Leather manufacturing is the process of making leather products from raw materials. Leather is a strong, durable fabric that is used in many different fields, including apparel, furniture, and holsters. In order to create a high-quality product, special care must be taken during the manufacturing process.

There are many factors that determine the quality of a leather product. Designing for leather manufacturing requires knowledge of both the material and the process. Properly understanding these variables can result in a more successful product.

In today’s guide, we’ll discuss thoroughly about designing for leather manufacturing and related concepts. Let’s discuss:

- Meaning of Designing for Leather Manufacturing

- Need for Designing for Leather Manufacturing

- Most Important Factor to Consider When Designing for Leather Manufacturing

- Importance of Considering Manufacturing Techniques in the Design Process

- Common Design Considerations for Leather Manufacturing

- Determining Whether a Design is Suitable for Leather

- How can Designers Ensure that their Leather Products are Sustainable?

- Is Leather More Expensive than Other Materials?

- How Can Designers Ensure that their Leather Products are of High Quality?

- Challenges and Opportunities

- Case Studies

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Meaning of Designing for Leather Manufacturing

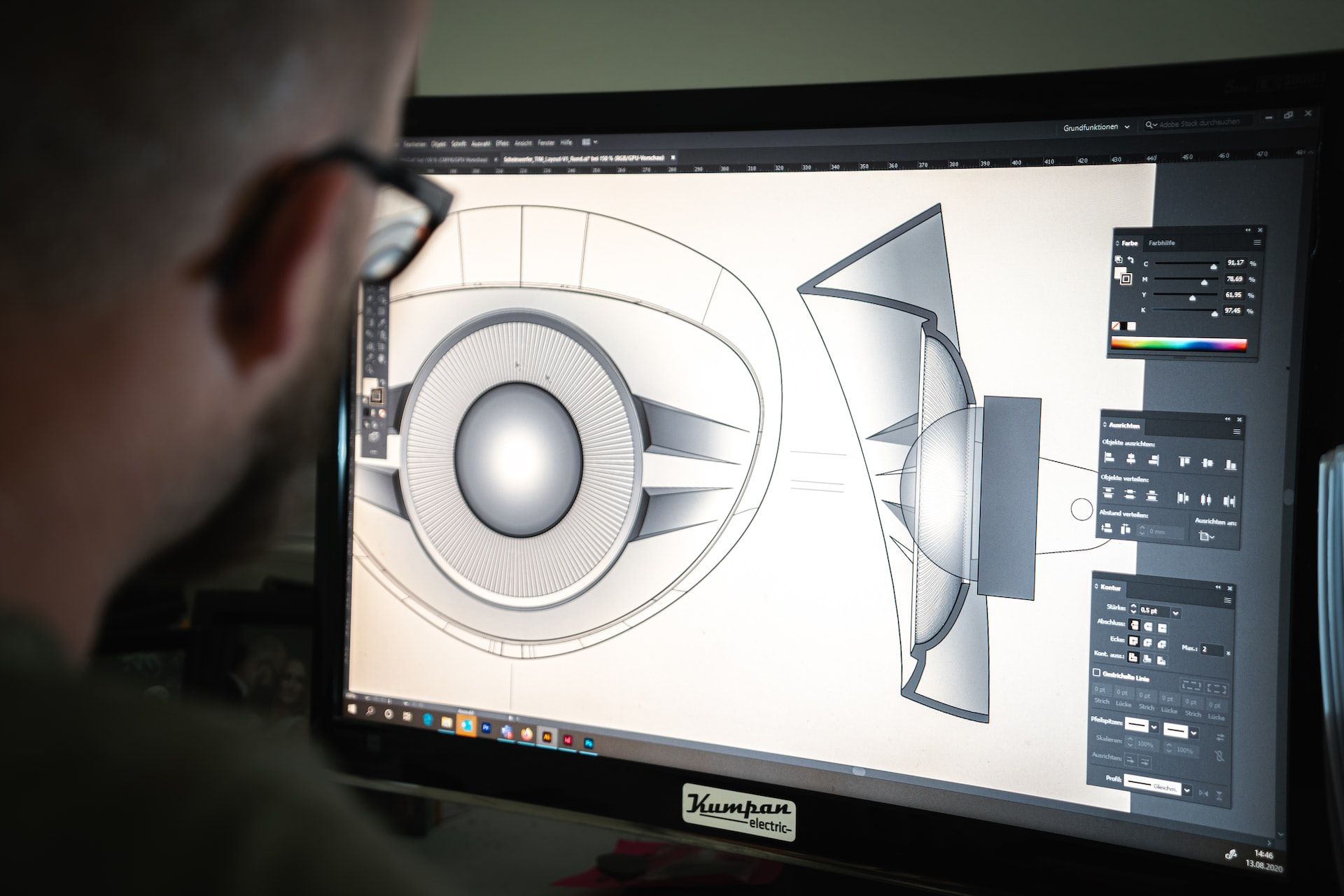

Designing for leather manufacturing is the process of creating products made of leather while taking into consideration the manufacturing process. The design process for leather products is not just about the visual aesthetics of the final product but also about the practicalities of making it.

Designers need to consider the characteristics of leather such as its thickness, texture, and flexibility, and how it will be cut and sewn during the manufacturing process. They need to take into account the properties of the leather, such as its stretchiness and how it will react to various treatments, such as dyeing and embossing.

Moreover, designers need to consider the manufacturing techniques used for the specific leather product they are designing. For instance, if they are designing a leather handbag, they need to consider the different types of stitching techniques, the thickness of the leather, and the hardware that will be used to attach straps, zippers, and other features.

Furthermore, designers need to consider the cost and sustainability of the materials used in the design process. Leather products are often more expensive than synthetic materials, and designers need to balance the aesthetic and functional needs of the product with the cost of the materials used.

Consequently, designing for leather manufacturing is a process that involves considering the manufacturing process, properties of the leather, manufacturing techniques, cost, and sustainability of materials. By taking these factors into account, designers can create leather products that are both visually appealing and practical to manufacture.

Need for Designing for Leather Manufacturing

Designing for leather manufacturing is essential because it ensures that the final product is not only aesthetically pleasing but also practical to produce. Here are some reasons why designing for leather manufacturing is crucial:

