Why do machines break down even when spare parts are available? Because many businesses stock MRO items without truly managing them. Maintenance, Repair, and Operations (MRO) inventory often sits in the background—unnoticed until a missing bolt, filter, or spare part brings production to a halt. This makes MRO inventory management less about storage and more about ensuring operational continuity.

MRO inventory management focuses on controlling the non-production items that keep equipment running smoothly. These items may not directly appear in finished goods, but they play a critical role in preventing downtime, maintaining safety standards, and supporting maintenance teams. Without a structured approach, organizations often struggle with excess stock, emergency purchases, and unplanned maintenance delays.

As operations scale and equipment becomes more complex, managing MRO inventory manually becomes increasingly risky. Lack of visibility, inconsistent tracking, and disconnected maintenance schedules can quickly inflate costs and reduce asset reliability. A well-defined MRO inventory strategy helps businesses balance availability with cost control while improving maintenance efficiency.

This is where Deskera Manufacturing ERP adds measurable value. Deskera Manufacturing ERP provides centralized visibility into MRO inventory, real-time stock tracking, and automated reorder alerts to prevent shortages. By integrating inventory management with maintenance planning and advanced reporting, Deskera Manufacturing ERP helps manufacturers streamline MRO operations, reduce downtime, and make data-driven inventory decisions with confidence.

What Is MRO Inventory?

MRO stands for Maintenance, Repair, and Operations, and it refers to the activities and resources required to keep a company’s facilities, equipment, and day-to-day operations running smoothly. This includes everything from routine machinery maintenance and emergency repairs to everyday operational needs such as cleaning and office administration.

Although MRO does not directly contribute to finished goods, it plays a critical role in ensuring uninterrupted operations. In fact, studies indicate that MRO costs can account for up to 4.5% of revenue in some industries, making effective control essential for protecting profitability.

MRO inventory comprises the consumable materials, tools, equipment, and supplies needed to support maintenance, repair, and operational activities. Unlike raw materials, MRO items are used during the production process but are not incorporated into the final product.

Examples include spare parts for machinery, safety gear for employees, and cleaning supplies for facilities. Because MRO inventory supports nearly every department, inadequate availability can quickly lead to downtime, safety risks, and productivity losses.

Despite its importance, MRO inventory is often overlooked—especially in small and mid-sized businesses—because it represents a smaller portion of overall inventory spend.

This lack of focus can result in hidden costs such as emergency purchases, excess stock, or unplanned equipment failures. A structured approach to MRO inventory management helps businesses maintain the right balance between availability and cost control while supporting preventive and corrective maintenance.

MRO Inventory Examples

MRO inventory covers a wide and diverse range of items, including:

- Maintenance and repair supplies: machine oil, lubricants, bearings, valves, cutting fluids, motors, and gears

- Safety equipment: masks, earplugs, hard hats, respirators, safety goggles, and face shields

- Janitorial supplies: cleaning chemicals, disinfectants, mops, brooms, rags, buckets, and disposable gloves

- Office supplies: computers, printers, toner, furniture, paper, pens, and stationery

- Laboratory and testing supplies: beakers, test tubes, syringes, scales, and measuring instruments

Together, these items form the backbone of efficient operations, making MRO inventory management a foundational element of operational reliability and cost efficiency.

What Is MRO Inventory Management?

MRO inventory management refers to the systematic process of purchasing, storing, tracking, using, and replenishing all items classified under Maintenance, Repair, and Operations inventory. The primary objective is to ensure that the right MRO items are available at the right time, in the right quantity, and at the right cost, without tying up excess capital in unused stock. Given the wide variety of MRO items—often ranging into the hundreds or thousands—managing this inventory efficiently can be both complex and time-consuming.

Unlike traditional inventory management, which focuses on goods meant for sale, MRO inventory management deals with items that support daily operations but do not generate direct revenue. Because these items are “not for sale,” many organizations fail to prioritize their management. However, MRO inventory is essential to business continuity—without it, equipment failures, maintenance delays, and operational disruptions can quickly bring work to a standstill.

