In today's fast-paced and highly competitive business landscape, manufacturing executives face numerous challenges in meeting customer demand, optimizing production processes, and managing inventory efficiently.

To address these challenges, an increasing number of manufacturing companies are turning to real-time demand forecasting as a valuable tool in their strategic decision-making process.

By leveraging advanced data analytics and cutting-edge technologies, real-time demand forecasting enables manufacturing executives to gain valuable insights into customer demand patterns, optimize production planning, and enhance overall operational efficiency.

This article covers the following:

- Improved Production Planning: How real-time demand forecasting optimizes production planning for manufacturing executives.

- Enhanced Inventory Management: Leveraging real-time demand forecasting to optimize inventory levels and reduce costs.

- Streamlined Supply Chain Operations: The impact of real-time demand forecasting on supply chain efficiency and effectiveness.

- Increased Customer Satisfaction: Exploring how real-time demand forecasting leads to better customer service and satisfaction.

- Minimized Stockouts and Overstocking: The role of real-time demand forecasting in preventing stockouts and avoiding excess inventory.

- Agile Decision-Making: How real-time demand forecasting empowers manufacturing executives to make informed and agile decisions.

- Cost Reduction and Efficiency: Unveiling the cost-saving potential of real-time demand forecasting in manufacturing operations.

- Accurate Demand Planning: The importance of real-time demand forecasting in accurately predicting customer demand and improving decision-making.

- Adaptive Production and Capacity Management: How real-time demand forecasting enables manufacturing executives to adjust production and capacity to meet changing demand.

- Market Opportunity Identification: How real-time demand forecasting helps manufacturing executives identify new market opportunities and capitalize on them.

- Enhanced Profitability: Examining the positive impact of real-time demand forecasting on manufacturing companies' bottom line.

- Competitive Advantage: Understanding how real-time demand forecasting provides a competitive edge for manufacturing executives in a dynamic marketplace.

Improved Production Planning: How real-time demand forecasting optimizes production planning for manufacturing executives.

Effective production planning is crucial for manufacturing executives to meet customer demands, optimize resources, and stay competitive in today's dynamic market.

Real-time demand forecasting plays a pivotal role in enhancing production planning processes, enabling manufacturing executives to make informed decisions and achieve operational efficiency. This article delves into the benefits of real-time demand forecasting and how it optimizes production planning for manufacturing executives.

- Accurate Demand Prediction: Real-time demand forecasting provides manufacturing executives with up-to-date and accurate insights into customer demand patterns.

By analyzing real-time data, such as sales trends, customer behavior, and market dynamics, executives can make more precise demand predictions. This accuracy allows for better resource allocation, reducing the risk of overproduction or stockouts.

- Just-in-Time Inventory Management: Real-time demand forecasting enables manufacturing executives to adopt a just-in-time (JIT) inventory management approach.

By aligning production with actual demand, executives can minimize inventory carrying costs while ensuring that products are available when customers need them. JIT inventory management reduces waste, optimizes cash flow, and improves overall supply chain efficiency.

- Efficient Resource Allocation: With real-time demand forecasting, manufacturing executives gain insights into the specific products and variants that are in high demand.

This information enables them to allocate resources efficiently, ensuring the right production capacities and workforce are in place. By optimizing resource allocation, executives can streamline operations, minimize downtime, and maximize productivity.

- Improved Production Scheduling: Real-time demand forecasting provides visibility into demand fluctuations, allowing manufacturing executives to create more accurate and responsive production schedules.

By adjusting production schedules based on real-time demand insights, executives can optimize machine utilization, reduce lead times, and improve on-time delivery performance. This level of agility is especially valuable in industries with short product lifecycles or volatile demand patterns.

- Demand-Driven Procurement: Real-time demand forecasting enables manufacturing executives to align procurement processes with demand fluctuations.

By accurately predicting future demand, executives can optimize procurement quantities, negotiate better pricing with suppliers, and reduce excess inventory. This demand-driven approach helps minimize stockouts and excess stock while maintaining a lean and efficient supply chain.

- Rapid Response to Market Changes: In today's fast-paced business environment, manufacturing executives need to respond swiftly to market changes.

Real-time demand forecasting equips executives with the necessary information to adapt quickly to shifting customer preferences, emerging trends, or unexpected events. By proactively adjusting production plans based on real-time insights, executives can seize opportunities, mitigate risks, and maintain a competitive edge.

Real-time demand forecasting empowers manufacturing executives to optimize production planning by accurately predicting customer demand, adopting JIT inventory management, efficiently allocating resources, improving production scheduling, and responding rapidly to market changes.

By leveraging the benefits of real-time demand forecasting, manufacturing executives can enhance operational efficiency, reduce costs, and meet customer expectations more effectively in today's dynamic marketplace.

Enhanced Inventory Management: Leveraging real-time demand forecasting to optimize inventory levels and reduce costs.

