintenance

The platform enables scheduled and preventive maintenance planning. By maintaining machines at the right time—not too early, not too late—Deskera reduces unexpected breakdowns, which are major capacity killers.

8. Multi-Level BOM and Routing Optimization

With multi-level BOMs, routing details, and cost breakdowns, Deskera helps engineers optimize operations. Properly defined routing ensures each job flows through the most efficient path, improving capacity utilization and reducing cycle times.

9. Scalability to Support Business Growth

Whether you're handling 100 or 100,000 orders, Deskera MRP scales effortlessly. As your business grows, the system expands operational capacity through automation, improved coordination, and optimized workflows—without proportionally increasing labor or machinery.

Key Takeaways

- A clear understanding of production capacity helps manufacturers assess how much they can realistically produce, plan smarter, and respond better to market demand.

- Different capacity types—design, effective, actual, and rated—offer unique insights into how operations perform and where improvement opportunities lie.

- Machine performance, labor skills, material availability, workflows, and technology significantly shape how much output your facility can truly achieve.

- Using formulas like standard output, machine capacity, line capacity, and practical capacity helps you quantify current performance and set realistic improvement targets.

- Bottlenecks, downtime, skill gaps, poor scheduling, aging equipment, and fluctuating demand limit operational efficiency and require proactive monitoring.

- Enhancing capacity improves demand fulfillment, operational efficiency, profitability, competitiveness, sustainability, and long-term organizational growth.

- Improving production capacity requires a strategic blend of optimized workflows, balanced resource utilization, upgraded technology, proactive maintenance, and data-driven planning—ensuring manufacturers can increase output without unnecessary costs or operational strain.

- KPIs such as OEE, TEEP, utilization, cycle time, throughput, and capacity utilization offer real-time visibility into how well your resources are performing.

- Deskera MRP boosts production capacity through smarter forecasting, automated scheduling, inventory accuracy, bottleneck detection, real-time insights, and scalable operations.

Related Articles