At its core, MRO inventory management helps businesses prevent stockouts, avoid emergency purchases, and reduce unplanned downtime. It supports both preventive and corrective maintenance by ensuring critical supplies and spare parts are always accessible when needed. Poor MRO inventory control, on the other hand, can lead to inflated maintenance costs and reduced asset reliability.

While some businesses still rely on spreadsheets or manual tracking, modern inventory software often delivers better outcomes. Digital MRO inventory management tools provide real-time visibility, automated reorder alerts, and accurate usage tracking, making it easier to maintain optimal stock levels and keep operations running smoothly and cost-effectively.

Importance of MRO Inventory Management

MRO inventory may not be directly linked to finished goods or sales, but it plays a mission-critical role in keeping operations running smoothly. Effective MRO inventory management ensures operational continuity, cost control, safety compliance, and workforce productivity. When managed poorly, even small missing items can trigger major disruptions across the entire supply chain.

Preventing Production Downtime and Work Stoppages

One of the most important reasons to manage MRO inventory effectively is to avoid unplanned downtime. If a critical machine component, tool, or maintenance supply is unavailable, production can come to a complete halt. Without proper tracking, businesses may not realize a shortage until it is too late—leading to hours or even days of lost production, missed delivery deadlines, and strained customer relationships.

Avoiding Overstocking and Controlling Costs

While stockouts are costly, overstocking MRO inventory can be just as damaging. Excess inventory ties up working capital, increases storage costs, and raises the risk of items becoming obsolete over time. Effective MRO inventory management helps organizations maintain optimal stock levels by analyzing usage patterns, forecasting demand, and aligning purchases with actual operational needs.

Maintaining Productivity Across Teams

MRO inventory directly impacts employee productivity. When maintenance teams or frontline workers waste time searching for tools, spare parts, or supplies, small delays accumulate into significant inefficiencies. A well-managed MRO inventory ensures that employees have immediate access to what they need, allowing them to focus on preventive maintenance, repairs, and core operational tasks.

Ensuring Safety and Regulatory Compliance

Many MRO items—such as personal protective equipment, safety tools, and maintenance supplies—are essential for meeting health, safety, and environmental regulations. Poor MRO inventory control can result in missing safety gear, neglected equipment maintenance, and increased risk of accidents or regulatory violations. Proper management helps organizations remain compliant while protecting employees and assets.

Improving Overall Operational Efficiency

Disorganized or manually tracked MRO inventory often leads to duplicate purchases, misplaced items, and inaccurate stock records. This creates confusion and wastes valuable time. A structured MRO inventory management approach improves visibility, streamlines workflows, and ensures that maintenance, operations, and procurement teams stay aligned—ultimately strengthening the entire operational ecosystem.

MRO Inventory Management Challenges

Despite its critical role in keeping operations running, MRO inventory management is often underestimated and treated as an afterthought. Unlike raw materials or finished goods, MRO items are indirect in nature, highly diverse, and used unpredictably—making them significantly harder to control. When MRO inventory is managed in silos or without a structured strategy, organizations face a range of operational and financial challenges.

Lack of Centralized Control and Fragmented Purchasing

In many organizations, different departments independently purchase and manage their own MRO supplies. This fragmented approach leads to inconsistent procurement practices, limited oversight, and higher administrative effort. Without centralized control, companies struggle to standardize vendors, consolidate orders, or enforce purchasing policies.

High Acquisition and Administrative Costs

MRO inventory typically consists of thousands of low-value items ordered frequently and in small quantities. Without an efficient procurement process, the administrative cost of creating purchase orders, invoices, and receipts can exceed the cost of the items themselves. In addition, skilled technicians may spend valuable time searching for parts or tracking orders instead of focusing on maintenance tasks.

Duplication and Maverick Spending

When departments fear delays or shortages, they often stockpile their own MRO supplies—even if similar items already exist elsewhere in the organization. This duplication results in excess inventory, increased storage costs, and unnecessary spending. Maverick purchasing outside approved processes further reduces cost control and visibility.

