Are your maintenance metrics helping you prevent failures—or just reporting them after the damage is done? For many operations managers, maintenance KPIs still function as rearview mirrors rather than forward-looking tools. In 2025, that approach is no longer enough. With rising production pressures, tighter margins, and increasingly complex assets, maintenance performance must be measured in ways that actively support uptime, reliability, and cost control.

Maintenance KPIs have evolved from simple downtime trackers into strategic indicators of operational health. Metrics such as MTBF, MTTR, OEE, and planned maintenance ratios now play a direct role in shaping preventive and predictive maintenance strategies. When tracked correctly, these KPIs help operations managers identify failure patterns early, optimize maintenance schedules, and align maintenance efforts with broader business goals.

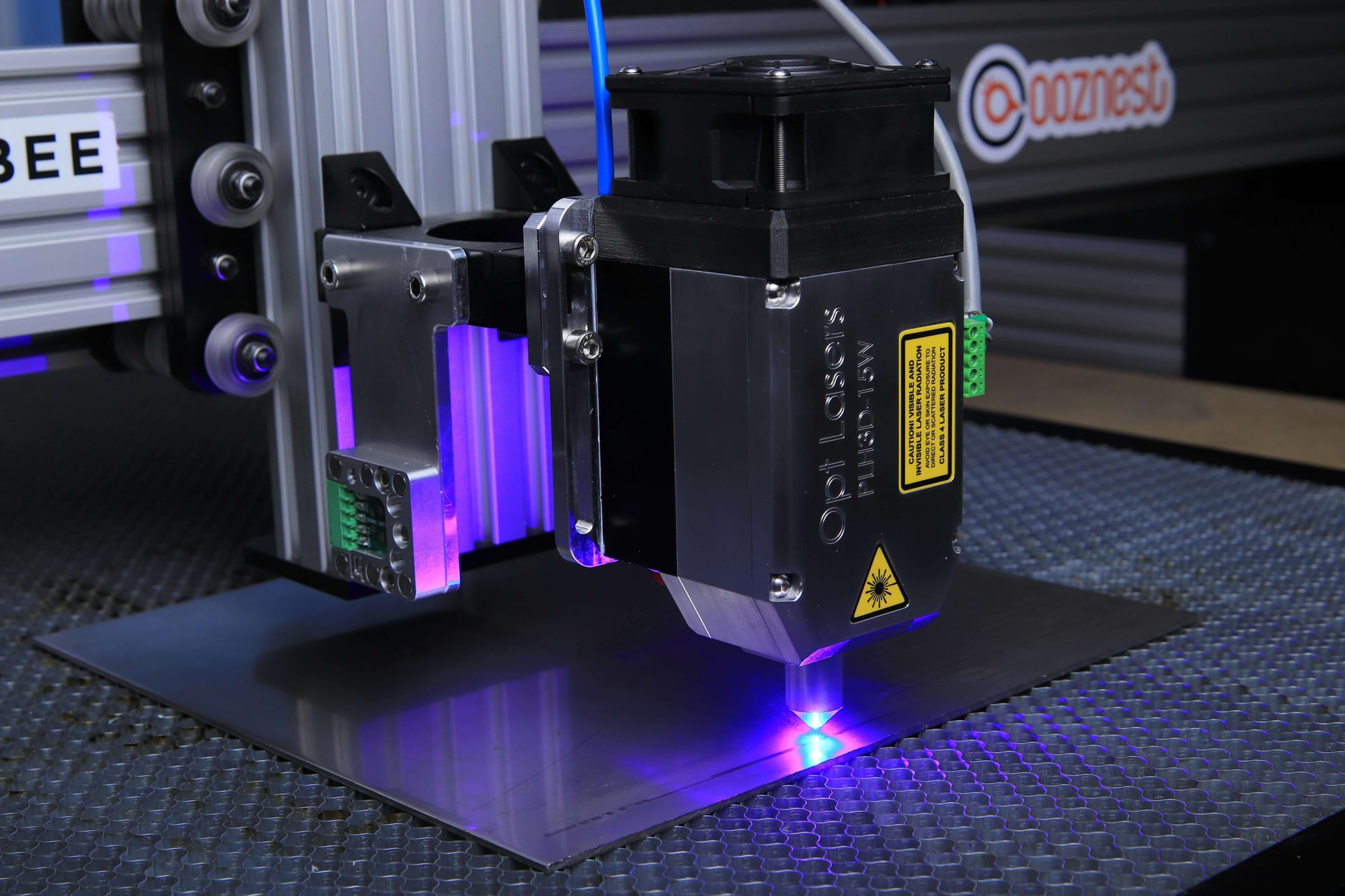

The urgency to track the right maintenance KPIs is greater than ever in 2025. Aging equipment, skilled labor shortages, and the growing adoption of automation and IoT have made maintenance both more data-rich and more complex. Operations managers must move beyond tracking “everything” and focus instead on KPIs that deliver clear, actionable insights—ones that reduce unplanned downtime, improve asset utilization, and support long-term operational resilience.

