According to the Global Chemicals Outlook II, published by the United Nations Environment Programme (UNEP) in 2019, the chemical industry is one of the most significant contributors to air pollution, accounting for around 3% of global energy-related greenhouse gas emissions.

Furthermore, the World Health Organization (WHO) estimates that air pollution, including pollution from chemicals, is responsible for approximately 7 million premature deaths each year worldwide.

Chemical production has driven innovation and technological progress in various industries, from agriculture to medicine. However, the environmental impact of chemical production is a growing concern for many.

As we continue to rely on chemicals to meet our modern needs, it is important to carefully analyze and address their environmental impact.

This article will explore how chemical production can impact the environment and discuss potential solutions for mitigating these impacts.

- Chemical Production and its Importance to Various Industries

- Analyzing the Environmental Impact Of Chemical Production

- Environmental Impacts of Chemical Production

- Examples of the Negative Effects Of Chemical Production

- Why is the Analysis Important?

- Case Studies

- Solutions For Reducing the Environmental Impact

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Chemical Production and its Importance to Various Industries

Chemical production plays a crucial role in meeting the needs of many industries worldwide. Let’s take a quick look at the process of chemical production.

Chemical Production: An Overview

Chemical manufacturing entails the process of manufacturing chemicals and chemical products through a series of chemical reactions, physical separations, and purification steps. This involves transforming raw materials, such as natural gas, crude oil, minerals, or plant-based materials, into a wide range of chemical products used in various industries, such as pharmaceuticals, plastics, agriculture, and electronics.

The chemical manufacturing process typically involves several stages, including synthesizing the chemical compound, purification of the product, and packaging and distribution. Chemical manufacturing can be carried out in small-scale or large-scale facilities, depending on the intended application and demand for the product.

The chemical manufacturing industry is critical in driving innovation and technological progress in many industries. However, it also presents environmental and health risks due to using hazardous chemicals and generating waste products. Therefore, it is important to carefully manage the manufacturing process and adopt sustainable practices to minimize these risks and ensure the industry's long-term sustainability.

Significance in Various Industries

From agriculture to medicine, chemicals are used to improve and enhance the products we rely on in our daily lives. Here are some of the ways that chemical production is important to various industries:

- Agriculture: Chemicals are used to enhance crop yields and protect them from pests and disease. Fertilizers, pesticides, and herbicides are just a few examples of chemicals that are commonly used in agriculture.

- Pharmaceuticals: Chemicals are the building blocks of many pharmaceuticals, including prescription drugs, over-the-counter medications, and vaccines. Without chemical production, we would not have access to many life-saving drugs we rely on.

- Plastics: Chemical production is essential for the production of plastics, which are used in a wide range of products, from water bottles to car parts. Without plastics, many industries would struggle to function.

- Electronics: Chemicals are used in the production of electronic components, including semiconductors and circuit boards. Without these chemicals, we would not have access to the advanced technology that we rely on in our daily lives.

While chemical production is essential to these industries and many others, it is important to consider the potential environmental impacts of these chemicals. By carefully analyzing the environmental impact of chemical production, we can work to ensure that these industries continue to thrive while minimizing harm to the environment.

Analyzing the Environmental Impact Of Chemical Production

Analyzing the environmental impact of chemical production is a complex process that involves several steps. Here are some of the key elements of this analysis:

- Identifying potential hazards: The first step in analyzing the environmental impact of chemical production is to identify potential hazards associated with the chemicals and manufacturing processes involved. This can include assessing the toxicity of the chemicals, the risks associated with their use and disposal, and the potential for accidental releases or spills.

- Quantifying the impact: Once potential hazards have been identified, the next step is to quantify the environmental impact of chemical production. This can involve measuring the number of pollutants released into the air, water, and soil and assessing the long-term impacts of these pollutants on the environment and human health.

- Developing mitigation strategies: Based on the results of the environmental impact analysis, the next step is to develop mitigation strategies to minimize the impact of chemical products on the environment. This can include measures such as pollution prevention, waste management, and the use of less toxic chemicals.

- Monitoring and reporting: After mitigation strategies have been implemented, it is important to monitor the environmental impact of chemical products on an ongoing basis. This can involve regular testing of air, water, and soil for pollutants and monitoring the health of nearby ecosystems and human populations. It is also important to report on the results of these monitoring efforts to stakeholders, including regulatory agencies, community groups, and customers.

