Plastic pollution is one of the biggest environmental challenges of our time, with devastating effects on the planet's ecosystems and wildlife. As a result, there is increasing demand for sustainable and eco-friendly alternatives to traditional plastics.

Bioplastics offer a potential solution to this demand, as they are made from renewable resources, biodegradable and compostable, and have lower greenhouse gas emissions compared to traditional plastics.

In this article, we will explore the potential of bioplastics as a solution for sustainable plastic manufacturing. We will discuss the properties and types of bioplastics, their benefits over traditional plastics, their applications in different industries, and the challenges and ongoing research efforts in the field.

We will also examine successful examples of bioplastic use in different industries and predict the potential growth and development of bioplastics in the plastic manufacturing industry.

Discover a comprehensive overview of bioplastics and their role in creating a more sustainable future for plastic production and consumption.

- Plastic Pollution and its Impact on the Environment

- Bioplastics and their Properties

- Bioplastics: Potential Solution for Sustainable Plastic Manufacturing

- Various Types of Bioplastics

- Various Applications of Bioplastics

- Difference between Bioplastics and Traditional Plastics

- Benefits of Using Bioplastics Over Traditional Plastics

- Potential for Bioplastics to Reduce Plastic Pollution in Oceans and Landfills

- Key Challenges that Need to be Addressed before Adoption of Bioplastics

- Key Concerns and Considerations

- Successful Examples of Bioplastic Use in Different Industries

- Potential Growth and Development of Bioplastics in the Plastic Manufacturing Industry

- Ongoing Research and Development Efforts to Improve Bioplastic Production and Processing

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Plastic Pollution and its Impact on the Environment

Plastic pollution is a growing environmental problem caused by the excessive and improper disposal of plastic waste.

The widespread use of plastic in everyday products and packaging has led to an increase in plastic waste in our environment, particularly in our oceans. Plastic pollution has significant negative impacts on the environment, including:

Harm to Wildlife: Plastic waste can be harmful to wildlife, both on land and in the ocean. Wildlife can become entangled in plastic waste or ingest it, leading to injury or death.

Environmental Damage: Plastic waste in our oceans and waterways can have long-term effects on ecosystems, including changes to water quality, disruptions to food webs, and damage to marine habitats.

Human Health Risks: Plastic waste can pose health risks to humans, particularly through the consumption of contaminated seafood.

Economic Costs: Plastic pollution has economic costs, including expenses related to cleanup efforts, damage to fishing and tourism industries, and loss of revenue from damaged ecosystems.

In addition to these impacts, plastic pollution also contributes to climate change through the release of greenhouse gases during production and disposal. Overall, plastic pollution is a significant environmental issue that requires urgent action to reduce its impact.

Bioplastics and their Properties

Bioplastics are a type of plastic made from renewable biomass sources, such as corn starch, sugarcane, or vegetable fats and oils. They can be produced using a variety of methods, including fermentation of sugars, chemical synthesis, and biodegradation of organic material.

Bioplastics have properties similar to traditional petroleum-based plastics, including durability, strength, and versatility. However, they also have unique properties that make them a potentially more sustainable alternative to traditional plastics.

Check out some of the properties of bioplastics include:

Renewable Sourcing: Bioplastics are made from renewable biomass sources, which can be replenished over time.

Biodegradability: Some bioplastics can be designed to biodegrade more readily than traditional plastics, reducing their environmental impact.

Reduced Greenhouse Gas Emissions: Some bioplastics can be produced with a lower carbon footprint than traditional plastics, reducing their impact on climate change.

Bioplastics: Potential Solution for Sustainable Plastic Manufacturing

Bioplastics are a type of plastic made from renewable biomass sources, such as corn starch, sugarcane, or vegetable fats and oils. Unlike traditional plastics made from fossil fuels, bioplastics have the potential to reduce the environmental impact of plastic manufacturing and disposal.

Bioplastics can be produced using a variety of methods, including fermentation of sugars, chemical synthesis, and biodegradation of organic material. They can be used in a range of applications, including packaging, agriculture, and consumer goods.