Effective inventory management is essential for manufacturing executives to maintain a balance between meeting customer demands and minimizing inventory costs.

Real-time demand forecasting plays a vital role in enhancing inventory management practices, enabling executives to optimize inventory levels, reduce carrying costs, and improve overall operational efficiency. This article explores the benefits of leveraging real-time demand forecasting to optimize inventory management for manufacturing executives.

- Accurate Demand Forecasting: Real-time demand forecasting provides manufacturing executives with timely and accurate insights into customer demand patterns.

By analyzing real-time data, such as sales trends, market dynamics, and customer behavior, executives can make more precise demand forecasts. Accurate demand forecasting helps in aligning inventory levels with expected demand, reducing the risk of excess inventory or stockouts.

- Right-sizing Inventory Levels: Real-time demand forecasting enables executives to determine the optimal inventory levels for different products and variants.

By understanding demand patterns, seasonality, and market trends in real-time, executives can adjust inventory levels accordingly. This prevents overstocking, avoids tying up capital in excessive inventory, and reduces carrying costs associated with holding inventory for extended periods.

- Efficient Replenishment and Ordering: With real-time demand forecasting, manufacturing executives can streamline replenishment and ordering processes.

By accurately predicting future demand, executives can optimize the timing and quantities of orders to suppliers. This helps prevent stockouts by ensuring that inventory is available when needed, minimizing disruptions in production and customer service.

- Reduction in Holding Costs: Real-time demand forecasting allows manufacturing executives to optimize inventory levels and reduce holding costs.

By avoiding excessive inventory, executives can minimize storage costs, obsolescence risks, and associated carrying costs. With accurate demand forecasts, executives can ensure that inventory is replenished just in time, reducing the need for long-term storage and associated expenses.

- Improved Supply Chain Collaboration: Real-time demand forecasting facilitates better collaboration with suppliers and other stakeholders in the supply chain.

By sharing demand forecasts with suppliers, executives can enhance coordination and enable suppliers to align their production and delivery schedules accordingly. This collaborative approach improves order fulfillment, reduces lead times, and enhances overall supply chain efficiency.

- Enhanced Customer Satisfaction: Real-time demand forecasting helps manufacturing executives meet customer demands more effectively, leading to improved customer satisfaction.

By ensuring that the right products are available when customers need them, executives can minimize stockouts, backorders, and delayed deliveries. Meeting customer demands promptly enhances the overall customer experience and strengthens customer loyalty.

- Cost Optimization: Leveraging real-time demand forecasting for inventory management enables manufacturing executives to optimize costs. By accurately aligning inventory levels with demand, executives can minimize carrying costs, reduce waste from excess inventory, and avoid costs associated with stockouts, such as rush orders or lost sales. This cost optimization directly contributes to improved profitability for the organization.

Real-time demand forecasting empowers manufacturing executives to enhance inventory management by accurately predicting demand, right-sizing inventory levels, optimizing replenishment processes, reducing holding costs, improving supply chain collaboration, enhancing customer satisfaction, and optimizing costs.

By leveraging the benefits of real-time demand forecasting, manufacturing executives can achieve efficient inventory management, reduce costs, and ensure better alignment between supply and demand in today's dynamic marketplace.

Streamlined Supply Chain Operations: The impact of real-time demand forecasting on supply chain efficiency and effectiveness.

Real-time demand forecasting can have a significant impact on the efficiency and effectiveness of supply chain operations. By accurately predicting customer demand patterns, businesses can optimize their inventory levels, production schedules, and distribution strategies, leading to improved overall performance. Here are some key benefits and impacts of real-time demand forecasting on supply chain operations:

- Inventory optimization: Real-time demand forecasting enables businesses to maintain optimal inventory levels. By accurately predicting demand fluctuations, organizations can adjust their inventory levels accordingly, reducing the risk of stockouts or overstocking. This helps in minimizing carrying costs and improving cash flow.

- Production planning and scheduling: With real-time demand insights, companies can align their production schedules to meet customer requirements effectively.

By accurately forecasting demand, businesses can plan production capacity, raw material procurement, and manufacturing timelines more efficiently. This reduces production bottlenecks and ensures a smooth flow of goods throughout the supply chain.

- Efficient procurement: Real-time demand forecasting allows businesses to streamline their procurement processes. By understanding customer demand patterns, organizations can optimize their purchasing activities, ensuring the right amount of materials or components are procured at the right time. This reduces lead times, minimizes stockouts, and avoids excess inventory.

- Improved customer service: Accurate demand forecasting enables businesses to meet customer expectations more effectively. By having the right products available at the right time, companies can enhance customer satisfaction and reduce order fulfillment times. Real-time forecasting also allows organizations to proactively address supply shortages or surpluses, ensuring a consistent and reliable supply to customers.