- Continuous improvement: Analyzing the environmental impact of chemical production is not a one-time effort. It is an ongoing process that requires continuous improvement to reduce the impact of chemical production on the environment. This can involve implementing new technologies, developing new best practices, and continually reassessing the impact of chemical production to identify new areas for improvement.

Overall, analyzing the environmental impact of chemical production is an essential part of responsible chemical manufacturing. By identifying potential hazards, quantifying the impact, developing mitigation strategies, monitoring and reporting, and continuously improving, companies can minimize the negative impact of their operations on the environment and human health.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) and Material Flow Analysis (MFA) are two commonly used methods for analyzing the environmental impact of chemical production.

Life Cycle Assessment (LCA) is a method for assessing the environmental impact of a product or process throughout its entire life cycle, from raw material extraction to disposal. LCA considers a range of environmental impacts, such as greenhouse gas emissions, water use, and resource depletion, and can be used to identify areas for improvement and compare the environmental performance of different products or processes.

Material Flow Analysis (MFA)

Material Flow Analysis (MFA) is a method for analyzing the flow of materials and substances through a system, such as a chemical production plant. MFA can be used to track the inputs and outputs of a system and to identify areas where materials are being wasted or where toxic substances are being released into the environment.

By analyzing material flows, companies can identify opportunities for waste reduction, pollution prevention, and resource efficiency.

Both LCA and MFA are useful tools for analyzing the environmental impact of chemical production. LCA is particularly useful for analyzing the overall environmental impact of a product or process, while MFA is useful for identifying specific areas for improvement within a production system.

By using both methods in conjunction, companies can gain a more comprehensive understanding of the environmental impact of their operations and develop more effective strategies for reducing their environmental footprint.

Environmental Impacts Of Chemical Production

Chemical production can have several environmental impacts, including:

- Air Pollution: The manufacturing process for chemicals can release pollutants into the air, such as nitrogen oxides, sulfur oxides, and volatile organic compounds (VOCs). These pollutants can contribute to smog, acid rain, and other forms of air pollution, which can harm human health and the environment.

- Water Pollution: Chemical production can also generate wastewater that contains hazardous chemicals, which can contaminate surface water and groundwater. This can harm aquatic ecosystems and the human population that relies on these water sources.

- Soil Pollution: Chemical spills and leaks can contaminate soil, making it unsuitable for agriculture or other uses. This can have long-term impacts on the environment and human health.

- Climate Change: Chemical production can also contribute to climate change by releasing greenhouse gases, such as carbon dioxide and methane, during manufacturing. These gases can trap heat in the atmosphere, contributing to global warming and climate change.

- Land Use: Chemical production can require large amounts of land to produce and store raw materials and finished products. This can lead to deforestation and habitat destruction, which can harm biodiversity and ecosystem function.

- Waste Generation: Chemical production can generate hazardous waste, such as spent solvents, that can have long-term impacts on the environment if not disposed of properly.

It is important to note that not all chemical production has the same environmental impact, and the level of impact can vary depending on the specific chemicals and manufacturing processes involved.

Examples of the Negative Effects of Chemical Production

Here are some specific examples of the negative effects of chemical production:

- Lead contamination: The production of lead-based paints, batteries, and other products has resulted in lead contamination in soil, water, and air. Exposure to lead can cause neurological damage, especially in children.

- Mercury pollution: Mercury is a toxic metal that can be released during chemical production. When mercury enters the environment, it can accumulate in fish and other wildlife, posing a risk to human health when consumed.

- Dioxin exposure: Dioxins are a group of highly toxic chemicals that can be released during the production of certain chemicals, including pesticides and herbicides. Exposure to dioxins has been linked to cancer, reproductive problems, and other health issues.

- Eutrophication: Chemical fertilizers and other agricultural chemicals can contribute to eutrophication. It a process in which excess nutrients in water lead to the growth of harmful algal blooms. These blooms can deplete oxygen in the water, harming aquatic life and leading to "dead zones" in oceans and lakes.

- Climate change: The production of certain chemicals, such as hydrofluorocarbons (HFCs) and perfluorocarbons (PFCs), can contribute to climate change. The process releases greenhouse gases into the atmosphere.

These examples illustrate the potential for chemical production to negatively impact human health and the environment. The industry needs to adopt responsible practices and mitigate these negative impacts as much as possible.

Why is the Analysis Important?