Furthermore, the use of bioplastics has the potential to reduce the amount of plastic waste in the environment, as they can be designed to biodegrade more readily than traditional plastics. Additionally, some bioplastics can be produced with a lower carbon footprint than traditional plastics, further reducing their environmental impact.

Overall, bioplastics offer a promising solution for sustainable plastic manufacturing, and their use is gaining momentum as more companies and industries explore their potential benefits. However, there are also challenges and limitations to their adoption, which must be considered in evaluating their overall sustainability.

Various Types of Bioplastics

There are several types of bioplastics, each with unique properties and potential uses. Here are some of the most common types of bioplastics:

PLA (polylactic acid): PLA is a biodegradable plastic made from renewable sources such as corn starch or sugarcane. It is commonly used in food packaging, disposable tableware, and 3D printing.

PHA (polyhydroxyalkanoates): PHA is a biodegradable plastic produced by bacteria that can break down in both industrial and home composting facilities. It is used in packaging, medical devices, and agricultural films.

PBS (polybutylene succinate): PBS is a biodegradable plastic made from succinic acid and 1,4-butanediol, both of which can be produced from renewable sources. It is used in packaging, fibers, and films.

Starch-based plastics: These bioplastics are made from natural starches such as corn or potatoes. They are used in packaging, disposable utensils, and food trays.

Bio-based PET (polyethylene terephthalate): Bio-based PET is made from renewable biomass sources, such as sugarcane or corn. It is commonly used in beverage bottles and food packaging.

Cellulose-based plastics: These bioplastics are made from cellulose, which can be derived from plant sources such as wood pulp or cotton. They are used in packaging, films, and coatings.

Furthermore, the various types of bioplastics offer a range of potential applications, from food packaging and disposable tableware to medical devices and agricultural films.

However, their specific properties and potential uses vary depending on their composition and manufacturing processes. As bioplastics continue to gain momentum as a sustainable alternative to traditional plastics, it will be important to carefully evaluate the environmental benefits and limitations of each type of bioplastic in various industries and applications.

Various Applications of Bioplastics

Bioplastics have a wide range of applications across various industries, including packaging, agriculture, and consumer goods. Some of the key applications of bioplastics include:

Packaging:

Bioplastics are increasingly being used in packaging applications, particularly for food and beverage products. Bioplastics can be used to make packaging materials such as bags, films, and containers that are biodegradable, compostable, and renewable.

Agriculture:

Bioplastics can be used in agriculture to replace traditional plastic mulch films and plant pots. Biodegradable mulch films made from bioplastics can help to reduce waste and soil contamination, while plant pots made from bioplastics can be composted along with the plant waste.

Consumer Goods:

Bioplastics can be used in a range of consumer goods, such as toys, electronics, and personal care products. Bioplastics can be used to make durable and lightweight materials that are biodegradable and sustainable.

Medical:

Bioplastics can be used in medical applications, such as surgical implants, wound dressings, and drug delivery systems. Bioplastics can be designed to degrade over time in the body, reducing the need for additional surgeries or removal procedures.

Automotive:

Bioplastics can be used in the automotive industry to replace traditional plastics in interior and exterior parts, such as dashboards, door panels, and bumpers. Bioplastics can offer improved sustainability and environmental performance compared to traditional plastics.

Ultimately, bioplastics have a wide range of applications across various industries, and their use is expected to continue to grow as demand for more sustainable and eco-friendly materials increases. However, it is important to consider the full life cycle of bioplastics, from production to disposal, to ensure that they are truly sustainable and environmentally friendly.

Difference between Bioplastics and Traditional Plastics

The primary difference between bioplastics and traditional plastics is their composition and sourcing. Traditional plastics are made from non-renewable fossil fuels, such as oil and gas, while bioplastics are made from renewable biomass sources, such as corn starch, sugarcane, or vegetable fats and oils.

While both types of plastics share similar physical properties, such as durability and versatility, bioplastics have unique environmental benefits compared to traditional plastics.