- Enhanced supply chain visibility: Real-time demand forecasting provides valuable insights into customer behavior, market trends, and demand patterns. By integrating demand data with other supply chain information, such as production schedules, inventory levels, and transportation data, businesses can gain comprehensive visibility into their supply chain operations. This visibility enables proactive decision-making and agile responses to changes in demand or market conditions.

- Demand-driven replenishment: Real-time demand forecasting facilitates a shift from traditional forecast-based replenishment to demand-driven replenishment strategies.

By continuously monitoring customer demand and adjusting replenishment orders accordingly, businesses can reduce stockouts, improve order fill rates, and enhance supply chain responsiveness.

- Cost savings: Real-time demand forecasting helps in reducing costs throughout the supply chain. By optimizing inventory levels, minimizing stockouts, and improving production planning, organizations can reduce carrying costs, avoid rush orders, and optimize transportation and warehousing expenses. These cost savings contribute to improved supply chain profitability.

In summary, real-time demand forecasting enables businesses to make data-driven decisions, align their operations with customer demand, and optimize their supply chain processes.

By improving inventory management, production planning, procurement, and customer service, organizations can achieve greater efficiency, effectiveness, and competitiveness in the market.

Increased Customer Satisfaction: Exploring how real-time demand forecasting leads to better customer service and satisfaction.

Real-time demand forecasting plays a significant role in improving customer service and satisfaction. By accurately predicting customer demand, businesses can align their operations to meet those demands effectively. Here are several ways real-time demand forecasting contributes to better customer service and satisfaction:

- Enhanced Inventory Management: Real-time demand forecasting helps businesses optimize their inventory levels. By accurately predicting customer demand, companies can stock the right products in the right quantities.

This ensures that popular items are readily available, reducing instances of stockouts and backorders. Customers appreciate having access to the products they desire, leading to improved satisfaction.

- Reduced Waiting Times: With real-time demand forecasting, businesses can proactively plan their resources, such as staff and equipment, based on anticipated customer demand.

This enables them to allocate resources efficiently and reduce waiting times. Whether it's in retail stores, call centers, or service-based industries, shorter wait times lead to happier customers.

- Personalized Customer Experience: Real-time demand forecasting enables businesses to understand customer preferences and tailor their offerings accordingly.

By analyzing past data and current trends, companies can anticipate individual customer needs and provide personalized recommendations or promotions. This level of customization enhances the customer experience and fosters satisfaction.

- Accurate Order Fulfillment: Real-time demand forecasting helps businesses accurately anticipate customer orders. This enables efficient order processing and fulfillment, reducing errors and delays. By ensuring that orders are fulfilled correctly and promptly, companies can improve customer satisfaction and loyalty.

- Efficient Supply Chain Management: Real-time demand forecasting allows businesses to optimize their supply chain operations. By forecasting demand accurately, companies can align their procurement, production, and distribution activities accordingly.

This leads to improved supply chain efficiency, reduced lead times, and timely deliveries. Customers benefit from a smoother supply chain process, resulting in better service and satisfaction.

- Improved Customer Communication: Real-time demand forecasting provides businesses with valuable insights into customer behavior and preferences. This information enables targeted and timely communication with customers, such as proactive notifications about product availability, order updates, or personalized promotions. Effective communication fosters a positive customer experience and increases satisfaction.

- Better Product Availability: Real-time demand forecasting helps businesses avoid overstocking or understocking situations. By accurately predicting customer demand, companies can maintain optimal product availability. When customers can find the products they need when they need them, it leads to increased satisfaction and loyalty.

In summary, real-time demand forecasting enables businesses to align their operations with customer demand, leading to improved customer service and satisfaction.

By optimizing inventory management, reducing waiting times, personalizing the customer experience, ensuring accurate order fulfillment, streamlining the supply chain, improving communication, and maintaining product availability, businesses can create positive customer interactions and build long-term relationships.

Minimized Stockouts and Overstocking: The role of real-time demand forecasting in preventing stockouts and avoiding excess inventory.

Real-time demand forecasting plays a crucial role in minimizing stockouts and overstocking by providing accurate insights into future customer demand. By leveraging real-time data and advanced forecasting techniques, businesses can make informed decisions regarding inventory management and supply chain optimization. Here's how real-time demand forecasting helps prevent stockouts and avoid excess inventory:

- Accurate demand prediction: Real-time demand forecasting uses current and historical data to analyze patterns, trends, and seasonality in customer demand.

By employing sophisticated algorithms and machine learning models, it can generate accurate demand predictions at various levels, such as individual products, product categories, or geographical regions.

- Improved inventory planning: With real-time demand forecasting, businesses can optimize their inventory planning process. By knowing the expected demand for specific products or categories, they can adjust their inventory levels accordingly. This helps prevent stockouts by ensuring that there is sufficient inventory available to meet customer demand.

- Enhanced supply chain visibility: Real-time demand forecasting provides better visibility into the entire supply chain. It allows businesses to monitor demand fluctuations, identify potential bottlenecks, and take proactive measures to avoid stockouts.