Analyzing the environmental impact of chemical production is important for several reasons. Here are some of the key reasons why this analysis is crucial:

Protection of Human Health

Chemicals can have harmful effects on human health if they are not managed properly. By analyzing the environmental impact of chemical production, we can identify potential hazards and take steps to minimize exposure to these chemicals, protecting human health.

Protection of the Environment

Chemicals can also have harmful effects on the environment, including soil, water, and air pollution. Analyzing the environmental impact of chemical production can help identify potential sources of pollution and develop strategies to minimize their impact on the environment.

Compliance with Regulations

Many countries have strict regulations on the use and disposal of chemicals to protect human health and the environment. By analyzing the environmental impact of chemical production, companies can ensure that they are in compliance with these regulations, avoiding potential fines and legal issues.

Corporate Responsibility

Analyzing the environmental impact of chemical production is an essential part of corporate responsibility. Companies are responsible for minimizing the environmental impact of their operations, and analyzing the impact of their chemical production is an important step in fulfilling this responsibility.

Sustainability

The long-term sustainability of the chemical industry relies on minimizing its environmental impact. Analyzing the environmental impact of chemical products can help identify opportunities to improve sustainability and reduce the use of non-renewable resources.

In summary, analyzing the environmental impact of chemical production is essential for protecting human health and the environment, ensuring compliance with regulations, fulfilling corporate responsibility, and promoting sustainability.

Case Studies

There are several case studies that illustrate the importance of environmental impact analysis in chemical production. Here are a few examples:

Dow Chemical Company

The Dow Chemical Company conducted a life cycle assessment (LCA) of its Styrofoam insulation products to identify opportunities for improving the environmental performance of its production processes. The LCA found that the largest environmental impact was associated with the production of raw materials, particularly the extraction, and processing of petroleum.

As a result, Dow has focused on reducing the amount of petroleum used in the production of its insulation products and has also implemented recycling programs to reduce waste.

BASF

BASF, a global chemical company, has used Material Flow Analysis (MFA) to assess the environmental impact of its production processes. MFA helped BASF identify areas where waste was being generated and where recycling and resource efficiency opportunities existed.

As a result, the company has implemented a number of measures to reduce waste, including improved process design, more efficient use of raw materials, and the recycling of waste materials.

AkzoNobel

AkzoNobel, a multinational chemical company, used LCA to assess the environmental impact of its decorative paints. The LCA identified the production of titanium dioxide, a key raw material in the production of paint, as the largest source of environmental impact.

Consequently, AkzoNobel has focused on reducing the amount of titanium dioxide used in its products and has also implemented a number of measures to improve the energy efficiency of its production processes.

DuPont

DuPont, a chemical company that produces a wide range of products, has used LCA to assess the environmental impact of its Nylon 6,6 polymer production process. The LCA found that the production of raw materials was the largest source of environmental impact, particularly the extraction and processing of petroleum.

As a result, DuPont has focused on reducing the amount of petroleum used in its production processes and has also implemented measures to improve the energy efficiency of its production processes.

These case studies demonstrate the value of environmental impact analysis in chemical production. By identifying areas for improvement, companies can reduce their environmental footprint, improve their environmental performance, and ultimately enhance their long-term sustainability.

Solutions for Reducing the Environmental Impact

Several solutions can help to reduce the environmental impact of chemical production:

- Green Chemistry: Green Chemistry is an approach to chemical production that aims to minimize the use of hazardous materials and reduce waste. By using safer chemicals and optimizing production processes, companies can reduce their environmental impact and improve the sustainability of their operations.

- Recycling and Reuse: Recycling and reusing materials can help to reduce waste and conserve resources. By implementing recycling programs and reusing materials in production processes, companies can reduce the amount of waste they generate and minimize their environmental impact.

- Energy Efficiency: Improving production processes' energy efficiency can help reduce greenhouse gas emissions and lower energy costs. By implementing measures such as energy-efficient lighting, equipment, and production processes, companies can reduce their energy consumption and improve their environmental performance.

- Material Substitution: Substituting hazardous materials with safer alternatives can help reduce chemical production's environmental impact. By using safer chemicals and materials, companies can reduce the risks associated with the production and use of their products.

- Process Optimization: Optimizing production processes can help to reduce waste and improve the efficiency of chemical production. By using data analytics and process control techniques, companies can identify opportunities for waste reduction and process improvement.

- Life Cycle Assessment (LCA): LCA can be used to identify areas where the environmental impact of chemical production can be reduced. By analyzing the environmental impact of a product or process throughout its entire life cycle, companies can identify areas for improvement and develop more sustainable production processes.