Bioplastics can be designed to biodegrade more readily than traditional plastics, reducing their environmental impact in the event of improper disposal. Additionally, some bioplastics can be produced with a lower carbon footprint than traditional plastics, reducing their impact on climate change.

However, there are also challenges and limitations to the widespread adoption of bioplastics. Bioplastics can be more expensive to produce than traditional plastics, and there are concerns about their compatibility with existing plastic processing infrastructure. Additionally, some bioplastics may require large amounts of land and water to produce, potentially competing with food production.

Overall, while bioplastics offer a potentially more sustainable alternative to traditional plastics, their adoption requires careful consideration of their environmental benefits and limitations, as well as their economic and practical feasibility in various industries and applications.

Benefits of Using Bioplastics Over Traditional Plastics

There are several benefits to using bioplastics over traditional plastics. Here are some of the most significant benefits:

Renewable Sourcing:

Bioplastics are made from renewable biomass sources, such as corn starch, sugarcane, or vegetable fats and oils. This means that they can be replenished over time, unlike non-renewable fossil fuels used to produce traditional plastics.

Reduced Greenhouse Gas Emissions:

Bioplastics can be produced with a lower carbon footprint than traditional plastics, reducing their impact on climate change. This is because the production of bioplastics typically involves less energy and produces fewer greenhouse gas emissions than the production of traditional plastics.

Biodegradability:

Some bioplastics can be designed to biodegrade more readily than traditional plastics, reducing their environmental impact in the event of improper disposal. This can help to reduce the amount of plastic waste that accumulates in landfills and in the environment.

Versatility:

Bioplastics can be used in a range of applications, including packaging, agriculture, and consumer goods. This means that they offer a potentially more sustainable alternative to traditional plastics in a variety of industries.

Innovation Potential:

The development of bioplastics is still in its early stages, which means that there is significant potential for further innovation and improvement in the production and properties of bioplastics. This could lead to even greater environmental benefits in the future.

Eventually, the benefits of using bioplastics over traditional plastics include reduced greenhouse gas emissions, renewable sourcing, and the potential for biodegradability and versatility. As concerns about the environmental impact of traditional plastics continue to grow, bioplastics offer a promising alternative for more sustainable plastic manufacturing.

Potential for Bioplastics to Reduce Plastic Pollution in Oceans and Landfills

Bioplastics offer the potential to reduce plastic pollution in oceans and landfills in several ways. Here are some of the ways bioplastics can help:

Biodegradability:

As discussed previously, some types of bioplastics can be designed to biodegrade more readily than traditional plastics, reducing their environmental impact in the event of improper disposal. This means that if bioplastics end up in the ocean or in landfills, they are more likely to break down over time and cause less harm to the environment.

Reduced Plastic Waste:

Bioplastics can help to reduce the amount of plastic waste that ends up in oceans and landfills by offering a more sustainable alternative to traditional plastics. As more industries and consumers adopt bioplastics, the amount of traditional plastics used in packaging and other applications may decrease, reducing the overall amount of plastic waste.

Recycling Potential:

While some types of bioplastics can be composted or biodegraded, others can be recycled along with traditional plastics. This means that bioplastics can help to reduce the amount of plastic waste that is sent to landfills, and can potentially be repurposed for new products.

Awareness and Education:

The adoption of bioplastics may also help to raise awareness about plastic pollution and the need for more sustainable alternatives to traditional plastics. This can lead to greater education and behavior change around the use and disposal of plastic products, further reducing plastic pollution in oceans and landfills.

All in all, while bioplastics alone cannot solve the problem of plastic pollution, they offer a promising alternative to traditional plastics that can help to reduce the amount of plastic waste that ends up in oceans and landfills. As more research and development is done to improve the properties and sustainability of bioplastics, they may become an even more effective tool in the fight against plastic pollution.

Key Challenges that Need to be Addressed before Adoption of Bioplastics

While bioplastics offer many potential benefits as a more sustainable alternative to traditional plastics, there are also several challenges that must be addressed before they can be widely adopted. Some of the key challenges include:

Cost:

Bioplastics can be more expensive to produce than traditional plastics due to the cost of sourcing and processing renewable biomass materials. This can make them less competitive in price compared to traditional plastics, particularly for large-scale manufacturing operations.

