In today’s global economy, supply chains are under more pressure than ever before. Disruptions are no longer rare exceptions but common challenges — with nearly 80% of organizations experiencing at least one disruption in the past year. These risks come in many forms, from delayed shipments and supplier failures to regulatory hurdles and inventory mismanagement. For businesses, the ability to identify and mitigate these risks is not just a competitive advantage — it’s a survival strategy.

One of the fastest-growing threats is digital. Cyber-attacks on software supply chains are projected to impact 45% of organizations by 2025, a sharp rise from 2021 levels. This surge highlights how vulnerable modern supply chains have become as they rely more heavily on interconnected systems and digital platforms. When combined with external shocks such as natural disasters or geopolitical instability, the potential for disruption increases dramatically.

Beyond technology-driven risks, companies also face economic challenges like inflation, slow growth, and trade uncertainties, with almost 80% of businesses reporting negative impacts from these factors. Add to this the rising complexity of global regulations, labor shortages, and fluctuating customer demand, and it’s clear why supply chain risk management has moved to the top of executive agendas. The stakes are high — but so are the opportunities to build more resilient, adaptive operations.

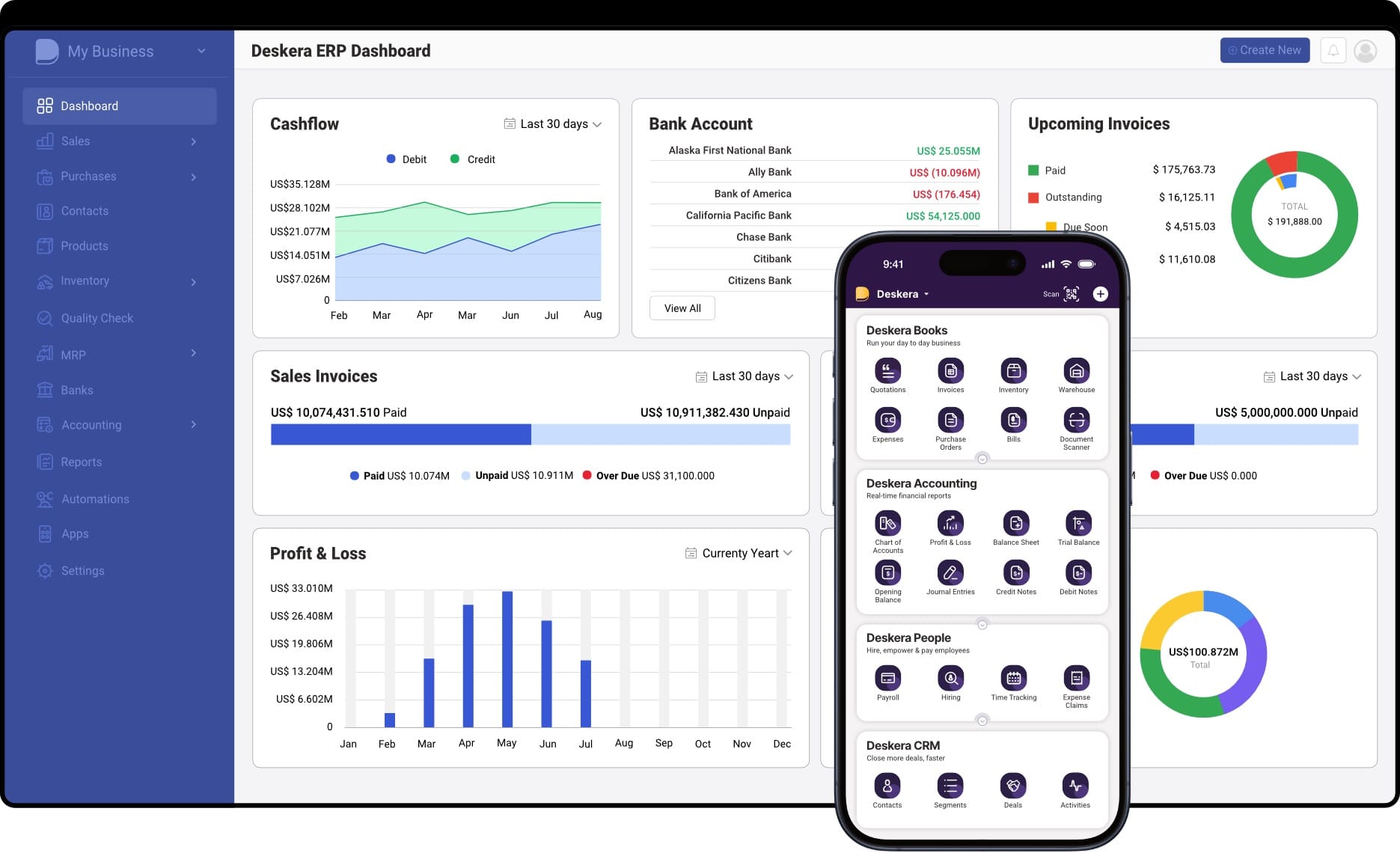

This is where technology can play a transformative role. Modern ERP platforms such as Deskera ERP provide businesses with end-to-end visibility, real-time tracking, and data-driven forecasting to minimize vulnerabilities across the supply chain. With features like AI-powered demand planning, inventory optimization, and supplier management, Deskera helps companies respond quickly to disruptions while improving efficiency and reducing costs. By leveraging such tools, organizations can not only anticipate risks but also turn uncertainty into resilience and growth.