- Manufacturing constraints: Leather products are usually manufactured using traditional techniques, such as hand-stitching and cutting, which can be time-consuming and require skilled labor. Designing for manufacturing ensures that the product is designed in a way that is efficient and practical to produce, reducing production time and costs.

- Material properties: Leather is a unique material that has specific properties such as thickness, texture, and flexibility. Designing for manufacturing considers the properties of the leather and how it will behave during the manufacturing process, ensuring that the final product meets quality standards and is durable.

- Cost and sustainability: Leather is an expensive and limited resource and designing for manufacturing considers the cost and sustainability of the materials used. By creating designs that use materials efficiently, designers can reduce the cost of the final product and reduce waste.

- Innovation: By considering manufacturing constraints and material properties, designers can create innovative designs that push the boundaries of traditional leather products. Designing for manufacturing allows designers to experiment with new materials and techniques, resulting in unique and exciting products.

Consequently, designing for leather manufacturing is crucial because it ensures that the final product is both visually appealing and practical to produce. Moreover, it helps in reducing the overall production time and costs, considers the cost and sustainability of the materials used, and encourages innovation in the industry.

Most Important Factor to Consider When Designing for Leather Manufacturing

The most important factor to consider when designing for leather manufacturing is the manufacturing process itself. Designers need to have a clear understanding of the techniques, tools, and machinery used in leather manufacturing to ensure that their designs are practical and efficient to produce.

Leather is a unique material with distinct properties such as thickness, texture, and flexibility. These properties can impact the manufacturing process and affect the final product's quality and durability. Furthermore, designers need to consider these properties when designing a product to ensure that it meets quality standards and is suitable for its intended use.

Designers also need to consider the various manufacturing constraints, including time, cost, and labor. Furthermore, leather products are often made using traditional techniques such as hand-stitching and cutting, which can be time-consuming and require skilled labor. Therefore, designers need to design their products in a way that is efficient and practical to produce, reducing production time and costs.

Another essential consideration for designers when designing for leather manufacturing is the sustainability of the materials used. Leather is an expensive and limited resource, and designers need to ensure that they use it responsibly. They can do this by creating designs that use materials efficiently, reducing waste, and considering the environmental impact of their design decisions.

Consequently, the most critical factor to consider when designing for leather manufacturing is the manufacturing process itself. Designers need to consider the unique properties of leather, the manufacturing constraints, and the sustainability of the materials used to create designs that are efficient, practical, and of high quality.

