Plastic manufacturing is an important industry for several reasons. It plays a key role in the production of consumer goods and medical supplies, providing materials for medical equipment, consumer electronics, and consumer packaging.

Plastic manufacturing is also a major contributor to the global economy, providing jobs and generating revenues. Additionally, plastic is a versatile material that can be used to create a wide range of products, from toys and housewares to medical devices and automotive parts. Finally, plastic manufacturing is a major contributor to reducing the environmental impact of products, as plastic is a durable, lightweight, and recyclable material.

This article covers the following:

- Overview of the Plastic Manufacturing Industry

- Trends in Plastic Manufacturing

- Challenges in Plastic Manufacturing

- Benefits of Plastic Manufacturing

- Opportunities in the plastic manufacturing industry

- How can Deskera assist you?

Overview of the Plastic Manufacturing Industry

The plastic manufacturing industry is one of the most important and widely used industries in the world today. It is responsible for producing a wide range of products, from everyday items like bottles and containers to large-scale industrial parts.

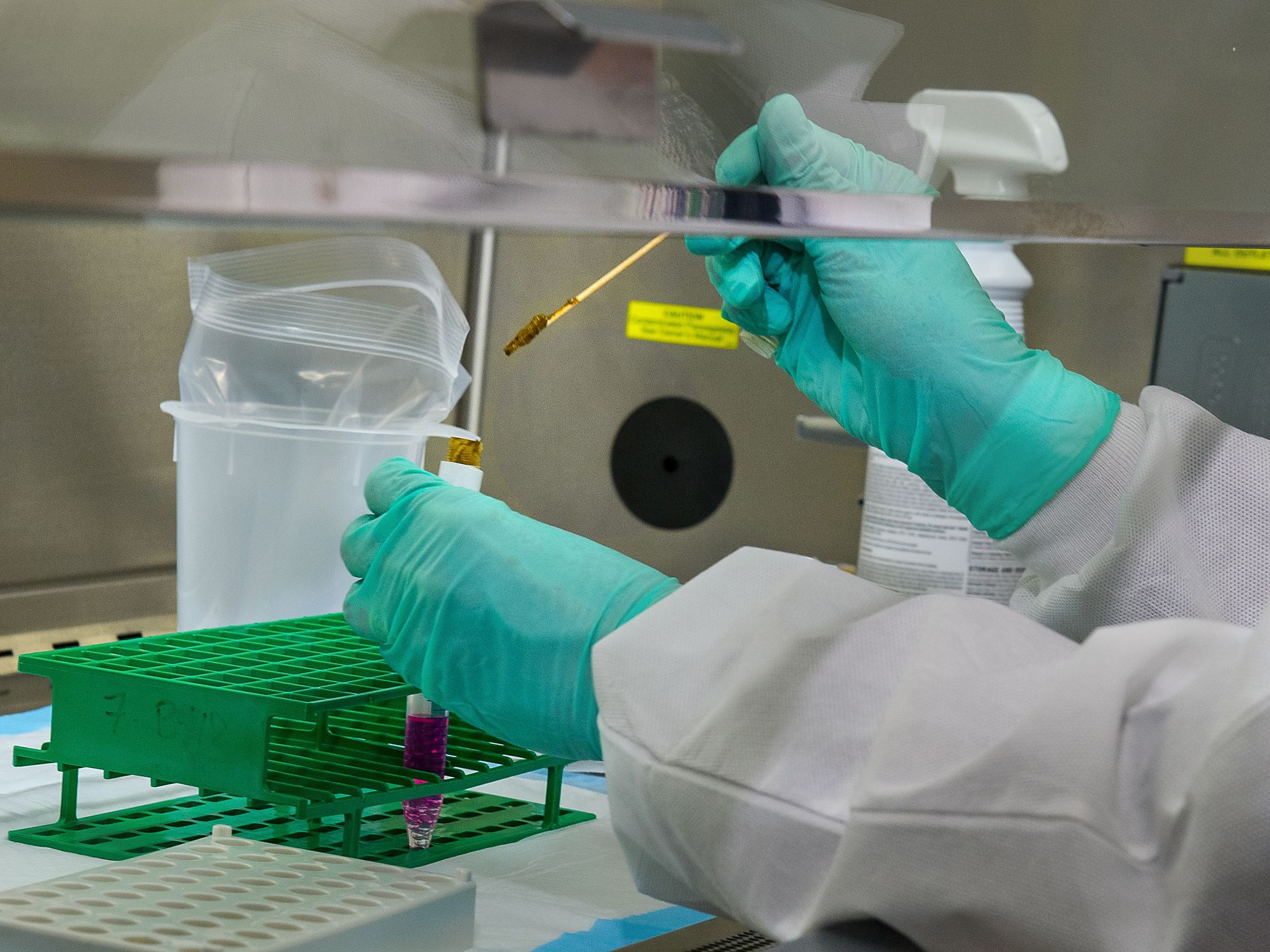

It is also one of the most important sources of employment in many countries, and is a major contributor to global economic growth. The plastic manufacturing process involves the conversion of raw materials into finished plastic products.

This is done through a range of different processes, including injection moulding, extrusion, blow moulding and thermoforming. Each process has its own unique characteristics, which make it suitable for the production of specific products.

The raw materials used in the plastic manufacturing process are typically polymers, which are organic compounds made up of long chains of atoms linked together. Common polymers used in the industry include polyethylene, polypropylene, polystyrene and polyvinyl chloride.

Other materials can also be used, such as rubber, metals and ceramics. The process of plastic manufacturing begins with the selection of the appropriate raw materials and their preparation for the production process.

This includes melting and mixing the polymers, as well as adding other additives such as colourants, fillers and plasticizers. Once the materials are ready, they are fed into a moulding machine and formed into the desired shape.

The plastic is then cooled and the finished product is removed from the mould. The plastic manufacturing industry is highly regulated, and companies must adhere to strict safety and quality standards in order to produce products that meet the needs of their customers.