Limited Inventory Visibility and Tracking Issues

Without a centralized MRO inventory system, organizations lack real-time visibility into stock levels and item locations. One team may assume a critical spare part is unavailable, while another department has it stored elsewhere. These visibility gaps can cause emergency purchases, maintenance delays, or prolonged downtime.

Unpredictable Demand and Poor Forecasting

MRO usage is often reactive, driven by unexpected equipment failures or urgent maintenance needs. Without accurate consumption data and historical insights, businesses struggle to forecast demand, set reorder points, or budget effectively. This unpredictability increases the risk of both stockouts and overstocking.

Risk of Obsolescence

Spare parts and specialized tools can quickly become obsolete when machinery is upgraded, replaced, or phased out. Poor inventory planning and excess stocking increase the likelihood of holding outdated items that no longer add value, tying up capital unnecessarily.

Accounting and Cost Allocation Complexity

MRO inventory is typically classified as an indirect expense, making it harder to track and analyze compared to direct materials. This lack of financial visibility can obscure true maintenance costs and limit opportunities for cost optimization.

Together, these challenges highlight why MRO inventory management requires a structured, centralized, and data-driven approach to support operational reliability and long-term cost efficiency.

Best Practices for MRO Inventory Management

MRO inventory may not command the same attention as raw materials or finished goods, but unmanaged MRO costs can quietly erode profitability and disrupt operations.

Following proven best practices helps organizations maintain availability of critical items, control indirect spending, and support maintenance teams without overstocking or waste. A disciplined, data-driven approach turns MRO from a reactive cost center into a strategic operational enabler.

Identify and Prioritize Critical MRO Items

Start by identifying all MRO items and classifying them based on criticality. Focus first on items whose absence would immediately halt production, create safety risks, or severely impact service delivery. Techniques such as ABC analysis or criticality-based classification help ensure that high-impact items receive priority attention and tighter inventory controls.

Conduct Regular Audits and Physical Counts

Routine audits and cycle counts help ensure inventory records accurately reflect what is physically available. Regular inspections uncover misplaced items, discrepancies, and obsolete or unused stock occupying valuable space. Accurate data from audits supports smarter replenishment decisions and reduces the risk of unexpected shutdowns caused by incorrect stock records.

Centralize and Standardize MRO Inventory

Centralizing MRO inventory—physically or virtually—improves visibility and reduces duplication across departments or locations. Standardizing item specifications, part numbers, and storage methods makes it easier for teams to find what they need and prevents unnecessary purchases of similar or incompatible items.

Optimize Supplier Selection and Consolidation

Reducing the number of MRO suppliers and building long-term relationships with strategic vendors simplifies procurement and lowers administrative costs. Supplier consolidation often leads to better pricing, more reliable delivery, and stronger service-level agreements, while also reducing paperwork and procurement complexity.

Implement Data-Driven Demand Forecasting

Although MRO usage can be unpredictable, analyzing historical consumption, maintenance schedules, seasonal trends, and production plans helps improve demand forecasting. Better forecasts reduce emergency purchases, prevent stockouts of critical items, and limit excess inventory that ties up working capital.

Establish Clear Reordering and Inventory Control Policies

Define reorder points, safety stock levels, and lead-time assumptions for key MRO items. Using KPIs such as stockout rates, lead times, and inventory turnover helps guide purchasing decisions and keeps inventory levels aligned with operational needs and budget constraints.

Educate and Empower Employees

Clear policies and training are essential to reduce maverick spending and duplicate purchases. Employees involved in requesting, using, or ordering MRO items should understand approval workflows, tracking requirements, and their role in inventory control. Accountability at every level leads to lower waste and better cost discipline.

Leverage Vendor-Managed Inventory (VMI) Where Appropriate

For high-usage or predictable MRO items, Vendor-Managed Inventory (VMI) can be highly effective. In a VMI model, suppliers monitor inventory levels and handle replenishment, reducing administrative burden and ensuring consistent availability of critical supplies.

Use Inventory Management Software and ERP Integration

Manual spreadsheets quickly become inefficient as MRO complexity grows. Inventory management software—especially when integrated into an ERP system—provides real-time visibility, automated alerts, usage tracking, and reporting. ERP integration aligns MRO inventory with maintenance planning, procurement, and financial controls for better decision-making.