Importance of Considering Manufacturing Techniques in the Design Process

Manufacturing techniques play a crucial role in the design process. Ignoring manufacturing considerations during the design phase can lead to issues during the production stage, which can result in delays, increased costs, and even the need for a complete redesign.

Therefore, designers must consider the manufacturing process during the design phase to ensure that the final product can be manufactured efficiently and effectively.

Here are some reasons why it's important to consider manufacturing techniques in the design process:

Cost-Effectiveness:

Manufacturing is a critical component of the production process. Understanding manufacturing techniques enables designers to create products that can be made with minimum waste, which can help to reduce the overall cost of production.

Quality Control:

If the manufacturing process is not taken into account during the design process, it can result in poor product quality. By considering manufacturing techniques during the design phase, designers can create products that can be manufactured with consistent quality, resulting in products that meet or exceed customer expectations.

Feasibility:

The design may be good on paper, but it may not be practical for manufacturing. Designers must consider the limitations and constraints of manufacturing when designing a product to ensure that it is feasible to produce.

Innovation:

By taking into account manufacturing techniques during the design process, designers can explore new and innovative ways to create products. Understanding the capabilities and limitations of manufacturing techniques can inspire designers to develop new and unique products that are efficient to produce.

Time-to-Market:

Considering manufacturing techniques during the design process can help to reduce the time-to-market for products. By designing products that can be manufactured efficiently and effectively, companies can bring their products to market faster.

Considering manufacturing techniques in the design process is crucial for creating products that can be manufactured efficiently, cost-effectively, and with consistent quality. By taking into account the limitations and capabilities of manufacturing techniques, designers can create innovative and unique products that meet customer expectations and can be produced efficiently.

Common Design Considerations for Leather Manufacturing

Leather is a popular material for a wide range of products, including clothing, accessories, footwear, and furniture. Designing with leather requires careful consideration of various factors to ensure that the final product is both aesthetically pleasing and durable.

Following, we've discussed common design considerations for leather manufacturing:

Material Usage:

Leather is a natural material that comes in a variety of grades and finishes. Designers must consider the type and quality of leather to use for their products, as it can affect the durability, texture, and appearance of the final product. Factors such as thickness, stretch, and flexibility of the leather must also be taken into account.

Stitching:

Stitching is a critical component of leather manufacturing, as it determines the strength and durability of the product. Designers must consider the type of stitching to use, the stitch length, and the number of stitches per inch. The stitching must also be positioned in a way that enhances the appearance of the product and complements the design.

Hardware Selection:

Hardware, such as zippers, snaps, and buckles, can add functionality and style to leather products. Designers must consider the type and quality of hardware to use, as it can affect the durability and appearance of the final product. Factors such as the size, shape, and color of the hardware must also be taken into account.

Surface Treatments:

Leather can be treated with various surface treatments, such as dyeing, embossing, and printing, to enhance its appearance and texture. Designers must consider the type of surface treatment to use and how it will affect the final product's durability and appearance.

Ergonomics:

Designers must consider the ergonomics of the product to ensure that it is comfortable and functional. Factors such as weight distribution, padding, and grip must be taken into account to create a product that is both comfortable and functional.

In summary, designing with leather requires careful consideration of various factors, including material usage, stitching, hardware selection, surface treatments, and ergonomics. By taking into account these design considerations, designers can create leather products that are both aesthetically pleasing and durable.

Determining Whether a Design is Suitable for Leather

Leather is a versatile material that can be used to create a wide range of products, including apparel, accessories, furniture, and automotive interiors. However, not every design is suitable for leather manufacturing.

One factor to consider when determining whether a design is suitable for leather is the thickness and texture of the leather.

Leather is available in different thicknesses and textures, and certain designs may require a specific type of leather to achieve the desired look and feel. For example, a thin, supple leather may be ideal for creating a lightweight jacket, while a thicker, more durable leather may be better suited for creating a backpack or briefcase.

Another consideration when designing for leather is the shape and structure of the product. Leather is a relatively rigid material and can be challenging to shape and manipulate. Designers need to consider the design's shape and structure when determining whether leather is the best material for the product.

Additionally, designers need to consider the cost of the materials and the manufacturing process. Leather is a premium material and using it for every design may not be cost-effective. Designers need to consider the tradeoffs between the cost of the materials and the perceived value of the final product.