By understanding demand patterns in real-time, companies can collaborate with suppliers and logistics partners to ensure timely replenishment of inventory.

- Efficient production and procurement: Accurate demand forecasting enables businesses to optimize their production and procurement processes. By aligning production schedules and procurement activities with the predicted demand, companies can avoid overstocking or understocking situations. This prevents excess inventory and reduces the risk of carrying obsolete or slow-moving stock.

- Responsive order fulfillment: Real-time demand forecasting facilitates agile and responsive order fulfillment. When businesses have accurate demand predictions, they can quickly process customer orders and ensure timely delivery. This responsiveness helps prevent stockouts and enhances customer satisfaction.

- Demand-driven promotions and pricing: Real-time demand forecasting enables businesses to identify opportunities for demand-driven promotions and pricing strategies.

By understanding the fluctuations in customer demand, companies can offer targeted promotions or adjust prices to stimulate demand during slower periods. This helps prevent overstocking by optimizing sales and reducing excess inventory levels.

- Minimized costs and increased profitability: By avoiding stockouts and overstocking, businesses can minimize costs and increase profitability. Stockouts can result in lost sales, dissatisfied customers, and damage to the brand reputation.

On the other hand, overstocking ties up capital, incurs carrying costs, and increases the risk of inventory obsolescence. Real-time demand forecasting helps strike the right balance between supply and demand, leading to cost savings and improved profitability.

In summary, real-time demand forecasting empowers businesses to make data-driven decisions, optimize inventory management, and prevent stockouts and overstocking. By accurately predicting customer demand, companies can achieve better supply chain efficiency, reduce costs, and enhance customer satisfaction.

Agile Decision-Making: How real-time demand forecasting empowers manufacturing executives to make informed and agile decisions.

Agile decision-making is a critical aspect of modern manufacturing, as it enables executives to respond quickly and effectively to changing market dynamics. One way to enhance agile decision-making is through real-time demand forecasting.

By leveraging advanced analytics and data-driven techniques, manufacturing executives can make informed and agile decisions that positively impact their operations. Here's how real-time demand forecasting empowers manufacturing executives:

- Accurate demand prediction: Real-time demand forecasting leverages historical data, market trends, customer insights, and external factors to generate accurate predictions of future demand.

This allows manufacturing executives to have a clear understanding of the expected demand patterns, enabling them to make proactive decisions and avoid reactive measures.

- Improved inventory management: Accurate demand forecasting helps manufacturing executives optimize their inventory levels. By understanding the expected demand, executives can align their production and procurement activities accordingly, avoiding stockouts or excess inventory. This leads to improved cash flow, reduced carrying costs, and enhanced overall operational efficiency.

- Enhanced production planning: Real-time demand forecasting enables manufacturing executives to optimize their production planning processes. By having timely and accurate demand insights, executives can adjust production schedules, prioritize certain products, allocate resources efficiently, and optimize capacity utilization. This agility helps in meeting customer demands promptly and improving customer satisfaction.

- Supply chain optimization: Demand forecasting also plays a crucial role in supply chain optimization. Manufacturing executives can collaborate with suppliers, distributors, and logistics partners based on real-time demand predictions.

This collaborative approach enables them to streamline the supply chain, reduce lead times, minimize transportation costs, and enhance overall supply chain responsiveness.

- Quick response to market changes: With real-time demand forecasting, manufacturing executives can quickly identify changes in demand patterns or market conditions.

This empowers them to make swift decisions, such as adjusting production volumes, introducing new product variants, or exploring new market opportunities. By staying agile, executives can capitalize on emerging trends, respond to competitor actions, and adapt their strategies accordingly.

- Risk mitigation: Real-time demand forecasting enables manufacturing executives to identify potential risks and take proactive measures to mitigate them.

By analyzing demand patterns, market dynamics, and external factors, executives can anticipate potential disruptions, such as supply shortages, economic fluctuations, or changing customer preferences. This proactive approach helps them develop contingency plans and make informed decisions to mitigate risks effectively.

- Continuous improvement: Real-time demand forecasting is an iterative process that allows manufacturing executives to continuously refine their models and decision-making approaches.

By analyzing the accuracy of past forecasts and comparing them with actual demand, executives can learn from previous experiences and improve their forecasting capabilities over time. This continuous improvement mindset ensures that decision-making remains agile and data-driven.

In conclusion, real-time demand forecasting empowers manufacturing executives to make informed and agile decisions. It provides accurate demand predictions, improves inventory management, enhances production planning, optimizes the supply chain, enables quick responses to market changes, mitigates risks, and fosters a culture of continuous improvement.

By leveraging the power of data and analytics, manufacturing executives can navigate the complexities of the modern manufacturing landscape and drive operational excellence.

Cost Reduction and Efficiency: Unveiling the cost-saving potential of real-time demand forecasting in manufacturing operations.

