Plastic manufacturing has become an important part of our global economy. It produces materials that are used in a vast array of products, from food to clothing to transportation. But even as plastic production has skyrocketed, the environmental impact of this industry has remained largely unknown.

The global market for plastics exceeds 300 million metric tons each year. In the United States alone, plastics are used in nearly every product imaginable, from packaging to automobiles. And while plastic is often considered a renewable resource, it's actually not quite that simple.

The growing demand for plastic has led to several negative impacts on both the environment and society as a whole. The manufacture of plastics requires significant amounts of energy and resources, often resulting in environmental pollution and damage to natural ecosystems. Furthermore, the disposal of plastic waste is also a major concern – it can end up polluting waterways and contributing to climate change.

In today’s guide, we’ll learn about plastic manufacturing and its environmental impact and sustainability. Let’s take a look at the table of content below:

- Meaning of Plastic Manufacturing

- Meaning of Sustainability in Plastic Manufacturing

- Impact of Plastic on Environment

- Importance of Sustainable Practices in Plastic Manufacturing

- 3 Main Sustainability Challenges that Plastics Manufacturers are Trying to Resolve

- How is the Industry Addressing this Impact on the Environment?

- Challenges and Difficulties that Hinders Adoption of Sustainable Practices in the Plastics Industry

- Injection Moulding: Is it Sustainable?

- Can Plastics Manufacturing be Environmentally Friendly?

- Frequently Asked Questions (FAQs) Associated with Sustainable Practices in Plastic Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Let’s delve in

Meaning of Plastic Manufacturing

The process of making plastic items involves turning raw ingredients like petroleum or natural gas into polymers that may be moulded or sculpted into a variety of shapes.

A number of steps are involved in the production process, including as

- compounding,

- extrusion,

- injection

- moulding,

- blow moulding, and

- thermoforming.

To produce plastic items with various shapes, sizes, and characteristics, each stage uses a distinct technique and piece of equipment.

Plastic manufacturing is used to create goods like bottles, containers, toys, automobile parts, pipes, and computer components in a variety of industries, including packaging, automotive, construction, and electronics.

Meaning of Sustainability in Plastic Manufacturing

Sustainability in plastic manufacturing refers to the use of practices and processes that minimize the negative impact of plastic production on the environment, society, and the economy. It also meets the needs of the present generation without compromising the ability of future generations to meet their own needs.

This simply means that sustainable plastic manufacturing involves balancing economic growth with environmental and social responsibility and taking into account the entire lifecycle of plastic products, from raw material extraction to disposal.

To achieve sustainability in plastic manufacturing, companies need to adopt a holistic approach that takes into account environmental, social, and economic factors. This further can involve using renewable and recycled materials, reducing waste and pollution, minimizing energy and water usage, promoting worker health and safety, and collaborating with stakeholders across the value chain.

In addition, sustainable plastic manufacturing also involves creating products that are designed to minimize their impact on the environment and maximize their value to society. This can involve designing products for durability, recyclability, and reuse, using eco-friendly materials and production methods, and collaborating with customers to find ways to reduce their environmental footprint.

So, sustainability in plastic manufacturing involves taking a long-term view of the impact of plastic production on the environment, society, and the economy, and working to create a more sustainable and equitable future for all.

Impact of Plastic on Environment

Plastic pollution has become a significant environmental problem in recent years, and its impacts can be seen in different ways. Here are some of the ways plastic affects the environment:

- Land pollution: One of the most apparent impacts of plastic on the environment is land pollution. Plastic waste that is not properly disposed of can litter streets, fields, and other natural environments. This waste can take hundreds of years to degrade, leading to the accumulation of plastic waste in the environment.

- Water pollution: Plastic waste can also end up in rivers, lakes, and oceans, leading to water pollution. The plastic can harm aquatic life, including fish, turtles, and birds that can mistake the plastic for food or become entangled in plastic waste.

- Microplastic contamination: Plastic pollution can also lead to the creation of microplastics. These are small particles of plastic that are less than 5mm in size, and they can be found in soil, water, and air. Microplastics can be ingested by animals and humans, leading to health problems.

- Climate change: Plastic production and disposal contribute to climate change. The manufacturing process of plastic releases greenhouse gases, and plastic waste in landfills can also generate methane, a potent greenhouse gas.