Ultimately, while leather is a versatile material that can be used to create a wide range of products, not every design is suitable for leather manufacturing. Designers need to consider the thickness and texture of the leather, the shape and structure of the product, and the cost of the materials and manufacturing process when determining whether leather is the best material for the design.

How can Designers Ensure that their Leather Products are Sustainable?

Designers can take several steps to ensure that their leather products are sustainable:

- Select eco-friendly materials: Designers can select leather from eco-friendly sources that use sustainable and ethical production practices. For example, they can look for leather that is vegetable-tanned, as it uses natural materials and avoids harsh chemicals.

- Reduce waste: Designers can minimize waste during the production process by designing patterns that maximize the use of the leather, reducing scrap material. They can also consider using leather remnants or scraps for smaller projects or to create accessories, minimizing waste further.

- Design for durability: Designers can create designs that are long-lasting and durable, reducing the need for frequent replacements. This can be achieved by using high-quality materials, sturdy construction techniques, and considering the product's end-of-life.

- Consider the product's end-of-life: Designers can design products that are recyclable or biodegradable, reducing the environmental impact of their products when they reach the end of their useful life. They can also consider designing products that can be repaired or repurposed, extending their lifespan and reducing waste.

- Educate consumers: Designers can educate consumers about the environmental impact of their products and how to care for them sustainably. This can include providing care instructions to ensure products are maintained correctly and suggesting alternative uses for products at the end of their useful life.

Ultimately, designers can ensure that their leather products are sustainable by selecting eco-friendly materials, minimizing waste during production, designing for durability, considering the product's end-of-life, and educating consumers. By taking these steps, designers can create products that are both stylish and sustainable, contributing to a more environmentally responsible industry.

Is Leather More Expensive than Other Materials?

Leather is generally more expensive than many other materials used in manufacturing products. This is due to several factors, including the production process, material quality, and availability.

Firstly, leather production involves an extensive and intricate process that requires skilled labor and specialized equipment. The process starts with the animal hide, which is treated and processed to remove hair, fats, and other impurities. The hide is then tanned, a process that involves soaking the leather in chemicals to preserve and stabilize it. This process is time-consuming and requires significant energy and resources.

Secondly, the quality of the leather can also impact its price. High-quality leather comes from animals that have been well-raised, with a strong focus on their diet, cleanliness, and treatment. The hide must be free from scars, blemishes, and other imperfections, making it more valuable.

Lastly, leather is not as readily available as other materials such as cotton, polyester, or nylon. Leather is a byproduct of the meat industry, and the availability of quality hides can be limited. As a result, the price of leather can be influenced by supply and demand factors.

While leather may be more expensive than other materials, it is often considered a premium material due to its unique properties and durability. Leather products are often of high quality and are long-lasting, making them a good investment for consumers. Additionally, the value of leather products often increases over time, making them a desirable item to own and pass down through generations.

Overall, leather is generally more expensive than other materials due to its production process, material quality, and availability. While leather may be more expensive, it is often considered a premium material that offers unique properties and durability, making it a desirable investment for consumers.

How Can Designers Ensure that their Leather Products are of High Quality?

Designers can take several steps to ensure that their leather products are of high quality. These steps include:

Select High-Quality Leather:

Designers must choose high-quality leather, which is free from scars, blemishes, and other imperfections. They must also consider the texture, thickness, and durability of the leather when selecting it for their product.

Pay Attention to Details:

Designers must ensure that the design is executed with precision and attention to detail. They must carefully select and position the hardware, zippers, and stitching to ensure they enhance the overall design and durability of the product.

Use High-Quality Hardware and Accessories:

The use of high-quality hardware and accessories, such as buckles, clasps, and zippers, can significantly impact the overall quality of a leather product. Designers must ensure that they choose hardware and accessories that complement the design and are durable.

Choose the Right Construction Techniques:

The construction techniques used in the manufacturing process can impact the quality of the product. Designers must consider the best techniques for the design of their product, including the stitching pattern and the type of thread used.

Test the Product:

Designers must test their product thoroughly to ensure it meets their standards and the needs of the intended user. This may include durability testing, strength testing, and other quality control measures.

