A key element that plays a vital role in optimizing operations within a factory is the implementation of effective job card processes. A job card serves as a comprehensive guide, capturing essential information about each task, enabling efficient resource allocation, tracking progress, and ensuring quality control.

The significance of this seemingly simple document cannot be overstated. Did you know that a study conducted by the Manufacturing Advisory Service revealed that 57% of factory downtime is caused by poor job scheduling and inadequate information flow?

Furthermore, according to a survey by the Aberdeen Group, companies that implement standardized job card processes experience a 26% reduction in production cycle times.

These statistics highlight the critical impact that well-executed job card procedures can have on a factory's productivity and profitability. In this article, we will explore the key steps to implementing effective job card processes and unleash their potential to revolutionize your factory's operations.

- Definition of a Job Card

- Importance of Effective Job Card Processes in a Factory

- Understanding the Purpose of Job Cards

- Designing an Effective Job Card Template

- Standardizing Job Card Procedures

- Training Employees on Job Card Usage

- Integrating Job Cards into Workflow Management Systems

- Monitoring and Evaluating Job Card Effectiveness

- Overcoming Challenges and Pitfalls

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Definition of a Job Card

A job card, also known as a work order or job ticket, is a document used in manufacturing or service industries to track and manage specific tasks or jobs within a factory. It serves as a detailed reference that contains essential information about a particular job, including the scope of work, instructions, materials required, deadlines, and any other relevant details.

The job card acts as a communication tool between different departments or individuals involved in the job, providing clear instructions and guidelines to ensure efficient execution. It serves as a reference point for workers, supervisors, and managers to monitor progress, allocate resources, and maintain quality control throughout the job's lifecycle.

The content and format of a job card may vary depending on the industry and specific requirements. However, its primary purpose is to document and standardize the necessary information for each job, enabling effective coordination, tracking, and completion of tasks within a factory environment.

Importance of Effective Job Card Processes in a Factory

Effective job card processes play a crucial role in enhancing efficiency, productivity, and overall operational success within a factory setting. Here are some key reasons highlighting their importance:

Clear Communication and Instructions: Job cards provide a standardized format for conveying clear instructions and information about each task. This ensures that workers have a clear understanding of their responsibilities, reducing errors and miscommunication.

Resource Allocation: Job cards outline the required materials, tools, and equipment for each job, enabling effective resource planning and allocation. This minimizes delays, prevents bottlenecks, and optimizes the utilization of resources.

Task Prioritization and Scheduling: Job cards allow managers to prioritize tasks based on their urgency, deadlines, and dependencies. This ensures that jobs are scheduled appropriately, preventing delays and improving overall workflow management.

Quality Control: Job cards can include quality control checkpoints, inspection criteria, and acceptance criteria for each task. This promotes adherence to quality standards, reduces defects, and enhances customer satisfaction and loyalty.

Performance Monitoring and Tracking: Job cards provide a means to monitor the progress of each job, allowing managers to track completion rates, identify bottlenecks, and make timely adjustments to meet targets and deadlines.

Documentation and Traceability: Job cards serve as a documented record of work performed, facilitating traceability, accountability, and reference for future audits or analysis.

Continuous Improvement: Analyzing job cards and their associated data can reveal insights into process inefficiencies, areas for improvement, and potential cost-saving opportunities. This enables continuous improvement efforts within the factory.

By implementing effective job card processes, factories can achieve smoother operations, reduced downtime, improved productivity, and enhanced overall performance. It allows for better coordination, resource management, and quality control, ultimately contributing to the factory's success in meeting customer demands and staying competitive in the market.

Understanding the Purpose of Job Cards

When it comes to optimizing operations in a factory, understanding the purpose of job cards is essential. Job cards serve as invaluable tools that encapsulate the core objectives of each task, ensuring streamlined processes, efficient resource allocation, and effective quality control. These comprehensive documents capture key information, ranging from task details to deadlines, providing a roadmap for successful completion.

By utilizing job cards, factories can foster clear communication, enhance productivity, and minimize errors and delays. The purpose of this section is to delve deeper into the significance of job cards, highlighting their objectives and the benefits they bring to a factory setting. By grasping the essence of job cards, factory managers and employees can harness their power to transform operations, improve coordination, and maximize overall efficiency.

A. Defining the objectives of job cards

The objectives of job cards revolve around achieving specific outcomes that contribute to the overall efficiency and effectiveness of a factory. By clearly defining these objectives, factories can ensure that job cards serve their intended purpose. The following are key objectives of job cards:

Clear Task Definition: Job cards aim to provide a concise and accurate description of each task or job to be performed in the factory. This includes outlining the scope of work, specific requirements, and any relevant instructions. Clarity in task definition ensures that workers have a clear understanding of their responsibilities, reducing ambiguity and minimizing errors.

Resource Allocation: An important objective of job cards is to facilitate efficient resource allocation. They specify the materials, tools, equipment, and manpower required for each task. By clearly identifying resource needs, job cards enable proper planning and allocation, preventing delays and ensuring optimal utilization of resources.

Time Management: Job cards help in managing time effectively by including deadlines, milestones, and estimated durations for each task. By setting clear time frames, job cards assist in scheduling and prioritizing tasks, enabling efficient workflow management and preventing delays.

Quality Control: Job cards incorporate quality control objectives by specifying quality standards, inspection criteria, and acceptance requirements for each task. This ensures that the work performed meets the desired quality standards, minimizing defects, rework, and customer dissatisfaction.

Task Sequencing and Dependencies: Job cards establish task sequencing and dependencies, ensuring that tasks are performed in the appropriate order. By clearly identifying task dependencies, job cards assist in streamlining workflow, preventing bottlenecks, and facilitating smooth progress across different stages of production.

Documentation and Record-Keeping: Job cards serve as essential documentation, capturing details of work performed, materials used, and any relevant notes or observations. This objective facilitates record-keeping, traceability, and reference for future analysis, audits, or process improvements.

By aligning job cards with these objectives, factories can enhance coordination, productivity, and quality control. Job cards become powerful tools that enable efficient task execution, resource management, and the achievement of overall operational goals.

B. Identifying the key information to include in a job card

Identifying the key information to include in a job card is crucial for ensuring that the document effectively serves its purpose. The following are essential pieces of information that should be included in a job card:

Job Title or Description: Clearly state the title or description of the job to provide a concise overview of the task at hand.

Task Details: Include a comprehensive description of the task, outlining its scope, objectives, and specific requirements. This ensures that workers have a clear understanding of what needs to be done.

Materials and Equipment: Specify the materials, tools, and equipment needed to complete the job. This helps in efficient resource allocation and ensures that the necessary resources are readily available.

Task Duration and Deadlines: Indicate the estimated duration for completing the task and any specific deadlines that need to be met. This assists in scheduling and prioritizing tasks, avoiding delays, and optimizing workflow management.

Task Sequence and Dependencies: If the job is part of a larger process or has dependencies on other tasks, clearly identify the task's position in the sequence and any dependencies it may have on preceding or concurrent tasks. This helps in coordinating workflow and preventing bottlenecks.

Work Instructions: Provide detailed step-by-step instructions on how to carry out the task. Include any specific procedures, safety guidelines, or quality control measures that need to be followed.

Personnel Assignments: Assign the responsible personnel or team for the job, ensuring that roles and responsibilities are clearly defined. This aids in accountability and ensures that the right individuals are assigned to the task.

Quality Control Checkpoints: Outline any specific quality control checkpoints, inspection criteria, or acceptance requirements that need to be met during the execution of the job. This ensures that the work is performed to the desired quality standards.

Reporting and Documentation: Specify any reporting requirements, such as progress updates, completion reports, or data collection. Also, provide space for workers to document any relevant observations, measurements, or notes.

Review and Approval: Include a section for review and approval signatures or initials from relevant stakeholders, such as supervisors or quality control personnel. This verifies that the job has been reviewed and approved before proceeding.

By including these key pieces of information in a job card, factories can ensure that workers have all the necessary details to perform their tasks accurately, efficiently, and in accordance with the factory's quality standards.

C. Benefits of using job cards in a factory setting

Using job cards in a factory setting offers numerous benefits that contribute to improved efficiency, productivity, and overall operational success. The following are key benefits of implementing job cards:

Enhanced Communication and Clarity: Job cards provide a standardized format for communicating task details, instructions, and requirements. This ensures clear and consistent communication between different departments and individuals involved in the job, minimizing confusion and errors.

Improved Workflow Management: Job cards facilitate efficient workflow management by outlining task sequences, dependencies, and deadlines. This enables better coordination, prioritization, and allocation of resources, resulting in smoother operations and reduced downtime.

Optimal Resource Allocation: Job cards specify the required materials, tools, equipment, and personnel for each task. By providing a clear overview of resource needs, job cards help in effective resource planning, minimizing waste, and maximizing resource utilization.

Increased Accountability and Traceability: Job cards serve as documented records of work performed, providing a trail of accountability. They enable tracking and tracing of tasks, allowing supervisors and managers to monitor progress, identify bottlenecks, and address any issues that may arise.

Standardization and Consistency: By using job cards, factories can establish standardized procedures and processes for each task. This ensures consistency in job execution, quality control, and adherence to industry or company standards.

Improved Quality Control: Job cards include quality control checkpoints, inspection criteria, and acceptance requirements. This ensures that tasks are performed to the desired quality standards, reducing defects, rework, and customer complaints.

Efficient Training and Onboarding: Job cards serve as valuable training tools for new employees. They provide a structured overview of tasks, requirements, and procedures, facilitating effective onboarding and ensuring consistent training across the workforce.

Data Collection and Analysis: Job cards capture important data related to task completion, resource usage, and quality control. This data can be analyzed to identify trends, areas for improvement, and opportunities for cost-saving or process optimization.

Continuous Improvement: Job cards allow for the documentation of observations, notes, and suggestions from workers. This feedback can be used to drive continuous improvement initiatives, making processes more efficient and effective over time.

Documentation for Audits and Compliance: Job cards provide documented evidence of work performed, aiding in audits, compliance checks, and regulatory requirements. They ensure that necessary information is readily available for inspections or internal/external audits.

By leveraging the benefits of job cards, factories can streamline operations, reduce errors, enhance productivity, and maintain consistent quality standards. Job cards become essential tools for effective task management, resource allocation, and continuous improvement within the factory environment.

Designing an Effective Job Card Template

Designing an effective job card template is a crucial step in optimizing task management and coordination within a factory. A well-designed template ensures that essential information is captured in a clear and organized manner, facilitating efficient workflow and minimizing errors.

By creating a template that aligns with the specific needs of the factory, managers and employees can streamline processes, enhance communication, and improve overall productivity.

In this section, we will delve into the key considerations for designing an effective job card template, including determining the required fields and sections, organizing information logically, and ensuring readability, comprehensiveness, and scalability. By understanding the importance of a well-crafted job card template, factories can establish a solid foundation for effective task management and set the stage for improved operational efficiency.

A. Determining the required fields and sections in a job card

Determining the required fields and sections in a job card is essential for capturing all the necessary information while ensuring clarity and ease of use. The following considerations can guide the selection and organization of the required fields and sections in a job card:

Job Identification: Include fields to capture the job title or description, a unique job ID or reference number, and the date when the job card was created.

Task Details: Allocate space for a comprehensive description of the task, including the scope of work, objectives, and any specific requirements.

Materials and Equipment: Designate sections to list the materials, tools, equipment, and quantities required for the job. This helps ensure that all necessary resources are readily available.

Task Duration and Deadlines: Include fields to specify the estimated duration for completing the task and any relevant deadlines or milestones to be met.

Work Instructions: Provide a clear and organized section for step-by-step work instructions, including procedures, safety guidelines, and quality control measures.

Personnel Assignments: Allocate space to assign responsible individuals or teams for the task, indicating their roles and responsibilities.

Task Sequence and Dependencies: If the job is part of a larger process or has dependencies on other tasks, include sections to outline the task's position in the sequence and any dependencies it may have.

Quality Control Checkpoints: Design fields to specify quality control checkpoints, inspection criteria, and acceptance requirements, ensuring adherence to quality standards.

Reporting and Documentation: Allocate space for workers to document progress updates, measurements, observations, and any other relevant notes throughout the task execution.

Review and Approval: Include sections for review and approval signatures or initials from supervisors or relevant stakeholders, indicating that the job has been reviewed and approved before proceeding.

It is important to strike a balance between providing sufficient fields and sections to capture essential information and avoiding overwhelming the job card with excessive detail. The template should be adaptable and flexible enough to accommodate various types of jobs and tasks within the factory's operations. By carefully determining the required fields and sections, factories can create a job card template that effectively captures all the essential information needed for successful task execution and management.

B. Organizing information in a clear and logical manner

Organizing information in a clear and logical manner within a job card is crucial for easy comprehension and efficient use. Here are some key guidelines to consider when organizing information in a job card:

Logical Flow: Arrange the sections and fields in a logical order that follows the natural sequence of the task. Start with job identification and task details, followed by materials and equipment, work instructions, personnel assignments, and so on. This ensures a smooth and intuitive flow of information.

Grouping Related Information: Group related information together to enhance readability and ease of reference. For example, place materials and equipment details in one section, work instructions in another, and quality control checkpoints in a separate section. This grouping helps users locate and understand information quickly.

Clear Headings and Labels: Use clear and descriptive headings or labels for each section or field to indicate what information should be provided. This helps users navigate the job card and locate specific details easily.

Consistent Formatting: Maintain consistency in formatting throughout the job card to create a professional and organized appearance. Use consistent font styles, sizes, and formatting for headings, subheadings, and content. Consistency in formatting aids in visual clarity and makes the information easier to comprehend.

Adequate White Space: Leave sufficient white space between sections and fields to prevent overcrowding and improve legibility. White space provides visual breathing room, making the job card appear less cluttered and facilitating focus on each section's content.

Highlighting Key Information: Use formatting techniques like bolding, underlining, or color coding to emphasize important information or instructions. This draws attention to critical details, making them stand out and reducing the chances of oversight.

Numbering or Bullet Points: When listing items or steps, use numbering or bullet points to make the information more organized and scannable. This format allows users to quickly identify individual items or steps within a larger set of information.

Consider User Experience: Consider the perspective of the users who will be filling out or referring to the job card. Ensure that the layout and organization make the information easily accessible and user-friendly, minimizing the time and effort required to navigate the document.

