In today’s competitive industrial landscape, manufacturers face mounting pressure to optimize operations, cut costs, and improve product quality. The growing reliance on data-driven decision-making has made manufacturing analytics a vital tool in achieving these goals. By analyzing vast amounts of operational data, manufacturers can uncover hidden inefficiencies, reduce waste, and streamline processes, leading to higher productivity and profitability.

The adoption of analytics in manufacturing is accelerating rapidly. The global manufacturing analytics market is projected to reach $19.1 billion by 2032, expanding at a robust CAGR of 15.70%. This growth reflects the increasing importance of leveraging data for predictive maintenance, inventory optimization, quality control, and supply chain visibility. Businesses that successfully embrace analytics are not only able to minimize downtime but also unlock opportunities for innovation and long-term growth.

Efficiency is no longer just a cost-saving measure—it’s a competitive advantage. From predictive maintenance that prevents costly breakdowns to demand forecasting that aligns production with customer needs, analytics applications are reshaping the manufacturing ecosystem. Companies that fail to adapt risk falling behind, while those investing in smart data strategies position themselves as industry leaders.

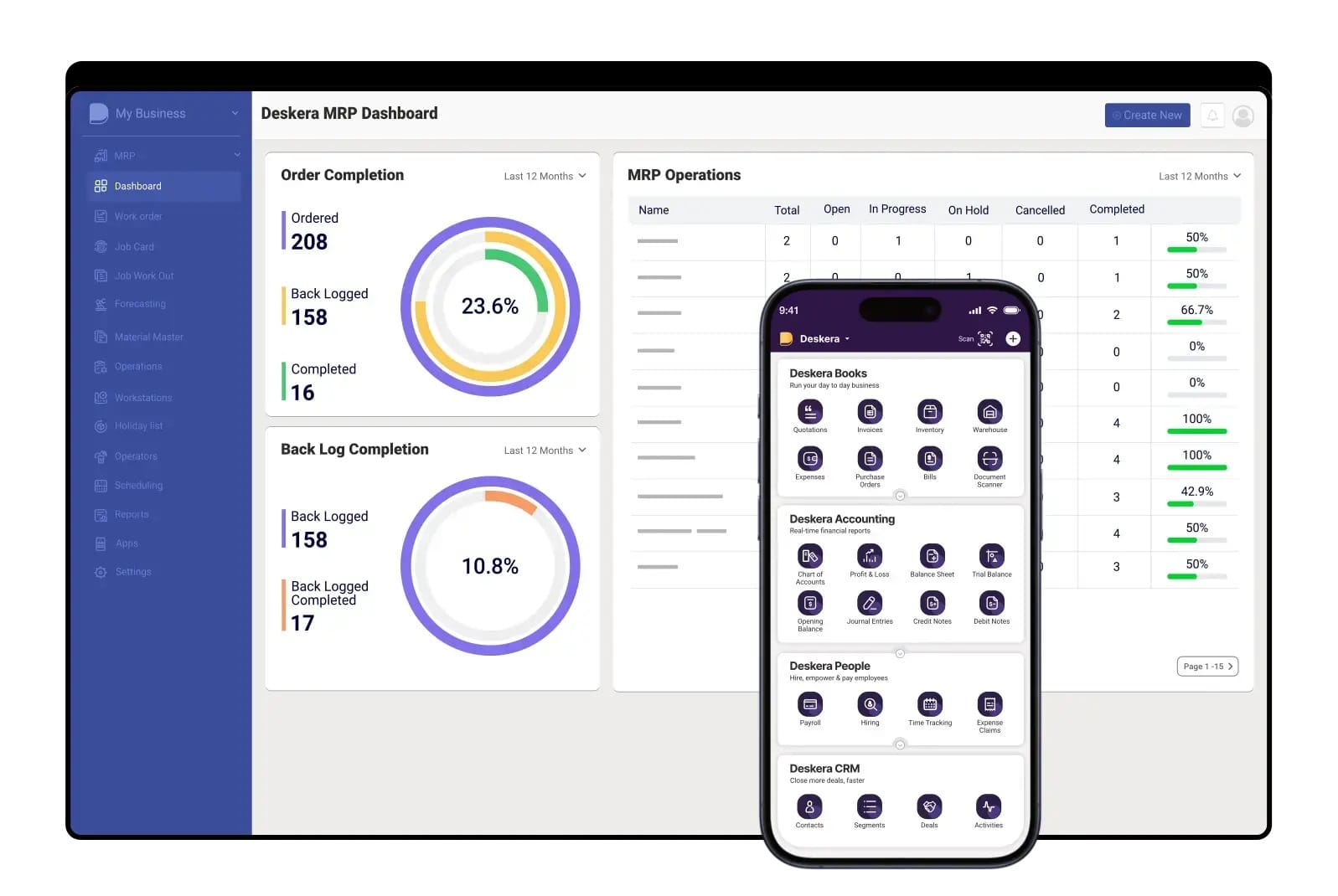

To support this transition, platforms like Deskera Manufacturing ERP provide end-to-end solutions tailored for modern manufacturers. With features such as demand forecasting, production planning, quality management, inventory tracking, and AI-powered assistance through David, Deskera enables businesses to harness analytics effectively. Its cloud-based, mobile-friendly design ensures accessibility for enterprises of all sizes, making it easier to achieve efficiency, reduce costs, and scale sustainably.

What is Manufacturing Analytics?

Manufacturing analytics is the practice of using real-time data, insights, and advanced technologies to optimize factory operations, enhance decision-making, and drive efficiency.

By collecting and analyzing data from across the production floor and business systems, manufacturers can identify bottlenecks, predict equipment failures, reduce defects, and track key performance indicators (KPIs) through intuitive visualization tools. The result is higher productivity, lower costs, and a smoother manufacturing workflow.

At its core, manufacturing analytics unites two critical data streams: operational technology (OT), which includes machine and equipment data from the factory floor, and information technology (IT), which comes from enterprise systems that manage finances, supply chains, human resources, and more.

When these datasets are integrated, businesses gain a holistic view of operations, allowing them to spot inefficiencies, mitigate risks, and make proactive decisions before production slowdowns or stoppages occur.