Consider Aftercare:

Designers must also consider how their product will be cared for after purchase. They can provide care instructions to customers, recommend specific leather care products, and suggest ways to prolong the life of the product.

Choosing high-quality leather, paying attention to details, utilizing high-quality hardware and accessories, picking the proper construction techniques, testing the product, and taking into account aftercare are all ways that designers can make sure their leather items are of a high caliber.

Furthermore, designers may create leather goods that meet their requirements, are robust, and offer value to their clients by following these procedures.

Challenges and Opportunities

Discussion of the challenges facing designers when designing for leather manufacturing, such as sustainability and ethical concerns

Exploration of opportunities for innovation and improvement in the leather industry through design, such as exploring new materials and manufacturing techniques

Designers face various challenges when designing for leather manufacturing, including sustainability and ethical concerns. Here are some of the challenges:

- Sustainability: Leather manufacturing can have significant environmental impacts, including water and energy consumption and greenhouse gas emissions. Designers must consider the sustainability of the materials used, the manufacturing process, and the end-of-life disposal of the product.

- Ethical concerns: The leather industry has come under scrutiny for its use of animal hides and skins, which raises ethical concerns. Designers must consider the ethical implications of their material selection and manufacturing processes, such as using alternative materials or sourcing hides and skins from ethical and sustainable sources.

- Cost: High-quality leather can be expensive, which can limit designers' options when designing products. Designers must consider the cost of materials, manufacturing processes, and labor when designing products that are both functional and affordable.

Despite these challenges, there are opportunities for innovation and improvement in the leather industry through design. Following, we've discussed some crucial opportunities:

- New materials: Designers can explore alternative materials that are more sustainable and ethical than traditional leather, such as plant-based leather alternatives like pineapple leather or mushroom leather.

- Sustainable manufacturing: Designers can explore more sustainable manufacturing techniques, such as using waterless tanning or recycling leather scraps.

- Circular economy: Designers can explore designing products for a circular economy, where products are designed to be reused or recycled at the end of their life cycle.

- Customization: Designers can explore customization options that allow customers to personalize their leather products, reducing waste and increasing customer satisfaction.

In conclusion, while designing for leather manufacturing presents obstacles for designers, such as sustainability and ethical issues, there are also chances for innovation and progress in the sector through design. To create more ethical and sustainable leather products, designers might look into alternative materials, green manufacturing methods, and circular economy models.

Case Studies

Following, we’ve discussed few examples of successful leather products and their design considerations:

Hermes Birkin Handbag:

The Hermes Birkin handbag is an iconic luxury product that is highly sought after by fashion enthusiasts worldwide. The Birkin bag is made from high-quality leather, such as calf leather or exotic leathers like crocodile, ostrich, or alligator.

Furthermore, the manufacturing process used is highly artisanal and involves extensive hand-stitching, which adds to the durability and craftsmanship of the bag. The bag's design features include a spacious interior, a sturdy top handle, and a lock and key closure that adds to the bag's security and exclusivity.

Red Wing Shoes:

Red Wing Shoes is a brand known for its high-quality leather boots. The boots are made from high-quality full-grain leather, which is highly durable and resistant to wear and tear.

Furthermore, the manufacturing process used involves a combination of machine and hand-stitching, which adds to the durability and craftsmanship of the boots. The boots' design features include a sturdy construction, a comfortable insole, and a slip-resistant sole, making them ideal for outdoor and industrial work.

Eames Lounge Chair:

The Eames Lounge Chair is an iconic piece of furniture designed by Charles and Ray Eames. The chair is made from high-quality leather, which is highly durable and comfortable.

Furthermore, the manufacturing process used involves a combination of machine and hand-stitching, which adds to the durability and craftsmanship of the chair. The chair's design features include a molded plywood frame, a plush cushion, and a swivel base, making it both comfortable and functional.

Coach Rogue Handbag:

The Coach Rogue handbag is a popular luxury product that is known for its high-quality leather and craftsmanship. The handbag is made from high-quality leather, such as calf leather or exotic leathers like crocodile or alligator.

The manufacturing process used involves a combination of machine and hand-stitching, which adds to the durability and craftsmanship of the bag. The bag's design features include a spacious interior, multiple pockets, and a detachable strap, making it both functional and stylish.

In summary, successful leather products share common design considerations, including high-quality material selection, careful manufacturing processes that balance machine and hand-stitching, and functional and aesthetically pleasing design features. These considerations ensure that the products are both durable and stylish, which adds value and appeal to consumers.

