Are rising maintenance costs and unexpected equipment downtime eating into your operational efficiency? The answer often lies in how well—or how poorly—your MRO inventory is being tracked. In 2026, maintenance, repair, and operations (MRO) supplies are no longer a background function. They directly influence asset uptime, maintenance responsiveness, and overall cost control, making the right inventory metrics more important than ever.

Despite this, MRO inventory continues to be one of the most overlooked cost centers in manufacturing and asset-intensive industries. Excess spare parts lock up working capital, while missing or delayed critical components can bring entire production lines to a halt. Without clearly defined MRO inventory metrics, organizations struggle to balance availability with cost, leading to reactive decisions and preventable downtime.

Tracking the right MRO inventory metrics in 2026 enables organizations to move from guesswork to data-driven maintenance planning. Metrics such as inventory turnover, stockout rates, lead times, and critical spare availability provide actionable insights into where money is being tied up and where risks to uptime exist. When aligned with maintenance KPIs, these metrics help operations teams improve reliability while maintaining tighter control over inventory spend.

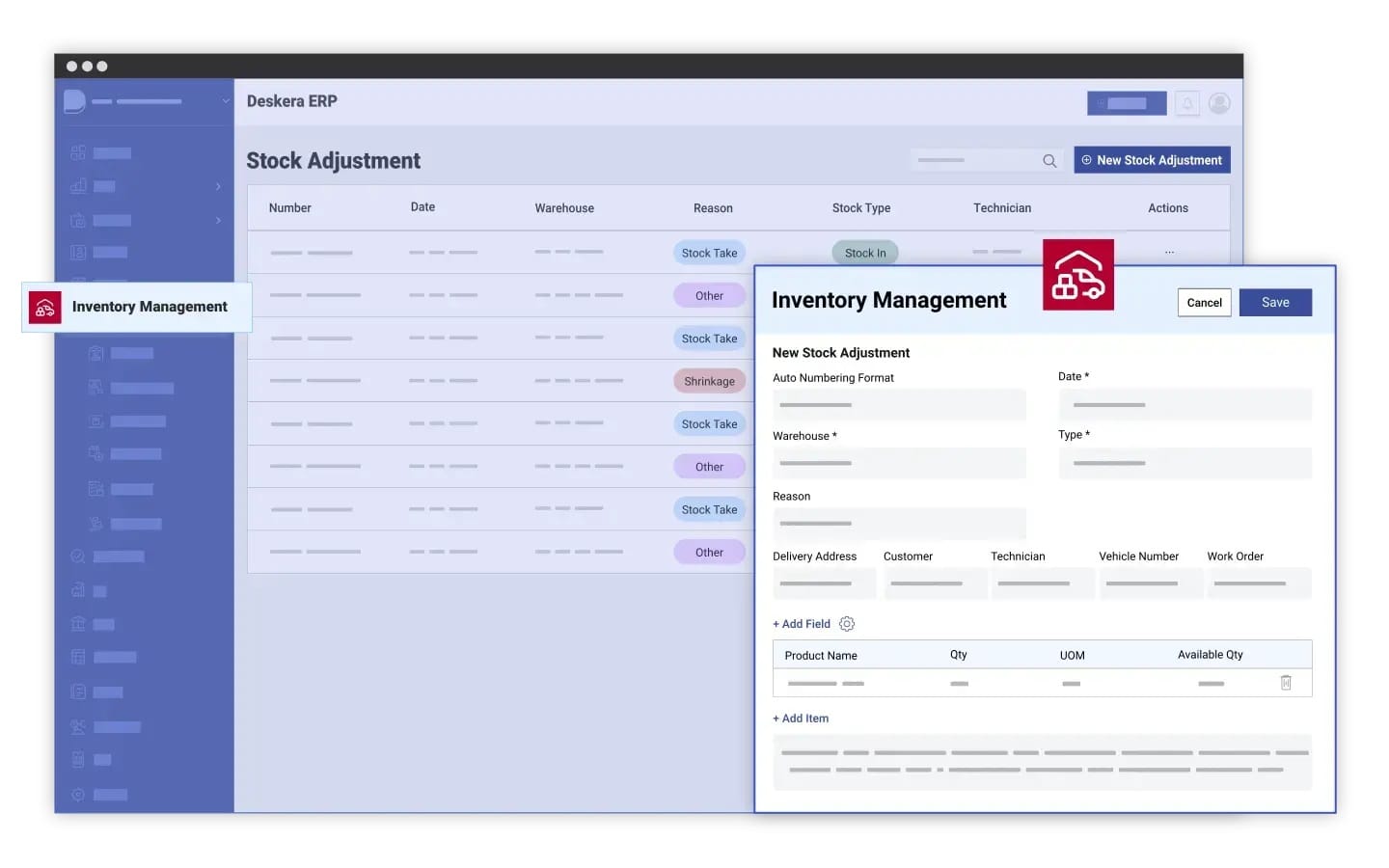

This is where solutions like Deskera Manufacturing ERP play a critical role. Deskera provides centralized visibility into MRO inventory, maintenance activities, and procurement data on a single platform. With real-time stock tracking, automated reorder alerts, and seamless integration between maintenance and inventory modules, Deskera enables organizations to monitor the right MRO metrics and take timely, informed actions that protect both costs and uptime.

What Is MRO Inventory and Why It’s Often Overlooked

MRO inventory—short for Maintenance, Repair, and Operations inventory—includes all the supplies, spare parts, tools, and consumables required to keep equipment, facilities, and production processes running smoothly. These items do not become part of the finished product, but they are essential for maintaining asset reliability and preventing unplanned downtime. Common examples include spare parts, lubricants, safety equipment, cleaning supplies, fasteners, and maintenance tools.

One reason MRO inventory is often overlooked is that it is typically viewed as an indirect or non-production expense. Unlike raw materials or work-in-progress inventory, MRO items do not directly generate revenue, which leads many organizations to treat them as low-priority purchases. As a result, MRO spending is frequently decentralized, poorly tracked, and managed reactively—only addressed when something breaks down.