What Are Supply Chain Risks?

Supply chain risks are potential threats that disrupt the smooth flow of goods, services, and information across a company’s supply chain network. These risks can arise from internal weaknesses, external shocks, or a combination of both, and they directly impact efficiency, costs, and customer satisfaction.

Broadly, supply chain risks fall into four major categories:

- Economic Risks: Supplier bankruptcies, recessions, or labor strikes that halt production.

- Environmental Risks: Natural disasters like floods, earthquakes, or droughts, along with sustainability concerns such as regulatory fines for pollution.

- Political Risks: Civil unrest, trade restrictions, or sudden tariffs that affect global sourcing and logistics.

- Ethical Risks: Issues such as child labor, unsafe working conditions, or unsustainable sourcing practices that harm both reputation and compliance.

These challenges are not entirely new, but they have intensified over the past two decades. Data from the EM-DAT international disaster database shows that natural disasters have steadily increased, adding further unpredictability to global supply chains. Meanwhile, consumers and regulators are paying closer attention to environmental, social, and governance (ESG) practices, demanding transparency about how and where products are made.

In addition, cybersecurity vulnerabilities have become one of the fastest-growing risks in supply chain management. As companies depend more on digital platforms, IoT devices, and ERP systems to manage global operations, the threat of cyber-attacks continues to escalate. For many businesses, especially smaller ones, mitigating this risk requires working with technology providers that follow strong cybersecurity standards.

To reduce exposure, businesses can adopt strategies such as supply chain mapping, supplier diversification, weighted risk assessments, scenario planning, and inventory optimization. By doing so, they not only strengthen resilience but also ensure continuity in their supply chain operations, even during disruptions.

Top 18 Supply Chain Risks and How to Mitigate Them

Supply chains in 2025 face an intricate web of risks, ranging from global politics to technological vulnerabilities. Below are the top 10 risks businesses must watch closely—and the strategies to counter them effectively.

1. Financial Risk

Risk: Financial risks arise from unfavorable economic factors such as exchange rate fluctuations, rising costs, or credit issues. A sudden currency depreciation can increase the cost of imports overnight, while supplier bankruptcy or delayed payments may disrupt operations entirely.

Even minor issues, like missing early-bird pricing or incurring late-payment penalties, can add up and create financial strain. These risks affect both buyers and suppliers, reducing liquidity and threatening long-term stability.

In today’s volatile global economy, where inflation and interest rates shift unpredictably, financial vulnerabilities can quickly spread across the entire supply chain network.

Mitigation: Companies can mitigate financial risks by conducting thorough partner assessments to ensure supplier stability and creditworthiness. Hedging against currency fluctuations through derivatives protects against sudden cost spikes, while negotiating long-term contracts locks in prices and provides budget predictability.

Diversifying financing sources reduces reliance on a single channel, ensuring liquidity during unexpected crises. In addition, adopting ERP tools to integrate financial forecasting with procurement and supply planning helps businesses anticipate risks earlier.

Together, these strategies create a safety net that enables companies to remain financially resilient despite market volatility.

2. Geopolitical Risk

Risk: Geopolitical risks stem from political instability, trade wars, sanctions, or sudden regulatory changes that disrupt supply chain operations. A new government policy can instantly increase tariffs, alter trade agreements, or restrict exports, forcing companies to reconsider sourcing strategies. Businesses that rely heavily on cheaper but less politically stable regions often find themselves vulnerable during crises.

These risks are not only financial but also reputational, as operating in politically sensitive markets may lead to compliance issues. As global supply chains stretch across multiple regions, geopolitical volatility has become a persistent challenge affecting budgets, production timelines, and long-term growth.

Mitigation: Mitigating geopolitical risk requires a combination of foresight and flexibility. Businesses should continuously monitor global political and economic trends to anticipate changes before they occur. Diversifying suppliers across multiple regions prevents overdependence on unstable markets, while involving trade and legal experts helps navigate evolving regulations.

Preparing contingency plans — such as re-allocating budgets, working with alternative suppliers, or ensuring compliance with new rules — enables faster adaptation during crises. By treating geopolitical disruptions as inevitable and preparing multiple backup scenarios, companies can strengthen resilience and protect their supply chains from sudden shocks.

3. Environmental Risk

Risk: Environmental risks threaten supply chains from two directions: natural disasters and sustainability concerns. Earthquakes, floods, and hurricanes can disrupt manufacturing hubs, halt logistics, and delay shipments. At the same time, climate change is driving long-term challenges such as water scarcity, rising energy costs, and resource depletion.

Another dimension of this risk is non-compliance with environmental standards. Companies tied to suppliers with poor practices — such as polluting water systems or violating sustainability laws — face reputational damage, legal penalties, and even shutdowns. With extreme weather events increasing in frequency, environmental risks are no longer rare disruptions but recurring business threats.

Mitigation: Organizations can address environmental risks by first identifying and monitoring vulnerable points across their supply chains. Developing comprehensive response and recovery plans — including alternative suppliers and delivery routes — ensures business continuity during disasters.