By organizing information in a clear and logical manner, factories can enhance the usability and effectiveness of their job cards. A well-structured job card facilitates quick understanding, improves task execution, and promotes efficient coordination among team members.

C. Considering factors such as readability, comprehensiveness, and scalability

When designing a job card, it is crucial to consider factors such as readability, comprehensiveness, and scalability. These factors ensure that the job card is user-friendly, contains all the necessary information, and can accommodate various types of tasks and future growth.

Here are key considerations for each factor:

Readability: a. Font and Font Size: Choose a legible font and an appropriate font size that is easy to read. b. Text Formatting: Use headings, subheadings, and bullet points to break up the content and improve readability. c. Clear and Concise Language: Use clear and concise language to convey instructions and information effectively. d. Adequate Whitespace: Leave enough whitespace between sections and fields to enhance readability and prevent visual clutter.

Comprehensiveness: a. Capture Essential Information: Ensure that the job card includes all necessary fields to capture important details about the task, materials, instructions, deadlines, and quality control requirements. b. Include Relevant Sections: Organize the job card into sections that cover different aspects of the task, such as task details, resource allocation, work instructions, and quality control. c. Eliminate Ambiguity: Use specific and unambiguous language to avoid confusion and misinterpretation of instructions or requirements.

Scalability:

a. Flexible Field Layout: Design the job card template in a way that allows for easy addition or modification of fields as needed for different types of tasks or changing requirements.

b. Expandable Sections: Consider using expandable sections or additional pages for tasks that require more extensive information.

c. Standardized Structure: Establish a standardized structure for the job card template that can be easily replicated or adapted to accommodate future growth or changes in the factory's operations.

By considering readability, comprehensiveness, and scalability, the job card becomes a valuable tool that can effectively guide task execution, promote consistency, and accommodate the evolving needs of the factory. A well-designed job card ensures that crucial information is easily accessible, reducing errors, improving efficiency, and enhancing overall productivity in the factory environment.

Standardizing Job Card Procedures

Standardizing job card procedures is a critical step in establishing consistency, efficiency, and quality control within a factory. By implementing standardized procedures, factories can ensure that job cards are created and utilized in a consistent manner across different tasks and departments.

This section focuses on the importance of standardization in job card procedures, including the establishment of consistent protocols, adherence to standards, and implementing a review and approval process. By standardizing job card procedures, factories can streamline operations, improve communication, and maintain a high level of accuracy and quality throughout the job execution process.

A. Establishing consistent protocols for creating and filling out job cards

Establishing consistent protocols for creating and filling out job cards is crucial to ensure uniformity, accuracy, and effectiveness in their usage. Consistent protocols provide clear guidelines to all individuals involved in the job card process, including workers, supervisors, and managers.

Here are key steps to consider when establishing protocols:

Clear Guidelines and Instructions: Develop clear and comprehensive guidelines that outline the process of creating and filling out job cards. Specify the required fields, format, and any specific instructions or conventions to be followed.

Standardized Templates: Create standardized job card templates that encompass the necessary fields and sections. This ensures that all job cards maintain a consistent structure and capture essential information.

Documented Procedures: Document the step-by-step procedures for creating and filling out job cards. This helps in training new employees and serves as a reference for existing staff, ensuring consistency in the process.

Training and Education: Conduct training sessions to educate employees on the protocols and procedures for job card creation and completion. Provide clear instructions on how to fill out each field accurately and emphasize the importance of adherence to the protocols.

Cross-Functional Collaboration: Involve key stakeholders from different departments or teams in the development of the protocols. This ensures that the protocols consider the perspectives and requirements of various roles and facilitates cross-functional collaboration.

Continuous Improvement: Encourage feedback from employees regarding the protocols and procedures. Regularly review and assess the effectiveness of the protocols, making necessary adjustments to address any identified issues or bottlenecks.

Quality Control Measures: Implement quality control measures, such as random checks or reviews, to ensure compliance with the established protocols. This helps identify any deviations or errors, allowing for timely corrective actions.

Documentation and Accessibility: Establish a central repository or system for storing and accessing job cards. This ensures easy retrieval and reference, facilitating transparency, and collaboration among team members.

By establishing consistent protocols for creating and filling out job cards, factories can streamline processes, reduce errors, and enhance overall efficiency. Standardization promotes clarity, accuracy, and effective communication, enabling seamless coordination and improved productivity throughout the factory.

B. Ensuring adherence to established standards across the factory

Ensuring adherence to established standards across the factory is essential for maintaining consistency, quality, and efficiency in job card processes. By establishing clear standards and implementing mechanisms to enforce adherence, factories can optimize their operations. Here are key steps to consider:

Clearly Define Standards: Clearly define the standards for creating, filling out, and using job cards. This includes specifying required fields, formatting guidelines, information accuracy, and any other relevant criteria.

Communicate Standards: Communicate the established standards to all employees involved in the job card processes. Provide training sessions, written guidelines, or visual aids to ensure that everyone understands the expectations and requirements.

Regular Training and Reinforcement: Conduct regular training sessions to refresh employees' understanding of the standards and reinforce their importance. This helps to ensure that all employees are up to date and aligned with the established practices.

Documentation and Examples: Provide examples of properly filled-out job cards that adhere to the standards. These examples serve as reference points for employees, illustrating the desired format, content, and level of detail.

Supervision and Review: Implement a system of supervision and review to monitor adherence to the standards. Assign designated personnel or teams to review job cards periodically, providing feedback and addressing any non-compliance issues.

Corrective Actions and Continuous Improvement: Establish a process for addressing non-compliance and taking corrective actions when deviations from the standards are identified. Use these instances as opportunities for continuous improvement, updating the standards as necessary.

Collaboration and Feedback: Encourage collaboration and feedback from employees regarding the established standards. Employees often have valuable insights and suggestions that can contribute to refining the standards and making them more practical and effective.

Performance Metrics: Implement performance metrics related to job card adherence and quality. Track and analyze data to assess compliance levels, identify areas for improvement, and recognize and reward employees who consistently meet the standards.

By ensuring adherence to established standards across the factory, factories can maintain consistency, minimize errors, and improve overall efficiency in job card processes. Standardization fosters a culture of quality and accountability, leading to enhanced communication, smoother operations, and optimized resource utilization throughout the factory.

C. Implementing a review and approval process for job cards

Implementing a review and approval process for job cards is crucial to ensure accuracy, quality, and accountability in their content and usage. A review and approval process helps verify that job cards meet the required standards, align with the intended objectives, and have undergone appropriate scrutiny.

Here are key considerations for implementing a review and approval process:

Designate Reviewers and Approvers: Identify the individuals or roles responsible for reviewing and approving job cards. This may include supervisors, managers, quality control personnel, or subject matter experts depending on the nature and complexity of the tasks.

Clear Criteria for Review: Define clear criteria for the review process, specifying what aspects of the job card will be evaluated. This may include completeness, accuracy, compliance with standards, alignment with task requirements, and adherence to established protocols.

Review Timelines: Establish timelines for the review process to ensure timely completion. This helps prevent delays in task execution and enables efficient workflow management.

Documentation of Review Feedback: Encourage reviewers to provide clear and constructive feedback on the job cards. This feedback should highlight any necessary revisions, improvements, or compliance issues identified during the review process.

Revision and Resubmission: Establish a mechanism for job card creators to revise and resubmit their cards based on the review feedback. This allows for collaborative refinement and ensures that job cards meet the required standards before they are approved.

Approval Authority: Determine the appropriate authority or role responsible for approving job cards. This individual or role should have the necessary expertise and authority to validate the completeness, accuracy, and compliance of the job cards.

Record Keeping: Maintain a record of the review and approval process, including dates, reviewers' names, revisions made, and final approval. This record serves as an audit trail and can be useful for future reference, analysis, or compliance purposes.

Continuous Improvement: Regularly assess the effectiveness of the review and approval process. Seek feedback from reviewers, job card creators, and other stakeholders to identify areas for improvement and implement necessary adjustments.

By implementing a review and approval process for job cards, factories can enhance accuracy, adherence to standards, and overall quality control. This process ensures that job cards undergo a thorough evaluation, minimizing errors, promoting compliance, and instilling confidence in the accuracy and reliability of the information contained within the cards.

Training Employees on Job Card Usage

Training employees on job card usage is essential for maximizing the benefits and effectiveness of this valuable tool within a factory setting. Proper training ensures that employees understand how to create, fill out, and utilize job cards accurately and efficiently. This section focuses on the significance of training, providing clear instructions, and offering ongoing support to employees.

By equipping the workforce with the necessary knowledge and skills, factories can promote consistency, minimize errors, and enhance overall productivity. Effective training on job card usage empowers employees to leverage this tool to its full potential, enabling streamlined processes, improved communication, and successful task management throughout the factory.

A. Conducting training sessions to educate employees on job card procedures

Conducting training sessions to educate employees on job card procedures is a vital step in ensuring their proficiency and adherence to established protocols. These sessions provide an opportunity to familiarize employees with the purpose, importance, and proper utilization of job cards. Here are key considerations when conducting training sessions:

Clearly Define Objectives: Clearly communicate the objectives of the training sessions, emphasizing the importance of job card procedures in facilitating efficient task management and coordination within the factory.

Tailor Training to Audience: Adapt the training content and delivery to suit the knowledge level and roles of the employees. Consider conducting separate sessions for different departments or teams, addressing their specific needs and challenges related to job card procedures.

Explain Job Card Components: Provide a detailed explanation of the various sections and fields included in the job card template. Clarify the purpose of each section and the information that should be filled out accurately.

Step-by-Step Instruction: Guide employees through the process of creating and filling out a job card, demonstrating the proper sequence of steps and highlighting any specific instructions or conventions to be followed.

Hands-On Practice: Offer hands-on practice opportunities for employees to complete sample job cards or work on simulated scenarios. This allows them to apply their learning, ask questions, and gain confidence in their ability to use job cards effectively.

Address Common Mistakes and Challenges: Identify common mistakes or challenges that employees may encounter when working with job cards. Discuss these challenges during the training sessions and provide guidance on how to overcome them.

Reinforce Compliance with Standards: Emphasize the importance of adhering to the established standards and protocols for job card procedures. Highlight the benefits of consistency, accuracy, and quality control in utilizing job cards.

Q&A and Feedback: Allocate time for questions and answers to address any concerns or uncertainties raised by employees. Encourage feedback from participants to identify areas for improvement in the training sessions or job card procedures.

Training Materials and Resources: Provide participants with training materials, such as handouts or digital resources, summarizing key points covered during the training. These materials serve as references for employees to consult as needed.

Ongoing Support and Refresher Training: Offer ongoing support and refresher training opportunities to reinforce employees' understanding of job card procedures. This can include periodic check-ins, additional training sessions, or access to resources for continuous learning.

By conducting comprehensive training sessions, factories can ensure that employees have the necessary knowledge and skills to create, fill out, and utilize job cards effectively. Proper training promotes consistency, reduces errors, and fosters a culture of efficient task management and communication throughout the factory.

B. Providing clear instructions on how to complete job cards accurately

Providing clear instructions on how to complete job cards accurately is crucial for ensuring consistency and minimizing errors in their usage. Clear instructions empower employees to fill out job cards with precision, ensuring that the necessary information is captured correctly. Here are key considerations when providing instructions:

Overview of Job Card Purpose: Begin by explaining the purpose and benefits of job cards, highlighting their role in facilitating efficient task management, resource allocation, and quality control within the factory.

Step-by-Step Guidance: Break down the process of completing a job card into clear and concise steps. Provide a systematic guide on how to fill out each section, emphasizing the required information and any specific formats or conventions to follow.

Field Descriptions: Clearly describe the purpose and expected content for each field in the job card. Explain the significance of the information to be provided, ensuring that employees understand the relevance and accuracy required.

Data Entry Guidelines: Provide guidelines on entering data accurately, such as using legible handwriting, using standardized abbreviations if applicable, and double-checking numerical values or measurements.

Quality Control Requirements: Explain any quality control checkpoints or inspection criteria that need to be considered when completing the job card. Clarify the importance of adhering to quality standards and the role of the job card in ensuring compliance.

Safety and Compliance Considerations: Highlight any safety guidelines or compliance requirements that employees should be aware of when completing job cards. Emphasize the importance of following these guidelines to maintain a safe working environment.

Examples and Samples: Include examples or samples of properly completed job cards that illustrate the desired format and content. These examples serve as visual references to help employees understand the expected level of detail and accuracy.

Clarify Ambiguities: Address any potential ambiguities or common areas of confusion related to job card completion. Anticipate questions or uncertainties employees may have and provide clear explanations to alleviate any confusion.

Visual Aids and Demonstrations: Utilize visual aids, such as flowcharts or diagrams, to visually illustrate the process of completing a job card accurately. Demonstrations or simulations can also be effective in showcasing the step-by-step process.

Q&A and Ongoing Support: Allow for questions and answers during the instruction session, and encourage employees to seek clarification as needed. Offer ongoing support and be available to address any queries or concerns that arise during job card completion.

By providing clear instructions, factories can ensure that employees have a thorough understanding of how to complete job cards accurately. This clarity promotes consistency, reduces errors, and enhances the overall effectiveness of job card usage within the factory environment.

C. Offering ongoing support and guidance for employees

Offering ongoing support and guidance for employees is vital to reinforce their understanding of job card procedures and ensure their continued proficiency. Ongoing support helps employees navigate any challenges, address questions or concerns, and stay up to date with evolving requirements.

Here are key considerations for providing ongoing support and guidance:

Accessible Points of Contact: Designate specific individuals or a support team that employees can reach out to for assistance or guidance related to job card procedures. Clearly communicate their contact information and availability.

Regular Check-Ins: Conduct regular check-ins with employees to assess their understanding of job card procedures and address any issues or questions they may have. These check-ins can be one-on-one sessions or group discussions.

Refresher Training: Offer refresher training sessions periodically to reinforce employees' understanding of job card procedures and address any updates or changes to the protocols. These sessions can serve as opportunities for knowledge reinforcement and skill enhancement.

Frequently Asked Questions (FAQs): Create an FAQ document or knowledge base that addresses commonly asked questions or challenges related to job card procedures. Make this resource easily accessible to employees, either through a shared drive, intranet, or digital platform.

Job Aids and Reference Materials: Provide job aids and reference materials that employees can consult for quick guidance on job card procedures. These can include step-by-step guides, visual aids, or flowcharts that simplify the process and highlight key considerations.

Peer Support and Mentoring: Encourage a culture of peer support and mentoring, where employees with experience in job card procedures can assist and guide their colleagues. Foster collaboration and knowledge-sharing among employees.

Continuous Improvement Feedback: Encourage employees to provide feedback on the job card procedures, suggesting improvements or identifying areas of confusion. Actively listen to their input and incorporate relevant suggestions to enhance the clarity and effectiveness of the procedures.

Documented Best Practices: Capture and share documented best practices related to job card procedures. These can be success stories, tips, or techniques that employees can refer to for inspiration and guidance in optimizing their use of job cards.

Recognition and Rewards: Recognize and reward employees who consistently demonstrate proficiency and adherence to job card procedures. This can be through public acknowledgement, incentives, or performance evaluations that take into account job card compliance.

Continuous Learning Opportunities: Provide employees with opportunities for continuous learning related to job card procedures. This can include workshops, webinars, or access to relevant industry resources that enhance their understanding and skills.

By offering ongoing support and guidance, factories can ensure that employees have the necessary resources and assistance to navigate job card procedures effectively. This support fosters a culture of continuous improvement, knowledge sharing, and skill development, resulting in optimized job card usage and improved overall factory operations.

Integrating Job Cards into Workflow Management Systems

Integrating job cards into workflow management systems is a pivotal step towards streamlining operations, enhancing efficiency, and leveraging technology in the factory environment. By seamlessly integrating job cards with digital systems, factories can optimize task management, resource allocation, and communication.

This section focuses on the significance of integrating job cards into workflow management systems, including the benefits of automation, real-time visibility, and data-driven insights.

By harnessing the power of technology, factories can unlock new levels of productivity, accuracy, and adaptability, ultimately driving success in a fast-paced and competitive industrial landscape.

A. Exploring digital tools and software solutions for job card management

Exploring digital tools and software solutions for job card management opens up a world of possibilities for enhancing efficiency, accuracy, and collaboration within a factory setting. These tools offer advanced features and automation capabilities that streamline job card processes and integrate them seamlessly into overall workflow management.

Here are key considerations when exploring digital tools and software solutions for job card management:

Job Card Management Systems: Look for specialized job card management systems or software that are designed to handle the creation, tracking, and analysis of job cards. These systems often provide customizable templates, automated notifications, and centralized storage for easy access and management.

Workflow Management Platforms: Consider utilizing workflow management platforms that allow for the integration of job card functionalities. These platforms provide a holistic approach to managing tasks, resources, and communication, enabling seamless collaboration and real-time updates.

Mobile Applications: Explore mobile applications specifically developed for job card management. These apps allow employees to create, update, and access job cards on mobile devices, providing flexibility and convenience in capturing information directly from the factory floor.

Cloud-Based Solutions: Opt for cloud-based solutions that offer scalability, accessibility, and data security. Cloud platforms enable real-time synchronization of job card data across multiple devices, facilitating collaboration and eliminating the need for manual data transfer.

Automation and Templates: Seek tools that offer automation features, such as pre-defined templates, auto-population of fields, and automated notifications. These features streamline the job card creation process, reduce errors, and save time for employees.

Integration with Other Systems: Look for tools that integrate smoothly with existing systems used in the factory, such as inventory management, resource planning, or enterprise resource planning (ERP) systems. Integration allows for seamless data exchange, eliminating duplicate entries and ensuring accurate information flow.

Analytics and Reporting: Consider tools that provide robust analytics and reporting capabilities. These features enable data-driven insights into job card performance, resource utilization, and productivity metrics, empowering managers to make informed decisions and drive continuous improvement.

User-Friendly Interface: Prioritize tools with intuitive and user-friendly interfaces. A well-designed interface enhances user adoption, reduces training time, and promotes efficient utilization of the digital tool for job card management.

Technical Support and Training: Assess the availability of technical support, training resources, and documentation provided by the tool or software vendor. Adequate support and training ensure a smooth implementation and assist employees in effectively utilizing the digital tool for job card management.

Scalability and Customization: Consider the scalability and customization options offered by the digital tool or software. As the factory evolves and requirements change, the tool should be able to adapt and accommodate new workflows, fields, or reporting needs.

By exploring and adopting digital tools and software solutions for job card management, factories can revolutionize their processes, streamline operations, and achieve new levels of efficiency and productivity. These tools enhance collaboration, provide real-time insights, and enable data-driven decision-making, positioning the factory for success in a digital era.

B. Benefits of integrating job cards with existing systems

Integrating job cards with existing systems offers numerous benefits that enhance efficiency, accuracy, and overall workflow management within a factory. Here are key benefits of integrating job cards with existing systems:

Streamlined Data Management: Integration allows for seamless data flow between job cards and other systems, such as inventory management, scheduling, or quality control. This eliminates the need for manual data entry or transfer, reducing errors and saving time.

Real-Time Visibility: Integration provides real-time visibility into job card status, progress, and resource utilization. Managers and stakeholders can access up-to-date information, enabling proactive decision-making and efficient resource allocation.

Improved Collaboration: Integration facilitates better collaboration among different departments and teams involved in the job card processes. Relevant stakeholders can access and contribute to job card information, ensuring clear communication and coordinated efforts.

Enhanced Task Management: Integration with workflow management systems allows for seamless task assignment, tracking, and monitoring. Managers can assign job cards to employees, track progress, and receive notifications for updates or delays, ensuring tasks are completed on time.

Automation and Efficiency: Integrating job cards with existing systems enables automation of routine tasks, such as data entry, notifications, or generating reports. This reduces manual effort, minimizes errors, and increases overall efficiency in job card management.

Data-Driven Insights: Integration with analytics or reporting systems provides valuable data-driven insights into job card performance, resource utilization, and productivity metrics. Managers can analyze trends, identify bottlenecks, and make informed decisions to optimize operations.

Standardization and Consistency: Integration promotes standardization and consistency in job card processes. By aligning job card procedures with existing systems, factories can enforce uniform practices, reduce variability, and ensure adherence to established standards.

Scalability and Flexibility: Integrating job cards with existing systems allows for scalability as the factory grows or evolves. The integrated system can accommodate new workflows, additional fields, or changes in requirements, adapting to the factory's changing needs.

Compliance and Traceability: Integration with compliance or auditing systems enhances traceability and ensures adherence to regulatory or industry standards. Job card data can be easily accessed and audited, simplifying compliance checks and reducing administrative burden.

Continuous Improvement: Integrated systems provide a foundation for continuous improvement initiatives. With access to accurate and comprehensive data, factories can identify areas for optimization, implement process enhancements, and drive continuous improvement in job card management.

By integrating job cards with existing systems, factories can harness the power of technology to streamline processes, improve collaboration, and drive operational excellence. The benefits of integration include increased efficiency, real-time visibility, data-driven insights, and improved overall productivity within the factory environment.

C. Ensuring compatibility and ease of use for employees

Ensuring compatibility and ease of use for employees is crucial when integrating job cards with existing systems in a factory setting. The successful integration should consider the following factors to ensure a smooth transition and optimal user experience:

User-Friendly Interface: The integrated system should have a user-friendly interface that is intuitive and easy to navigate. Clear labels, logical organization of information, and intuitive controls contribute to a positive user experience.

Seamless Integration: The integration should be seamless and transparent to employees. It should minimize disruptions to their workflow and ensure that the transition between systems is smooth, with minimal additional steps or complexities.

Compatibility with Existing Workflows: The integrated system should align with the existing workflows and processes within the factory. It should accommodate the specific needs and requirements of different departments and teams, ensuring that the integrated job card solution seamlessly fits into their daily operations.

Training and Support: Adequate training and support should be provided to employees to familiarize them with the integrated system. This includes comprehensive training sessions, user manuals, and access to support resources to address any questions or concerns that may arise during the transition.

Clear Communication: Transparent communication about the integration process is essential. Employees should be informed about the purpose, benefits, and expected impact of the integration. Regular updates and open channels of communication ensure that employees are aware of changes and can provide feedback or seek clarification.

Flexibility and Customization: The integrated system should offer flexibility and customization options to accommodate different user preferences and specific requirements. Employees should have the ability to tailor certain aspects of the system, such as user interfaces or notifications, to their individual needs and work styles.

User Testing and Feedback: Prioritize user testing and gather feedback from employees during the integration process. This allows for iterative improvements and ensures that the integrated system is optimized for usability and addresses any usability issues or pain points identified by employees.

Ongoing Evaluation and Enhancement: Continuously evaluate the compatibility and ease of use of the integrated system. Monitor user feedback, conduct surveys, and gather insights to identify areas for improvement. Regularly update and enhance the system based on user needs and changing requirements.

By prioritizing compatibility and ease of use, factories can ensure that employees can seamlessly transition to the integrated job card system and effectively leverage its benefits. A user-friendly and compatible solution promotes user adoption, enhances productivity, and contributes to a positive work environment within the factory.

Monitoring and Evaluating Job Card Effectiveness

Monitoring and evaluating the effectiveness of job cards is essential for continuous improvement and maximizing their impact within a factory. By implementing a systematic approach to monitor and evaluate job card effectiveness, factories can assess their efficiency, accuracy, and contribution to overall operational goals.

This section focuses on the significance of monitoring and evaluating job card effectiveness, including key metrics, data analysis, and feedback mechanisms. By gaining insights into the strengths and weaknesses of job card processes, factories can refine their practices, optimize resource utilization, and drive continuous improvement in task management and productivity.

A. Implementing metrics to assess the efficiency and accuracy of job card processes

Implementing metrics to assess the efficiency and accuracy of job card processes provides factories with quantitative measures to evaluate the effectiveness of their job card systems. These metrics offer valuable insights into how well job cards are being utilized and the impact they have on operational efficiency.

Here are key considerations when implementing metrics:

Completion Time: Measure the time it takes for a job card to be created, filled out, reviewed, and approved. This metric assesses the efficiency of the process and identifies potential bottlenecks or delays.

Task Duration: Evaluate the actual time it takes to complete tasks as recorded in the job cards. Compare it with the estimated duration to gauge accuracy and identify areas where task completion times deviate significantly.

Resource Utilization: Assess how effectively resources, such as materials, equipment, and personnel, are allocated and utilized. This metric helps identify areas where resources are underutilized or overburdened, enabling better resource management.

Error Rates: Track the frequency and types of errors encountered in job cards, such as incorrect data entry, missing information, or inconsistencies. This metric provides insights into the accuracy of job card processes and highlights areas that require improvement or additional training.

Task Dependencies: Measure the percentage of job cards with task dependencies accurately identified and captured. This metric reflects the effectiveness of job card processes in considering dependencies and coordinating tasks accordingly.

Compliance with Standards: Evaluate the degree to which job cards adhere to established standards, protocols, and quality control requirements. This metric helps ensure consistency and adherence to best practices within the factory.

Task Completion Rate: Monitor the rate at which tasks documented in job cards are successfully completed. This metric provides an indication of the effectiveness of job cards in facilitating task execution and meeting deadlines.

Feedback and Issue Resolution: Capture feedback from employees regarding job card processes and the ease of use. Monitor the rate at which reported issues or concerns related to job cards are resolved. This metric ensures that employee feedback is valued and improvements are made accordingly.

Cost and Resource Efficiency: Assess the cost-effectiveness and resource efficiency of job card processes. This metric considers factors such as the time and resources invested in job cards relative to the outcomes achieved, helping identify opportunities for optimization.

Continuous Improvement Initiatives: Measure the rate of implementation of improvement initiatives based on insights gained from job card metrics. This metric reflects the responsiveness of the factory in using job card data to drive continuous improvement.

By implementing metrics to assess the efficiency and accuracy of job card processes, factories can gain valuable insights into their performance and identify areas for improvement. These metrics provide a basis for data-driven decision-making and enable targeted efforts to enhance operational efficiency, accuracy, and overall productivity.

B. Analyzing data to identify areas for improvement

Analyzing data to identify areas for improvement is a crucial step in leveraging the insights gained from job card processes. By analyzing relevant data, factories can identify patterns, trends, and areas of inefficiency or suboptimal performance within their job card systems.

Here are key considerations for analyzing data to identify areas for improvement:

Data Collection and Storage: Ensure that data from job cards, including completion times, task durations, resource utilization, error rates, and other relevant metrics, is consistently and accurately collected. Store the data in a centralized and accessible location for analysis.

Establish Baselines: Establish baselines or benchmarks for key performance metrics based on historical data or industry standards. These baselines provide a reference point for evaluating current performance and identifying areas that require improvement.

Identify Patterns and Trends: Use data analysis techniques to identify patterns, trends, or anomalies in the job card data. Look for recurring issues, common errors, or areas where performance consistently falls short of expectations.

Root Cause Analysis: Perform root cause analysis to understand the underlying factors contributing to identified issues or inefficiencies. Identify the root causes behind errors, delays, or resource bottlenecks to address the fundamental issues rather than just addressing symptoms.

Prioritize Improvement Areas: Prioritize improvement areas based on their impact and feasibility. Focus on areas that have the potential to yield significant improvements and where interventions are feasible and within the control of the factory.

Collaborative Approach: Involve relevant stakeholders, such as employees, supervisors, and managers, in the data analysis process. Gather insights, perspectives, and suggestions from those directly involved in job card processes to gain a comprehensive understanding of the challenges and improvement opportunities.

Data Visualization: Use data visualization techniques, such as charts, graphs, or dashboards, to present the analyzed data in a clear and concise manner. Visual representations facilitate better understanding and enable stakeholders to identify patterns and trends more easily.

Set Improvement Goals: Set specific and measurable improvement goals based on the data analysis findings. These goals should be realistic, achievable, and aligned with the overall objectives of the factory. Use the data to establish targets and track progress over time.

Continuous Monitoring and Evaluation: Continuously monitor and evaluate the impact of improvement initiatives implemented based on the data analysis. Regularly assess the effectiveness of interventions and make necessary adjustments to ensure continuous improvement.

Feedback Loop: Establish a feedback loop to gather feedback from employees, supervisors, and managers regarding the effectiveness of improvement efforts. Encourage open communication and create a culture that values feedback as a valuable source of insights for ongoing improvements.

By analyzing data, factories can gain actionable insights into areas for improvement within their job card systems. This data-driven approach enables targeted interventions, process enhancements, and the optimization of job card processes to enhance efficiency, accuracy, and overall factory performance.

C. Making necessary adjustments to optimize job card procedures

Making necessary adjustments to optimize job card procedures is a crucial step in leveraging the insights gained from data analysis and feedback. By continuously improving job card procedures, factories can enhance efficiency, accuracy, and overall effectiveness.

Here are key considerations for making necessary adjustments:

Reviewing Current Processes: Conduct a thorough review of the existing job card procedures, taking into account the data analysis findings, feedback from employees, and identified areas for improvement. Identify specific aspects of the processes that require adjustment.

Process Simplification: Streamline and simplify the job card procedures to eliminate unnecessary steps or redundancies. Look for opportunities to reduce complexity and improve the clarity and ease of use for employees.

Standardization and Consistency: Ensure that job card procedures are standardized across different departments and teams within the factory. Consistency in the format, fields, and required information helps streamline processes and improve communication.

Automation and Technology: Explore opportunities for automation and leveraging technology to enhance job card procedures. Identify tasks that can be automated, such as data entry or notifications, to reduce manual effort and increase efficiency.

Training and Education: Provide targeted training and education to employees on the adjusted job card procedures. Communicate the reasons behind the adjustments, provide clear instructions, and offer support to ensure a smooth transition.

Pilot Testing: Consider conducting pilot tests of the adjusted job card procedures in specific departments or teams before implementing them across the entire factory. Pilot testing allows for validation, feedback collection, and refinement of the adjusted procedures.

Continuous Monitoring and Evaluation: Continuously monitor the impact of the adjustments on job card processes. Evaluate key performance metrics, solicit feedback from employees, and assess whether the adjustments have achieved the desired improvements.

Feedback Integration: Integrate feedback mechanisms to gather ongoing input from employees regarding the adjusted job card procedures. Actively listen to their suggestions, concerns, and experiences to identify any potential issues or further areas for optimization.

Iterative Approach: Embrace an iterative approach to optimization, recognizing that job card procedures may need further adjustments over time. Regularly revisit and refine the procedures based on new insights, changing requirements, and feedback from stakeholders.

Documentation and Communication: Document the adjusted job card procedures and communicate them clearly to all relevant stakeholders. Ensure that employees have access to up-to-date instructions and guidelines to follow.

By making necessary adjustments to optimize job card procedures, factories can enhance their efficiency, accuracy, and overall effectiveness. This iterative approach to improvement allows for continuous refinement, aligning job card processes with the evolving needs of the factory and driving ongoing success in task management and productivity.

Overcoming Challenges and Pitfalls

Overcoming challenges and pitfalls is an integral part of implementing effective job card processes in a factory. While job cards can greatly enhance efficiency and task management, various obstacles can hinder their successful implementation.

This section focuses on identifying common challenges and pitfalls that factories may encounter when implementing job card processes and provides strategies to overcome them. By proactively addressing these challenges, factories can optimize the benefits of job cards and ensure their smooth integration into the workflow, ultimately leading to improved productivity and operational success

A. Addressing common obstacles in implementing job card processes

By anticipating and proactively addressing these obstacles, factories can overcome barriers and foster a smooth transition.

Here are key considerations for addressing common obstacles:

Resistance to Change: Address resistance to change by clearly communicating the purpose, benefits, and goals of implementing job card processes. Engage employees in the process, provide training and support, and highlight the positive impact on their work and the overall efficiency of the factory.

Lack of Employee Buy-In: Foster employee buy-in by involving them in the decision-making process. Seek their input, address their concerns, and communicate the advantages of job cards in improving task management, communication, and resource allocation.

Insufficient Training and Guidance: Provide comprehensive training and ongoing support to employees regarding job card processes. Ensure that they understand the purpose, procedures, and benefits of using job cards and offer resources for continuous learning and improvement.

Inadequate Communication and Collaboration: Promote effective communication and collaboration among different departments and teams involved in job card processes. Encourage open dialogue, establish clear channels of communication, and foster a culture of collaboration and knowledge sharing.

Lack of Standardization: Establish clear standards and protocols for creating, filling out, and using job cards. Ensure consistency across departments and teams to streamline processes, enhance communication, and improve overall efficiency.

Technological Limitations: Address technological limitations by carefully selecting digital tools or software solutions that align with the factory's requirements. Provide training and support to employees to ensure they can effectively utilize the technology and address any technical issues that may arise.

Inadequate Data Analysis: Emphasize the importance of data analysis in evaluating the effectiveness of job card processes. Provide the necessary resources and tools to collect and analyze data, and ensure that managers and supervisors are equipped to utilize data insights for decision-making and process improvement.

Lack of Continuous Improvement Culture: Foster a culture of continuous improvement by encouraging employees to provide feedback, share insights, and suggest enhancements to job card processes. Recognize and reward innovative ideas that contribute to process optimization.

Overcomplicated Job Card Templates: Simplify job card templates to avoid unnecessary complexity. Ensure that the required fields and information are clear and relevant, reducing the risk of confusion or errors during job card completion.

Inadequate Monitoring and Evaluation: Implement a system for monitoring and evaluating job card processes regularly. Use key performance metrics and data analysis to identify areas for improvement and make necessary adjustments to enhance the effectiveness of job card processes.

By addressing these common obstacles, factories can overcome challenges and pitfalls in implementing job card processes, paving the way for successful integration and realizing the full benefits of improved task management, communication, and overall operational efficiency.

B. Strategies for overcoming resistance or reluctance from employees

Overcoming resistance or reluctance from employees is essential to ensure a successful implementation of job card processes in a factory. By employing effective strategies, factories can address employee concerns, encourage buy-in, and foster a positive mindset towards the changes.

Here are key strategies for overcoming resistance or reluctance from employees:

Clear Communication: Clearly communicate the reasons behind implementing job card processes, emphasizing the benefits they bring to employees and the overall efficiency of the factory. Address concerns and misconceptions, and provide a clear vision of how job cards will improve their work processes and outcomes.

Employee Involvement: Involve employees in the decision-making process and actively seek their input. Create opportunities for them to share their opinions, ideas, and suggestions regarding job card processes. By involving them, employees feel valued and become more invested in the implementation.

Training and Education: Provide comprehensive training and education on job card processes, highlighting the importance of the change and providing clear instructions on how to use job cards effectively. Offer hands-on practice and address any technical or operational concerns to build employees' confidence and competence.

Address Individual Concerns: Take the time to understand and address individual concerns or reservations about job card processes. Provide personalized support, clarification, or additional training as needed to alleviate their concerns and help them adapt to the changes.

Highlight Benefits and Rewards: Clearly communicate the individual benefits of job cards to employees. Emphasize how job cards can streamline their tasks, improve communication, enhance resource allocation, and ultimately contribute to their own productivity and job satisfaction. Consider introducing incentives or rewards for employees who effectively utilize job cards.

Change Champions: Identify and empower change champions among employees who are enthusiastic about the implementation of job card processes. Encourage them to share their positive experiences, act as mentors to their colleagues, and serve as role models for embracing the changes.

Continuous Support and Feedback: Provide ongoing support and guidance to employees throughout the implementation process. Establish channels for employees to provide feedback, ask questions, and voice concerns. Actively listen to their feedback and make necessary adjustments based on their input.

Celebrate Successes: Recognize and celebrate small successes and milestones achieved through the effective use of job cards. Publicly acknowledge employees' efforts and the positive impact they have made. This fosters a sense of achievement and motivates others to embrace the changes.

Monitor and Evaluate Progress: Regularly monitor and evaluate the progress of job card implementation. Use data and metrics to showcase the improvements and positive outcomes resulting from the changes. Share these results with employees to demonstrate the value of their efforts.

Patience and Persistence: Change takes time, and it's important to remain patient and persistent. Allow employees the necessary time and space to adapt to the changes, and continuously reinforce the benefits of job card processes through consistent communication and support.

By implementing these strategies, factories can overcome resistance or reluctance from employees, paving the way for a successful adoption of job card processes. Engaging employees, addressing their concerns, and highlighting the benefits of the changes are key elements in fostering a positive mindset and achieving widespread acceptance and utilization of job cards.

C. Continuous improvement and adaptation to changing factory requirements

Continuous improvement and adaptation to changing factory requirements are essential for the long-term success of job card processes. As factories evolve, it is crucial to continuously refine and adapt job card procedures to align with new needs and challenges. Here are key strategies for continuous improvement and adaptation:

Regular Evaluation: Regularly evaluate the effectiveness of job card processes through data analysis, employee feedback, and performance metrics. Identify areas for improvement, assess the impact of implemented changes, and make necessary adjustments based on the evolving requirements of the factory.

Embrace a Learning Culture: Foster a learning culture within the factory where employees are encouraged to share ideas, provide feedback, and suggest improvements for job card processes. Create opportunities for cross-functional collaboration and knowledge-sharing to drive innovation and continuous improvement.

Keep Up with Technological Advancements: Stay abreast of technological advancements relevant to job card processes. Continuously explore new tools, software, or digital solutions that can enhance efficiency, accuracy, and integration with other systems. Embrace emerging technologies that can streamline job card management and improve overall productivity.

Collaboration with Stakeholders: Engage with stakeholders, including employees, managers, supervisors, and other relevant parties, to gather insights and perspectives on improving job card processes. Foster collaborative discussions and involve stakeholders in decision-making to ensure alignment with their needs and experiences.

Pilot Testing and Iterative Approach: Conduct pilot testing of proposed changes or enhancements to job card processes. Gather feedback, evaluate the results, and refine the changes before implementing them on a larger scale. Embrace an iterative approach, allowing for continuous refinements and adjustments based on real-world experiences.

Continuous Training and Development: Provide ongoing training and development opportunities to employees regarding job card processes. Offer refresher sessions, workshops, or access to resources that enable them to stay updated on best practices, new techniques, and evolving requirements.

Flexibility in Job Card Templates: Maintain flexibility in job card templates to accommodate changing factory requirements. Regularly review and update the templates to capture relevant information, align with new standards or regulations, and address emerging needs within the factory.

Performance Measurement and Benchmarking: Establish performance measurement benchmarks to track the effectiveness of job card processes over time. Compare performance against industry standards, best practices, or internal goals. Use the benchmarks to identify areas where further improvements can be made.

Agile and Responsive Approach: Embrace an agile and responsive approach to job card processes. Be open to change, adapt quickly to new circumstances, and continuously seek opportunities for optimization. Encourage experimentation, risk-taking, and innovation in job card procedures.

Continuous Monitoring and Feedback: Continuously monitor the performance of job card processes and gather feedback from employees, supervisors, and managers. Regularly review the data, analyze trends, and seek input to identify areas for further improvement and adapt job card processes accordingly.

By prioritizing continuous improvement and adaptation to changing factory requirements, factories can ensure that job card processes remain effective and relevant. Embracing a culture of learning, collaboration, and agility enables factories to respond to evolving needs, optimize operational efficiency, and drive sustained success in task management and productivity.

Conclusion

Implementing effective job card processes in a factory is crucial for optimizing task management, improving efficiency, and enhancing overall productivity. Throughout this article, we have explored various aspects of implementing job card processes, including understanding their purpose, designing effective templates, standardizing procedures, training employees, integrating with workflow management systems, and monitoring effectiveness.

By addressing common obstacles and challenges, such as resistance to change or lack of employee buy-in, factories can successfully implement job card processes and overcome potential pitfalls.

The benefits of implementing effective job card processes are numerous. They include streamlined task management, improved resource allocation, enhanced communication and collaboration, data-driven insights, and continuous improvement opportunities. Job cards provide a structured framework for capturing essential information, ensuring clarity, accountability, and traceability throughout the factory.

To achieve success, factories must prioritize continuous evaluation and adaptation of job card processes. This involves analyzing data, gathering feedback, and making necessary adjustments to optimize efficiency, accuracy, and alignment with changing factory requirements. By fostering a culture of continuous improvement, embracing technological advancements, and nurturing employee engagement, factories can harness the full potential of job card processes.

Ultimately, effective job card processes serve as a foundation for operational excellence, enabling factories to meet production targets, minimize errors, improve quality control, and adapt to dynamic market demands. By implementing and continuously refining job card processes, factories can pave the way for enhanced productivity, streamlined operations, and sustainable growth in today's competitive manufacturing landscape.

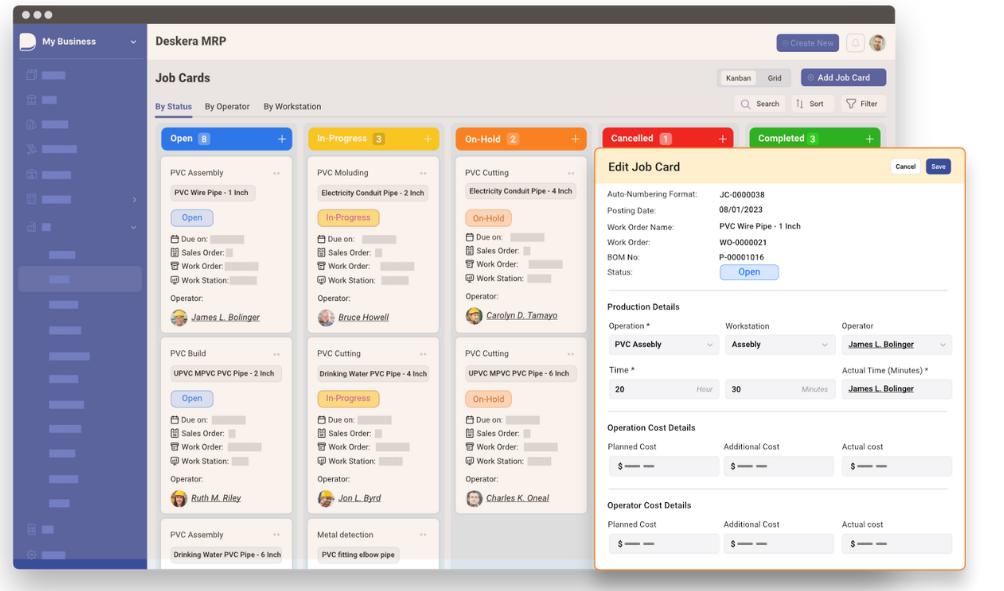

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.