Another challenge lies in the unpredictable usage patterns of MRO inventory. Spare parts may sit unused for long periods and suddenly become critical during equipment failures. This unpredictability makes it difficult to forecast demand accurately, causing organizations to either overstock “just in case” or risk stockouts that lead to costly downtime. Without proper classification and criticality assessment, these risks remain hidden.

In reality, overlooking MRO inventory can have serious financial and operational consequences. Excess MRO stock ties up working capital and increases carrying costs, while shortages delay maintenance activities and reduce asset uptime. By clearly defining MRO inventory and giving it the same analytical attention as production inventory, organizations can uncover significant opportunities for cost control, efficiency, and improved maintenance performance.

Benefits of Effective MRO Inventory Metrics

Tracking MRO inventory metrics effectively delivers measurable operational and financial advantages, especially in asset-intensive environments where downtime and maintenance costs can escalate quickly. When the right metrics are consistently monitored, organizations gain visibility, control, and the ability to act proactively rather than reactively.

Improved Operational Efficiency

Effective MRO inventory metrics provide real-time visibility into stock levels, usage patterns, and procurement timelines. Metrics such as inventory accuracy, order lead time, and stock availability help maintenance teams access the right parts at the right time. This reduces delays in maintenance activities, prevents last-minute emergency purchases, and keeps production schedules on track without unnecessary interruptions.

Lower Inventory and Maintenance Costs

Cost control is one of the most direct benefits of tracking MRO inventory metrics. Monitoring metrics like inventory turnover, carrying cost, obsolescence rate, and inactive stock helps organizations avoid overstocking while minimizing the risk of stockouts. By eliminating excess and obsolete inventory, businesses can free up working capital and reduce storage, insurance, and write-off costs associated with poorly managed MRO supplies.

Better Maintenance Planning and Reduced Downtime

When MRO metrics are aligned with maintenance data, organizations can significantly improve asset uptime. Tracking stockout-related downtime, spare part criticality, and replenishment lead times ensures that critical components are always available when needed. This enables smoother preventive and predictive maintenance execution, reducing unplanned breakdowns and improving overall equipment reliability.