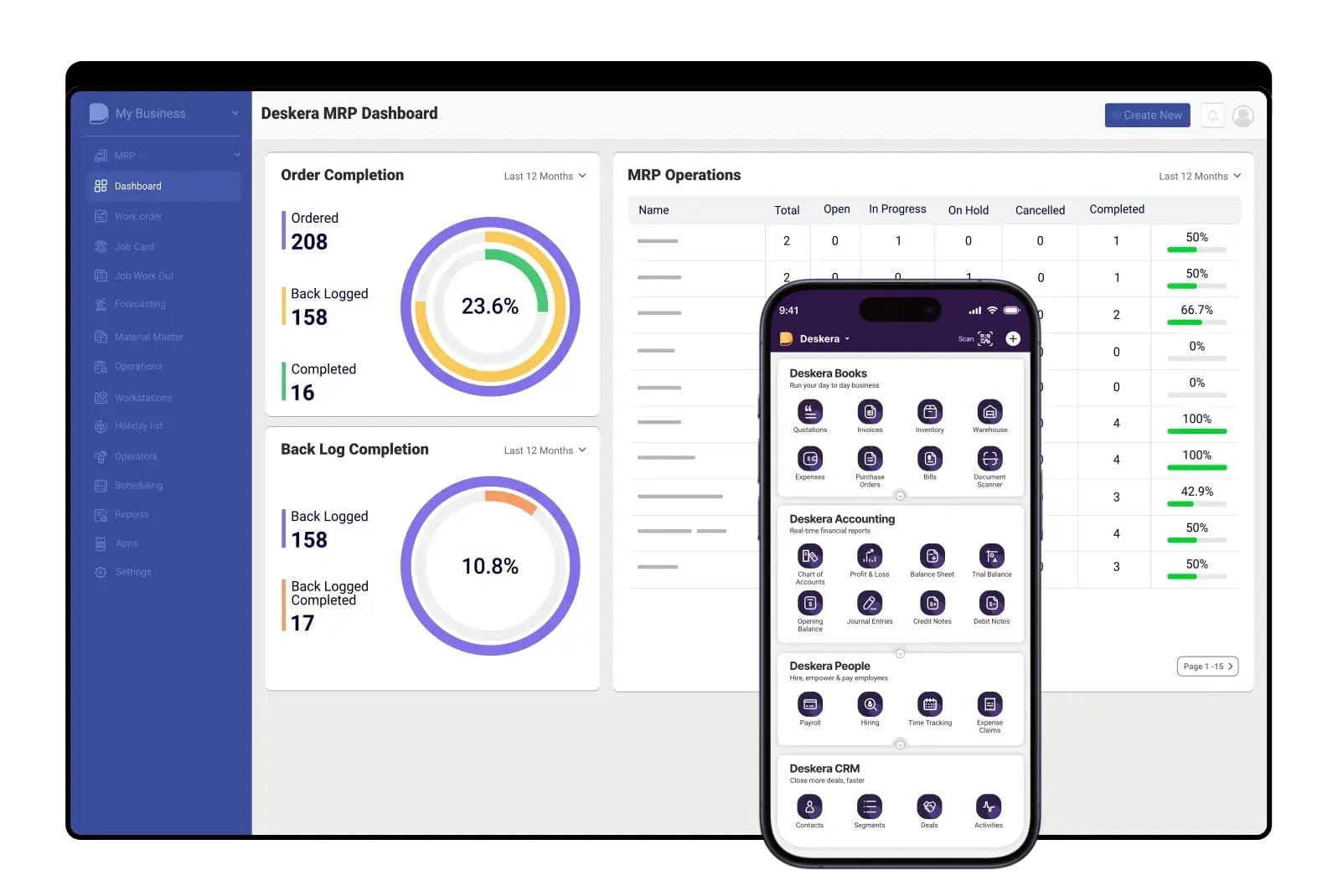

This is where Deskera Manufacturing ERP plays a critical role. Deskera provides centralized visibility into maintenance activities, asset performance, work orders, and inventory—all in real time. With integrated maintenance tracking, automated reporting, and data-driven dashboards, Deskera helps operations managers monitor key maintenance KPIs accurately and act on them faster. By connecting maintenance data with production and financial insights, Deskera enables smarter, more proactive maintenance decisions in 2025 and beyond.

Maintenance Metrics vs Maintenance KPIs

Although maintenance metrics and maintenance KPIs are often used interchangeably, they play different roles in maintenance performance management. Metrics capture what is happening on the ground, while KPIs translate that data into goal-driven insights. Understanding how they work together helps operations managers shift from activity tracking to continuous improvement.

What Are Maintenance Metrics?

Maintenance metrics are quantitative data points that measure day-to-day maintenance activities and outcomes. They focus on actual performance and operational results.

Key characteristics of maintenance metrics:

- Measure what has already happened

- Track operational and technical performance

- Used for monitoring trends and identifying issues

Common examples of maintenance metrics include:

- Equipment uptime and downtime

- Mean Time Between Failures (MTBF)

- Mean Time to Repair (MTTR)

- Number of preventive maintenance tasks completed

- Maintenance labor hours

Metrics primarily answer the question: “What happened?”

What Are Maintenance KPIs?

Maintenance KPIs (Key Performance Indicators) are target-based benchmarks built using maintenance metrics. They define what success looks like and measure progress toward maintenance and business goals.

Key characteristics of maintenance KPIs:

- Combine a metric with a defined target

- Aligned with organizational and maintenance objectives

- Designed to drive improvement and accountability

Example:

- Metric: Asset uptime

- KPI: Increase asset uptime by 15% within the next 12 months

KPIs answer the question: “Are we meeting our maintenance goals?”

Metrics vs KPIs: How They Differ in Practice

The core difference lies in measurement versus intent.