Limited Availability:

The availability of bioplastics can be limited compared to traditional plastics, particularly in certain regions or industries. This can make it difficult for businesses to source bioplastics at scale, which can limit their ability to adopt them as a viable alternative to traditional plastics.

Compatibility with Current Plastic Processing Infrastructure:

Bioplastics may require different processing equipment or methods than traditional plastics, which can add to the cost and complexity of manufacturing. Additionally, bioplastics may not be compatible with some recycling or composting systems, which can limit their ability to be recycled or biodegraded.

Performance Limitations:

Some types of bioplastics may not offer the same level of performance or durability as traditional plastics, which can limit their use in certain applications. This can make it difficult for businesses to adopt bioplastics as a replacement for traditional plastics in all cases.

Lack of Standardization:

There is currently no universal standard for what constitutes a bioplastic, which can lead to confusion among consumers and businesses about the sustainability and properties of different types of bioplastics.

Overall, the challenges facing the widespread adoption of bioplastics are complex and multifaceted. While progress is being made to address these challenges, further innovation and investment will be needed to make bioplastics a viable and competitive alternative to traditional plastics on a large scale.

Key Concerns and Considerations

While bioplastics offer many potential benefits as a more sustainable alternative to traditional plastics, there are also concerns about their environmental impact, particularly in relation to land use and potential competition with food production. Here are some of the key concerns and considerations:

Land use:

One concern is that the production of biomass crops for bioplastics could lead to increased land use and deforestation, particularly if it competes with food production or displaces natural ecosystems. However, many bioplastics can be made from waste materials such as agricultural residue or food waste, which can reduce the need for additional land use.

Competition with Food Production:

Another concern is that the use of biomass crops for bioplastics could compete with food production, particularly in regions where food security is already a concern. However, many bioplastics can be made from non-food biomass sources such as wood chips or switchgrass, which can help to mitigate this concern.

Carbon Footprint:

While bioplastics offer the potential to reduce greenhouse gas emissions compared to traditional plastics, the production and disposal of bioplastics can still have a carbon footprint depending on the energy sources used and disposal methods. It is important to consider the full life cycle of bioplastics, from production to disposal, to assess their environmental impact.

Waste Management:

Bioplastics may require separate waste management systems or composting facilities compared to traditional plastics, which can add to the complexity and cost of their disposal.

Overall, while there are concerns about the environmental impact of bioplastics, these concerns can be mitigated with careful sourcing and production practices, and by considering the full life cycle of bioplastics.

Additionally, it is important to recognize that bioplastics are not a panacea for the problem of plastic pollution, and that reducing plastic waste at the source and improving recycling and waste management systems are also important components of a sustainable approach to plastic use.

Successful Examples of Bioplastic Use in Different Industries

There are several successful examples of bioplastic use in different industries, showcasing the potential of these materials as sustainable alternatives to traditional plastics. Here are a few examples:

Packaging:

Nestlé, a global food and beverage company, has developed a biodegradable and compostable packaging material made from plant-based polymers. The packaging is being used for some of Nestlé's popular products such as KitKat chocolate bars and Nescafé coffee products.

Agriculture:

BASF, a chemical company, has developed a biodegradable mulch film made from a biopolymer called ecovio. The mulch film is used by farmers to suppress weeds and retain soil moisture, and it can be plowed into the soil after use, reducing waste and pollution.

Consumer Goods:

The LEGO Group has developed a line of sustainable building bricks made from a plant-based bioplastic called polyhydroxyalkanoate (PHA). The bioplastic is made from sustainably sourced sugar cane and offers the same durability and functionality as traditional plastic.

Medical:

A biodegradable and biocompatible polymer called polycaprolactone (PCL) is being used in the medical industry to create implants for tissue regeneration and drug delivery. PCL is designed to degrade over time in the body, reducing the need for additional surgeries or removal procedures.