Data-Driven and Confident Decision-Making

Accurate MRO inventory metrics provide managers with reliable, data-backed insights into performance trends and risks. With clear visibility into consumption patterns and supplier performance, organizations can forecast demand more accurately, optimize reorder points, and negotiate better procurement terms. This data-driven approach supports smarter budgeting and aligns inventory decisions with long-term operational goals.

Stronger Cross-Functional Alignment

Effective MRO metrics create a shared source of truth across maintenance, procurement, finance, and operations teams. When everyone works from the same data, silos are reduced, accountability improves, and decisions are made faster. This alignment ensures that MRO inventory supports broader business objectives such as cost optimization, uptime improvement, and operational resilience.

Top MRO Inventory Metrics to Track in 2026

In 2026, effective MRO inventory management depends on tracking metrics that connect maintenance reliability, warehouse efficiency, and financial performance.

Beyond traditional inventory KPIs, organizations must also monitor warehouse execution and fulfillment metrics that directly influence spare part availability, response time, and operational continuity.

The following metrics provide a comprehensive framework for improving cost control and asset uptime.

4.1 MRO Inventory Turnover Ratio

- What it measures and why it matters

- Tracks how often MRO inventory is used or replenished within a given period

- Helps identify overstocking and slow-moving spare parts

- How low or high turnover affects cash flow

- Low turnover ties up capital in unused inventory

- Excessively high turnover increases dependency on suppliers and stockout risk

4.2 Inventory Accuracy

- What it measures

- Compares system-recorded inventory against physical stock levels

- Industry best practice targets accuracy above 99%

- Why it’s critical for MRO operations

- Prevents unexpected stockouts and duplicate purchases

- Forms the foundation for reliable forecasting and planning

4.3 Stockout Rate for Critical MRO Items

- Measuring availability of mission-critical spares

- Tracks how frequently essential MRO items are unavailable

- Ideal stockout rate is below 1%

- How stockouts directly contribute to downtime

- Delays maintenance activities and extends equipment outages

- Drives emergency procurement and expedited shipping costs

4.4 MRO Carrying Cost Percentage

- What it includes

- Storage, insurance, handling, obsolescence, and cost of capital

- Reveals the true cost of holding MRO inventory

- Why carrying cost visibility is crucial in 2026

- Rising warehousing and capital costs demand tighter control

- Enables organizations to balance availability with cost efficiency

4.5 Spare Parts Criticality Index

- Identifying and prioritizing mission-critical spares

- Classifies parts based on impact on safety, compliance, and uptime

- Differentiates critical, essential, and non-critical inventory

- Linking criticality to maintenance strategies

- Ensures high-criticality parts are always stocked

- Supports preventive and predictive maintenance execution

4.6 Maintenance Downtime Due to Parts Unavailability

- What this metric tracks

- Measures downtime directly caused by missing or delayed MRO items

- Isolates inventory-related downtime from other failure causes

- Using this metric to justify inventory optimization

- Quantifies the cost of understocking critical spares

- Strengthens the business case for inventory investment

4.7 Order Lead Time for MRO Procurement

- Supplier reliability and procurement efficiency

- Measures time from purchase order placement to receipt

- Highlights supplier performance and internal process gaps

- Reducing lead times to improve maintenance response

- Shorter lead times reduce safety stock requirements

- Improves agility during unplanned maintenance events

4.8 Order Accuracy

- What it measures

- Percentage of MRO orders fulfilled without errors

- Ensures the right part reaches the right location

- Why order accuracy matters for MRO

- Prevents maintenance delays caused by incorrect parts

- Reduces returns, rework, and wasted labor

4.9 Fill Rate

- Measuring fulfillment performance

- Tracks the percentage of MRO requests fulfilled from available stock

- High fill rates indicate strong inventory planning

- Impact on maintenance operations

- Improves maintenance responsiveness

- Reduces reliance on emergency purchases

4.10 Average Order Picking Time

- What it measures

- Time taken to pick MRO items from storage for issue or dispatch

- Reflects warehouse workflow efficiency

- Why it affects uptime

- Faster picking speeds up maintenance response

- Reduces delays during breakdown scenarios

4.11 Average Putaway Turnaround Time

- What it measures

- Time required to store received MRO items in assigned locations

- Impacts inventory availability and accuracy

- Operational benefits of faster putaway

- Makes parts available sooner for maintenance use

- Reduces congestion and warehouse bottlenecks

4.12 Days Inventory on Hand (DIH)

- What it measures

- Average number of days MRO inventory is held before use

- Balances availability with carrying cost

- Why DIH matters for cost control

- Excessive DIH increases holding costs

- Optimized DIH improves cash flow and space utilization

4.13 Emergency Supply Costs

- What this metric captures

- Costs incurred from urgent, unplanned MRO purchases

- Often includes premiums, expedited shipping, and overtime

- Why it’s a warning signal

- Indicates poor forecasting or insufficient safety stock

- Directly impacts maintenance budgets

4.14 Obsolete and Slow-Moving MRO Inventory Rate

- Identifying dead stock and aging inventory

- Tracks parts no longer used or tied to retired equipment

- Highlights excess inventory risk

- Financial and operational impact

- Leads to write-offs and wasted storage space

- Reduces overall inventory efficiency

4.15 Inactive Stock Rate

- What it measures

- Inventory not used within a defined time period

- Signals opportunities for liquidation or reallocation

- Why inactive stock must be controlled

- Frees up working capital and warehouse capacity

- Improves overall MRO inventory health

Aligning MRO Metrics with Maintenance KPIs

Tracking MRO inventory metrics in isolation limits their impact. To truly improve asset reliability and cost control in 2026, MRO metrics must be closely aligned with maintenance KPIs.

This alignment ensures that spare parts availability, procurement efficiency, and warehouse performance directly support maintenance outcomes such as reduced downtime, faster repairs, and higher equipment availability.

When inventory and maintenance data work together, organizations can shift from reactive firefighting to proactive and predictive maintenance.

Connecting MRO Inventory Metrics with MTTR (Mean Time to Repair)

MRO metrics such as stockout rate, order picking time, and order accuracy have a direct influence on MTTR. When critical spare parts are unavailable or incorrectly issued, repair times increase significantly. By ensuring high fill rates, accurate inventory records, and fast picking and issuing processes, maintenance teams can access the right parts quickly, enabling faster repairs and shorter downtime windows.

Linking Spare Parts Availability to MTBF (Mean Time Between Failures)

MTBF improves when preventive and predictive maintenance activities are executed on time. Metrics like spare parts criticality index, inventory accuracy, and order lead time ensure that required components are always available before a failure occurs. Consistent availability of critical spares allows maintenance teams to replace worn components proactively, reducing unexpected breakdowns and extending asset life.

Supporting Asset Availability and Equipment Uptime

Asset availability is directly affected by maintenance downtime caused by parts unavailability. Aligning MRO metrics such as maintenance downtime due to parts shortages, fill rate, and emergency supply costs with uptime KPIs helps organizations identify inventory-related reliability gaps. This alignment enables targeted inventory optimization efforts that improve overall equipment availability.

Improving Preventive Maintenance Compliance

Preventive maintenance schedules often fail due to missing or delayed spare parts. Metrics like days inventory on hand (DIH), procurement lead time, and inventory turnover help ensure that planned maintenance tasks are not postponed due to inventory constraints. When MRO planning supports preventive maintenance execution, organizations reduce corrective maintenance costs and improve long-term reliability.

Enhancing Maintenance Cost Control

Maintenance cost KPIs are strongly influenced by MRO carrying costs, obsolete inventory rates, and emergency procurement expenses. By aligning these inventory metrics with maintenance budgets, organizations can identify cost leakage caused by overstocking, inactive stock, or last-minute purchases. This visibility supports better cost planning and more disciplined inventory investment decisions.

Enabling Predictive and Condition-Based Maintenance

Advanced maintenance strategies rely on timely access to the right spare parts. MRO metrics such as inventory accuracy, lead time variability, and critical spare availability provide the foundation for predictive maintenance initiatives. When inventory data is aligned with asset condition monitoring, maintenance teams can plan interventions confidently and avoid disruptions caused by part shortages.

Driving Cross-Functional Collaboration Between Maintenance and Inventory Teams

Aligning MRO metrics with maintenance KPIs creates a shared performance framework for maintenance, procurement, and warehouse teams. With common visibility into metrics that impact both inventory health and asset performance, teams can collaborate more effectively, resolve issues faster, and make decisions that support operational reliability and business objectives.

Common Mistakes to Avoid When Measuring MRO Inventory Performance

Measuring MRO inventory performance is essential, but doing it incorrectly can lead to misleading insights and poor decisions. In many organizations, MRO metrics fail to deliver value not because the data is unavailable, but because of how it is tracked, interpreted, or applied. Avoiding the following common mistakes can help ensure that MRO inventory metrics truly support cost control, maintenance efficiency, and asset uptime.

Tracking Too Many Metrics Without Clear Objectives

One of the most common mistakes is measuring every possible inventory metric without linking them to business or maintenance goals. When teams track too many KPIs, focus is lost and decision-making slows down. MRO metrics should be selected based on their impact on uptime, maintenance responsiveness, and cost efficiency—not simply because the data is easy to collect.

Ignoring Spare Parts Criticality

Treating all MRO items the same leads to poor stocking decisions. Failing to distinguish between critical and non-critical spare parts often results in shortages of high-impact items and excess stock of low-importance parts. Without a spare parts criticality framework, metrics like turnover or stock levels can be misleading and may increase downtime risk.

Relying on Inaccurate or Incomplete Inventory Data

Inventory accuracy is the foundation of effective MRO performance measurement. Using outdated, incomplete, or inaccurate data undermines the reliability of every metric, from stockout rate to lead time. Poor data quality often leads to emergency purchases, inflated safety stock, and lost trust in inventory reports.

Measuring Inventory in Isolation from Maintenance KPIs

Another common pitfall is evaluating MRO inventory metrics separately from maintenance performance indicators. When inventory data is not aligned with KPIs such as MTTR, MTBF, or asset availability, organizations fail to see how inventory decisions directly affect downtime and maintenance costs. This disconnect limits the strategic value of MRO metrics.

Overlooking Obsolete and Inactive Inventory

Many organizations focus on availability while ignoring slow-moving, inactive, or obsolete MRO stock. This leads to excessive carrying costs, wasted warehouse space, and unexpected write-offs. Regularly tracking obsolescence and inactive stock rates is essential to maintaining a healthy and cost-efficient MRO inventory.

Failing to Act on Insights

Collecting and reporting metrics without taking corrective action is a wasted effort. MRO inventory metrics should drive decisions such as adjusting reorder points, renegotiating supplier terms, or reclassifying spare parts. Without accountability and follow-through, even the most accurate metrics provide little value.

Using Manual Tools and Siloed Systems

Relying on spreadsheets or disconnected systems makes it difficult to track MRO inventory performance consistently. Manual processes increase the risk of errors and limit real-time visibility. Integrated systems that connect inventory, maintenance, and procurement data are essential for accurate measurement and timely decision-making in 2026.

Best Practices for Tracking MRO Inventory Metrics in 2026

As MRO inventory management becomes more complex and data-driven, organizations must adopt structured, technology-enabled practices to ensure their metrics are accurate, actionable, and aligned with business outcomes. In 2026, successful MRO tracking is less about collecting more data and more about creating visibility, consistency, and accountability across maintenance, inventory, and procurement functions.

Define Clear Objectives for Each Metric

Start by clearly defining why each MRO inventory metric is being tracked and how it supports broader goals such as cost control, uptime improvement, or maintenance efficiency. Every metric should have a clear purpose, an owner, and a target value. This prevents unnecessary reporting and ensures that metrics lead to informed decisions rather than data overload.

Standardize MRO Item Classification and Criticality

Consistent classification of MRO items is essential for meaningful measurement. Establish standardized naming conventions, units of measure, and categories across all locations. Implement a spare parts criticality framework to distinguish high-impact items from routine consumables, ensuring metrics reflect operational risk and maintenance priorities.

Prioritize Inventory Accuracy and Data Quality

High-quality data is the foundation of reliable MRO metrics. Conduct regular cycle counts, audits, and reconciliations to maintain accurate inventory records. In 2026, maintaining inventory accuracy above industry benchmarks is critical for preventing stockouts, excess inventory, and emergency purchases that inflate maintenance costs.

Leverage Automation and Real-Time Visibility

Manual tracking methods are no longer sufficient for modern MRO environments. Use automated inventory systems with real-time dashboards to monitor key metrics such as stock levels, lead times, and turnover. Automated alerts for reorder points, stockouts, and slow-moving inventory enable faster responses and proactive decision-making.

Align MRO Metrics with Maintenance and Financial KPIs

MRO inventory metrics should be reviewed alongside maintenance KPIs like MTTR, MTBF, and asset availability, as well as financial indicators such as carrying cost and working capital. This alignment helps organizations understand how inventory decisions impact downtime, maintenance budgets, and overall operational performance.

Review Metrics Regularly and Adjust Thresholds

MRO requirements change as equipment, suppliers, and maintenance strategies evolve. Regularly review metric performance and adjust targets, reorder points, and safety stock levels based on actual usage trends and risk profiles. Static thresholds can quickly become outdated and misleading.

Encourage Cross-Functional Ownership and Accountability

Effective MRO tracking requires collaboration between maintenance, warehouse, procurement, and finance teams. Assign clear ownership for each metric and establish regular review meetings to discuss trends, issues, and corrective actions. Shared accountability ensures that metrics drive continuous improvement rather than isolated reporting.

Use Metrics to Drive Action, Not Just Reporting

The true value of MRO inventory metrics lies in how they are used. Metrics should trigger specific actions—such as supplier reviews, inventory optimization initiatives, or maintenance planning adjustments. In 2026, organizations that treat metrics as decision-making tools rather than reports will achieve stronger cost control and higher asset uptime.

How Deskera Manufacturing ERP Helps Track and Optimize MRO Inventory Metrics

In 2026, organizations cannot rely on spreadsheets or siloed systems to manage complex MRO inventory and maintenance requirements. Deskera Manufacturing ERP offers an integrated, data-driven platform that connects inventory, procurement, maintenance, and finance—enabling real-time visibility and actionable insights. By unifying workflows and automating key processes, Deskera helps teams measure, analyze, and optimize the critical MRO metrics that drive cost control and uptime.

Centralized MRO Inventory Visibility

Deskera provides a single source of truth for all MRO inventory data across locations and warehouses. With real-time stock levels, item classifications, and consumption history, teams can:

- Monitor inventory accuracy and stock positions

- Track slow-moving, obsolete, and inactive parts

- Identify and prioritize critical spares based on usage and risk profiles

This centralized visibility ensures that MRO inventory metrics are reliable, consistent, and actionable.

Automated Reorder Management and Safety Stock Alerts

Manual tracking often leads to costly stockouts or excess carrying costs. Deskera uses intelligent rules and historical demand patterns to:

- Set dynamic reorder points and safety stock levels

- Trigger automated notifications before stockouts occur

- Reduce emergency procurement expenses

By automating replenishment and alerts, Deskera reduces the risk of unplanned downtime linked to missing parts.

Real-Time Tracking of Lead Times and Supplier Performance

Understanding procurement performance is essential to improving order lead times and fill rates. Deskera helps teams:

- Monitor supplier lead times and on-time delivery performance

- Compare actual vs. expected receipt times

- Flag delivery delays that could impact maintenance schedules

With this data, procurement and maintenance planners can make more informed supplier decisions and optimize reorder timing.

Integrated Maintenance and Inventory Workflows

One of Deskera’s strengths is its ability to link maintenance work orders with inventory usage, enabling:

- Automatic deduction of MRO parts when work orders are executed

- Tracking of maintenance downtime related to parts availability

- Clear visibility into how inventory decisions affect maintenance KPIs

This integration ensures that MRO inventory metrics are context-rich and meaningfully tied to maintenance outcomes.

Advanced Reporting and Dashboards

Deskera’s customizable dashboards and reports allow teams to visualize key MRO metrics at a glance. Users can:

- Generate real-time dashboards for metrics such as turnover ratio, stockout rate, DIH, and carrying cost

- Schedule automated reports for maintenance planners, warehouse managers, and finance teams

- Compare trends over time to identify improvement areas

This analytical capability turns raw inventory data into insights that support proactive decisions.

Predictive Insights and Demand Forecasting

By leveraging historical usage patterns and equipment maintenance cycles, Deskera helps organizations:

- Forecast demand for spare parts more accurately

- Plan inventories based on predictive maintenance schedules

- Avoid overstock during low-demand periods

This predictive approach brings MRO inventory metrics closer to strategic planning and minimizes reactive, cost-heavy decisions.

Cross-Functional Collaboration and Accountability

Deskera’s role-based access and shared data environment foster collaboration across:

- Inventory and warehouse teams

- Maintenance and engineering departments

- Procurement and finance groups

Everyone works from the same data, facilitating joint reviews of MRO performance metrics and collective accountability for outcomes.

In summary, Deskera Manufacturing ERP transforms the way organizations track and optimize MRO inventory metrics by providing real-time data, integrated workflows, automated alerts, and powerful analytics. This integration helps reduce costs, improve uptime, and strengthen the connection between inventory management and maintenance performance—making Deskera an essential tool for MRO excellence in 2026 and beyond.

Key Takeaways

- MRO inventory may not contribute directly to production, but poor visibility and control can significantly increase downtime, maintenance delays, and hidden operational costs.

- As maintenance strategies become more predictive and cost-focused, tracking the right MRO metrics is essential for balancing spare part availability with working capital efficiency.

- A balanced MRO inventory turnover ratio helps avoid excess stock while ensuring critical spares are available, directly impacting cash flow and maintenance responsiveness.

- High inventory accuracy is the foundation of all MRO metrics, preventing stockouts, duplicate purchases, and unreliable maintenance planning.

- Keeping stockout rates for critical MRO items near zero is crucial to avoiding unplanned downtime and costly emergency procurement.

- Visibility into MRO carrying costs reveals the true financial impact of holding spare parts and highlights opportunities to reduce excess inventory.

- Classifying spare parts by criticality ensures that inventory investment aligns with asset risk, safety requirements, and uptime priorities.

- Measuring maintenance downtime caused by parts unavailability directly links inventory gaps to lost production and supports data-backed optimization decisions.

- Shorter and more predictable MRO procurement lead times reduce dependence on high safety stock and improve maintenance agility.

- High order accuracy ensures maintenance teams receive the correct parts the first time, minimizing repair delays and rework.

- A strong fill rate reflects effective inventory planning and enables faster maintenance response without relying on emergency purchases.

- Faster order picking times improve maintenance turnaround, especially during breakdown scenarios where delays significantly increase downtime costs.

- Efficient putaway turnaround ensures newly received MRO items are quickly available for use, supporting inventory accuracy and operational responsiveness.

- Optimizing days inventory on hand helps balance spare part availability with carrying cost reduction and improved cash flow.

- Elevated emergency supply costs signal weaknesses in forecasting, safety stock policies, or supplier reliability.

- Regularly tracking obsolete and slow-moving MRO inventory prevents capital lock-up, write-offs, and wasted warehouse space.

- Identifying and addressing inactive stock creates opportunities to free up storage capacity and recover working capital.

- Aligning MRO inventory metrics with maintenance KPIs such as MTTR, MTBF, and asset availability maximizes their impact on reliability and cost control.

- Standardization, automation, and cross-functional ownership are essential to keeping MRO metrics accurate, consistent, and actionable.

- Tracking too many metrics without clear objectives, ignoring spare parts criticality, or failing to act on insights can significantly reduce the value of MRO performance measurement.

- Deskera Manufacturing ERP enables real-time visibility, automated tracking, and seamless integration across inventory, maintenance, and procurement—turning MRO metrics into measurable business outcomes.

Related Articles