- Wildlife disruption: Plastic pollution can also disrupt ecosystems and wildlife. Plastic debris can cause physical harm to animals, leading to injury or death. The ingestion of plastic waste can also interfere with an animal's ability to eat or digest food, leading to malnutrition or starvation.

- Economic impacts: Plastic pollution also has economic impacts, including the cost of cleaning up plastic waste, loss of revenue for the tourism industry, and damage to fishing and shipping industries.

Importance of Sustainable Practices in Plastic Manufacturing

Sustainable practices in plastic manufacturing are becoming increasingly important due to the environmental, social, and economic impact of plastic production and waste.

The following are some of the key reasons why sustainable practices are important in plastic manufacturing:

Environmental Impact:

The production and disposal of plastic can have a significant impact on the environment, including pollution, habitat destruction, and greenhouse gas emissions.

Furthermore, sustainable practices can help minimize this impact by reducing waste and pollution, promoting the use of renewable and recycled materials, and minimizing energy and water usage.

Social Impact:

The production of plastic can also have a significant impact on local communities, including the health and safety of workers, and the social and economic impacts of waste disposal.

Moreover, sustainable practices can help promote worker health and safety, reduce the impact of waste on local communities, and create more sustainable and equitable economic systems.

Economic Impact:

Sustainable practices in plastic manufacturing can also have a positive economic impact by promoting resource efficiency, reducing waste and pollution, and creating new opportunities for innovation and growth.

By adopting sustainable practices, companies can also enhance their reputation and brand value, and improve their ability to attract and retain customers and investors.

Regulatory Compliance:

As governments around the world introduce more stringent environmental regulations, companies that adopt sustainable practices are more likely to comply with these regulations and avoid the potential risks and costs of non-compliance.

3 Main Sustainability Challenges that Plastics Manufacturers are Trying to Resolve

The three primary sustainability issues that plastics producers are attempting to solve are as follows.

Petroleum Usage:

The primary raw material used to manufacture plastics is petroleum, which is a non-renewable resource. The increasing demand for plastics has led to significant consumption of petroleum, which has raised concerns about its sustainability.

To tackle this challenge, plastic manufacturers are looking at various solutions. it includes developing alternative raw materials, such as plant-based sources like sugarcane and corn, recycling plastic waste to reduce the need for virgin petroleum, and using bio-based feedstocks like biodegradable plastics.

The use of alternative raw materials can help reduce petroleum usage, conserve resources, and decrease greenhouse gas emissions.

High Energy Consumption:

The production of plastics requires high energy consumption, which can contribute to climate change. Manufacturers are exploring ways to reduce energy consumption by improving manufacturing processes and using renewable energy sources, such as solar, wind, or hydropower, to power their plants.

By investing in energy-efficient technologies, optimizing manufacturing processes, and adopting renewable energy sources, plastic manufacturers can reduce their carbon footprint and energy consumption.

End-of-life Waste:

One of the biggest challenges with plastic use is the large amounts of waste generated at the end of its life. Plastics can take hundreds of years to decompose, and if not disposed of properly, they can pollute the environment and harm wildlife.

Plastic manufacturers are looking at ways to improve the end-of-life management of plastics, including developing biodegradable and compostable plastics that break down more easily, implementing recycling programs, and reducing plastic packaging.

By adopting circular economy approaches that prioritize reuse, recycling, and reducing waste, plastic manufacturers can reduce the amount of plastic waste that ends up in landfills and the environment.

All in all, the three main sustainability challenges that plastics manufacturers are looking to tackle are petroleum usage, high energy consumption, and end-of-life waste.

By adopting sustainable practices and exploring alternative materials, energy sources, and end-of-life management solutions, the plastic industry can reduce its environmental impact and contribute to a more sustainable future.

How is the Industry Addressing this Impact on the Environment?

Since that it has been proved that plastics have a negative influence on both human health and the environment, more consumers, governments, and activist groups than ever are pressing plastics manufacturers to improve the sustainability of their business practices.

By purchasing more ecologically friendly plastics, increasing manufacturing's energy efficiency, and processing waste or end-of-life products in a way that has the least detrimental environmental impact, the industry is making great efforts to become more sustainable.