Automotive:

Ford Motor Company has developed a sustainable foam made from soybeans that is being used in the seats of some of their vehicles. The soy-based foam reduces petroleum use and greenhouse gas emissions compared to traditional petroleum-based foam.

These examples demonstrate the potential for bioplastics to be used across a range of industries as sustainable and eco-friendly alternatives to traditional plastics. As more companies invest in research and development of bioplastics, we can expect to see further innovations and success stories in the use of these materials.

Potential Growth and Development of Bioplastics in the Plastic Manufacturing Industry

The potential for growth and development of bioplastics in the plastic manufacturing industry is significant. As more consumers and businesses become aware of the environmental impact of traditional plastics, there is increasing demand for sustainable and eco-friendly alternatives.

Bioplastics offer a solution to this demand, as they are made from renewable resources, can be biodegradable and compostable, and have lower greenhouse gas emissions compared to traditional plastics.

According to a report by Grand View Research, the global bioplastics market size was valued at USD 10.5 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 14.5% from 2021 to 2028.

This growth is driven by factors such as increased focus on sustainable packaging, government regulations and initiatives supporting the use of bioplastics, and technological advancements in bioplastic manufacturing.

In addition, there are several ongoing research and development efforts focused on improving the properties and performance of bioplastics, which could further drive their adoption in the plastic manufacturing industry. For example, researchers are exploring ways to improve the mechanical strength, thermal stability, and durability of bioplastics to make them more suitable for a wider range of applications.

However, there are also challenges facing the widespread adoption of bioplastics, including cost, limited availability, and compatibility with current plastic processing infrastructure. These challenges will need to be addressed in order for bioplastics to reach their full potential in the plastic manufacturing industry.

Overall, the potential for growth and development of bioplastics in the plastic manufacturing industry is significant, and their adoption is expected to continue to increase as demand for sustainable and eco-friendly materials grows.

Ongoing Research and Development Efforts to Improve Bioplastic Production and Processing

There are ongoing research and development efforts focused on improving bioplastic production and processing. Here are a few examples:

Genetic Engineering:

Researchers are exploring ways to genetically engineer plants to produce more efficient and sustainable bioplastics. For example, scientists are working on modifying the genes of plants such as sugarcane and corn to produce bioplastics with improved properties.

Alternative Feedstocks:

While many bioplastics are made from food crops such as corn and sugarcane, researchers are exploring alternative feedstocks such as algae, bacteria, and waste products. These alternative feedstocks have the potential to reduce competition with food production and provide a more sustainable source for bioplastics.

Recycling and Processing:

Currently, bioplastics cannot be processed together with traditional plastics due to differences in chemical properties. Researchers are developing new processing methods that will enable the recycling and reprocessing of bioplastics along with traditional plastics. For example, a group of researchers in the UK have developed a new recycling process that can recycle both traditional and biodegradable plastics together.

Improved Properties:

Researchers are exploring ways to improve the mechanical properties and durability of bioplastics to make them more suitable for a wider range of applications. For example, scientists are working on developing bioplastics with improved strength and heat resistance.

Biodegradability:

While biodegradability is a key benefit of some bioplastics, not all bioplastics are biodegradable or compostable. Researchers are exploring ways to improve the biodegradability and composability of bioplastics, which could help to reduce plastic waste in the environment.

These ongoing research and development efforts demonstrate the potential for bioplastics to become even more sustainable, efficient, and cost-effective in the future.

As more investment is made in this field, we can expect to see continued improvements in bioplastic production and processing, as well as increased adoption in various industries.

Wrapping Up

In conclusion, bioplastics have the potential to revolutionize the plastic manufacturing industry, offering a sustainable and eco-friendly alternative to traditional plastics.

Bioplastics are made from renewable resources, biodegradable, and compostable, and have lower greenhouse gas emissions compared to traditional plastics. They can be used in a wide range of applications, from packaging to consumer goods, and are already being successfully adopted by various industries.

However, there are still challenges facing the widespread adoption of bioplastics, including cost, limited availability, and compatibility with current plastic processing infrastructure.

Ongoing research and development efforts are focused on improving bioplastic production and processing, including genetic engineering, alternative feedstocks, recycling and processing, improved properties, and biodegradability.