Real-time demand forecasting can play a crucial role in cost reduction and efficiency improvement within manufacturing operations. By accurately predicting demand patterns and adjusting production accordingly, companies can optimize their inventory levels, reduce wastage, and enhance overall operational efficiency. Here are several ways in which real-time demand forecasting can unlock cost-saving potential:

- Inventory Optimization: One of the significant costs in manufacturing operations is tied up in inventory. Overstocking or understocking can result in increased holding costs or missed sales opportunities, respectively.

Real-time demand forecasting enables companies to adjust their production and inventory levels based on the current and anticipated demand. By maintaining optimal inventory levels, businesses can reduce carrying costs while ensuring they meet customer demand efficiently.

- Production Planning and Scheduling: Real-time demand forecasting allows manufacturers to plan and schedule their production activities more accurately. By aligning production with demand fluctuations, companies can optimize their resource allocation, labor utilization, and machine utilization. This helps in reducing downtime, minimizing setup and changeover times, and improving overall production efficiency.

- Supply Chain Optimization: Real-time demand forecasting also facilitates effective supply chain management. By sharing demand information with suppliers and partners, companies can enhance collaboration, streamline procurement processes, and negotiate better terms. This can lead to cost savings through bulk purchasing, improved delivery schedules, and reduced lead times.

- Minimizing Wastage: Accurate demand forecasting enables manufacturers to produce just what is required, minimizing overproduction and resulting wastage.

By avoiding excess inventory and reducing obsolete or expired products, companies can significantly reduce costs associated with storage, handling, and disposal.

- Improved Pricing Strategies: Real-time demand forecasting provides insights into customer demand patterns, allowing manufacturers to adjust their pricing strategies accordingly.

By understanding demand fluctuations, companies can implement dynamic pricing mechanisms, promotional offers, and discounts to stimulate demand during slow periods. This can help maximize revenue and optimize profit margins.

- Enhanced Customer Satisfaction: By accurately predicting demand and optimizing production accordingly, manufacturers can improve their ability to fulfill customer orders promptly.

Meeting customer expectations consistently leads to enhanced customer satisfaction, increased repeat business, and positive brand reputation. Satisfied customers are more likely to become loyal customers, contributing to long-term revenue growth and cost reduction associated with customer acquisition.

- Demand-Sensitive Resource Allocation: Real-time demand forecasting enables manufacturers to allocate their resources in a demand-sensitive manner. By aligning labor, equipment, and raw materials with demand patterns, companies can avoid unnecessary costs related to idle resources or excessive overtime. Efficient resource allocation based on accurate demand forecasting helps reduce operational costs and enhances overall productivity.

In summary, real-time demand forecasting has the potential to unlock significant cost-saving opportunities for manufacturing operations. By optimizing inventory levels, improving production planning, enhancing supply chain management, minimizing wastage, implementing effective pricing strategies, and aligning resource allocation with demand, companies can achieve improved efficiency, reduced costs, and enhanced customer satisfaction.

Accurate Demand Planning: The importance of real-time demand forecasting in accurately predicting customer demand and improving decision-making.

Accurate demand planning is crucial for businesses to effectively manage their supply chains, optimize inventory levels, and meet customer demands. Real-time demand forecasting plays a vital role in this process by providing up-to-date insights into customer demand patterns, enabling businesses to make more accurate predictions and informed decisions. Here are some key reasons why real-time demand forecasting is important for accurate demand planning:

- Enhanced Responsiveness: Real-time demand forecasting allows businesses to respond quickly to changes in customer demand. By leveraging real-time data and advanced analytical techniques, companies can identify demand fluctuations, market trends, and shifts in consumer preferences as they occur.

This enables proactive decision-making, such as adjusting production schedules, reallocating inventory, or launching targeted marketing campaigns to capitalize on emerging opportunities.

- Optimal Inventory Management: Accurate demand planning helps businesses strike a balance between excess inventory and stockouts. By accurately forecasting customer demand in real time, organizations can optimize their inventory levels, reducing carrying costs associated with excess stock while ensuring sufficient supply to meet customer requirements. This leads to improved working capital management and minimizes the risk of stockouts, backorders, or lost sales.

- Supply Chain Optimization: Real-time demand forecasting facilitates efficient supply chain management. By understanding customer demand patterns in real time, businesses can align their procurement, production, and distribution processes accordingly.

This enables streamlined operations, reduced lead times, and minimized supply chain disruptions. Additionally, real-time demand insights can help identify potential bottlenecks or constraints, allowing businesses to take proactive measures to address them.

- Improved Customer Satisfaction: Accurate demand planning contributes to better customer service and satisfaction. By accurately predicting customer demand in real time, businesses can ensure product availability, reduce order fulfillment lead times, and minimize backorders or stockouts. Meeting customer expectations consistently enhances brand reputation, fosters customer loyalty, and drives repeat business.