The plastic sector is taking various steps to tackle the environmental impact of plastic production and usage. Here are some of the ways the sector is addressing the issue:

Sustainable Plastics Development

Developing sustainable plastics is a critical step in reducing the environmental impact of plastic production and usage. Following, we've discussed some ways that plastic manufacturers are developing sustainable plastics:

Biodegradable plastics: Biodegradable plastics are designed to break down more quickly than traditional plastics, reducing their impact on the environment. These plastics are made from biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), which are derived from renewable resources such as corn, sugarcane, or bacteria.

Bio-based plastics: Bio-based plastics are made from renewable resources such as biomass, agricultural waste, or algae. These plastics have a lower carbon footprint than traditional plastics, as they do not rely on petroleum-based feedstocks. Bio-based plastics include materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and bio-polyethylene (bio-PE).

Recyclable plastics: Recyclable plastics are designed to be reused, reducing the amount of plastic waste that ends up in landfills or the environment. These plastics can be recycled into new products such as packaging, automotive parts, and building materials. Common recyclable plastics include polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP).

Chemical recycling: Chemical recycling involves breaking down plastic waste into its component molecules, which can then be used to create new materials. This process can convert a broader range of plastics, including non-recyclable plastics, into useful products.

Compostable plastics: Compostable plastics are designed to break down completely in a composting environment, producing no harmful byproducts. These plastics are made from biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA) and require specific conditions for proper composting.

Manufacturing Process Optimization

Optimizing manufacturing processes is a critical step in reducing the environmental impact of plastic production. Here are some ways that plastic manufacturers are optimizing their manufacturing processes:

Energy efficiency: One of the primary ways to optimize plastic manufacturing processes is to improve energy efficiency. This can be achieved by upgrading equipment to newer, more energy-efficient models, using energy management systems to monitor and control energy usage, and implementing energy-saving measures such as turning off equipment when not in use.

Waste reduction: Reducing waste is another critical step in optimizing plastic manufacturing processes. This can be achieved by using raw materials more efficiently, reducing scrap rates, and recycling waste materials. By reducing waste, manufacturers can also save on material costs and reduce their environmental impact.

Water management: Water is a critical resource for plastic manufacturing processes, and optimizing water usage can reduce the environmental impact of plastic production. This can be achieved by using closed-loop water systems, which recycle and reuse water, and implementing water-saving measures such as monitoring and reducing water usage.

Supply chain optimization: Optimizing the supply chain can also help reduce the environmental impact of plastic manufacturing. This includes reducing transportation distances, optimizing shipping routes, and working with suppliers to reduce waste and energy usage.

Lean manufacturing: Lean manufacturing is a philosophy that aims to reduce waste and improve efficiency in manufacturing processes. This can be achieved by implementing process improvements such as reducing setup times, optimizing production flows, and implementing just-in-time inventory systems.

Turning off Equipment when Not in Use: Switching off machinery when not in use is an essential step in optimizing energy usage in plastic manufacturing processes. By turning off machinery when it is not needed, manufacturers can save significant amounts of energy and reduce their carbon footprint. Here are some benefits of switching off machinery when not in use:

- Energy savings: The most significant benefit of switching off machinery when not in use is the energy savings that can be achieved. This can result in significant cost savings for manufacturers, as energy costs are typically one of the largest expenses in plastic production.

- Reduced carbon footprint: By reducing energy usage, switching off machinery can also reduce the carbon footprint of plastic manufacturing processes. This can help manufacturers meet sustainability goals and reduce their impact on the environment.

- Equipment lifespan: Switching off machinery when not in use can also help extend the lifespan of equipment. This is because machinery that is not in use is not subject to wear and tear, which can help reduce maintenance costs and increase the lifespan of equipment.

- Safety: Switching off machinery when not in use can also improve safety in the workplace. This is because machinery that is not in use is less likely to cause accidents or injuries.

To effectively switch off machinery when not in use, manufacturers can implement energy management systems that monitor and control energy usage. This can include automatic shut-off systems that turn off machinery after a certain period of inactivity, or scheduling systems that turn off machinery during non-operational hours.

Additionally, training employees on the importance of switching off machinery when not in use can help reinforce the importance of energy efficiency in the workplace.

Optimizing Operational Efficiency:

Optimizing operational efficiency is an essential strategy for reducing the environmental impact of plastic manufacturing. By improving efficiency in manufacturing processes, manufacturers can reduce their energy usage, waste production, and environmental footprint.

Following, we've listed some crucial ways that plastic manufacturers can optimize operational efficiency:

- Process improvements: One way to optimize operational efficiency is to identify process improvements that can be made. This can include streamlining production flows, reducing setup times, and improving material handling. By optimizing processes, manufacturers can improve production efficiency, reduce waste, and save energy.

- Equipment upgrades: Upgrading equipment can also help improve operational efficiency in plastic manufacturing. This can include upgrading to newer, more energy-efficient machinery, implementing automation technologies, and using software to monitor and control equipment usage. By upgrading equipment, manufacturers can improve production efficiency, reduce energy usage, and reduce waste.

- Maintenance and repairs: Regular maintenance and repairs are essential for optimizing operational efficiency in plastic manufacturing. This includes routine maintenance such as cleaning and lubrication, as well as repairs to equipment that is not functioning correctly. By keeping equipment in good working order, manufacturers can reduce downtime, improve efficiency, and reduce energy usage.

- Employee training: Employee training is another critical factor in optimizing operational efficiency. By training employees on best practices for energy efficiency, waste reduction, and process improvements, manufacturers can improve production efficiency and reduce their environmental footprint. Additionally, training employees on workplace safety can help reduce accidents and injuries, improving overall operational efficiency.

- Data analysis: Data analysis can also be a valuable tool for optimizing operational efficiency in plastic manufacturing. By analyzing production data, manufacturers can identify areas where improvements can be made, such as reducing energy usage or improving production flows. This data can be used to develop strategies for improving operational efficiency and reducing the environmental impact of plastic manufacturing.

Wider Energy Usage Focus

Focusing on wider energy usage in plastic manufacturing involves reducing energy consumption throughout the entire production process. This can include everything from the energy used to manufacture raw materials to the energy used during product disposal. By focusing on wider energy usage, plastic manufacturers can reduce their carbon footprint and improve the sustainability of their operations.

Here are some ways that plastic manufacturers can focus on wider energy usage:

- Using renewable energy: One way to reduce the environmental impact of energy usage is to use renewable energy sources, such as solar or wind power. By investing in renewable energy sources, plastic manufacturers can reduce their carbon footprint and improve the sustainability of their operations.

- Energy-efficient lighting and equipment: Using energy-efficient lighting and equipment can also help reduce energy usage in plastic manufacturing. This can include using LED lighting, which uses less energy than traditional lighting, and investing in energy-efficient machinery that uses less energy during operation.

- Energy recovery: Another way to reduce energy usage is through energy recovery. This involves capturing and reusing energy that would otherwise be lost during the production process. For example, heat generated during the production process can be captured and used to heat buildings or generate electricity.

- Transport efficiency: Transport efficiency is also an essential factor in reducing energy usage. This includes optimizing transport routes, using fuel-efficient vehicles, and reducing the number of trips required to transport materials or products.

- Product design: Finally, product design can also play a role in reducing energy usage. Designing products that require less energy to manufacture, transport, and dispose of can help reduce the overall environmental impact of plastic manufacturing.

Plastic Waste Prevention

Preventing plastic waste is a critical strategy for reducing the environmental impact of plastic manufacturing. By preventing waste, manufacturers can reduce the amount of plastic that ends up in landfills, oceans, and other ecosystems, where it can harm wildlife and ecosystems.

Here are some ways that plastic manufacturers can prevent plastic waste:

- Reduce packaging: One way to prevent plastic waste is to reduce the amount of packaging used in products. This can include using less plastic in packaging or switching to more sustainable materials, such as paper or biodegradable plastics.

- Recycling: Recycling is another critical strategy for preventing plastic waste. Plastic manufacturers can promote recycling by using recycled plastic in their products, designing products with recycling in mind, and supporting recycling programs in their communities.

- Product design: Product design can also play a role in preventing plastic waste. Designing products that are durable and long-lasting can help reduce the amount of plastic that is discarded, while designing products that are easy to disassemble can help promote recycling.

- Closed-loop systems: Closed-loop systems are another strategy for preventing plastic waste. This involves designing systems where plastic products are collected, recycled, and used to create new products. This can help reduce the amount of plastic that is discarded and promote a more sustainable use of resources.

- Education and awareness: Finally, education and awareness are critical for preventing plastic waste. Plastic manufacturers can work to educate consumers about the importance of reducing waste, recycling, and using sustainable products. This can include promoting recycling programs, creating educational materials, and partnering with organizations that promote sustainable living.

Challenges and Difficulties that Hinders Adoption of Sustainable Practices in the Plastics Industry

While there are numerous benefits to implementing sustainable practices in plastic manufacturing, there are also several challenges and obstacles that can hinder their adoption. The following are some of the key challenges:

Cost:

Sustainable practices can require significant upfront investment, which can be a deterrent for some companies. For example, using renewable or recycled materials can be more expensive than traditional materials, and upgrading equipment and processes to be more energy-efficient can be costly. According to a survey by McKinsey, around 40% of companies cited cost as a barrier to adopting sustainable practices.

Resistance to change:

Implementing sustainable practices can require changes to established production processes and organizational culture, which can be met with resistance from employees and stakeholders. This can require significant leadership and communication efforts to get buy-in and overcome resistance to change.

Lack of demand:

Some companies may not see a business case for investing in sustainable practices if there is not yet sufficient market demand for sustainable products. According to a survey by Accenture, only 32% of consumers said they were willing to pay more for sustainable products.

Limited expertise:

Implementing sustainable practices can require specialized knowledge and expertise, which may not be readily available within the company or the industry. This can make it difficult for companies to identify and implement sustainable practices, and may require them to hire consultants or collaborate with partners with the necessary expertise.

Limited visibility into supply chain:

Companies may not have full visibility into their supply chain and may not be aware of unsustainable practices used by suppliers. According to a survey by the Carbon Trust, only 44% of companies had assessed the sustainability of their supply chain.

Regulatory uncertainty:

The regulatory environment for sustainable practices in plastic manufacturing is constantly evolving, which can create uncertainty and hesitation for companies. Changing regulations and standards can require companies to adjust their practices and investments, which can create uncertainty around the return on investment.

Lack of market demand:

The demand for sustainable plastic products may not yet be high enough to justify the investment in sustainable practices for some companies. This can create a chicken-and-egg situation where companies hesitate to invest in sustainable practices until there is more demand, but demand may not increase until more sustainable products are available.

Data and statistics support these reasons for why some companies still use unsustainable practices in plastic manufacturing.

For example, according to a survey by the Ellen MacArthur Foundation, only 5% of plastic packaging is recycled effectively, and the majority ends up in landfill or the environment. This suggests that some companies are not investing in sustainable practices such as using recycled materials or designing products for recyclability.

Additionally, a report by the World Economic Forum found that only 9% of plastic waste has been recycled globally, highlighting the lack of demand for recycled plastics and the continued use of virgin plastics. This supports the notion that some companies may not see a business case for investing in sustainable practices.

Finally, a survey by the Carbon Trust found that 31% of companies cited cost as a barrier to implementing sustainable practices in their supply chain, supporting the idea that cost is a significant factor in hindering the adoption of sustainable practices.

Injection Moulding: Is it Sustainable?

Injection moulding can be sustainable if it is done with sustainability in mind. Injection moulding is a manufacturing process that involves melting plastic pellets and injecting them into a mould to create a part or product. This process can be used to create a wide range of products, from automotive parts to packaging materials.

Advantages of Injection Moulding:

Following, we've discussed some crucial advantages of injection moulding. Let's learn:

Cost-effective: Injection moulding is a cost-effective manufacturing process, as it allows for the creation of large quantities of products quickly and efficiently.

High precision and consistency: Injection moulding allows for high precision and consistency in the production of products. This makes it ideal for creating parts with complex geometries or tight tolerances.

Wide range of materials: Injection moulding can be used with a wide range of plastic materials, including biodegradable and recycled plastics.

Low waste: Injection moulding creates very little waste, as any excess plastic can be melted down and reused in the production process.