- Metrics report actual performance

- Example: 8 preventive maintenance tasks completed today

- KPIs define expected performance

- Example: Target of 10 preventive maintenance tasks per day

In simple terms:

- Metrics show what is happening

- KPIs show what should be happening

Leading vs Lagging Indicators in Maintenance

Maintenance KPIs and metrics can be classified as leading or lagging indicators, and effective maintenance management uses both.

Lagging indicators (results-focused):

- MTBF

- MTTR

- Total downtime

- Maintenance cost per asset

Leading indicators (predictive and preventive):

- Preventive maintenance compliance

- Schedule adherence

- Planned maintenance percentage

- Estimate vs. actual work performance

Leading indicators help prevent failures, while lagging indicators measure the impact of past events.

Why Both Metrics and KPIs Matter

Using metrics without KPIs leads to data overload without direction, while KPIs without reliable metrics lack accuracy.

Together, they help organizations:

- Reduce downtime and equipment failures

- Improve work planning and scheduling

- Control maintenance costs

- Align maintenance activities with business goals

- Build a data-driven maintenance culture

When tracked through a CMMS or ERP system, maintenance metrics and KPIs are transformed into actionable dashboards and insights, enabling smarter decisions and continuous improvement.

Why Do Maintenance KPIs Matter in 2026?

In 2026, maintenance is no longer a support function—it is a strategic driver of operational resilience, cost efficiency, and business continuity. With increasing asset complexity, tighter margins, and higher customer expectations, maintenance KPIs provide the visibility and control operations managers need to stay competitive. The right KPIs turn maintenance data into actionable insights that support proactive decision-making and long-term performance.

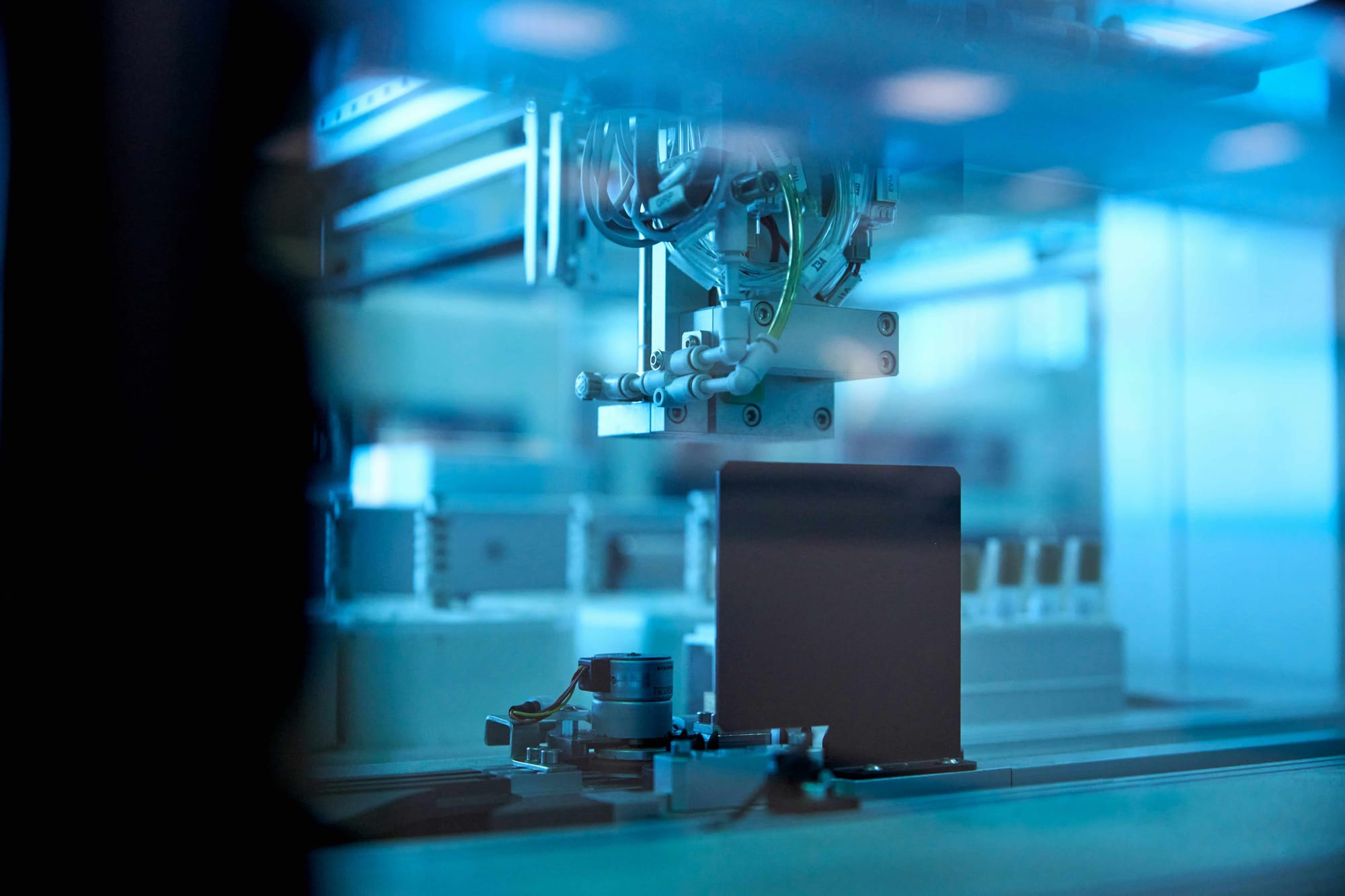

Rising Equipment Complexity and Automation

Modern production environments rely heavily on automated, interconnected, and sensor-driven equipment. As machines become more complex, failures are harder to predict and more expensive to fix.