Review and Optimize MRO Inventory Regularly

MRO inventory should be reviewed periodically to adapt to changes in equipment, production volume, or maintenance strategies. Regular reviews help identify opportunities to eliminate obsolete items, renegotiate supplier terms, and continuously improve inventory efficiency.

By applying these best practices consistently, organizations can reduce downtime, control indirect costs, improve compliance, and ensure their operations remain reliable, lean, and productive.

How Can Deskera Manufacturing ERP Help You with MRO Inventory Management?

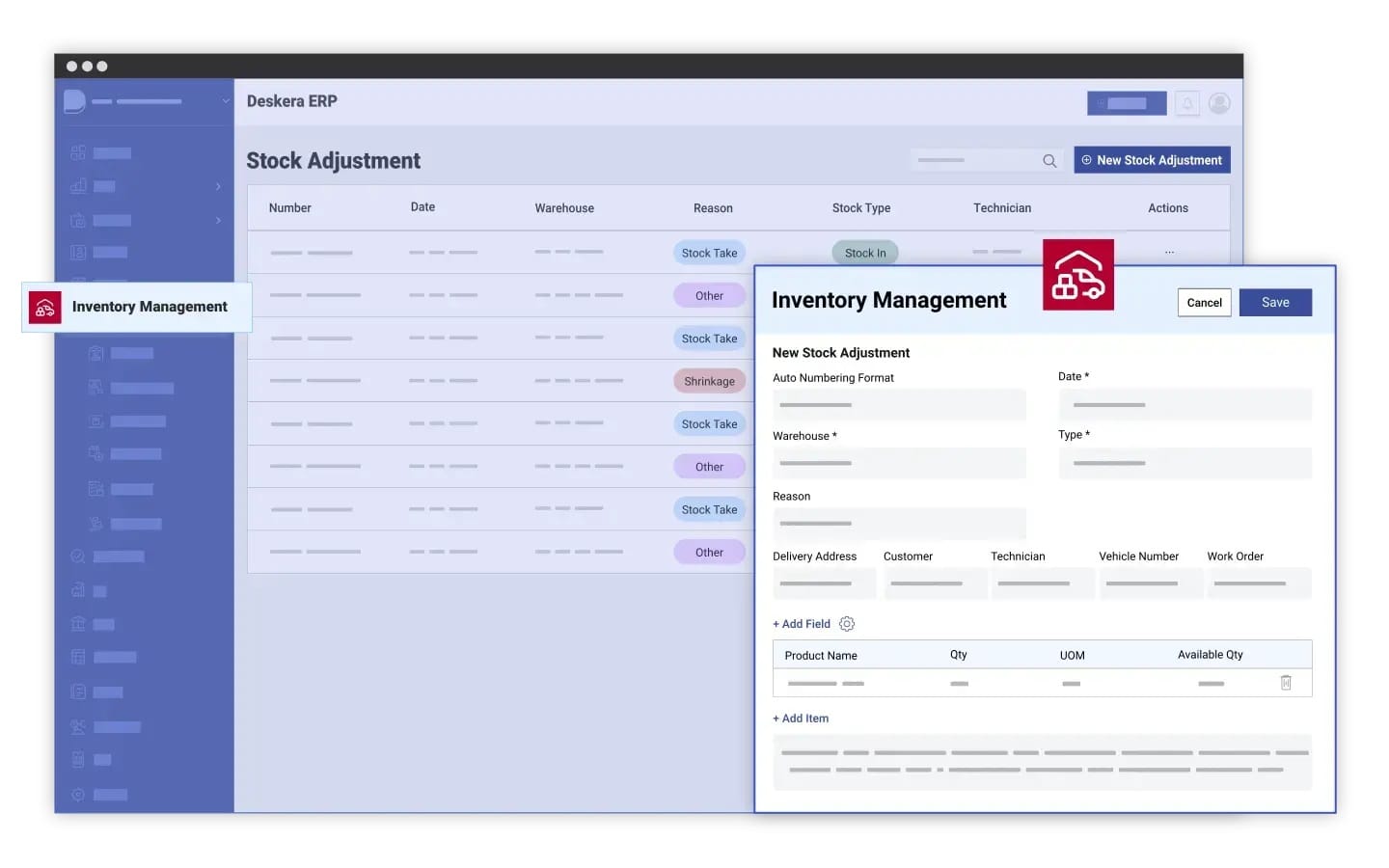

Managing MRO inventory can be complex, time-consuming, and costly—especially without real-time visibility into stock levels, usage trends, and maintenance schedules. Deskera Manufacturing ERP helps streamline and automate every aspect of MRO inventory management, turning what is often an overlooked cost center into a well-controlled operational asset.

1. Centralized Real-Time Inventory Visibility

Deskera Manufacturing ERP provides a single view of all MRO stock across multiple locations. Whether parts are stored in a central storeroom, maintenance closet, or on the plant floor, you’ll always know what you have, where it is, and how much remains—eliminating guesswork and reducing the risk of stockouts or excess inventory.

2. Automated Reordering and Alerts

Never run out of critical supplies again. Deskera enables you to set reorder points, safety stock levels, and replenishment rules for each MRO item. When stock drops below the threshold, the system automatically generates alerts or purchase requisitions—helping avoid emergency purchases and production stoppages.

3. Integration with Maintenance and Production

Unlike standalone spreadsheets or basic inventory tools, Deskera Manufacturing ERP connects MRO inventory with maintenance schedules and production plans. This integration ensures that maintenance teams can plan preventive upkeep and repairs without worrying about unavailable parts—leading to fewer breakdowns and improved equipment uptime.

4. Demand Forecasting and Consumption Tracking

By tracking historical usage data, consumption patterns, and maintenance frequency, Deskera helps you forecast future MRO needs more accurately. Smarter forecasting means better inventory optimization, fewer costly rush orders, and lower carrying costs.

5. Vendor and Purchase Management