Traditionally, manufacturers relied on manual data collection methods such as paper logs filled out by workers. While this approach provided basic oversight, it often introduced errors, delays, and even unreported issues.

Today, thanks to the Industrial Internet of Things (IIoT) and cloud technology, data is automatically aggregated, normalized, and analyzed in real time. This not only reduces errors and bias but also empowers manufacturers with deeper, more accurate insights.

Advanced analytics, supported by artificial intelligence (AI) and machine learning (ML), takes this further by diagnosing problems, forecasting potential outcomes, and recommending next-best actions.

For example, analytics can help managers track supplier reliability, predict bottlenecks across supply chains, and even improve perfect order rates—ensuring the right goods are delivered, in the right condition, on time, and with accurate documentation.

As a cornerstone of Industry 4.0, manufacturing analytics is transforming factories into smart, self-optimizing environments capable of adapting to dynamic business demands.

Why Efficiency Matters in Manufacturing

Efficiency is one of the most critical factors that determine the success of a manufacturing business. In today’s competitive market, companies cannot afford to waste resources, time, or opportunities. An efficient manufacturing system ensures that operations run smoothly, costs remain under control, and customer expectations are consistently met.

Below are the key reasons why efficiency matters in manufacturing.

Higher Profitability and Competitiveness

Efficiency directly impacts profitability. By reducing waste, optimizing resource use, and improving machine uptime, manufacturers can lower production costs while maximizing output. This not only increases profit margins but also strengthens competitiveness in the market. An efficient factory is better equipped to deliver high-quality products at a lower cost, giving it a clear edge over rivals.

Resilience in a Challenging Environment

Manufacturers today face pressures such as rising raw material costs, supply chain disruptions, and rapidly shifting customer demand. In this environment, efficiency becomes a driver of resilience. Streamlined and data-driven operations allow businesses to quickly adapt to changes, adjust production schedules, and reduce costly downtime. This agility ensures that companies can meet demand fluctuations without compromising performance.

Advancing Sustainability Goals

Efficiency is closely tied to sustainability. By reducing waste, minimizing energy consumption, and optimizing the use of raw materials, manufacturers can significantly lower their environmental footprint. Beyond compliance with regulations, sustainable efficiency also appeals to eco-conscious customers and business partners. In many cases, green operations also lead to long-term cost savings.