Investing in sustainable sourcing, renewable energy, and waste-reduction practices aligns businesses with ESG expectations and reduces long-term exposure.

Companies should also conduct due diligence on supply chain partners to confirm adherence to environmental responsibility. By blending resilience planning with sustainability initiatives, businesses can not only withstand environmental shocks but also improve their brand reputation and regulatory compliance.

4. Cybersecurity Risk

Risk: As supply chains digitize, cybersecurity risks have become one of the most pressing concerns. Software supply chain attacks, ransomware, and data breaches can paralyze operations, steal sensitive data, and compromise intellectual property.

According to predictions, nearly 45% of organizations will be affected by software supply chain attacks by 2025, marking a sharp increase from 2021.

The interconnected nature of supply chains — where a single weak vendor can expose the entire network — amplifies the risk. Beyond financial losses, cyber incidents erode customer trust, damage reputations, and can result in regulatory fines under frameworks like GDPR or CCPA.

Mitigation: Companies can mitigate cybersecurity risks by implementing zero-trust security frameworks, multi-factor authentication, and strong encryption protocols across their networks. Regular audits of vendor systems and third-party risk assessments ensure that partners meet cybersecurity standards.

Training employees to recognize phishing attempts reduces human error, often the weakest link. Integrating cybersecurity into enterprise systems, such as ERP platforms with secure cloud hosting, enables real-time monitoring and quick incident response.

By treating cybersecurity as a core supply chain responsibility, businesses protect not only themselves but also their wider partner ecosystems.

5. Operational Risk

Risk: Operational risks emerge from inefficiencies, errors, or disruptions within internal processes such as production delays, poor inventory control, or logistics failures. A single breakdown — like equipment malfunction on a factory floor — can cascade into missed deadlines and customer dissatisfaction.

Supply chains with limited visibility often struggle to identify bottlenecks until it’s too late. Moreover, manual processes increase the chance of miscommunication between teams, leading to duplicated efforts or lost shipments.

In highly competitive markets, operational inefficiencies not only drive up costs but also weaken a company’s ability to respond quickly to customer demands.

Mitigation: The best way to reduce operational risks is by strengthening visibility and automation. Using ERP and MRP systems provides real-time insights into production schedules, inventory levels, and logistics, allowing businesses to spot and resolve issues early. Lean manufacturing practices, combined with continuous process improvement, streamline workflows and reduce errors.

Building redundancy into critical operations — such as maintaining backup equipment or dual suppliers — minimizes the impact of sudden breakdowns. By adopting technology-driven oversight and embedding operational discipline, businesses create agile supply chains that can withstand everyday disruptions.

6. Reputational Risk

Risk: Reputational risks arise when a company’s brand is linked to unethical practices, supply chain failures, or poor-quality products. For instance, if a supplier is exposed for labor violations or unsafe working conditions, the negative publicity can quickly damage the buying company’s image. With today’s digital media, consumer backlash spreads rapidly, leading to lost sales and long-term brand erosion.

Additionally, missed delivery commitments or substandard products often harm customer trust. Since reputation is one of the hardest assets to rebuild, businesses must recognize that reputational risks in supply chains carry long-term financial and competitive consequences.

Mitigation: To safeguard reputation, companies must enforce strict supplier codes of conduct and conduct regular audits to ensure compliance with ethical, labor, and environmental standards. Transparent communication with customers during disruptions — such as explaining delays honestly — helps preserve trust. Leveraging traceability solutions, like blockchain, allows companies to verify product origins and demonstrate accountability.

Building strong relationships with responsible suppliers and committing to sustainability initiatives also boost brand credibility. By embedding ethics, transparency, and accountability into the supply chain, businesses not only mitigate reputational risks but also strengthen their market position.

7. Quality Risk

Risk: Quality risks occur when products or raw materials fail to meet required standards, leading to recalls, customer complaints, and warranty costs. Defective components in critical industries, such as automotive or healthcare, can have life-threatening consequences. These risks are often rooted in poor supplier quality control, lack of standardized inspection, or pressure to reduce costs.

Global sourcing further complicates quality management, as companies may struggle to monitor distant suppliers effectively. A single defective batch can disrupt production, tarnish brand image, and incur significant legal and financial liabilities.

Mitigation: Businesses can mitigate quality risks by establishing robust supplier qualification processes and enforcing strict quality benchmarks. Implementing quality management systems (QMS) with automated checks ensures that non-conformities are detected early. Periodic audits, combined with statistical process control, help maintain consistency across suppliers.

Encouraging long-term partnerships with trusted vendors fosters accountability and continuous improvement. Advanced ERP systems with built-in quality tracking provide real-time alerts on potential issues, ensuring that corrective actions are swift. Prioritizing quality not only prevents costly disruptions but also enhances customer satisfaction and loyalty.

8. Supply Risk

Risk: Supply risks occur when businesses cannot source the right quantity or quality of materials at the right time. These disruptions may stem from supplier insolvency, labor shortages, capacity limitations, or dependency on a single vendor. For example, overreliance on one supplier in a politically unstable region magnifies vulnerability during crises.

