The use of Integrated Pest Management in pest control manufacturing has become increasingly popular in recent years, as more companies are adopting sustainable and eco-friendly practices. By implementing an IPM program, manufacturers can reduce the number of pesticides and other chemicals used in their facilities, which can have a positive impact on the environment and worker safety.

As a pest control manufacturer, you must have experienced firsthand the challenges that come with developing products that effectively combat pests while still meeting the growing demand for environmentally friendly and sustainable solutions. It's a delicate balance, but one that can be achieved through the implementation of integrated pest management (IPM) practices.

By taking a holistic approach to pest control, we can not only create safer and more effective products but also help to protect the health of our customers and the environment.

In this article, we shall explore the role of integrated pest management in pest control manufacturing and how it is changing the industry for the better.

- What is Integrated Pest Management?

- Significance of Integrated Pest Management in Pest Control Manufacturing

- Need for Integrated Pest Management in Pest Control Manufacturing

- 5 Key Components of Integrated Pest Management in Pest Control Manufacturing

- Benefits of Integrated Pest Management

- Challenges and Limitations of Integrated Pest Management in Pest Control Manufacturing

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What is Integrated Pest Management?

Integrated Pest Management (IPM) is an approach to pest control that combines a variety of pest management strategies to effectively and sustainably control pest populations. IPM is a holistic approach that considers the entire ecosystem in which pests exist, rather than simply treating the symptoms of pest infestations.

IPM programs focus on preventing pest infestations from occurring in the first place by identifying and addressing the root causes of pest problems. This may involve implementing physical barriers, maintaining proper sanitation and hygiene practices, and using cultural practices to discourage pests from establishing themselves.

In addition to prevention, IPM also emphasizes the use of non-toxic or less-toxic pest control methods, such as biological control agents, pheromone traps, and insect growth regulators. These methods are used in a targeted and precise manner to minimize their impact on non-target organisms and the environment.

Chemical pesticides are only used as a last resort in IPM programs and are chosen based on their effectiveness, selectivity, and minimal impact on non-target organisms. Monitoring and regular evaluation of pest control strategies are also integral components of IPM programs to ensure that they remain effective and sustainable over time.

Overall, IPM is a comprehensive approach to pest control that prioritizes prevention and sustainability while minimizing the use of chemical pesticides. By implementing an IPM program, individuals and organizations can effectively manage pest populations while reducing their environmental impact and protecting human health.

Significance of Integrated Pest Management in Pest Control Manufacturing

Integrated Pest Management (IPM) is highly significant in pest control manufacturing for several reasons:

- Environmental Protection: IPM strategies use non-toxic or less-toxic pest control methods, such as biological control agents, pheromone traps, and insect growth regulators. This helps reduce the use of chemical pesticides that can have harmful effects on the environment, including water and air pollution, and the depletion of beneficial insect populations.

- Cost-effective: Implementing IPM strategies can be more cost-effective than relying solely on chemical pesticides. Prevention methods and cultural practices, such as proper sanitation, sealing entry points, and reducing sources of food and water for pests, can help prevent infestations from occurring in the first place. This can result in fewer pest control treatments being needed, which can ultimately reduce costs.

- Safety: IPM programs prioritize the safety of workers, customers, and the environment. By minimizing the use of chemical pesticides, IPM can help reduce the risk of exposure to potentially harmful substances for workers and customers in manufacturing facilities.

- Sustainability: IPM focuses on long-term pest management solutions, rather than simply treating the symptoms of pest infestations. By implementing preventative measures, such as regular inspections and monitoring, and adopting cultural practices that discourage pest populations, IPM can help maintain a sustainable environment for pest control manufacturing.

By combining a range of pest management strategies, including prevention methods, non-toxic or less-toxic pest control measures, and regular monitoring, IPM can help reduce the impact of pests while promoting environmental and human safety.

Need for Integrated Pest Management in Pest Control Manufacturing

Integrated Pest Management (IPM) is crucial in pest control manufacturing for several reasons:

Preventing pest infestations

IPM programs focus on preventing pest infestations from occurring in the first place. This can involve implementing physical barriers, maintaining proper sanitation and hygiene practices, and using cultural practices to discourage pests from establishing themselves. Prevention is always the first and most effective line of defense in pest control.

Minimizing use of chemical pesticides

IPM strategies prioritize the use of non-toxic or less-toxic pest control methods, such as biological control agents, pheromone traps, and insect growth regulators. Chemical pesticides are only used as a last resort in IPM programs and are chosen based on their effectiveness, selectivity, and minimal impact on non-target organisms. This helps reduce the amount of chemical pesticides used in manufacturing facilities, minimizing the risk of exposure to harmful substances for workers and customers.

Environmental protection

By using non-toxic or less-toxic pest control methods, IPM helps reduce the negative impact of pest control on the environment. Chemical pesticides can have harmful effects on water and air quality, as well as beneficial insect populations. IPM strategies help protect the environment by reducing the use of these harmful substances.

Cost-effective

Implementing IPM strategies can be more cost-effective than relying solely on chemical pesticides. Prevention methods and cultural practices, such as proper sanitation, sealing entry points, and reducing sources of food and water for pests, can help prevent infestations from occurring in the first place. This can result in fewer pest control treatments being needed, which can ultimately reduce costs.

Sustainable pest management

IPM programs focus on long-term pest management solutions, rather than simply treating the symptoms of pest infestations. By implementing preventative measures, such as regular inspections and monitoring, and adopting cultural practices that discourage pest populations, IPM can help maintain a sustainable environment for pest control manufacturing.

By implementing IPM strategies, manufacturing facilities can effectively manage pest populations while reducing their impact on the environment and protecting human health.

5 Key Components of Integrated Pest Management in Pest Control Manufacturing

The five key components of Integrated Pest Management (IPM) in pest control manufacturing are as follows:

- Inspection and Monitoring: The first step in an IPM program is to identify potential pest problems through regular inspections and monitoring. This involves identifying the types of pests present, their life cycles, and the conditions that may be contributing to their presence.

- Prevention: Once potential pest problems are identified, the next step is to implement prevention measures. This includes identifying and addressing potential entry points, removing potential food and water sources, and practicing proper sanitation and hygiene.

- Cultural Control: Cultural control measures involve modifying the environment to make it less favorable for pests. This may include modifying landscaping, reducing clutter and debris, and implementing pest-resistant building design.

- Biological Control: Biological control measures involve using natural enemies of pests, such as parasites, predators, or pathogens, to control pest populations. This method is highly targeted and can be effective in reducing pest populations.

- Chemical Control: Chemical control measures are only used as a last resort and only when necessary. This includes the use of pesticides, but only when they are selected based on their effectiveness, selectivity, and minimal impact on non-target organisms. Chemicals are used in a targeted and precise manner to minimize their impact on the environment and human health.

Overall, the key components of an IPM program in pest control manufacturing involve identifying potential pest problems, implementing prevention measures, modifying the environment to discourage pests, using natural enemies of pests to control populations, and only using chemical control measures when necessary and in a targeted manner.

Benefits of Integrated Pest Management

There are several benefits of Integrated Pest Management (IPM) in pest control manufacturing:

Effective pest control

IPM programs are highly effective in controlling pests while minimizing the use of chemical pesticides. By focusing on prevention and implementing multiple pest control methods, IPM programs can effectively manage pest populations.

Reduced reliance on chemical pesticides

IPM programs prioritize the use of non-toxic or less-toxic pest control methods, such as biological control agents and cultural practices. This helps reduce the reliance on chemical pesticides, minimizing the risk of exposure to harmful substances for workers and customers.

Environmental protection

By using non-toxic or less-toxic pest control methods, IPM helps reduce the negative impact of pest control on the environment. Chemical pesticides can have harmful effects on water and air quality, as well as beneficial insect populations. IPM strategies help protect the environment by reducing the use of these harmful substances.

Cost-effective

Implementing IPM strategies can be more cost-effective than relying solely on chemical pesticides. Prevention methods and cultural practices, such as proper sanitation, sealing entry points, and reducing sources of food and water for pests, can help prevent infestations from occurring in the first place. This can result in fewer pest control treatments being needed, which can ultimately reduce costs.

Long-term pest management

IPM programs focus on long-term pest management solutions, rather than simply treating the symptoms of pest infestations. By implementing preventative measures, such as regular inspections and monitoring, and adopting cultural practices that discourage pest populations, IPM can help maintain a sustainable environment for pest control manufacturing.

Improved worker and customer safety

By reducing the use of chemical pesticides, IPM programs help improve worker and customer safety. Chemical pesticides can be harmful to human health, and reducing exposure to these substances can help protect the health and safety of workers and customers.

Challenges and Limitations of Integrated Pest Management in Pest Control Manufacturing

While IPM has been shown to be effective in controlling pests, there are several challenges and limitations that must be considered in pest control manufacturing.

- Resistance: Over time, pests can develop resistance to the methods used in IPM, including chemical pesticides. This can make it difficult to control pests effectively, and alternative strategies may need to be developed.

- Cost: Implementing an IPM program can be costly due to the need for training, equipment, and ongoing monitoring. This can be a barrier for small-scale manufacturers or those operating on a tight budget.

- Expertise: IPM requires a high level of expertise in pest control, including knowledge of pest behavior and biology, as well as the ability to identify and diagnose pest problems. Manufacturers may need to invest in training or hire specialists to implement an effective IPM program.

- Limited effectiveness for some pests: While IPM can be effective for many pests, some pests may require more intensive methods, such as fumigation or heat treatment. In some cases, chemical pesticides may still be necessary to achieve control.

- Time-consuming: IPM can be a time-consuming process, requiring ongoing monitoring and adjustment of control strategies. This can be challenging for manufacturers who are already stretched thin with other tasks.

- Regulatory compliance: Manufacturers must comply with regulations governing the use of pesticides and other pest control methods. Failure to comply can result in fines, legal action, or reputational damage.

- Cultural barriers: In some cases, cultural barriers may make it difficult to implement certain IPM methods. For example, some cultural practices may interfere with the use of pheromone traps or other non-chemical control methods.

Overall, while IPM offers many benefits in pest control manufacturing, it also presents several challenges and limitations that must be carefully considered and addressed.

How can Deskera Help You?

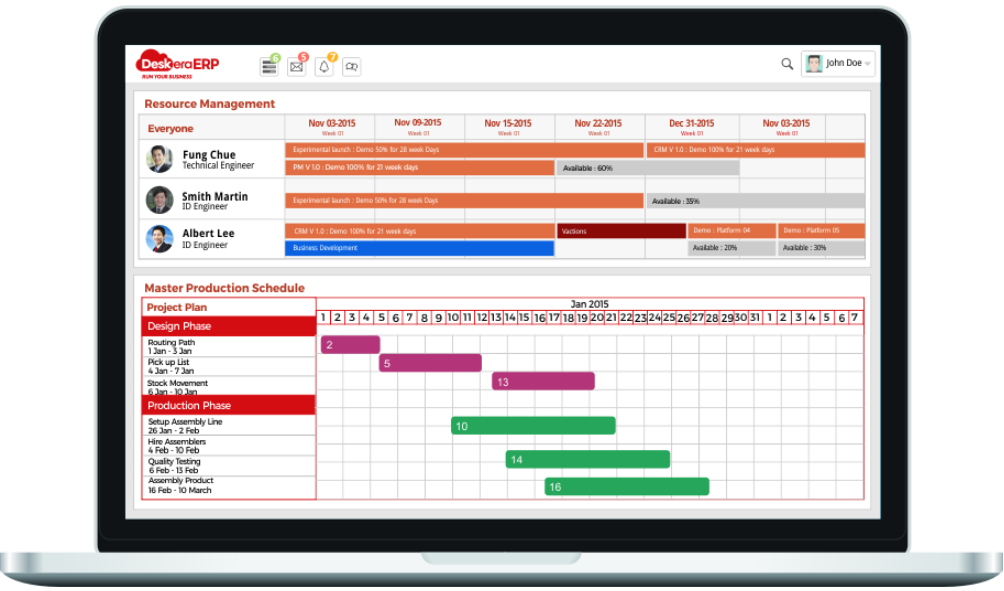

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Integrated pest management (IPM) is a holistic approach to pest control that involves a combination of techniques and strategies to prevent and manage pest infestations.

- IPM is becoming increasingly important in the pest control manufacturing industry as traditional pest control methods are proving to be less effective and harmful to the environment and human health.

- The key components of IPM include inspection, identification, treatment, evaluation, and prevention, which are implemented to identify the root cause of pest problems and develop a customized pest management plan.

- IPM has many benefits for pest control manufacturers, including cost-effectiveness, sustainability, improved safety, and compliance with regulatory requirements and customer expectations.

- While there are some challenges and limitations to implementing IPM, such as the need for specialized knowledge and training, ongoing education and collaboration can help address these issues.

- Overall, adopting integrated pest management practices in pest control manufacturing can lead to safer, more effective, and sustainable pest control solutions that benefit both the environment and public health.

Related Articles