Disadvantages of Injection Moulding:

Following, we've disucussed some drawbacks associated with injection moulding. Let's learn:

Energy usage: Injection moulding can be energy-intensive, as it requires the use of high temperatures and pressure to melt and inject plastic. This can contribute to greenhouse gas emissions and other environmental impacts.

Chemical emissions: Injection moulding can also release chemicals into the environment, such as volatile organic compounds (VOCs), which can be harmful to human health and the environment.

Equipment cost: Injection moulding requires specialized equipment, which can be expensive to purchase and maintain.

Limited design flexibility: Injection moulding is a rigid process, which means that it may not be suitable for all product designs. This can limit the flexibility of product design.

In conclusion, injection moulding can be sustainable if it is implemented with a focus on reducing energy consumption, optimizing operational efficiency, and sourcing sustainable materials.

By using energy-efficient machinery, optimizing production processes, and prioritizing the use of renewable energy sources, injection moulding can significantly reduce its carbon footprint.

Additionally, by sourcing sustainable materials and implementing waste reduction strategies, the environmental impact of injection moulding can be further reduced.

Can Plastics Manufacturing be Environmentally Friendly?

Yes, plastics manufacturing can be environmentally friendly if sustainable practices are prioritized. The following are some ways that plastics manufacturing can become more environmentally friendly:

Considering energy efficiency: Energy consumption is a major contributor to environmental impacts in plastics manufacturing. Companies can prioritize energy efficiency by investing in energy-efficient equipment, optimizing production processes, and using renewable energy sources. This can reduce the carbon footprint of plastic manufacturing and lower operating costs.

Sourcing sustainable plastics: The use of sustainable plastics can significantly reduce the environmental impact of plastics manufacturing. Sustainable plastics include bio-based plastics made from renewable sources, such as corn starch or sugarcane, and recycled plastics. Companies can prioritize the use of sustainable plastics in their products to reduce their dependence on fossil fuels and reduce waste.

Reducing waste: Plastics manufacturing can generate a significant amount of waste, including plastic scraps and packaging waste. Companies can prioritize waste reduction by implementing recycling programs, designing products for recyclability, and reducing excess packaging. This can help to reduce the amount of waste sent to landfills and promote a circular economy.

Using eco-friendly additives: Plastics manufacturing can also involve the use of additives that can be harmful to the environment, such as plasticizers and flame retardants. Companies can prioritize the use of eco-friendly additives, such as natural-based additives, that are less harmful to the environment.

Eventually, plastics manufacturing can become more environmentally friendly through the adoption of sustainable practices. By prioritizing energy efficiency, using sustainable plastics, reducing waste, and using eco-friendly additives, companies can significantly reduce their environmental impact and contribute to a more sustainable future.

Frequently Asked Questions (FAQs) Associated with Sustainable Practices in Plastic Manufacturing

Here are some frequently asked questions (FAQs) related to sustainable practices in plastic manufacturing:

Que 1: What is Sustainable Plastic Manufacturing?

Ans: Sustainable plastic manufacturing involves the use of environmentally friendly practices in the production of plastic products. This includes the use of sustainable materials, energy-efficient production processes, waste reduction strategies, and eco-friendly additives.

Que 2: What are Some Sustainable Materials Used in Plastic Manufacturing?

Ans: Sustainable materials used in plastic manufacturing include bio-based plastics made from renewable sources such as corn starch, sugarcane, and algae, as well as recycled plastics.

Que 3: How Can Plastic Manufacturing Reduce its Carbon Footprint?

Ans: Plastic manufacturing can reduce its carbon footprint by using renewable energy sources, optimizing production processes to reduce energy consumption, and using sustainable materials.

Que 4: How Can Plastic Waste be Reduced in the Manufacturing Process?

Ans: Plastic waste can be reduced in the manufacturing process by implementing recycling programs, designing products for recyclability, and reducing excess packaging.

Que 5: What are Some Challenges to Implementing Sustainable Practices in Plastic Manufacturing?

Ans: Challenges to implementing sustainable practices in plastic manufacturing include the high cost of sustainable materials, lack of infrastructure for recycling and composting, and the difficulty in finding eco-friendly alternatives to traditional plastic additives.