Supply risks directly impact production schedules, customer orders, and revenue streams. In extreme cases, prolonged shortages can push customers to competitors. As global supply chains become increasingly complex, the risk of supply gaps remains a constant challenge for businesses across industries.

Mitigation: The most effective mitigation strategy for supply risks is diversification. Companies should maintain a balanced portfolio of suppliers across different regions and avoid dependency on a single vendor. Strategic partnerships with reliable suppliers, backed by service-level agreements (SLAs), ensure consistent performance.

Real-time inventory and demand forecasting tools in ERP systems help anticipate shortages and adjust procurement schedules proactively. Building safety stocks for critical components also provides a buffer against sudden disruptions. By blending strategic sourcing with technology-enabled planning, businesses can keep production steady even when supply chains face turbulence.

9. Demand Risk

Risk: Demand risks arise from sudden changes in customer preferences, market trends, or inaccurate forecasting. A sharp drop in demand leads to excess inventory and storage costs, while unexpected surges can cause stockouts and lost sales. Seasonal businesses are particularly vulnerable, as predicting customer behavior months in advance is challenging.

Inaccurate demand planning also leads to wasted resources and inefficiencies across the supply chain. With consumer preferences shifting rapidly, demand risks threaten profitability and competitiveness if not managed proactively.

Mitigation: Mitigating demand risk requires advanced forecasting tools that integrate historical sales, market trends, and external factors like economic shifts. ERP and MRP systems with predictive analytics improve accuracy by using real-time data. Flexible production and distribution models allow businesses to scale operations up or down as demand fluctuates.

Close collaboration between sales, marketing, and supply chain teams ensures alignment between demand planning and execution. By fostering agility and relying on data-driven forecasting, companies can reduce mismatches and stay competitive in dynamic markets.

10. Legal Risk

Risk: Legal risks stem from non-compliance with international trade laws, labor regulations, intellectual property rights, and environmental standards. For global businesses, navigating diverse and evolving legal frameworks is complex.

A minor oversight, such as mislabeling products or violating export restrictions, can lead to lawsuits, fines, or even operational shutdowns.

Furthermore, with increased scrutiny on issues like sustainability and ethical sourcing, companies risk legal challenges if their suppliers fail to comply. Legal risks not only create financial burdens but also damage credibility and long-term partnerships.

Mitigation: Organizations can mitigate legal risks by staying updated on local and international regulations and integrating compliance checks into procurement and logistics workflows. Legal teams should collaborate closely with supply chain managers to interpret new laws and ensure adherence.

Standardizing contracts with clear terms reduces ambiguity and protects against disputes. Auditing supplier practices regularly helps identify potential non-compliance before it escalates.

Additionally, ERP systems with compliance management features automate documentation and ensure regulatory requirements are consistently met. Proactive compliance safeguards businesses from legal liabilities while building trust with stakeholders.

11. Economic Instability

Risk: Economic instability, driven by inflation, recessions, and volatile demand, adds uncertainty to supply chain planning. High inflation raises procurement and logistics costs, while recessions shrink demand, leading to overcapacity and excess inventory. Fluctuations in interest rates and currency values further complicate cross-border transactions. These dynamics make forecasting less reliable, exposing businesses to costly mismatches between supply and demand.

Economic volatility also strains supplier financial health, with smaller vendors particularly vulnerable to insolvency during downturns. Without safeguards, economic instability creates cascading effects throughout the supply chain, eroding profitability and weakening competitiveness in already challenging markets.

Mitigation: To mitigate economic instability, organizations must build agility into procurement and logistics strategies. Diversifying transport modes and sourcing channels reduces exposure to sudden market fluctuations. Creating inventory buffers for high-demand or critical materials ensures continuity during shortages. Strong, collaborative supplier relationships allow companies to renegotiate terms or share risks during financial turbulence.

Leveraging predictive analytics through ERP systems helps identify demand shifts early, enabling faster adjustments. Companies that maintain flexible strategies while safeguarding critical resources can weather economic instability more effectively and seize opportunities when conditions stabilize.

12. AI and Emerging Technologies

Risk: While AI and automation promise transformative supply chain efficiencies, over-reliance on immature systems carries significant risks. Poor-quality data or untested algorithms can lead to costly missteps, from inaccurate demand forecasts to flawed procurement decisions. Early adopters may also face integration challenges, particularly when legacy systems lack compatibility with emerging technologies.

Overconfidence in AI can overshadow human judgment, exposing businesses to hidden vulnerabilities. In industries where precision is critical, flawed AI insights can escalate disruptions rather than prevent them. Without careful oversight, AI adoption risks becoming a liability rather than an asset in modern supply chain operations.

Mitigation: Mitigating AI-related risks begins with small-scale pilot projects that validate return on investment before broader implementation. Businesses should prioritize strong data governance to ensure AI systems operate on clean, reliable inputs. Integrating technologies like IoT sensors and digital twins enhances accuracy by providing real-time feedback and predictive modeling.

Human oversight remains essential, ensuring that automated insights are interpreted and validated by domain experts. By approaching AI adoption cautiously and strategically, businesses can harness its benefits for resilience and agility without falling prey to immature or misaligned systems.

13. CFO Pressures and Cost Controls

Risk: Supply chain teams increasingly face pressure from CFOs to balance tight cost controls with long-term strategic investments. Financial scrutiny intensifies during periods of economic volatility, where immediate savings often take priority over innovation. This creates risks of underinvestment in critical areas such as technology, sustainability, or risk management.