Maintenance KPIs help by:

- Identifying early signs of asset degradation

- Measuring the effectiveness of preventive and predictive maintenance

- Ensuring critical assets receive the right level of attention

Higher Cost Pressures and Margin Sensitivity

Inflation, supply chain volatility, and rising labor costs have made unplanned downtime significantly more expensive in 2026.

Maintenance KPIs enable organizations to:

- Track and control maintenance spending

- Reduce emergency repairs and overtime costs

- Optimize maintenance budgets based on asset criticality

Shift From Reactive to Predictive Maintenance

Reactive maintenance is no longer sustainable in asset-intensive industries. Organizations are increasingly moving toward predictive and condition-based maintenance models.

KPIs support this shift by:

- Measuring preventive maintenance compliance

- Tracking failure trends and recurring issues

- Validating whether predictive strategies are actually reducing breakdowns

Workforce Challenges and Skill Gaps

The ongoing shortage of skilled maintenance technicians has made efficiency and productivity more important than ever.

Maintenance KPIs help operations managers:

- Monitor workforce utilization and response times

- Improve work planning and scheduling

- Ensure limited resources are used where they create the most value

Greater Focus on Reliability, Safety, and Compliance

Regulatory requirements and safety standards continue to tighten across industries in 2026.

Maintenance KPIs allow organizations to:

- Track compliance-related maintenance activities

- Reduce safety incidents caused by equipment failure

- Demonstrate audit readiness with measurable performance data

Data-Driven Decision-Making and Digital Transformation

With ERP, CMMS, IoT, and AI systems generating massive volumes of data, organizations need structured ways to interpret performance.

Maintenance KPIs matter because they:

- Convert raw maintenance data into meaningful insights

- Enable real-time visibility through dashboards and reports

- Align maintenance performance with broader operational and business goals

In 2026, maintenance KPIs are not just about tracking performance—they are essential tools for improving reliability, controlling costs, and building a future-ready maintenance strategy.

Categories of Maintenance KPIs Operations Managers Should Track

Maintenance KPIs can be grouped into clear categories to help operations managers monitor performance without being overwhelmed by data. Each category focuses on a specific aspect of maintenance effectiveness, ensuring a balanced view of reliability, efficiency, cost control, and compliance.

Reliability and Asset Performance KPIs

These KPIs measure how consistently equipment performs and how often failures occur. They are critical for improving uptime and extending asset life.

Key KPIs include:

- Mean Time Between Failures (MTBF)

- Overall Equipment Effectiveness (OEE)

- Equipment availability

- Failure rate

Maintenance Efficiency and Productivity KPIs

Efficiency KPIs evaluate how well maintenance teams use time, labor, and resources to complete work.

Key KPIs include:

- Mean Time to Repair (MTTR)

- Schedule compliance

- Planned maintenance percentage (PMP)

- Work order completion rate

Downtime and Responsiveness KPIs

These KPIs focus on how quickly issues are identified and resolved, and how much production time is lost due to maintenance events.

Key KPIs include:

- Equipment downtime percentage

- Emergency maintenance rate

- Maintenance response time

- Backlog of corrective work

Cost and Financial Performance KPIs

Cost-related KPIs help operations managers control maintenance spending and evaluate return on assets.

Key KPIs include:

- Maintenance cost as a percentage of asset value (RAV)

- Maintenance cost per unit produced

- Labor vs. material cost ratio

- Overtime maintenance costs

Preventive and Predictive Maintenance KPIs

These KPIs measure how effectively preventive and predictive strategies are being executed.

Key KPIs include:

- Preventive maintenance (PM) compliance

- Ratio of planned vs. unplanned maintenance

- Predictive maintenance success rate

- Repeat failure rate

Inventory and Spare Parts Management KPIs

Inventory KPIs ensure spare parts availability while minimizing excess stock and carrying costs.

Key KPIs include:

- Spare parts inventory turnover

- Stockout rate

- Inventory carrying cost

- Critical spares availability

Safety, Compliance, and Quality KPIs

These KPIs track how maintenance activities support workplace safety, regulatory compliance, and quality standards.

Key KPIs include:

- Maintenance-related safety incidents

- Compliance audit pass rate

- Maintenance rework rate

- Equipment-related quality defects

By tracking KPIs across these categories, operations managers gain a comprehensive view of maintenance performance—helping them balance reliability, efficiency, cost control, and risk management in 2026 and beyond.

Top Maintenance KPIs Every Operations Manager Should Track in 2026

In 2026, maintenance success depends on visibility, predictability, and execution discipline. Operations managers must track a complete set of maintenance KPIs, not just a few popular metrics, to balance reliability, cost control, workforce efficiency, and compliance. The KPIs below cover all critical maintenance dimensions required for modern, asset-intensive operations.

Mean Time Between Failures (MTBF)

Category: Reliability & Asset Performance

Measures the average time equipment operates before failing.

Why it matters in 2026:

- Indicates asset reliability and maintenance effectiveness

- Helps prioritize preventive and predictive maintenance

Formula:

MTBF = Total Operating Time ÷ Number of Failures

Mean Time to Repair (MTTR)

Category: Maintenance Efficiency

Measures how quickly equipment is restored after failure.