Wrapping Up

In conclusion, designing for leather manufacturing requires careful consideration of material selection, manufacturing processes, and design features to create products that are both functional and aesthetically pleasing.

Successful leather products, such as handbags, shoes, and furniture, share common design considerations, including high-quality material selection, careful manufacturing processes that balance machine and hand-stitching, and functional and aesthetically pleasing design features. However, designers face challenges such as sustainability and ethical concerns, cost, and customer demand for customization.

Despite these challenges, there are opportunities for innovation and improvement in the leather industry through design, including exploring alternative materials, sustainable manufacturing techniques, and circular economy models.

Ultimately, designers have a significant role to play in creating sustainable and ethical leather products that meet the needs and desires of consumers while minimizing environmental and social impacts.

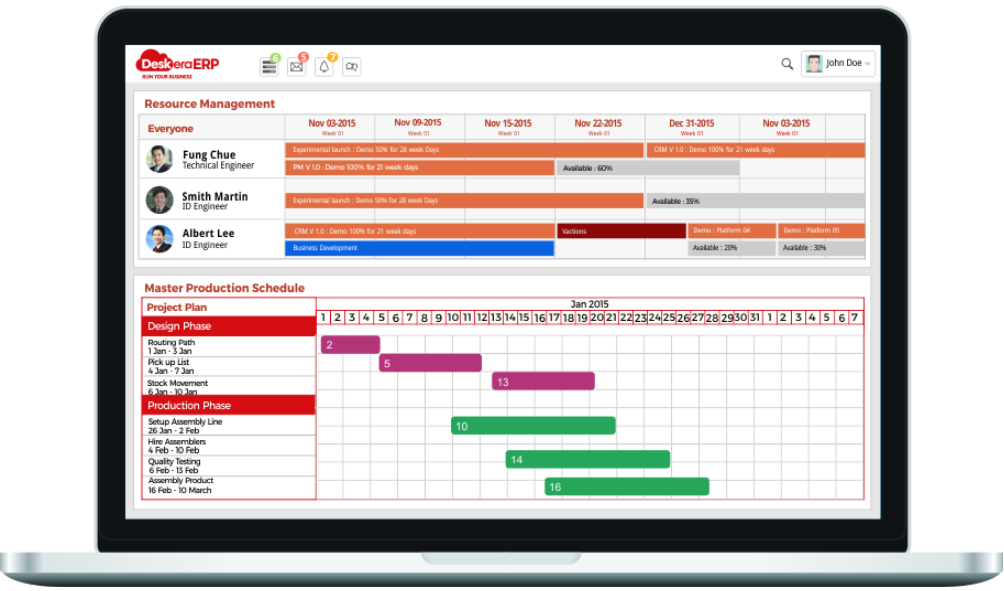

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Designing for leather manufacturing is the process of creating products made of leather while taking into consideration the manufacturing process. The design process for leather products is not just about the visual aesthetics of the final product but also about the practicalities of making it.

- Leather products are usually manufactured using traditional techniques, such as hand-stitching and cutting, which can be time-consuming and require skilled labor.

- Designers also need to consider the various manufacturing constraints, including time, cost, and labor. Leather products are often made using traditional techniques such as hand-stitching and cutting, which can be time-consuming and require skilled labor. Therefore, designers need to design their products in a way that is efficient and practical to produce, reducing production time and costs.

- Designers can ensure that their leather products are sustainable by selecting eco-friendly materials, minimizing waste during production, designing for durability, considering the product's end-of-life, and educating consumers. By taking these steps, designers can create products that are both stylish and sustainable, contributing to a more environmentally responsible industry.

- Choosing high-quality leather, paying attention to details, utilising high-quality hardware and accessories, picking the proper construction techniques, testing the product, and taking into account aftercare are all ways that designers can make sure their leather items are of a high caliber.

- If the manufacturing process is not taken into account during the design process, it can result in poor product quality. By considering manufacturing techniques during the design phase, designers can create products that can be manufactured with consistent quality, resulting in products that meet or exceed customer expectations.

- Designers must consider the ergonomics of the product to ensure that it is comfortable and functional. Factors such as weight distribution, padding, and grip must be taken into account to create a product that is both comfortable and functional.

Related Articles