- Cost Reduction: Real-time demand forecasting helps businesses optimize their cost structures. By aligning production and procurement activities with accurate demand predictions, companies can avoid overproduction or excessive inventory, leading to reduced storage and carrying costs. Moreover, effective demand planning enables better negotiation and utilization of supplier contracts, minimizing procurement expenses.

- Data-Driven Decision-Making: Real-time demand forecasting empowers businesses to make data-driven decisions. By leveraging real-time data analytics and forecasting models, organizations can gain actionable insights into customer demand patterns, sales trends, and market dynamics.

These insights enable informed decision-making, supporting strategic planning, resource allocation, new product introductions, and marketing strategies.

Overall, accurate demand planning through real-time demand forecasting provides businesses with a competitive edge in today's dynamic market. By leveraging up-to-date data and advanced analytics, organizations can anticipate and respond to customer demand changes effectively, optimize their supply chains, and drive improved decision-making across all aspects of their operations.

Adaptive Production and Capacity Management: How real-time demand forecasting enables manufacturing executives to adjust production and capacity to meet changing demand.

Adaptive production and capacity management refers to the ability of manufacturing executives to dynamically adjust production and capacity in response to changing demand conditions.

Real-time demand forecasting plays a crucial role in enabling this agility and responsiveness. By accurately predicting customer demand in real-time, manufacturing executives can make informed decisions to optimize production and capacity utilization.

Here's how real-time demand forecasting enables manufacturing executives to adjust production and capacity:

- Demand Sensing: Real-time demand forecasting leverages advanced analytics techniques, such as machine learning and artificial intelligence, to analyze a wide range of data sources in real-time.

This includes historical sales data, customer orders, market trends, social media sentiment, and other relevant factors. By continuously monitoring and analyzing this data, manufacturing executives gain timely insights into demand patterns and fluctuations.

- Agile Planning: Armed with real-time demand forecasts, manufacturing executives can adjust their production plans and schedules accordingly. They can identify potential demand surges or lulls and allocate resources more efficiently to meet changing customer needs.

Agile planning allows manufacturers to avoid underproduction or overproduction scenarios, leading to improved customer satisfaction and reduced costs.

- Inventory Optimization: Real-time demand forecasting helps manufacturers optimize their inventory levels. By accurately predicting demand, executives can determine the right amount of inventory to keep on hand at any given time.

This prevents stockouts or excess inventory, minimizing carrying costs and optimizing working capital. Timely inventory adjustments based on real-time demand forecasts also reduce the risk of obsolescence or waste.

- Supply Chain Collaboration: Real-time demand forecasting enables effective collaboration with suppliers and partners across the supply chain. Manufacturers can share demand forecasts with suppliers to facilitate proactive planning and ensure the availability of necessary raw materials or components. Collaborative supply chain relationships allow for faster response times and improved overall supply chain efficiency.

- Dynamic Capacity Management: Real-time demand forecasts allow manufacturing executives to optimize capacity utilization. They can adjust production schedules, labor allocation, and equipment usage based on the predicted demand levels.

This flexibility helps prevent underutilization of resources during periods of low demand and ensures sufficient capacity during peak periods. By dynamically managing capacity, manufacturers can enhance operational efficiency and reduce costs.

- Faster Response to Market Changes: Real-time demand forecasting enables manufacturing executives to proactively respond to market changes, such as shifts in customer preferences, emerging trends, or unexpected events.

By continuously monitoring demand signals and adjusting production and capacity in real-time, manufacturers can stay ahead of the competition, seize new market opportunities, and mitigate risks effectively.

In summary, real-time demand forecasting empowers manufacturing executives to adapt production and capacity management strategies to meet changing demand conditions.

It enables agile planning, inventory optimization, supply chain collaboration, dynamic capacity management, and faster response to market changes. By leveraging real-time insights, manufacturers can improve customer satisfaction, reduce costs, and drive operational excellence in today's dynamic business environment.

Market Opportunity Identification: How real-time demand forecasting helps manufacturing executives identify new market opportunities and capitalize on them.

Real-time demand forecasting plays a crucial role in helping manufacturing executives identify new market opportunities and capitalize on them. By accurately predicting customer demand, manufacturing executives can proactively adjust their production plans, optimize resource allocation, and align their operations with market needs. Here's how real-time demand forecasting can facilitate market opportunity identification:

- Timely market insights: Real-time demand forecasting leverages advanced data analytics and machine learning techniques to analyze current market trends, customer behavior, and external factors impacting demand.

By monitoring real-time data streams, such as sales data, social media sentiment, and economic indicators, manufacturing executives gain valuable insights into emerging market opportunities. They can identify shifts in customer preferences, emerging product trends, or untapped market segments that can be capitalized on.

- Agile production planning: With real-time demand forecasting, manufacturing executives can dynamically adjust their production plans based on accurate demand projections.

This agility enables them to respond quickly to changes in customer demand, unexpected market events, or the introduction of new products by competitors. By aligning production with current demand, manufacturers can avoid overproduction or stockouts, optimize inventory levels, and reduce wastage, thereby increasing overall efficiency and profitability.