Que 6: Can Sustainable Plastic Manufacturing be Cost-Effective?

Ans: Yes, sustainable plastic manufacturing can be cost-effective in the long run. While there may be higher upfront costs associated with implementing sustainable practices, these can be offset by savings from reduced energy consumption, waste reduction, and lower operating costs over time.

Que 7: What is the Role of Government in Promoting Sustainable Plastic Manufacturing?

Ans: Governments can play a role in promoting sustainable plastic manufacturing by providing incentives for companies to adopt sustainable practices, setting regulations and standards for sustainable materials and production processes, and investing in research and development of new sustainable materials and technologies.

How Deskera Can Assist You?

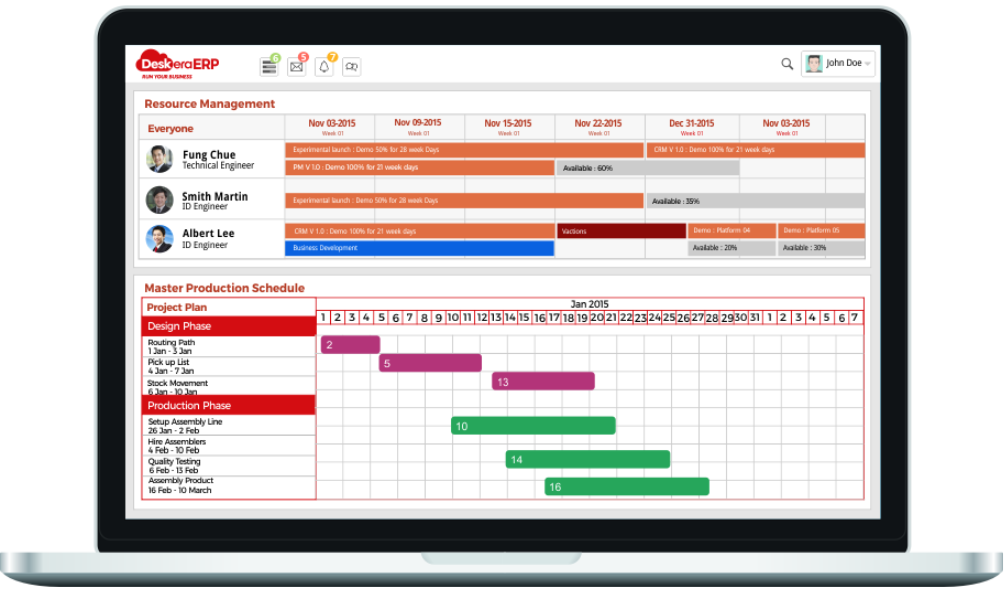

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- To achieve sustainability in plastic manufacturing, companies need to adopt a holistic approach that takes into account environmental, social, and economic factors. This can involve using renewable and recycled materials, reducing waste and pollution, minimizing energy and water usage, promoting worker health and safety, and collaborating with stakeholders across the value chain.

- The production and disposal of plastic can have a significant impact on the environment, including pollution, habitat destruction, and greenhouse gas emissions. Sustainable practices can help minimize this impact by reducing waste and pollution, promoting the use of renewable and recycled materials, and minimizing energy and water usage.

- The primary raw material used to manufacture plastics is petroleum, which is a non-renewable resource. The increasing demand for plastics has led to significant consumption of petroleum, which has raised concerns about its sustainability.

- Plastic manufacturers are looking at ways to improve the end-of-life management of plastics, including developing biodegradable and compostable plastics that break down more easily, implementing recycling programs, and reducing plastic packaging.

- Biodegradable plastics are designed to break down more quickly than traditional plastics, reducing their impact on the environment. These plastics are made from biodegradable polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), which are derived from renewable resources such as corn, sugarcane, or bacteria.

- Lean manufacturing is a philosophy that aims to reduce waste and improve efficiency in manufacturing processes. This can be achieved by implementing process improvements such as reducing setup times, optimizing production flows, and implementing just-in-time inventory systems.

- Closed-loop systems are another strategy for preventing plastic waste. This involves designing systems where plastic products are collected, recycled, and used to create new products. This can help reduce the amount of plastic that is discarded and promote a more sustainable use of resources.

Related Articles