These solutions can help companies to reduce the environmental impact of chemical production and improve the sustainability of their operations. By adopting these practices, companies can also enhance their reputation and meet the growing demand for sustainable and environmentally responsible products.

Conclusion

The environmental impact of chemical production is a complex and pressing issue that requires careful analysis and intervention. While chemicals are integral to our modern way of life, the environmental costs of their production and use are substantial, including air and water pollution, habitat destruction, and the release of greenhouse gases.

Fortunately, various strategies and technologies are available to reduce the environmental impact of chemical production, such as green chemistry, pollution prevention, and resource conservation. By implementing these practices, chemical producers can not only reduce their environmental footprint but also improve their bottom line through reduced waste and increased efficiency.

We must continue to prioritize chemical production's sustainability and work together to ensure a healthier and more sustainable future for both people and the planet.

How can Deskera Help You?

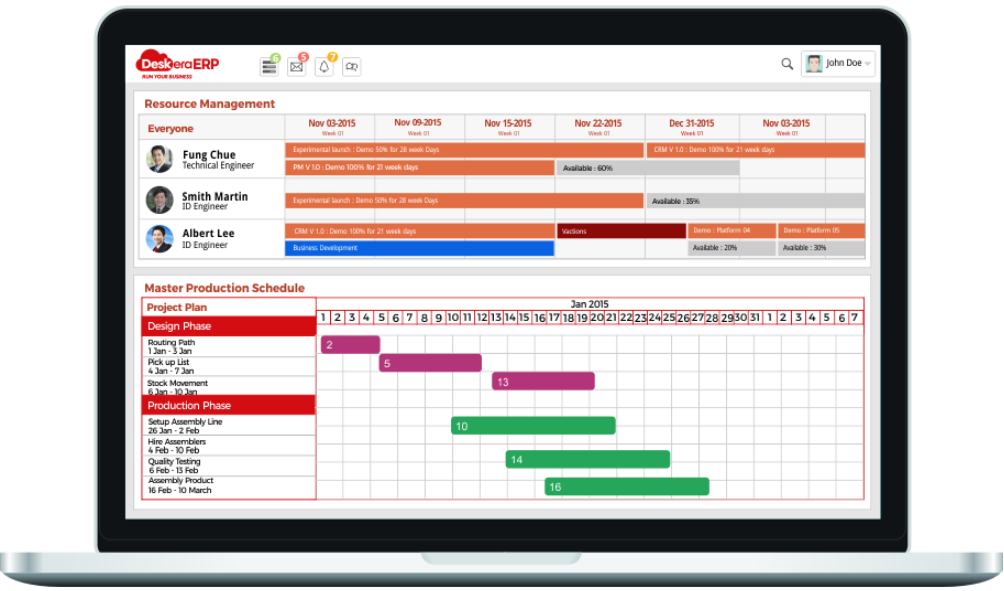

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera MRP enables real-time monitoring of the manufacturing process. The solution assists you in staying on top of your game and maintaining your company's competitive edge, from the bill of materials to the production planning features.

Deskera Books can help you automate your accounting and reduce business risks. Deskera simplifies the creation of invoices by automating many other procedures, reducing the administrative workload of your team.

Deskera also provides integrated applications to assist businesses with financial, inventory, and operations management. Other business aspects include HR (Deskera People), CRM (Deskera CRM), and Deskera ERP.

Key Takeaways

- Chemical manufacturing is the process of producing chemicals and chemical products through a series of chemical reactions, physical separations, and purification steps.

- Analyzing the environmental impact of chemical production is an essential part of responsible chemical manufacturing.

- By identifying potential hazards, quantifying the impact, developing mitigation strategies, monitoring and reporting, and continuously improving.

- Life Cycle Assessment (LCA) and Material Flow Analysis (MFA) are two commonly used methods for analyzing the environmental impact of chemical production.

- Life Cycle Assessment (LCA) is a method for assessing the environmental impact of a product or process throughout its entire life cycle, from raw material extraction to disposal.

- Material Flow Analysis (MFA) is a method for analyzing the flow of materials and substances through a system, such as a chemical production plant.

- It is important to note that not all chemical production has the same environmental impact, and the level of impact can vary depending on the specific chemicals and manufacturing processes involved.

- Lead contamination, mercury pollution, and dioxin exposure are some of the negative effects of chemical production.

Related Articles