Short-term cost cutting can weaken supplier relationships, reduce resilience, and undermine long-term competitiveness. For many businesses, misalignment between financial priorities and operational needs results in reactive strategies that fail to address structural vulnerabilities. Without careful management, CFO-driven cost pressures can hinder supply chain agility and performance.

Mitigation: Organizations can address these pressures by integrating financial forecasting into supply chain planning. Rate intelligence tools and index-linked contracts provide transparency on costs, reducing surprises. Supply chain leaders should engage CFOs in scenario planning, demonstrating the long-term financial benefits of resilience investments.

Data-driven performance metrics help justify spending on technology, sustainability, and supplier development. By aligning supply chain initiatives with overall business strategy, teams can strike the right balance between efficiency and resilience. This collaboration transforms cost controls from a barrier into a driver of sustainable growth.

14. Extreme Weather Events

Risk: Climate-driven disruptions are rising in frequency and severity, with floods, wildfires, hurricanes, and droughts increasingly disrupting logistics, manufacturing, and shipping. Extreme weather can destroy physical assets, close transportation routes, and halt production for extended periods. For global supply chains, unpredictable climate events compound other risks like geopolitical uncertainty or economic instability.

Beyond direct disruptions, extreme weather impacts raw material availability — such as agricultural outputs — creating upstream shortages. Companies without climate-resilient strategies face escalating costs, delivery delays, and reputational risks as stakeholders demand greater accountability for sustainability and disaster preparedness.

Mitigation: Businesses can mitigate weather-related risks by balancing global and local sourcing to minimize regional exposure. Flexible logistics planning, including multiple transport routes and carriers, ensures continuity during climate-related blockages. Collaborating with logistics partners to prepare for seasonal risks strengthens readiness for recurring events.

Investments in climate modeling and predictive analytics provide early warnings, enabling proactive adjustments to production or shipping schedules. Building physical resilience, such as flood-proofing facilities, also reduces vulnerability. By embedding climate adaptation into supply chain design, companies improve continuity while aligning with broader sustainability commitments.

15. ESG and Sustainability Mandates

Risk: As sustainability becomes a global priority, companies face rising regulatory and stakeholder pressure to align supply chain practices with environmental, social, and governance (ESG) goals. Risks include stricter emissions limits, bans on unethical sourcing, and penalties for non-compliance with sustainability reporting standards. Failure to meet ESG mandates exposes companies to legal action, financial fines, and reputational backlash.

Consumer expectations amplify this risk, as growing demand for ethically sourced and low-carbon products holds companies accountable. Businesses that neglect ESG compliance risk losing market share and facing operational barriers in regions with aggressive climate or labor regulations.

Mitigation: Organizations can address ESG risks by embedding sustainability into procurement and logistics strategies. Tracking carbon emissions using digital tools like the Carbon Emissions Index (CEI) ensures compliance with environmental regulations. Partnering with low-carbon carriers and suppliers strengthens ESG performance. Transparent reporting on sourcing practices builds stakeholder trust and reduces reputational risk.

Aligning procurement practices with broader ESG goals — such as renewable energy use or fair labor standards — turns compliance into a competitive advantage. By integrating ESG into the supply chain, companies not only reduce risks but also capture emerging opportunities in sustainability-focused markets.

16. Procurement Transformation

Risk: Traditional procurement models are often too rigid to cope with today’s continuous disruptions. Long-term contracts, limited supplier visibility, and siloed processes prevent companies from responding quickly to change. Outdated procurement systems may prioritize cost savings over resilience, exposing businesses to shortages or compliance failures.

In fast-moving markets, such inflexibility reduces competitiveness and increases exposure to unexpected shocks. As supply chain risks multiply, procurement that fails to evolve leaves businesses reactive rather than proactive, undermining resilience and strategic growth.

Mitigation: Procurement teams can strengthen resilience by adopting shorter, more flexible contracts that allow quick adjustments to supplier portfolios. Real-time intelligence tools provide visibility into supplier performance and market trends, enabling data-driven decisions.

Aligning procurement objectives with wider business priorities — beyond just cost savings — ensures greater adaptability. Investing in digital procurement platforms integrates processes across sourcing, compliance, and risk management. By modernizing procurement, companies transform it into a strategic enabler of supply chain resilience and competitive advantage.

17. Data Integrity and Quality

Risk: Data lies at the core of modern supply chain decision-making, but poor or outdated information introduces significant risks. Inaccurate data leads to misguided strategies, wasted spending, and failed AI or forecasting initiatives. Errors in demand planning or supplier performance tracking can cascade into overstocking, stockouts, or missed opportunities.

As businesses adopt more advanced analytics and automation, the consequences of unreliable data grow even more severe. Without trustworthy data, digital transformation initiatives stall, leaving companies vulnerable to inefficiencies and competitive disadvantage.

Mitigation: Organizations must prioritize data governance to ensure accuracy, consistency, and reliability. Real-time monitoring tools validate inputs, reducing reliance on outdated information. Blockchain solutions offer immutable records, enhancing transparency and trust across partners.

Establishing data quality standards and frequent audits ensures alignment across departments and systems. Training employees to follow data best practices further reduces errors. By investing in clean, reliable data, businesses unlock the full value of analytics and AI, enabling smarter, more resilient supply chain strategies.

18. Ongoing Talent Shortages

Risk: Persistent skills gaps are a growing challenge for supply chains, particularly in procurement, logistics, and advanced analytics. A shortage of qualified talent reduces efficiency, slows adoption of new technologies, and limits innovation. Aging workforces in some regions and increased competition for digital skills amplify the problem.

Without adequate talent, businesses struggle to implement resilience strategies or optimize performance. Over time, talent shortages create structural weaknesses, making organizations more vulnerable to disruptions and less capable of capitalizing on new opportunities.

Mitigation: Businesses can address talent shortages by investing in continuous training, mentorship, and workforce development programs. Building T-shaped teams — where employees combine deep expertise with cross-functional knowledge — increases flexibility and collaboration.

Automation of routine tasks allows skilled employees to focus on strategic initiatives. Partnerships with universities, training institutes, and professional organizations expand talent pipelines. By proactively nurturing talent and embracing hybrid human-digital teams, companies strengthen both immediate capabilities and long-term supply chain resilience.

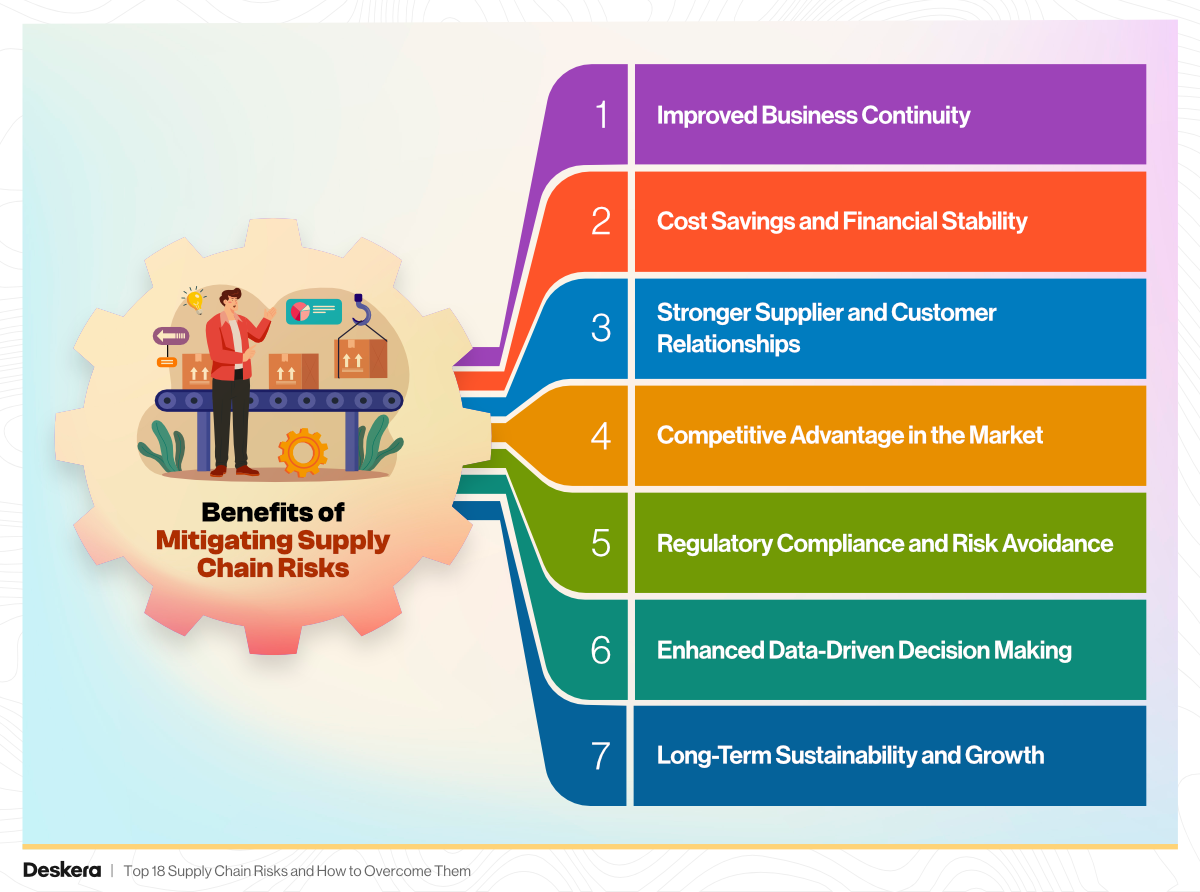

Benefits of Mitigating Supply Chain Risks

Mitigating supply chain risks isn’t just about avoiding problems — it’s about creating stronger, more resilient operations that deliver long-term business value. Companies that proactively address vulnerabilities enjoy smoother workflows, stronger supplier relationships, and improved financial performance.

Beyond protection, effective risk management can become a competitive advantage, positioning businesses as reliable partners in uncertain markets. Below are the key benefits explained in detail.

1. Improved Business Continuity

When disruptions occur, companies with strong risk mitigation strategies can continue operations with minimal interruptions. Whether it’s alternative suppliers, backup logistics routes, or contingency stock, these measures ensure production doesn’t grind to a halt.

Consistent continuity not only keeps customers satisfied but also strengthens brand reliability, making the organization a trusted partner in the market.

2. Cost Savings and Financial Stability

Unmanaged risks often lead to emergency expenses such as expedited shipping, supplier penalties, or lost revenue from halted production. Mitigation strategies — like hedging currency fluctuations, negotiating long-term contracts, or diversifying financing — protect against financial shocks. By reducing volatility, companies stabilize cash flow and maintain profitability even during turbulent times.

3. Stronger Supplier and Customer Relationships

Effective risk management builds trust with both suppliers and customers. When businesses invest in transparent communication, collaborative contingency planning, and long-term agreements, they create partnerships built on reliability. Suppliers are more willing to prioritize dependable clients, while customers stay loyal to companies that consistently deliver despite disruptions.

4. Competitive Advantage in the Market

In industries where competitors struggle during crises, companies with resilient supply chains can capture new opportunities. For example, while others face shortages, a prepared business can maintain inventory and fulfill demand. This agility helps secure market share, win new contracts, and strengthen reputation as a dependable industry leader.

5. Regulatory Compliance and Risk Avoidance

Mitigation strategies also ensure alignment with evolving regulations on trade, data security, and sustainability. Proactively addressing compliance requirements reduces the risk of fines, lawsuits, or reputational damage.

With governments imposing stricter ESG and cybersecurity standards, companies that manage risks effectively stay ahead of regulatory shifts and avoid costly penalties.

6. Enhanced Data-Driven Decision Making

By monitoring risks and implementing digital tools for forecasting, companies gain access to cleaner, more reliable data. This leads to sharper insights into supplier performance, demand patterns, and market conditions.

Data-driven decision-making reduces guesswork, supports long-term planning, and helps organizations respond faster to disruptions.

7. Long-Term Sustainability and Growth

Mitigating risks ensures that supply chains are not just resilient but also sustainable. By adopting environmentally conscious practices, balancing sourcing strategies, and investing in talent development, businesses create supply chains that can scale and adapt over time. This proactive approach turns risk management into a driver of innovation and sustainable growth.

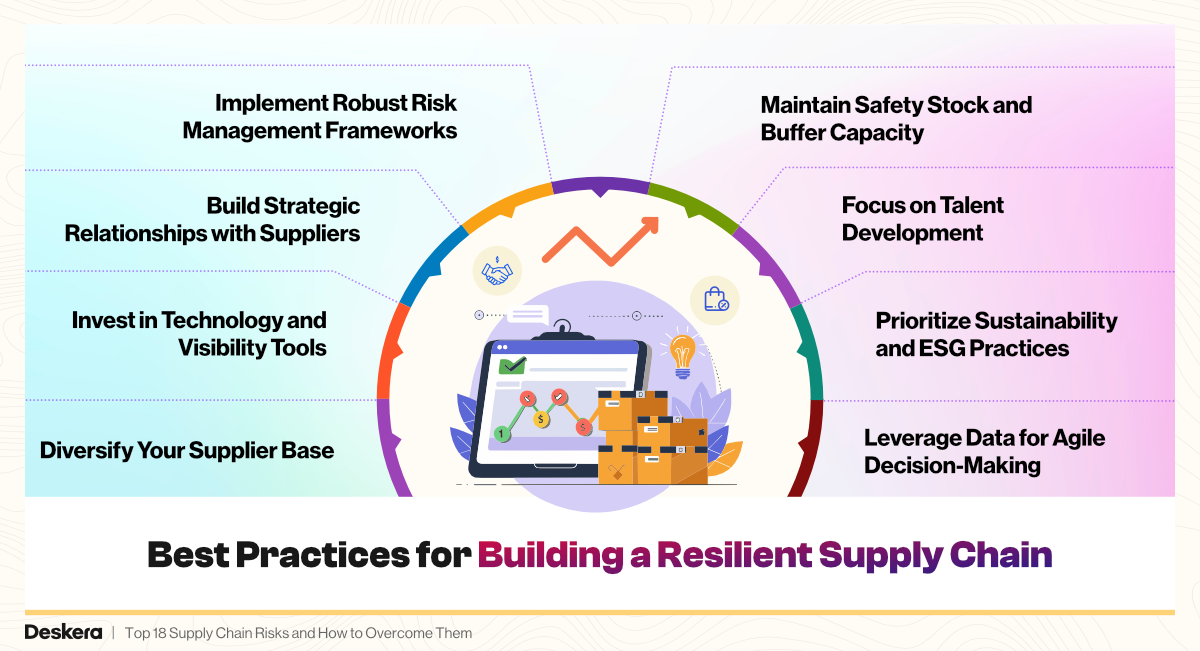

Best Practices for Building a Resilient Supply Chain

A resilient supply chain is not only about withstanding disruptions but also about adapting quickly to change and emerging stronger. Organizations that invest in resilience are better prepared for financial, environmental, and geopolitical challenges while ensuring consistent service delivery. Building resilience requires foresight, collaboration, and the smart use of technology.

Below are some of the best practices that companies can adopt to strengthen their supply chains.

1. Diversify Your Supplier Base

Relying heavily on a single supplier increases vulnerability. By working with multiple suppliers across regions, businesses can minimize the impact of localized disruptions such as political unrest, natural disasters, or regulatory changes. Diversification ensures alternative sources are available when one supplier fails, keeping production on track.

2. Invest in Technology and Visibility Tools

Digital solutions like ERP, MRP, IoT, and AI-driven analytics give businesses real-time visibility into their supply chain. These tools help monitor inventory, track shipments, and forecast demand more accurately. Enhanced visibility allows managers to anticipate risks early, take corrective action, and make informed decisions to reduce vulnerabilities.

3. Build Strategic Relationships with Suppliers

Strong supplier relationships foster trust, collaboration, and open communication. Instead of transactional arrangements, long-term partnerships enable businesses and suppliers to work together on contingency planning and quality improvements. This collaboration ensures faster responses during crises and guarantees priority in times of scarcity.

4. Implement Robust Risk Management Frameworks

Mapping out potential risks and developing contingency plans are key steps in resilience. Companies should regularly conduct risk assessments, scenario planning, and stress testing. A structured framework ensures that risks are prioritized, responsibilities are clear, and action plans are ready when disruptions strike.

5. Maintain Safety Stock and Buffer Capacity

While lean operations are important, keeping a buffer stock of critical materials provides insurance against sudden shortages. Similarly, building excess production capacity or flexible logistics arrangements ensures businesses can scale up or down quickly depending on market conditions.

6. Focus on Talent Development

A skilled workforce is central to supply chain resilience. Continuous training in risk management, data analytics, and digital tools equips employees to adapt quickly to challenges. Cross-functional teams that can collaborate effectively across procurement, logistics, and operations also strengthen resilience.

7. Prioritize Sustainability and ESG Practices

Sustainability is not just a compliance requirement but a resilience driver. Companies that adopt sustainable sourcing, reduce emissions, and comply with ESG mandates are better positioned to meet evolving regulations and consumer expectations. Ethical practices also safeguard reputation and reduce long-term risks.

8. Leverage Data for Agile Decision-Making

Data-driven supply chains respond faster to changes in demand, supply, or external shocks. By using predictive analytics and digital twins, companies can model different scenarios and prepare adaptive strategies. Agile decision-making helps businesses pivot quickly and seize opportunities while competitors struggle.

How Can Deskera ERP Help You Mitigate Supply Chain Risks?

Mitigating supply chain risks requires not only strong strategies but also the right technology to execute them effectively. Deskera ERP offers an integrated platform that enables businesses to improve visibility, enhance collaboration, and make informed decisions across their supply chain operations. By unifying procurement, inventory, production, and finance, Deskera ERP empowers organizations to anticipate risks and respond proactively.

1. End-to-End Visibility and Transparency

Deskera ERP provides real-time insights into inventory levels, order status, and supplier performance. With complete visibility, businesses can identify disruptions early—whether it’s a stock shortage, supplier delay, or logistics bottleneck—and take immediate corrective action.

2. Smarter Demand Forecasting

Leveraging AI-powered forecasting and built-in MRP capabilities, Deskera ERP helps predict demand more accurately. This minimizes risks of stockouts or overstocking, ensuring businesses can maintain smooth operations while reducing carrying costs.

3. Supplier and Vendor Management

Strong supplier relationships are essential for resilience. Deskera ERP centralizes supplier data, tracks performance, and supports multi-supplier management, making it easier to diversify the supplier base and mitigate dependency risks.

4. Risk-Ready Inventory Control

Deskera ERP allows businesses to set reorder points, safety stock, and automated replenishment triggers. These features ensure critical materials are always available, reducing the risk of operational downtime during supply chain disruptions.

5. Agile Production and Resource Planning

With Deskera’s MRP features, companies can align production schedules with available resources and market demand. This flexibility enables quick adaptation during supply chain shocks, such as sudden demand fluctuations or raw material shortages.

6. Data-Driven Decision Making

Deskera ERP’s advanced reporting and analytics provide actionable insights through customizable dashboards and templates. Decision-makers can evaluate risks, model scenarios, and choose the best course of action with confidence.

7. AI Assistant “David” for Proactive Risk Management

Deskera’s AI-powered assistant, David, helps users identify potential risks, forecast future requirements, and optimize processes. By flagging anomalies and suggesting improvements, it strengthens proactive risk mitigation.

By combining these features, Deskera ERP enables organizations to build resilient, agile, and future-ready supply chains that can withstand disruptions and maintain operational efficiency.

Key Takeaways

- Supply chain risks are disruptions caused by economic, environmental, political, ethical, or technological factors, and businesses must recognize them early to build resilience.

- From demand fluctuations to cybersecurity threats, each risk can be minimized through proactive measures such as supplier diversification, data validation, ESG alignment, and investment in technology.

- Mitigation not only ensures business continuity but also enhances cost efficiency, customer trust, regulatory compliance, and long-term competitiveness.

- Resilient supply chains are built on agility, strong supplier relationships, advanced planning, sustainability, and technology adoption.

- Deskera ERP provides end-to-end visibility, smarter forecasting, supplier management, risk-ready inventory control, and AI-driven insights to proactively address risks and improve decision-making.

Related Articles