Building Customer Trust and Loyalty

Timely deliveries, consistent product quality, and reliable service are the hallmarks of efficient manufacturing. When companies operate efficiently, they not only meet deadlines but also avoid errors that can damage customer relationships. Over time, this builds trust, strengthens loyalty, and creates opportunities for long-term business growth. In contrast, inefficiency often results in missed deadlines, higher costs, and dissatisfied customers.

Benefits of Manufacturing Analytics

Manufacturing analytics delivers a wide range of advantages that empower companies to run smarter, leaner, and more competitive operations. By harnessing real-time data from machines, systems, and supply chains, manufacturers can reduce risks, improve productivity, and make better business decisions.

Below are some of the most impactful benefits of adopting manufacturing analytics.

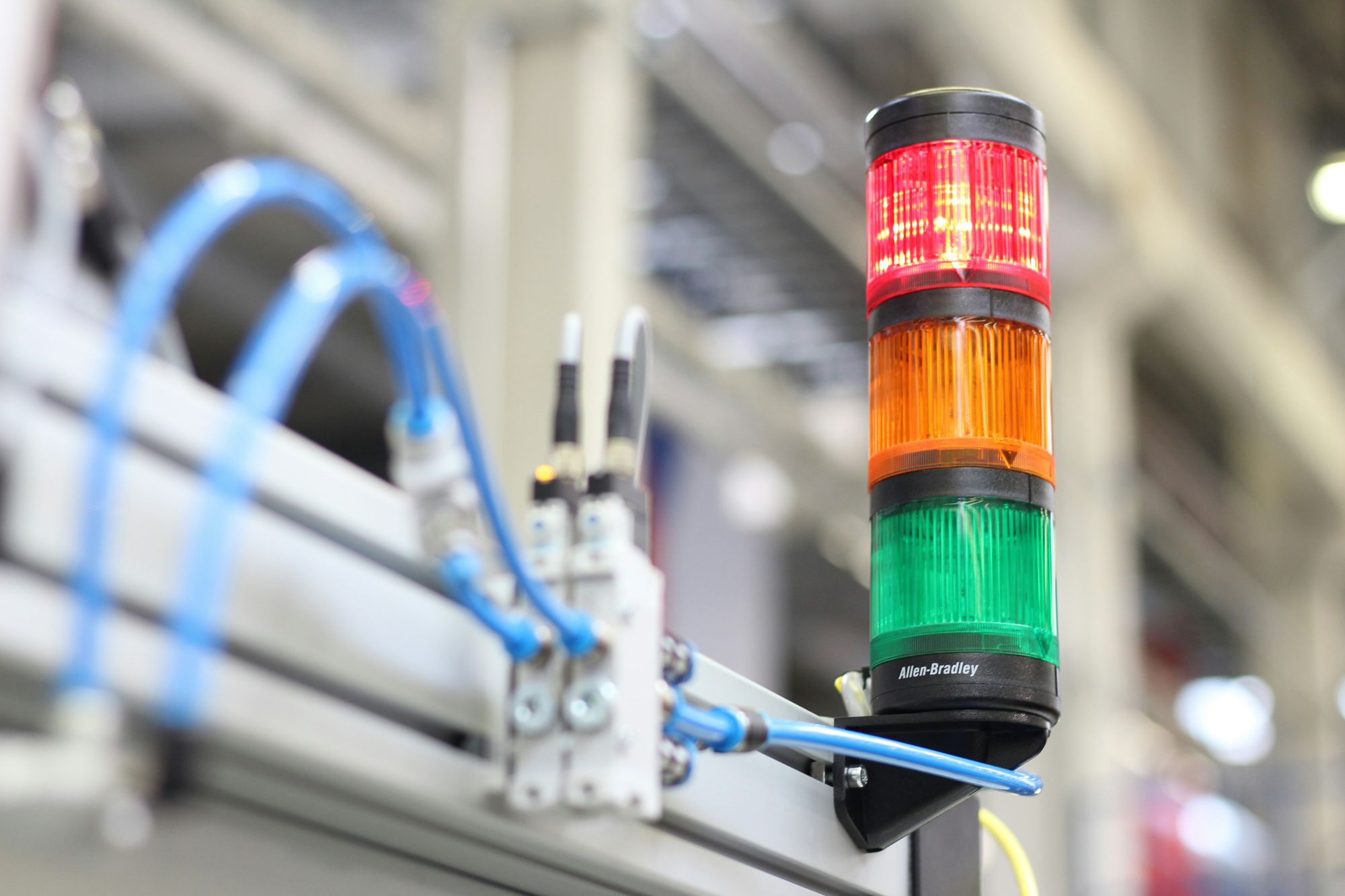

Prevent Unscheduled Downtime

Unplanned machine failures are one of the costliest issues in manufacturing. With predictive analytics, sensor data can reveal early warning signs—such as unusual vibrations or temperature changes—allowing maintenance teams to intervene before breakdowns occur. This keeps equipment running smoothly and ensures production lines remain on schedule.

Improve Productivity and Profit Margins

Analytics helps manufacturers optimize machine performance, workforce efficiency, and throughput. According to McKinsey, applying analytics can boost profit margins by up to 10%, as companies identify hidden capacity, reduce reliance on external suppliers, and streamline production. This not only increases output but also drives significant cost savings.

Support New Business Models

Beyond traditional manufacturing, analytics enables innovative models such as product-as-a-service. For example, an engine manufacturer may charge airlines based on hours of engine use rather than selling the equipment outright. Analytics ensures uptime, predicts maintenance needs, and supports ongoing service-based revenue streams—all while strengthening customer relationships.

Optimize Costs and Resources

From raw material purchases to labor allocation, analytics provides visibility into true cost drivers. It helps identify anomalies such as overstocking safety stock or inefficient energy use, enabling companies to minimize waste and increase margins without compromising production quality.

Strengthen KPI Tracking

Key performance indicators (KPIs) such as overall equipment effectiveness (OEE), yield, on-time delivery, throughput, and capacity utilization are essential for monitoring factory performance. Analytics offers real-time visibility into these metrics and provides insights into their root causes, helping managers act quickly to resolve bottlenecks and inefficiencies.

Enhance Supplier and Supply Chain Visibility

Manufacturing analytics improves supply chain reliability by tracking supplier performance, delivery timelines, and compliance with quality standards. It also enables end-to-end visibility of inventory and materials in transit, ensuring that shortages or delays are addressed before they impact production.

Prioritize Work Orders Effectively

By analyzing order deadlines, inventory levels, and resource availability, analytics helps supervisors decide which production runs to prioritize. This ensures that high-value or time-sensitive orders are completed on schedule, improving customer satisfaction and minimizing production delays.

Boost Workforce Productivity

Analytics optimizes employee scheduling and reduces downtime by aligning maintenance and production tasks. For instance, maintenance crews can be scheduled during machine idle times, minimizing disruption and improving overall labor efficiency. In addition, insights into workforce utilization can guide training and role adjustments.

Reduce the Scope of Product Recalls

In cases of defects, analytics enables manufacturers to pinpoint exactly when and where a problem occurred. This level of precision limits the scope of recalls, reducing costs and reputational damage while ensuring faster corrective action.

Improve Employee Retention and Safety

By identifying safety hazards, overly long shifts, and underutilized skills, analytics helps manufacturers create better working conditions. Employees benefit from safer workplaces and career growth opportunities, leading to higher morale and lower attrition rates.

Deliver Accurate and Consistent Financial Data

Manual spreadsheets and disconnected systems often introduce reporting errors. With analytics, financial data is automatically consolidated and standardized across systems and equipment, ensuring managers have accurate, real-time insights to make informed decisions.

12 Proven Applications of Manufacturing Analytics to Boost Efficiency

Manufacturing analytics is more than just tracking numbers—it’s about applying data-driven insights to make processes faster, smarter, and more cost-effective. By analyzing both real-time machine data and historical performance metrics, manufacturers can uncover hidden inefficiencies, reduce downtime, and improve overall productivity.

Below are some proven applications of manufacturing analytics that directly contribute to operational efficiency.