- Enhanced product innovation: Accurate demand forecasting helps manufacturing executives identify gaps in the market and understand customer needs and preferences.

Armed with this knowledge, they can develop innovative products or modify existing offerings to meet emerging demand patterns. By proactively introducing new products or product variations, manufacturers can stay ahead of the competition and capture new market segments, leading to revenue growth and increased market share.

- Supply chain optimization: Real-time demand forecasting not only provides insights into market opportunities but also helps optimize the entire supply chain.

By aligning production schedules with demand forecasts, manufacturers can optimize procurement, logistics, and inventory management. This leads to reduced lead times, lower holding costs, and improved customer service levels. Streamlined supply chain operations enable manufacturers to respond quickly to market opportunities, fulfill customer demands promptly, and gain a competitive edge.

- Data-driven decision-making: Real-time demand forecasting relies on the analysis of vast amounts of data from various sources. Manufacturing executives can leverage this data to make informed decisions regarding market expansion, product diversification, or strategic partnerships.

By combining demand forecasts with market intelligence, manufacturers can evaluate the feasibility and potential profitability of new market opportunities. This data-driven decision-making approach minimizes risks and increases the chances of success when pursuing new market ventures.

In summary, real-time demand forecasting empowers manufacturing executives to identify new market opportunities by providing timely market insights, enabling agile production planning, enhancing product innovation, optimizing the supply chain, and facilitating data-driven decision-making.

By leveraging these capabilities, manufacturers can capitalize on emerging trends, satisfy customer demands, and stay ahead of the competition in today's dynamic business environment.

Enhanced Profitability: Examining the positive impact of real-time demand forecasting on manufacturing companies' bottom line.

n today's dynamic business landscape, manufacturing companies face increasing challenges in optimizing their operations and maximizing profitability. One crucial aspect of achieving these goals is accurately forecasting demand.

Traditional demand forecasting methods often fall short due to their reliance on historical data and inability to adapt to rapidly changing market conditions. However, the emergence of real-time demand forecasting techniques presents a promising solution to this problem.

Manufacturing companies operate in a highly competitive environment where meeting customer demand efficiently and effectively is essential for success. Accurate demand forecasting enables companies to align their production, inventory management, and supply chain operations with customer requirements.

Real-time demand forecasting leverages advanced analytics and data integration to provide up-to-the-minute insights into market dynamics, allowing manufacturers to make proactive decisions and drive profitability.

- Real-Time Demand Forecasting: This section discusses the concept of real-time demand forecasting and its key features. It explores how advanced technologies, such as artificial intelligence, machine learning, and big data analytics, enable companies to gather and process vast amounts of data from diverse sources in real-time.

- These technologies empower manufacturers to monitor market trends, customer behavior, and external factors impacting demand, providing them with accurate and timely forecasts.

- Optimized Production Planning and Inventory Management: Real-time demand forecasting enables manufacturing companies to optimize their production planning and inventory management processes.

By having precise demand insights, companies can adjust production schedules, allocate resources effectively, and minimize wastage. This proactive approach helps reduce stockouts, excess inventory, and associated carrying costs, leading to improved operational efficiency and cost savings.

- Supply Chain Optimization: The ability to anticipate demand fluctuations in real-time allows manufacturing companies to optimize their supply chain activities.

By collaborating closely with suppliers and leveraging demand forecasts, companies can streamline their procurement processes, negotiate favorable terms, and enhance overall supply chain resilience. These measures lead to reduced lead times, improved order fulfillment rates, and better customer satisfaction.

- Enhanced Customer Service: Real-time demand forecasting empowers manufacturing companies to enhance customer service by aligning their production capabilities with customer expectations.

By accurately predicting demand patterns, companies can offer shorter lead times, customized products, and improved product availability. This customer-centric approach fosters loyalty, increases customer satisfaction, and ultimately drives higher sales and profitability.

- Cost Reduction and Efficiency Gains: Accurate demand forecasting in real time facilitates cost reduction and efficiency gains throughout the manufacturing process.

By avoiding overproduction and underutilization of resources, companies can minimize costs associated with excess inventory, production downtime, and capacity underutilization. The optimized allocation of resources enhances operational efficiency and boosts profitability.

- Business Agility and Competitive Advantage: Real-time demand forecasting equips manufacturing companies with the agility needed to respond quickly to market changes and gain a competitive edge.

By staying ahead of market trends and customer preferences, companies can introduce new products, adapt pricing strategies, and seize emerging opportunities. This flexibility and proactive decision-making capability contribute significantly to the bottom line.

- Case Studies and Success Stories: This section highlights real-world examples of manufacturing companies that have successfully implemented real-time demand forecasting and witnessed significant improvements in their profitability.

It presents case studies from various industries, showcasing the positive impact of accurate and timely demand forecasting on financial performance.