Why it matters in 2026:

- Faster repairs reduce downtime losses

- Highlights technician efficiency and spare-part readiness

Formula:

MTTR = Total Repair Time ÷ Number of Repairs

Overall Equipment Effectiveness (OEE)

Category: Asset Performance

Combines availability, performance, and quality into one KPI.

Why it matters in 2026:

- Connects maintenance performance directly to production output

- Identifies losses caused by breakdowns, slow cycles, and defects

Formula:

OEE = Availability × Performance × Quality

Equipment Availability

Category: Reliability

Measures the percentage of time equipment is available for operation.

Why it matters in 2026:

- Reflects maintenance responsiveness and planning quality

- Directly impacts production capacity

Equipment Downtime Percentage

Category: Downtime & Responsiveness

Tracks the proportion of time assets are unavailable.

Why it matters in 2026:

- Downtime remains one of the highest operational cost drivers

- Helps distinguish planned vs. unplanned maintenance impact

Formula:

Downtime % = (Downtime Hours ÷ Total Operating Hours) × 100

Unscheduled (Unplanned) Downtime

Category: Downtime Control

Measures downtime caused by unexpected failures.

Why it matters in 2026:

- Indicates maturity of preventive and predictive maintenance

- High values signal reactive maintenance dependency

Preventive Maintenance (PM) Compliance

Category: Preventive Maintenance

Measures how many scheduled PM tasks are completed on time.

Why it matters in 2026:

- Strong PM compliance reduces failures and emergency work

- Indicates planning discipline

Benchmark:

- 90%+ compliance

Planned Maintenance Percentage (PMP)

Category: Maintenance Planning

Shows how much work is planned versus reactive.

Why it matters in 2026:

- Higher PMP means fewer firefighting activities

- Reflects maintenance maturity

Formula:

PMP = (Planned Maintenance Hours ÷ Total Maintenance Hours) × 100

Reactive Maintenance Percentage

Category: Maintenance Strategy

Tracks the share of unplanned maintenance work.

Why it matters in 2026:

- High reactive maintenance increases cost and risk

- Indicates poor preventive execution

Schedule Compliance

Category: Execution & Control

Measures how often scheduled work is completed as planned.

Why it matters in 2026:

- Reflects coordination between maintenance and operations

- Improves resource utilization

Work Order Completion Rate

Category: Task Management

Measures the percentage of work orders completed within a period.

Why it matters in 2026:

- Shows workload balance and execution efficiency

- Highlights bottlenecks in approval or execution

Maintenance Backlog

Category: Resource Planning

Tracks pending maintenance work relative to available labor.

Why it matters in 2026:

- Excess backlog signals understaffing or rising failures

- Too little backlog may indicate poor work identification

Measured as:

- Weeks of work or total labor hours

Maintenance Technician Productivity

Category: Workforce Efficiency

Measures productive time versus total available time.

Why it matters in 2026:

- Skilled labor shortages make productivity critical

- Identifies delays caused by planning or inventory issues

Maintenance Cost per Unit Produced

Category: Cost Control

Tracks maintenance cost relative to output.

Why it matters in 2026:

- Links maintenance spending directly to production efficiency

- Enables cross-plant and asset comparisons

Maintenance Cost as a Percentage of Replacement Asset Value (RAV)

Category: Financial Performance

Measures maintenance spending relative to asset value.

Why it matters in 2026:

- Prevents overspending on aging assets

- Supports repair vs. replace decisions

Maintenance Cost Relative to Estimated Replacement Value (MC/ERV)

Category: Asset Lifecycle Management

Compares maintenance cost to replacement cost.

Why it matters in 2026:

- Identifies assets nearing economic end-of-life

- Supports capital planning

Spare Parts Inventory Turnover

Category: Inventory Management

Measures how efficiently spare parts are used.

Why it matters in 2026:

- Balances availability with carrying costs

- Prevents excess or obsolete inventory

Spare Parts Stockout Rate

Category: Inventory Risk

Tracks how often required parts are unavailable.

Why it matters in 2026:

- Stockouts increase MTTR and downtime

- Indicates poor inventory planning

First Pass Yield (FPY)

Category: Quality & Effectiveness

Measures how often work is completed correctly the first time.

Why it matters in 2026:

- Reduces rework and repeat failures

- Reflects maintenance quality

Maintenance-Related Safety Incidents

Category: Safety & Compliance

Tracks incidents caused by equipment or maintenance failures.

Why it matters in 2026:

- Safety compliance is non-negotiable

- Equipment reliability directly impacts workplace safety

Compliance Audit Pass Rate

Category: Regulatory Compliance

Measures adherence to maintenance and safety standards.

Why it matters in 2026:

- Ensures audit readiness

- Reduces legal and operational risk

Failure Rate

Category: Reliability & Asset Performance

Measures how frequently an asset fails within a given period.

Why it matters in 2026:

- Helps identify unreliable equipment

- Supports root cause analysis and asset prioritization

Formula:

Failure Rate = Number of Failures ÷ Total Operating Time

Emergency Maintenance Rate

Category: Downtime & Responsiveness

Tracks the percentage of maintenance work that is unplanned and urgent.

Why it matters in 2026:

- High rates indicate reactive maintenance dependency

- Emergency work is more costly and disruptive

Formula:

Emergency Maintenance Rate = (Emergency Work Orders ÷ Total Work Orders) × 100

Maintenance Response Time

Category: Downtime & Responsiveness

Measures the time taken to respond after a failure or maintenance request is reported.

Why it matters in 2026:

- Faster response reduces downtime impact

- Reflects coordination between operations and maintenance

Formula:

Response Time = Time of First Action − Time of Failure Report

Labor vs. Material Cost Ratio

Category: Cost & Financial Performance

Compares labor costs to spare parts and material costs.

Why it matters in 2026:

- Highlights inefficiencies in workforce utilization or inventory usage

- Helps optimize maintenance budgets

Formula:

Labor vs. Material Ratio = Labor Costs ÷ Material Costs

Overtime Maintenance Costs

Category: Cost Control

Tracks the portion of maintenance labor cost spent on overtime.

Why it matters in 2026:

- Excessive overtime signals poor planning or staffing gaps

- Directly increases maintenance expenses

Formula:

Overtime Cost % = (Overtime Maintenance Cost ÷ Total Maintenance Labor Cost) × 100

Predictive Maintenance Success Rate

Category: Predictive Maintenance

Measures how effectively predictive maintenance prevents failures.

Why it matters in 2026:

- Validates ROI of condition monitoring and IoT investments

- Ensures predictive alerts lead to action

Formula:

PdM Success Rate = (Failures Prevented ÷ Total PdM Alerts) × 100

Repeat Failure Rate

Category: Reliability Improvement

Tracks how often the same asset fails repeatedly after repair.

Why it matters in 2026:

- Indicates poor root cause analysis or low repair quality

- Drives continuous improvement initiatives

Formula:

Repeat Failure Rate = (Repeat Failures ÷ Total Failures) × 100

Inventory Carrying Cost

Category: Inventory Management

Measures the cost of holding spare parts inventory over time.

Why it matters in 2026:

- Excess inventory ties up capital

- Helps balance availability with cost efficiency

Formula:

Inventory Carrying Cost = Storage + Insurance + Obsolescence + Capital Costs

Critical Spares Availability

Category: Inventory Risk Management

Tracks the availability of high-risk, high-impact spare parts.

Why it matters in 2026:

- Prevents extended downtime due to missing critical components

- Supports risk-based inventory planning

Formula:

Critical Spares Availability = (Available Critical Spares ÷ Total Required Critical Spares) × 100

Maintenance Rework Rate

Category: Quality & Effectiveness

Measures how often maintenance tasks must be redone due to improper execution.

Why it matters in 2026:

- High rework increases downtime and cost

- Reflects skill gaps or procedural issues

Formula:

Rework Rate = (Rework Work Orders ÷ Total Work Orders) × 100

Equipment-Related Quality Defects

Category: Quality & Production Impact

Tracks production defects caused by equipment or maintenance issues.

Why it matters in 2026:

- Connects maintenance performance directly to product quality

- Helps justify maintenance investment

Formula:

Equipment-Related Defects = Defective Units Attributed to Equipment Issues

In 2026, operations managers must track a complete ecosystem of maintenance KPIs, not isolated metrics. When reliability, efficiency, cost, inventory, workforce, and safety KPIs are viewed together, maintenance shifts from a reactive cost center to a strategic driver of operational resilience and profitability.

Benefits of Tracking Maintenance KPIs

Tracking maintenance KPIs goes far beyond monitoring numbers—it enables organizations to make smarter decisions, improve asset reliability, and drive measurable operational and financial gains.

When maintenance performance is consistently measured and analyzed, maintenance shifts from a reactive cost center to a strategic business function.

Improved Decision-Making

Maintenance KPIs provide accurate, real-time visibility into maintenance performance, enabling data-driven decisions instead of assumptions.

Key benefits include:

- Clear insights into what is working and what needs improvement

- Better prioritization of critical maintenance tasks

- More effective allocation of labor, tools, and spare parts

By relying on KPI-driven insights, operations managers can address issues proactively and focus resources where they create the most impact.

Reduced Downtime and Improved Equipment Availability

KPIs such as MTTR, PM compliance, and downtime percentage highlight opportunities to minimize equipment outages.

How KPIs help:

- Identify bottlenecks that increase repair time

- Strengthen preventive maintenance programs

- Reduce unexpected breakdowns and emergency repairs

Lower downtime directly improves production continuity and customer commitments.

Increased Equipment Reliability and Asset Lifespan

Maintenance KPIs reveal trends and patterns that affect long-term asset performance.

Reliability-focused benefits include:

- Early detection of recurring failures

- Improved root cause analysis

- Extended equipment lifespan through proactive maintenance

Reliable assets reduce capital expenditure pressure and improve return on asset investments.

Improved Operational Efficiency

By tracking KPIs like OEE, schedule compliance, and technician productivity, organizations can uncover inefficiencies in maintenance execution.

Efficiency gains include:

- Optimized maintenance schedules

- Better utilization of maintenance teams

- Reduced idle time and rework

This leads to smoother operations and higher overall productivity.

Cost Control and Maintenance Cost Reduction

Maintenance KPIs provide visibility into where money is being spent—and where it’s being wasted.

Cost-related advantages include:

- Lower overtime and emergency maintenance costs

- Reduced material waste and excess inventory

- Better control over maintenance budgets

Tracking cost KPIs helps organizations balance reliability with financial discipline.