Deskera’s procurement features allow you to manage supplier information, compare pricing, and streamline purchasing. You can track supplier performance, consolidate orders with preferred vendors, and automate approval workflows—reducing administrative burden and improving overall acquisition efficiency.

6. Enhanced Traceability and Audit-Ready Records

With Deskera, every transaction related to MRO inventory—receipts, issues, transfers, adjustments—is logged and easily traceable. This not only improves accountability but also simplifies audits, compliance reporting, and internal reviews.

7. Mobile Accessibility for On-The-Go Teams

Maintenance teams and warehouse staff can access Deskera from mobile devices to scan barcodes/QR codes, update stock movements, and check item details in real time. Mobile access speeds up physical counts, cycle audits, and material issuance—even from the shop floor.

8. Actionable Reporting and Insights

Deskera Manufacturing ERP delivers customizable reports and dashboards that highlight key performance indicators like inventory turnover, stock aging, carrying costs, and stockout events. These insights empower decision-makers to fine-tune inventory policies and align MRO strategy with broader business goals.

Deskera Manufacturing ERP helps you transform MRO inventory from an unmanaged cost liability into a streamlined and predictable process—improving operational continuity, reducing unnecessary costs, and enabling data-driven decisions across maintenance, procurement, and production teams.

Key Takeaways

- MRO inventory includes the tools, spare parts, consumables, and supplies required to keep equipment, facilities, and daily operations running—without becoming part of finished goods.

- MRO inventory management focuses on efficiently purchasing, storing, tracking, and replenishing indirect inventory to ensure availability at the right time and cost.

- Effective MRO inventory management prevents downtime, controls indirect costs, maintains safety compliance, and sustains productivity across operations.

- Fragmented purchasing, poor visibility, unpredictable demand, duplication, and obsolescence make MRO inventory more complex to manage than traditional inventory.

- Prioritizing critical items, centralizing inventory, auditing regularly, forecasting demand, educating employees, and leveraging technology are key to optimizing MRO control.

- Deskera Manufacturing ERP centralizes MRO inventory, automates replenishment, integrates maintenance and procurement, and delivers real-time insights to reduce downtime and costs.

Related Articles