- Conclusion: Real-time demand forecasting holds immense potential for manufacturing companies seeking to enhance their profitability. By leveraging advanced technologies and data-driven insights, companies can optimize production planning, inventory management, and supply chain operations.

The ability to anticipate and respond to market dynamics in real-time provides a competitive advantage, improves customer service, and drives cost savings. As manufacturers continue to embrace real-time demand forecasting, its positive impact on the bottom line is poised to grow exponentially in the future.

Competitive Advantage: Understanding how real-time demand forecasting provides a competitive edge for manufacturing executives in a dynamic marketplace.

Real-time demand forecasting is a powerful tool that provides manufacturing executives with a competitive advantage in a dynamic marketplace. By accurately predicting customer demand in real-time, executives can make informed decisions and optimize their operations to meet customer needs efficiently. Here's how real-time demand forecasting contributes to this advantage:

- Enhanced responsiveness: Real-time demand forecasting allows manufacturing executives to quickly adapt their production plans and adjust inventory levels based on changing market conditions.

By capturing up-to-the-minute data on customer demand, executives can respond promptly to fluctuations and avoid stockouts or excess inventory. This responsiveness enables them to meet customer expectations and maintain high service levels, which is crucial for customer satisfaction and loyalty.

- Efficient resource allocation: Accurate demand forecasting helps manufacturing executives optimize their resource allocation, including raw materials, labor, and production capacity.

By having real-time insights into customer demand patterns, executives can align their resources accordingly, avoiding underutilization or overutilization. This optimization minimizes costs, reduces waste, and maximizes operational efficiency, ultimately improving profitability and competitiveness.

- Effective production planning: Real-time demand forecasting provides manufacturing executives with valuable insights into product demand variations over different time horizons.

This information helps them develop more precise production plans, including production volumes, schedules, and sequencing. Executives can optimize their production processes to meet fluctuating demand while minimizing lead times and production bottlenecks. Effective production planning enables them to be agile in responding to market changes and fulfilling customer orders promptly.

- Improved inventory management: Real-time demand forecasting enables manufacturing executives to optimize inventory levels by aligning them with actual customer demand.

By accurately predicting demand patterns, executives can minimize excess inventory costs, reduce the risk of stockouts, and optimize inventory turnover. This improved inventory management leads to cost savings, increased cash flow, and competitive advantage by offering faster order fulfillment and reduced carrying costs.

- Strategic decision-making: Real-time demand forecasting empowers manufacturing executives to make strategic decisions based on data-driven insights.

With access to accurate and timely demand forecasts, executives can identify emerging trends, anticipate market shifts, and proactively respond to changing customer preferences.

They can make informed decisions regarding product development, pricing strategies, market expansion, and supply chain optimization, gaining a competitive edge in the dynamic marketplace.

- Collaborative partnerships: Real-time demand forecasting facilitates collaborative partnerships between manufacturers and their suppliers, distributors, and retailers.

By sharing accurate demand forecasts with supply chain partners, executives can improve coordination, synchronize production, and reduce lead times. This collaborative approach strengthens relationships and enables manufacturers to respond more effectively to market changes, enhancing their competitiveness.

In summary, real-time demand forecasting provides manufacturing executives with a competitive advantage by enhancing responsiveness, optimizing resource allocation, enabling effective production planning, improving inventory management, supporting strategic decision-making, and fostering collaborative partnerships.

By leveraging accurate and timely insights into customer demand, executives can navigate the dynamic marketplace with confidence, deliver superior customer experiences, and achieve sustainable growth in the face of fierce competition.

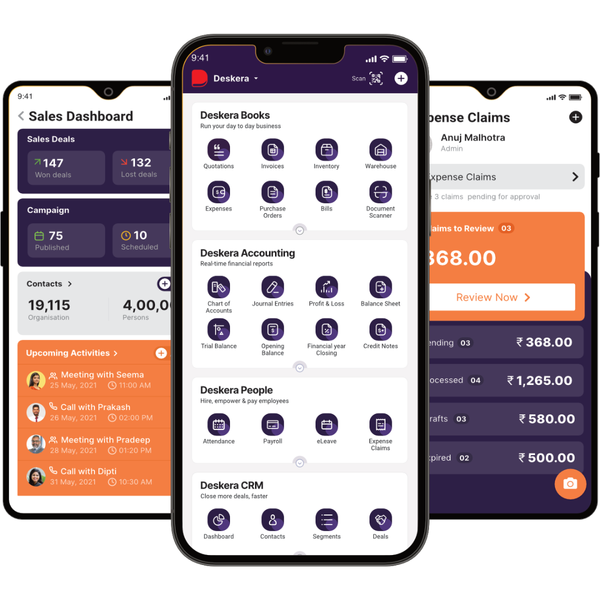

How Can Deskera Assist You?

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real time, as well as streamline a variety of other corporate operations.

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities, such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Related Articles: