Over the centuries, humans have developed a remarkable ability to manipulate and transform raw materials into useful products. One of the most significant advances in this area has been the evolution of multi-stage chemical production, a process that involves a series of interconnected steps to create complex compounds from simple starting materials.

Multi-stage chemical production has revolutionized the way we produce a wide variety of products, from pharmaceuticals and plastics to fuels and fertilizers. By breaking down complex chemical reactions into smaller, more manageable steps, scientists and engineers have been able to design more efficient and cost-effective production processes that can be scaled up to meet the demands of modern industry.

This article will explore the history of multi-stage chemical production, from its early beginnings to the present day, and examine the technological advancements that have driven this evolution. Let's take a look at the table of content:

- Early Beginnings

- The Industrial Revolution

- What is Multi-Stage Chemical Production?

- Significance of Multi-Stage Chemical Production

- Benefits of the Evolution of Multi-Stage Chemical Production

- Challenges of the Evolution of Multi-Stage Chemical Production

- Modern Advances

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Early Beginnings

The history of multi-stage chemical production can be traced back to the Middle Ages, when alchemists and chemists began experimenting with basic chemical reactions.

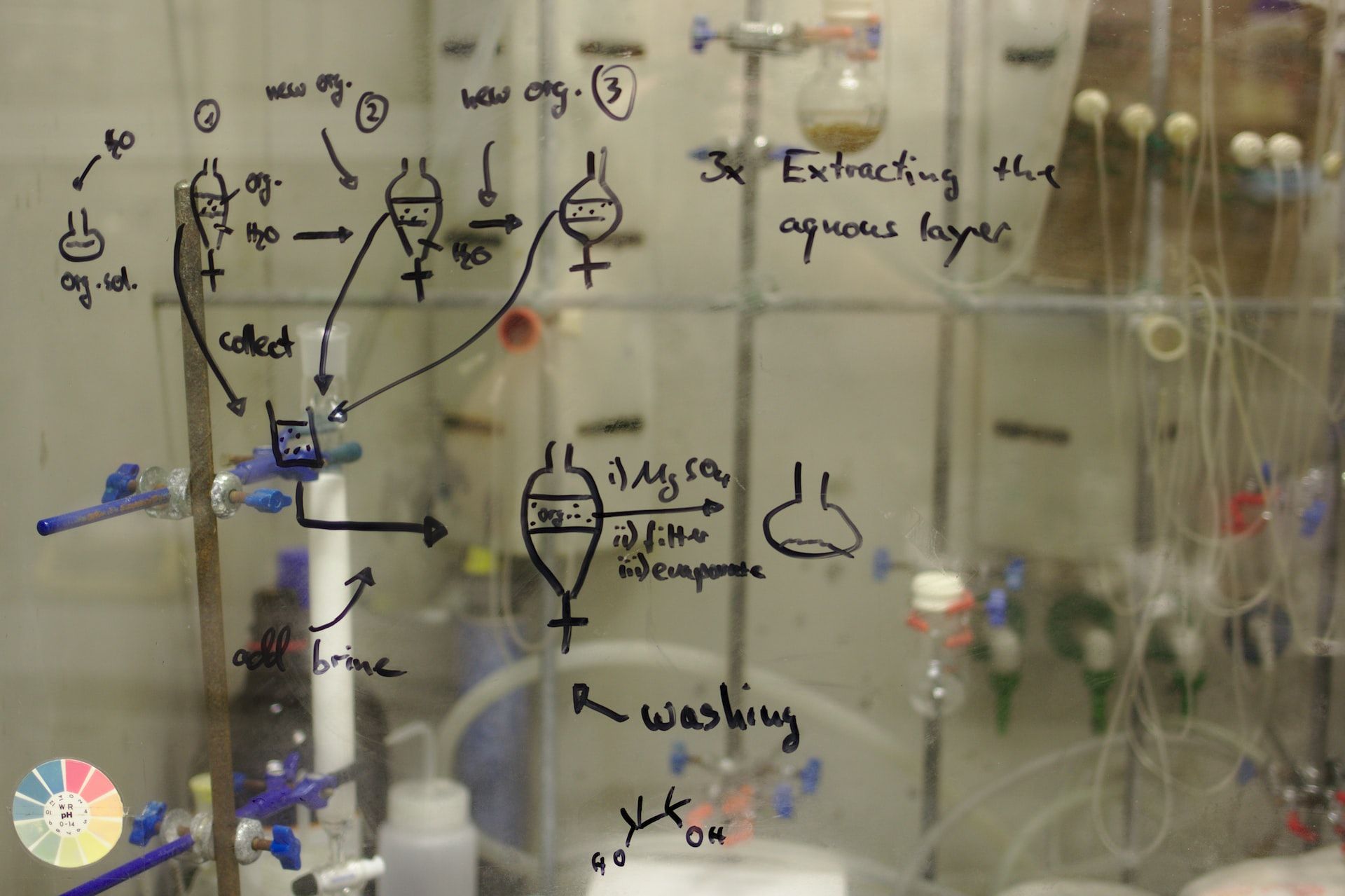

One of the earliest examples of multi-stage chemical production was the process of distillation, which was used to purify alcohol and other liquids. Over time, chemists began to develop more sophisticated techniques, such as the use of catalysts and the creation of complex organic compounds.

The Industrial Revolution

The industrial revolution of multi-stage chemical production involves the use of advanced technology and chemical processes to increase efficiency and lower costs. This revolution began in the late 19th century and has continued to evolve over the years.

The first step in multi-stage chemical production is to separate the raw material into its individual components. This is done by a process called fractional distillation, which allows for the separation of the chemical components. The separated components can then be further processed to create different products.

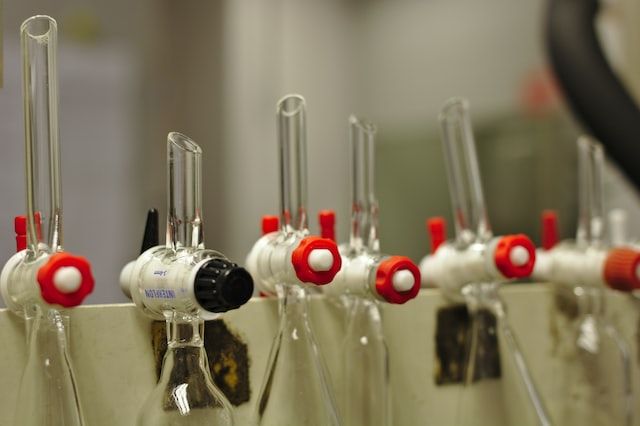

The next step of the process is to use chemical reactors to synthesize the desired products. Chemical reactors are used to mix and heat the chemicals in order to create the desired product. This process is highly efficient, as the chemicals are mixed and heated to the exact temperature and pressure needed to produce the desired product.

The final stage of the process is to purify the product. This includes removing any unwanted impurities, as well as drying and packaging the product. This step ensures that the product is safe and of the highest quality.

The industrial revolution of multi-stage chemical production has allowed companies to produce a wide variety of products at a much lower cost. This has allowed for the production of new and innovative products, as well as creating higher quality standards than what had been previously available.

Multi-stage chemical production has also allowed companies to reduce their environmental impact by reducing the use of hazardous materials, decreasing waste, and creating more efficient processes. The development of new materials and technologies has also made multi-stage chemical production much more cost-effective and efficient.

What is Multi-Stage Chemical Production?

Multi-stage chemical production is a manufacturing process used to produce complex chemicals or materials by running multiple chemical reactions or processing steps in a sequential manner.

Further, the process involves the use of multiple reactors, each designed to carry out a specific reaction or processing step, with the intermediate products transferred from one reactor to the next.

The chemical reactions may be exothermic or endothermic. And the intermediate products may require purification, separation, or other processing steps to produce the final product.

The multi-stage chemical production process can be used to produce a wide variety of chemicals and materials, including pharmaceuticals, polymers, plastics, and fuels.

The process is often used to produce complex molecules that cannot be synthesized in a single step, or to produce materials with specific properties that require careful control of the production process.

Multi-stage chemical production requires careful design, monitoring, and control of the production process to ensure that the final product meets the desired specifications.

The process can also involve significant investment in equipment, raw materials, and labor, and may require specialized skills and knowledge to carry out the reactions and processing steps involved.

Despite these challenges, multi-stage chemical production has become an important tool for producing complex chemicals and materials, with applications in a wide range of industries.

Significance of Multi-Stage Chemical Production

Multi-stage chemical production is a process of producing chemicals in multiple stages, each with a different purpose and process. This type of production is essential in the creation of more complex chemicals, such as pharmaceuticals, where multiple ingredients must be combined in a specific order and in a specific environment.

The benefits of multi-stage chemical production include improved product quality, increased efficiency and cost savings, reduced environmental impacts, and improved safety.

Improved Product Quality: By breaking down the production process into multiple stages, each stage can be optimized for a particular purpose. This allows for more precise control of the final product and improved product quality. Additionally, it can enable more complex chemical reactions and improve the purity of the final product.

Increased Efficiency and Cost Savings: By optimizing each stage of production, multi-stage chemical production can lead to increased efficiency. This can result in lower production costs, as well as improved energy efficiency.

Reduced Environmental Impacts: Multi-stage production can reduce the number of hazardous materials and waste that are released into the environment. This can lead to cleaner air and water, as well as safer disposal of hazardous materials.

Improved Safety: By breaking down the production process into multiple stages, each stage can be designed to be safer and more secure. This can reduce the risk of accidents and ensure that hazardous materials are handled properly.

Benefits of the Evolution of Multi-Stage Chemical Production

The evolution of multi-stage chemical production has brought many benefits to society, including the creation of new and more complex compounds, increased efficiency, and reduced costs.

Following, we will explore some of the main benefits of the evolution of multi-stage chemical production.

Creation of New Compounds

One of the primary benefits of the evolution of multi-stage chemical production is the creation of new and more complex compounds. This has enabled the development of new materials and products that can be used in a variety of applications, including medicine, agriculture, and electronics.

For example, the development of new polymers and resins has enabled the creation of lightweight and durable materials for use in aerospace and automotive industries. The creation of new pharmaceuticals has also enabled the treatment of a wide range of diseases and conditions.

Increased Efficiency

Another benefit of the evolution of multi-stage chemical production is increased efficiency. The use of new technologies and approaches, such as computer modeling and simulation and the development of new catalysts and materials, has enabled chemical production processes to become more efficient and less resource intensive.

This has led to reduced energy consumption and waste, as well as increased production yields and lower costs. For example, the use of nanocatalysts can significantly reduce the amount of energy required for chemical reactions, while the use of green chemistry can minimize waste and hazardous materials.

Reduced Costs

A third benefit of the evolution of multi-stage chemical production is reduced costs. By increasing efficiency and reducing waste, chemical production processes can become less costly and more competitive in the global marketplace.

This can also lead to reduced prices for consumers, making products and materials more accessible and affordable. For example, the use of bio-based feedstocks, such as plant oils and sugars, can reduce the cost of raw materials and increase the sustainability of chemical production processes.

Ultimately, the evolution of multi-stage chemical production has brought many benefits to society, including the creation of new and more complex compounds, increased efficiency, and reduced costs.

Challenges of the Evolution of Multi-Stage Chemical Production

The evolution of multi-stage chemical production has brought many benefits, such as the creation of new and more complex compounds, increased efficiency, and reduced costs. However, there are also several significant challenges associated with this evolution.

Following, we will explore some of the main challenges facing the field of multi-stage chemical production.

Environmental Impact

One of the most pressing challenges facing the field of multi-stage chemical production is minimizing its environmental impact. Chemical production processes can generate large amounts of waste and emissions that can have significant negative impacts on the environment, including air and water pollution, greenhouse gas emissions, and soil contamination.

To address this challenge, researchers and engineers are working to develop more sustainable and environmentally friendly chemical production processes. This includes the use of green chemistry, which focuses on minimizing waste and using less hazardous materials, as well as the development of new technologies and materials that reduce energy consumption and emissions.

Safety

Another significant challenge in the field of multi-stage chemical production is ensuring worker safety. Chemical production processes can involve hazardous materials and conditions that can pose a risk to workers, such as exposure to toxic chemicals, fires, and explosions.

To address this challenge, chemical production facilities must adhere to strict safety protocols and regulations. These can include the use of protective equipment, such as respirators and safety goggles, as well as regular training and drills to prepare workers for potential accidents or emergencies.

Cost and Efficiency

A third challenge in the evolution of multi-stage chemical production is finding the balance between cost and efficiency. Chemical production processes can be complex and costly, requiring significant investment in equipment, materials, and labor.

To address this challenge, researchers and engineers are working to develop new, more efficient production processes that use fewer materials, require less energy, and generate less waste.

This includes the use of computer modeling and simulation to optimize chemical reactions, as well as the development of new materials and technologies, such as nanocatalysts and biocatalysts, that can improve efficiency and reduce costs.

In sum, the evolution of multi-stage chemical production has brought many benefits to society, including the creation of new and more complex compounds, increased efficiency, and reduced costs.

However, there are also significant challenges associated with this evolution, including environmental impact, worker safety, and cost and efficiency.

As researchers and engineers continue to develop new technologies and approaches to chemical production, they must work to address these challenges in order to create a more sustainable and responsible chemical industry.

Modern Advances

In recent years, the evolution of multi-stage chemical production has been marked by a number of exciting technological advancements. These advances have led to the creation of new, more complex compounds and more efficient and sustainable chemical production processes.

Following, we will explore some of the most important latest advances in multi-stage chemical production.

Computer Modeling and Simulation:

One of the most important modern advances in multi-stage chemical production has been the use of computer modeling and simulation to design and optimize chemical processes.

By using computer algorithms to simulate chemical reactions, scientists and engineers can design more efficient and cost-effective production processes, while also reducing waste and minimizing environmental impact.

This has led to the creation of new compounds that were previously difficult or impossible to produce, as well as the optimization of existing production processes. Computer modeling and simulation have also been used to improve safety by identifying potential hazards and designing safeguards to prevent accidents.

Nanotechnology

Another important modern advance in multi-stage chemical production is the use of nanotechnology. By manipulating materials at the nanoscale level, scientists and engineers can create new catalysts and materials that can speed up chemical reactions, reduce waste, and improve efficiency.

For example, nanocatalysts have been developed that can perform complex chemical reactions with greater speed and selectivity than traditional catalysts. Nanoparticles have also been used to create new materials with unique properties, such as increased strength or thermal stability, that are useful in a variety of industrial applications.

Green Chemistry

A third important modern advance in multi-stage chemical production is the development of green chemistry. This approach focuses on reducing waste and environmental impact by designing chemical processes that use fewer hazardous materials, consume less energy, and produce fewer emissions.

One example of green chemistry is the use of bio-based feedstocks, such as plant oils and sugars, to create new chemicals. Another example is the use of biocatalysts, such as enzymes, to replace traditional chemical catalysts that can be toxic or hazardous.

All in all, the evolution of multi-stage chemical production has been marked by a number of exciting technological advances in recent years.

Computer modeling and simulation, nanotechnology, and green chemistry are just a few examples of the new approaches and tools being used to create more complex and efficient chemical production processes.

As these technologies continue to develop, we can expect to see even more exciting developments in the field of multi-stage chemical production.

Wrapping Up

The evolution of multi-stage chemical production has been a remarkable journey, full of innovation and advancement.

From the earliest days of alchemy and distillation to the modern use of computer modeling and nanotechnology, the field has undergone significant changes over the years.

While challenges remain, scientists and engineers continue to push the boundaries of what is possible, creating new compounds and processes that will shape the future of chemical production.

How Deskera Can Assist You?

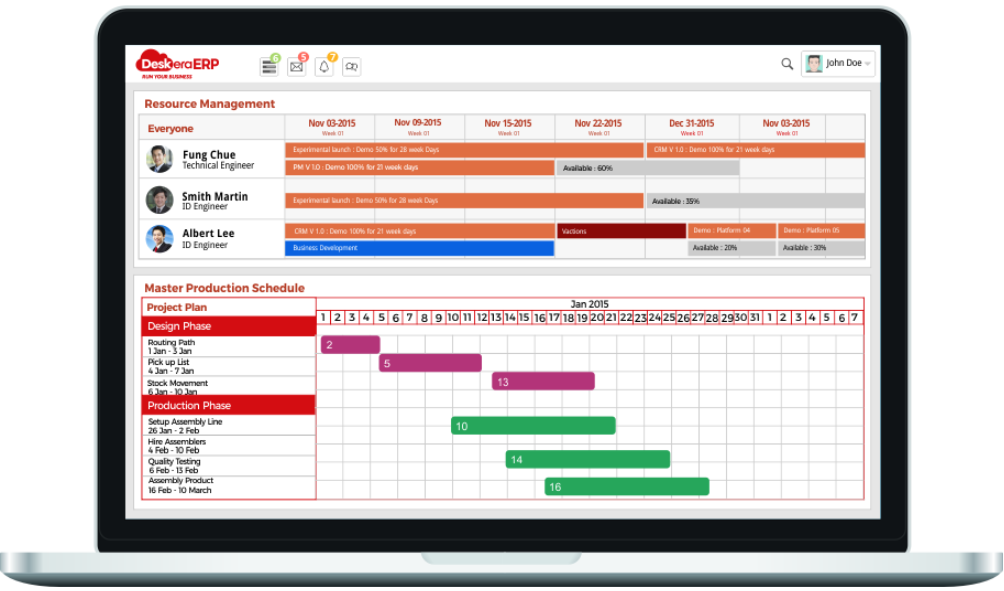

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Multi-stage chemical production is a manufacturing process used to produce complex chemicals or materials by running multiple chemical reactions or processing steps in a sequential manner.

- Multi-stage chemical production is a process of producing chemicals in multiple stages, each with a different purpose and process. This type of production is essential in the creation of more complex chemicals, such as pharmaceuticals, where multiple ingredients must be combined in a specific order and in a specific environment.

- By breaking down the production process into multiple stages, each stage can be optimized for a particular purpose. This allows for more precise control of the final product and improved product quality. Additionally, it can enable more complex chemical reactions and improve the purity of the final product.

- One of the primary benefits of the evolution of multi-stage chemical production is the creation of new and more complex compounds. This has enabled the development of new materials and products that can be used in a variety of applications, including medicine, agriculture, and electronics.

- One of the most pressing challenges facing the field of multi-stage chemical production is minimizing its environmental impact. Chemical production processes can generate large amounts of waste and emissions that can have significant negative impacts on the environment, including air and water pollution, greenhouse gas emissions, and soil contamination.

- A third challenge in the evolution of multi-stage chemical production is finding the balance between cost and efficiency. Chemical production processes can be complex and costly, requiring significant investment in equipment, materials, and labor.

- A third important modern advance in multi-stage chemical production is the development of green chemistry. This approach focuses on reducing waste and environmental impact by designing chemical processes that use fewer hazardous materials, consume less energy, and produce fewer emissions.

Related Articles