1. Predictive Maintenance – Using Analytics to Predict Equipment Failures Before They Occur

Unplanned equipment breakdowns are among the costliest issues manufacturers face. Traditional preventive maintenance helps, but it often leads to unnecessary downtime and premature replacement of parts. Predictive maintenance takes things a step further by using IoT sensors, real-time monitoring, and advanced analytics to identify the exact moment when a machine is likely to fail.

Data from vibration, temperature, oil levels, or pressure can be analyzed to detect early warning signs of wear and tear. This enables manufacturers to schedule maintenance only when it’s truly required, minimizing downtime while extending the lifespan of machinery. Beyond lowering repair costs, predictive maintenance also ensures production schedules stay on track and customer commitments aren’t disrupted.

In fact, research suggests predictive maintenance can reduce machine downtime by up to 50% and extend equipment life by 20–40%. For manufacturers operating in high-volume environments, this translates into significant cost savings, higher throughput, and a stronger competitive edge.

2. Quality Control & Defect Reduction – Real-Time Defect Tracking and Root Cause Analysis

Quality issues directly affect customer satisfaction and brand reputation. Traditional quality checks, often manual, are prone to errors and delays. Manufacturing analytics empowers companies to detect defects in real-time using computer vision, AI-powered image recognition, and sensor-based inspections.

Instead of sampling a few items, analytics allows manufacturers to inspect 100% of production output. If a defect is detected, the system can instantly flag the product, remove it from the line, and alert operators. Additionally, analytics platforms can track defect patterns across batches to perform root cause analysis—identifying whether issues stem from raw materials, machine settings, or human error.

This proactive approach reduces rework costs, minimizes waste, and ensures only high-quality products reach customers. Companies using advanced quality analytics have reported reducing defect rates by 25–30% while improving compliance with industry standards. The ability to link production data with customer feedback also enables continuous product improvement and greater trust in the brand.

3. Production Optimization – Identifying Bottlenecks, Reducing Cycle Times, and Streamlining Workflows

Efficiency on the shop floor depends on eliminating bottlenecks and maximizing throughput. Manufacturing analytics provides deep visibility into production processes by collecting real-time machine and operator data. By analyzing cycle times, changeovers, and downtime events, companies can pinpoint inefficiencies and streamline workflows.

For example, analytics can reveal if a certain machine consistently creates a bottleneck, if operators spend too much time on changeovers, or if specific tasks take longer than expected. With these insights, managers can reallocate resources, optimize shift planning, and implement lean strategies to keep production flowing smoothly.

The impact is significant: reduced lead times, higher capacity utilization, and better on-time delivery performance. Production optimization also directly contributes to cost savings, as streamlined operations reduce energy consumption, labor inefficiencies, and unnecessary overtime.

For modern manufacturers, production analytics isn’t just about visibility—it’s about creating a factory environment that continuously improves and adapts to real-world demands.

4. Demand Forecasting – Accurate Predictions to Align Production with Market Demand

Matching production with customer demand is one of the toughest challenges in manufacturing. Too much inventory leads to excess costs, while too little results in stockouts and lost sales. Manufacturing analytics leverages historical sales data, market trends, competitor activity, and even seasonal factors to provide accurate demand forecasts.

Advanced algorithms and AI-driven forecasting models allow manufacturers to predict demand weeks or even months ahead. This helps optimize raw material purchases, production scheduling, and labor planning. For instance, if analytics shows a likely sales spike around a holiday season, production can be adjusted proactively to meet demand without overburdening the supply chain.

Companies that use analytics for demand forecasting have reported inventory reductions of up to 20% while improving order fulfillment rates. The result is a more agile and customer-focused manufacturing strategy—one that balances efficiency, responsiveness, and profitability.

5. Inventory Optimization – Minimizing Excess Stock and Avoiding Stockouts

Inventory management directly affects working capital and production continuity. Without analytics, manufacturers often rely on guesswork, leading to either stockouts or excess stock sitting idle in warehouses. Analytics transforms this process by analyzing demand patterns, supplier performance, lead times, and production cycles to maintain the right balance of inventory.

For example, real-time monitoring can trigger automatic replenishment orders before a stockout occurs, while predictive models can help prevent over-purchasing materials that may not be needed. Additionally, inventory analytics highlights slow-moving stock, enabling companies to reallocate or discount products before they become obsolete.

By reducing excess stock and avoiding emergency shipments, inventory optimization drives both cost efficiency and improved customer service. Research shows that companies leveraging advanced inventory analytics can cut carrying costs by 15–25%, while significantly improving supply reliability.

6. Supply Chain Visibility – Tracking Suppliers, Logistics, and Delivery Performance with Data Insights

The modern supply chain is complex and vulnerable to disruptions—from raw material shortages to logistics delays. Manufacturing analytics provides end-to-end visibility by tracking supplier reliability, shipment timelines, and real-time logistics data.

By integrating analytics across the supply chain, manufacturers can assess supplier performance using KPIs like defect rate, fulfillment time, and on-time delivery. Similarly, IoT-enabled shipment tracking allows companies to monitor goods in transit, reducing uncertainty around delays. Predictive analytics can even forecast supply chain risks—such as geopolitical events or weather disruptions—and recommend contingency plans.

This level of transparency enables proactive decision-making. Manufacturers can quickly switch suppliers, reroute shipments, or adjust production schedules before disruptions escalate. The result: reduced lead times, lower logistics costs, and a more resilient supply chain capable of adapting to market shifts.

7. Energy Management – Monitoring Energy Use to Cut Costs and Support Sustainability

Energy is one of the largest cost drivers in manufacturing. Inefficient usage not only raises expenses but also hinders sustainability goals. With analytics, manufacturers can track energy consumption across machines, production lines, and facilities in real time.

Data from smart meters and IoT sensors highlights energy-intensive processes, peak usage periods, and anomalies that indicate waste. By analyzing this data, manufacturers can implement targeted energy-saving strategies—such as load balancing, equipment upgrades, or alternative energy sourcing.

Beyond cost savings, energy analytics helps companies align with sustainability initiatives and regulatory compliance. Studies show manufacturers can achieve up to 20% energy savings by implementing analytics-driven monitoring. In a business landscape where sustainability is a competitive advantage, energy management analytics helps manufacturers reduce costs while strengthening their environmental responsibility.

8. Labor Productivity Analysis – Measuring Workforce Efficiency and Reducing Downtime

The workforce is at the heart of every manufacturing operation, and analytics can significantly enhance labor efficiency. By tracking workforce performance metrics—such as output per hour, downtime, and skill utilization—companies can identify inefficiencies and improve scheduling.

For instance, analytics may reveal that certain shifts are less productive due to skill gaps or excessive downtime. Managers can then reassign resources, provide targeted training, or optimize staffing levels to boost productivity. Integration with production data also helps align labor allocation with demand forecasts, ensuring the right number of workers are available when needed.

Analytics-based labor optimization doesn’t just improve efficiency; it enhances employee satisfaction by reducing last-minute overtime and unpredictable scheduling. Ultimately, this leads to better operational performance, reduced labor costs, and a stronger, more engaged workforce.

9. Capacity Planning – Ensuring Resources Match Future Production Needs

Capacity planning ensures that manufacturers can meet future demand without under- or over-investing in resources. Analytics plays a crucial role by analyzing historical production data, current machine utilization, labor availability, and forecasted demand.

For example, if demand is expected to rise by 20% over the next quarter, analytics can determine whether existing machinery, workforce, and supply chain capacity can handle the increase—or if additional investments are needed. Conversely, if demand is likely to dip, analytics helps avoid overproduction and wasted resources.

With accurate capacity planning, manufacturers can balance flexibility with efficiency, ensuring they meet customer needs while keeping costs under control. This data-driven approach prevents both production bottlenecks and underutilized assets, creating a more scalable and resilient manufacturing system.

10. Cost Optimization – Identifying Hidden Expenses and Improving Resource Allocation

Manufacturing is full of hidden costs—from energy waste and material losses to inefficient workflows and underutilized equipment. Analytics uncovers these inefficiencies by analyzing cost drivers across the production cycle.

For example, advanced analytics can reveal that frequent small batch runs increase changeover costs, or that a particular machine consumes disproportionate energy relative to output. With these insights, managers can make informed decisions about process adjustments, equipment upgrades, or renegotiating supplier contracts.

Cost optimization through analytics not only reduces overheads but also frees up resources for innovation and growth. By continuously monitoring costs in real time, manufacturers can build a leaner, more profitable operation that sustains long-term competitiveness.

11. Waste Reduction & Lean Manufacturing – Leveraging Analytics to Support Lean Initiatives

Waste—whether from excess inventory, defective products, or inefficient processes—directly impacts profitability. Manufacturing analytics empowers companies to identify, measure, and reduce waste at every stage of production.

By tracking scrap rates, machine downtime, and process inefficiencies, analytics supports lean manufacturing initiatives like Six Sigma and Kaizen. Real-time monitoring ensures deviations are flagged immediately, enabling faster corrective actions. Over time, this leads to continuous process improvement and significant cost savings.

In addition to cost benefits, waste reduction enhances sustainability by lowering raw material usage and energy consumption. Analytics-driven lean strategies not only streamline production but also align with corporate responsibility goals—creating a win-win scenario for profitability and the environment.

12. Customer Insights & Personalization – Linking Production Data with Customer Needs for Better Satisfaction

Modern manufacturing is no longer just about producing goods efficiently; it’s about producing the right goods for the right customers. Manufacturing analytics bridges production data with customer insights by analyzing order history, usage patterns, and feedback.

This allows manufacturers to personalize offerings, create tailored product bundles, and even implement make-to-order strategies. For example, if analytics shows a customer segment frequently orders custom variations of a product, manufacturers can adjust production lines to accommodate those needs more efficiently.

Customer insights also feed back into product development, helping R&D teams create solutions that align with real market demand. By leveraging analytics to anticipate and respond to customer needs, manufacturers build stronger relationships, reduce churn, and unlock new revenue opportunities.

9 Best Practices for Manufacturing Analytics

Successful manufacturing analytics projects don’t just happen by chance — they are built on thoughtful planning, execution, and alignment with business goals. To ensure long-term impact, organizations must follow structured best practices that balance technology, data, and strategy.

Below are proven approaches to guide your analytics initiatives toward measurable success.

1. Make It a Business Project

Analytics should not be treated as just another IT initiative. Involve business stakeholders, including the C-suite, to align projects with strategic objectives. Early results tied to KPIs — such as improved on-time delivery or reduced downtime — demonstrate value and ensure broader adoption across the organization.

2. Start Small

Begin with focused projects rather than large-scale rollouts. Collect data from critical machines or bottleneck processes to deliver quick wins. This cost-effective approach helps build confidence in analytics and often creates momentum for broader adoption.

3. Inventory Your Data

Conduct a thorough assessment of all available data sources across departments, legacy systems, and even one-off applications. This discovery process ensures you know what data exists, where it resides, and how it can contribute to comprehensive analytics projects.

4. Include Operational Data

Don’t limit analytics to application data. Integrating operational data from machines and equipment provides a real-time picture of performance. For instance, combining ERP work order data with production cycle times can predict whether orders will be fulfilled on schedule.

5. Create a Single Data Repository

Centralize data into a cloud-based data lake or warehouse. This eliminates silos, improves accessibility, and streamlines analytics efforts, especially after acquisitions where systems may not integrate easily.

6. Measure What Needs to Be Managed

Align data collection with business objectives. If reducing downtime is a goal, prioritize sensor data on machine health. If improving throughput is the focus, capture metrics such as output volume and cycle times.

7. Embrace AI and Machine Learning

Leverage no-code AI/ML tools to uncover insights beyond traditional analysis. From predicting machine failures to spotting inventory backlogs, AI-driven analytics empower teams to act proactively rather than reactively.

8. Expand Analytics Capabilities Progressively

Grow analytics maturity step by step. Start with basic performance metrics like equipment utilization, then expand into advanced measures such as product quality or yield. This gradual scaling ensures sustainable improvements.

9. Adjust the Manufacturing Plan in Real Time

Use analytics insights to adapt production schedules dynamically. By integrating inventory, customer demand, sales, and operational data, manufacturers can make agile decisions that reduce waste and improve customer satisfaction.

The Future of Manufacturing Analytics

Manufacturing analytics is rapidly evolving, moving beyond traditional reporting toward intelligent, predictive, and prescriptive capabilities. As Industry 4.0 and digital transformation accelerate, the future of analytics will revolve around advanced technologies like AI, machine learning, IoT, and real-time data integration. These innovations will empower manufacturers to make smarter decisions, reduce risks, and optimize every aspect of their operations.

1. Predictive and Prescriptive Analytics

Future manufacturing analytics will go beyond identifying past trends. Predictive analytics will forecast machine failures, demand fluctuations, and supply chain disruptions, while prescriptive analytics will recommend the best course of action. This will minimize downtime and maximize efficiency.

2. Integration with IoT and Smart Factories

The rise of connected factories will drive analytics deeper into operations. IoT sensors will capture real-time data from machines, workers, and production lines, enabling immediate decision-making. Manufacturers will achieve greater transparency and proactive control across the shop floor.

3. AI and Machine Learning at the Core

AI-driven analytics will uncover hidden patterns in production, inventory, and customer behavior that humans cannot detect. Machine learning algorithms will continuously learn and adapt, allowing manufacturers to improve accuracy in forecasting, resource allocation, and quality control.

4. Cloud-Based Data Ecosystems

Future-ready manufacturers will rely on centralized, cloud-based data lakes that integrate data from multiple sources—ERP systems, supply chains, and operations. This unified ecosystem will eliminate data silos, enabling advanced analytics and collaboration across global teams.

5. Focus on Sustainability and Green Manufacturing

Analytics will also play a pivotal role in reducing waste, optimizing energy consumption, and ensuring compliance with sustainability goals. By monitoring carbon emissions, water usage, and recycling processes, manufacturers can align profitability with environmental responsibility.

6. Democratization of Analytics

No longer restricted to IT or data teams, the future of manufacturing analytics will empower employees at all levels. With user-friendly dashboards and no-code analytics tools, decision-making will become faster and more inclusive.

How Can Deskera Manufacturing ERP Help You?

While manufacturing analytics offers powerful insights, its true value comes from being paired with the right ERP system. Deskera Manufacturing ERP provides an integrated platform that brings together production, inventory, procurement, and financial data in one place—making analytics more actionable and accessible.

With Deskera, you can:

- Enable Real-Time Insights – Track production performance, inventory levels, and order statuses instantly, helping managers make quick, informed decisions.

- Improve Demand Forecasting – Leverage AI-powered forecasting tools to predict customer demand accurately and align production schedules accordingly.

- Optimize Resource Allocation – Automate material requirements planning (MRP) and ensure the right materials and labor are available at the right time.

- Enhance Quality Control – Monitor product quality trends and address issues early to reduce rework and waste.

- Boost Collaboration – Cloud-based accessibility ensures that teams across locations work with the same updated data.

- Gain Financial Clarity – Integrated accounting and reporting modules give you a clear picture of costs, profitability, and ROI from your manufacturing processes.

By combining analytics with Deskera’s powerful features, manufacturers can bridge the gap between data and decision-making, ultimately driving efficiency, profitability, and growth.

Key Takeaways

- The global manufacturing analytics market is on track to reach $19.1 billion by 2032, growing at a 15.7% CAGR, reflecting the industry’s increasing reliance on data-driven decision-making.

- Why Efficiency Matters in Manufacturing – Efficiency directly impacts cost savings, resource utilization, and customer satisfaction, making it a critical driver of long-term competitiveness.

- Benefits of Manufacturing Analytics – Manufacturing analytics delivers measurable advantages such as improved operational efficiency, reduced costs, better demand forecasting, and higher product quality.

- 12 Proven Applications of Manufacturing Analytics to Boost Efficiency – From predictive maintenance to supply chain optimization, manufacturing analytics empowers businesses to minimize downtime, reduce waste, and enhance productivity.

- Best Practices for Implementing Manufacturing Analytics – Following best practices like defining clear KPIs, ensuring data quality, and fostering a data-driven culture helps manufacturers unlock the full potential of analytics.

- The Future of Manufacturing Analytics – AI, IoT, and predictive analytics will shape the next era of smart factories, driving innovation, automation, and sustainable growth.

- How Deskera Manufacturing ERP Helps – Deskera provides a comprehensive platform that integrates production, inventory, finance, and analytics, enabling real-time insights, demand forecasting, and seamless collaboration to maximize efficiency.

Related Articles