Identification of Continuous Improvement Opportunities

KPIs make performance gaps visible and measurable.

Continuous improvement benefits include:

- Clear benchmarks for success

- Data-backed improvement initiatives

- Measurable progress over time

This creates a culture of accountability and ongoing optimization.

Better Resource Planning and Utilization

Maintenance KPIs help align workforce capacity, spare parts, and schedules with actual operational needs.

Planning benefits include:

- Improved workload balancing

- Reduced maintenance backlogs

- Higher technician productivity

Efficient resource planning ensures maintenance teams are neither overburdened nor underutilized.

Stronger Alignment Between Maintenance and Business Goals

When maintenance KPIs are linked to production, cost, and quality outcomes, maintenance efforts support broader organizational objectives.

Business-level benefits include:

- Improved profitability through reduced downtime

- Higher customer satisfaction from reliable operations

- Stronger justification for maintenance investments

In 2026, tracking maintenance KPIs is essential for organizations that want to remain competitive, resilient, and efficient. By focusing on the right KPIs, operations managers gain the clarity needed to reduce downtime, optimize costs, and build a proactive, data-driven maintenance strategy.

How to Choose the Right Maintenance KPIs

Choosing the right maintenance KPIs is not about tracking everything—it’s about tracking what truly drives performance, reliability, and cost control. With operations becoming more data-driven in 2026, operations managers must be deliberate in selecting KPIs that align with business goals, asset criticality, and long-term improvement initiatives.

Before diving into tracking methods, it’s essential to first get KPI selection right.

Align KPIs With Business and Operational Goals

Every maintenance KPI should tie directly to a broader business objective. If the organization’s priority is cost optimization, KPIs like Maintenance Cost as a Percentage of Asset Value (MCAV) or Planned vs. Unplanned Maintenance Ratio become critical. If uptime and customer commitments are the focus, KPIs such as Equipment Availability, MTBF, and Downtime Percentage take precedence.

Consider Asset Criticality and Risk

Not all assets deserve the same level of KPI tracking. High-risk or production-critical equipment should have more detailed KPIs tied to reliability, failure frequency, and response times. For example:

- Critical assets may require MTBF, MTTR, and Preventive Maintenance Compliance

- Non-critical assets may only need basic uptime or cost tracking

This approach prevents KPI overload while ensuring the most impactful assets receive focused attention.

Balance Leading and Lagging Indicators

A strong KPI framework includes both predictive and outcome-based indicators.

- Leading indicators (such as Preventive Maintenance Compliance or Schedule Compliance) help predict future performance.

- Lagging indicators (such as MTTR, MTBF, and Downtime) show the results of past actions.

Relying solely on lagging KPIs limits proactive decision-making.

Ensure KPIs Are Actionable and Measurable

A KPI is only valuable if it drives action. Ask:

- Can this KPI influence decision-making?

- Is it measurable with available ERP data?

- Can teams realistically improve it?

For example, tracking “number of breakdowns” without context offers limited insight. In contrast, tracking Breakdown Frequency alongside Root Cause Analysis Completion Rate provides clarity and direction.

Avoid vague KPIs that lack ownership or clear improvement paths.

Limit the Number of KPIs Tracked

More KPIs do not equal better performance. Tracking too many dilutes focus and reduces accountability. Most operations teams perform best with:

- 5–7 core KPIs at the leadership level

- Supporting KPIs at the team or asset level

This focused approach ensures KPIs remain visible, relevant, and consistently reviewed.

Validate KPI Feasibility Using ERP Data

Before finalizing KPIs, confirm that your ERP system can reliably capture the required data. Maintenance KPIs should be based on automated, real-time inputs such as work orders, asset histories, labor hours, and spare parts usage. This avoids manual reporting gaps and ensures KPI accuracy.

Review KPIs as the Business Evolves

The right KPIs today may not remain relevant tomorrow. As operations scale, assets age, or maintenance strategies shift from reactive to predictive, KPIs should be reassessed. However, frequent changes should be avoided—KPIs should evolve gradually, not reset entirely.

Once the right maintenance KPIs are selected, the real impact comes from how consistently and effectively they are tracked, analyzed, and acted upon—this is where best practices make the difference.

Best Practices for Tracking Maintenance KPIs

Tracking maintenance KPIs effectively requires more than selecting the right metrics—it demands a structured, disciplined, and data-driven approach. When done correctly, maintenance KPI tracking helps organizations improve reliability, reduce downtime, control costs, and align maintenance efforts with broader business goals.

The following best practices will help operations managers get the most value from maintenance KPIs in 2026.

Define Clear Objectives and Areas of Focus

Start by identifying what you want to achieve through maintenance KPI tracking. Trying to track everything at once often leads to poor data quality and unclear insights.

Best practices include:

- Define priority focus areas for a specific time period (e.g., downtime reduction or PM compliance)

- Align KPIs with operational and business objectives

- Avoid frequent, major changes to KPI goals

A focused approach ensures consistency and meaningful performance comparisons.

Set Specific, Measurable, and Realistic Targets

KPIs should always include clear benchmarks and timelines rather than vague improvement goals.

Best practices include:

- Replace general goals with measurable targets

- Set ambitious but achievable benchmarks

- Include clear timelines for evaluation

Example: Instead of “Improve work order completion rate,” set “Increase work order completion rate from 70% to 90% by year-end.”

Establish Baselines Before Measuring Progress

Before tracking improvement, establish baseline performance levels to understand where you currently stand.

Best practices include:

- Capture historical maintenance data

- Use baseline metrics as a reference point

- Compare progress consistently over time

Baselines provide context and prevent misinterpretation of KPI results.

Use ERP Systems to Automate Data Collection

Manual data collection increases errors and delays insight generation. A modern ERP system centralizes maintenance, asset, inventory, and labor data.

Best practices include:

- Use ERP dashboards for real-time KPI tracking

- Automate work order, asset, and inventory data capture

- Ensure data accuracy and consistency across departments

ERP-driven tracking improves visibility and reduces reporting effort.

Track Progress Continuously—Not Just at Period-End

Waiting until the end of a quarter or year to review KPIs limits their usefulness.

Best practices include:

- Monitor KPIs regularly through ERP dashboards

- Identify issues early and course-correct quickly

- Use leading indicators to predict future performance

Continuous tracking enables proactive maintenance management.

Analyze and Contextualize KPI Results

KPIs don’t tell the full story on their own—context matters.

Best practices include:

- Analyze trends, not just single data points

- Identify external factors influencing performance

- Review supporting metrics that may explain results

For example, rising downtime may be linked to aging equipment rather than poor technician performance.

Turn Insights into Action

The true value of maintenance KPIs lies in using them to drive improvement.

Best practices include:

- Convert KPI insights into corrective actions

- Adjust maintenance strategies, schedules, or training

- Use KPI data to justify investments in tools, technology, or headcount

KPIs should always lead to measurable operational change.

Communicate KPI Performance Across Teams

Maintenance KPI tracking should be transparent and collaborative.

Best practices include:

- Share KPI results regularly with maintenance and operations teams

- Encourage accountability and cross-team problem-solving

- Align stakeholders around shared performance goals

Clear communication ensures everyone works toward the same outcomes.

Adopt a Continuous Improvement Mindset

KPIs should evolve gradually as business conditions, assets, and strategies change.

Best practices include:

- Review KPIs periodically without frequent overhauls

- Make incremental adjustments to targets and benchmarks

- Use KPI trends to guide long-term maintenance strategy

A continuous improvement mindset ensures KPI tracking remains relevant and effective.

In 2026, successful maintenance KPI tracking depends on focus, clarity, automation, and action. By following these best practices and leveraging ERP systems for real-time visibility, organizations can transform maintenance KPIs into powerful tools for reliability, efficiency, and sustained operational excellence.

How Deskera Manufacturing ERP Can Help You with Maintenance KPIs

Tracking and analyzing maintenance KPIs is only effective if you have accurate, real-time data. Deskera Manufacturing ERP provides a centralized platform that streamlines maintenance management, making it easier to set, monitor, and act on KPIs.

Centralized Maintenance Data

Deskera ERP consolidates all maintenance records, work orders, and asset histories in one place. This centralized system ensures that KPIs—such as MTTR, MTBF, and Preventive Maintenance Compliance—are based on reliable, up-to-date data, eliminating the errors that often arise from manual tracking.

Automated KPI Tracking and Reports

The ERP automatically calculates key maintenance metrics and generates dashboards and reports. You can track equipment uptime, downtime, and maintenance costs in real time, making it easier to spot trends and identify areas for improvement without sifting through spreadsheets.

Preventive Maintenance Scheduling

Deskera ERP helps schedule preventive maintenance based on asset criticality and historical performance. By linking maintenance schedules to KPIs like Schedule Compliance and Preventive Maintenance Completion Rate, organizations can reduce unplanned downtime and improve equipment reliability.

Resource Optimization

ERP systems provide insights into labor, spare parts usage, and maintenance costs. This allows teams to optimize resource allocation and reduce waste, helping improve KPIs such as Maintenance Cost per Asset and Work Order Efficiency.

Trend Analysis and Continuous Improvement

With historical data stored in Deskera ERP, organizations can analyze trends, forecast equipment failures, and proactively adjust maintenance strategies. This continuous improvement loop ensures KPIs evolve with business needs and operations scale efficiently.

Deskera Manufacturing ERP turns maintenance KPI tracking from a manual, reactive process into a data-driven, proactive system, helping operations teams make smarter decisions, extend equipment life, and improve overall operational efficiency.

Key Takeaways

- Maintenance KPIs are quantifiable metrics that track maintenance performance and asset health, enabling organizations to monitor, evaluate, and optimize maintenance operations.

- KPIs focus on critical performance outcomes aligned with business goals, while maintenance metrics track specific operational data; understanding the difference helps prioritize what truly drives improvement.

- Organizing KPIs into categories such as equipment reliability, maintenance efficiency, cost control, and safety ensures a structured approach and makes performance measurement more actionable.

- Tracking key KPIs like MTTR, MTBF, OEE, and work order completion rate helps organizations improve equipment reliability, reduce downtime, and optimize maintenance operations.

- Measuring KPIs enables informed decision-making, increased equipment uptime, operational efficiency, cost savings, and supports a proactive maintenance culture.

- Select KPIs that are measurable, actionable, aligned with organizational objectives, and provide insights to optimize resources and performance.

- Follow a structured approach: set clear goals, track relevant metrics, analyze results, communicate with teams, and continuously refine KPIs for sustained improvement.

- Deskera ERP centralizes maintenance data, automates KPI tracking, supports preventive maintenance, optimizes resource allocation, and provides insights for data-driven decisions, making KPI management efficient and scalable.

Related Articles