As more investment is made in this field, we can expect to see continued improvements in bioplastic technology and increased adoption in various industries. In the long term, bioplastics have the potential to significantly reduce plastic pollution in oceans and landfills, contributing to a more sustainable future for our planet.

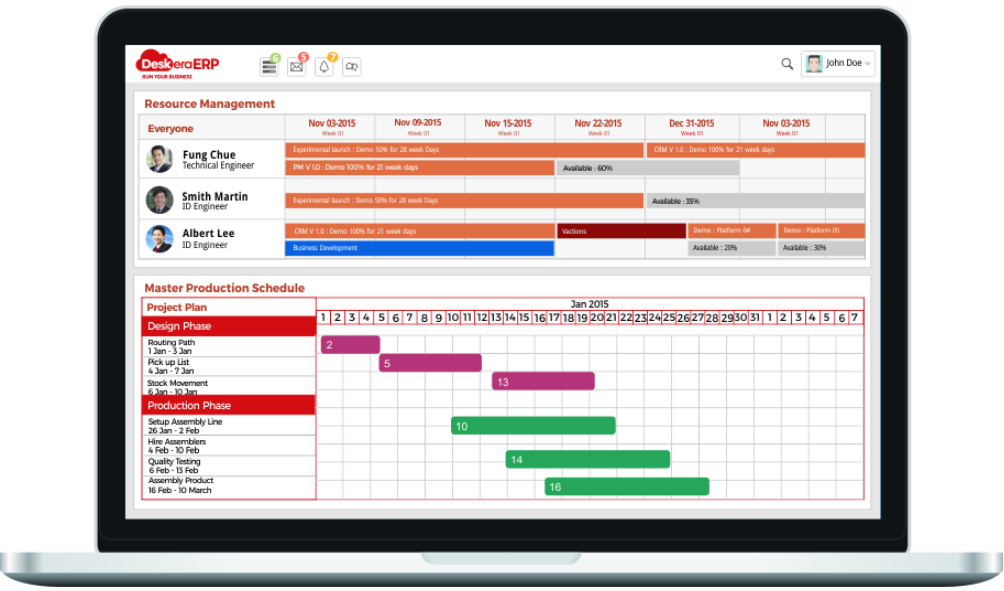

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Bioplastics are a type of plastic made from renewable biomass sources, such as corn starch, sugarcane, or vegetable fats and oils. Unlike traditional plastics made from fossil fuels, bioplastics have the potential to reduce the environmental impact of plastic manufacturing and disposal.

- The use of bioplastics has the potential to reduce the amount of plastic waste in the environment, as they can be designed to biodegrade more readily than traditional plastics. Additionally, some bioplastics can be produced with a lower carbon footprint than traditional plastics, further reducing their environmental impact.

- Reduced greenhouse gas emissions: Bioplastics can be produced with a lower carbon footprint than traditional plastics, reducing their impact on climate change. This is because the production of bioplastics typically involves less energy and produces fewer greenhouse gas emissions than the production of traditional plastics.

- The adoption of bioplastics may also help to raise awareness about plastic pollution and the need for more sustainable alternatives to traditional plastics. This can lead to greater education and behavior change around the use and disposal of plastic products, further reducing plastic pollution in oceans and landfills.

- Limited availability: The availability of bioplastics can be limited compared to traditional plastics, particularly in certain regions or industries. This can make it difficult for businesses to source bioplastics at scale, which can limit their ability to adopt them as a viable alternative to traditional plastics.

- Carbon footprint: While bioplastics offer the potential to reduce greenhouse gas emissions compared to traditional plastics, the production and disposal of bioplastics can still have a carbon footprint depending on the energy sources used and disposal methods. It is important to consider the full life cycle of bioplastics, from production to disposal, to assess their environmental impact.

- Automotive: Bioplastics can be used in the automotive industry to replace traditional plastics in interior and exterior parts, such as dashboards, door panels, and bumpers. Bioplastics can offer improved sustainability and environmental performance compared to traditional plastics.

Related Articles