This includes ensuring that the products are produced in a safe and hygienic environment, as well as ensuring that the products are of the highest quality. The plastic manufacturing industry is constantly evolving and changing, as new technology and materials become available.

This means that the industry is always looking for new ways to produce high-quality products at a lower cost. This has led to the development of a range of new processes and technologies, such as 3D printing and laser cutting, which are becoming increasingly popular in the industry.

The plastic manufacturing industry is an essential part of the global economy, and it is likely to continue to grow in the future. It is a highly competitive industry, and companies must stay ahead of the competition in order to remain successful. As such, companies must continually innovate and develop new products and processes in order to stay ahead of the curve.

Trends in Plastic Manufacturing

Plastics are one of the most versatile materials in the world. They are used in a variety of industries, from engineering and manufacturing to consumer products and packaging. As such, plastic manufacturing is an important industry that is constantly evolving to keep up with new trends and technologies.

First, sustainability is becoming an increasingly important factor for plastic manufacturing. As the world’s population grows and resources become scarcer, companies are being asked to create products that are more sustainable and eco-friendly.

This means using less energy, water, and other resources during the manufacturing process, as well as using recycled materials and reducing waste. Companies are also looking for ways to make their products more recyclable and biodegradable.

Another trend in plastic manufacturing is the use of 3D printing technology. 3D printing allows for the quick and efficient production of complex parts, which can save time and money in the manufacturing process.

It also allows for the production of customized parts, as well as the use of different materials, such as metal, plastic, and rubber. Finally, automation is becoming increasingly important in plastic manufacturing.

Automation can reduce labor costs and improve efficiency, as well as reduce waste and errors. Automation can also be used to monitor and control the manufacturing process, ensuring that quality standards are met.

These are just a few of the trends in plastic manufacturing that are emerging. As the industry continues to evolve, companies will need to stay up to date with the latest technologies and trends in order to remain competitive. For now, sustainability, 3D printing, and automation are some of the key trends to watch.

Challenges in Plastic Manufacturing

Plastic manufacturing is a complex process that requires precision and accuracy. It involves taking raw materials and transforming them into finished products. The production of plastic components can be a tricky process, with many challenges that may arise along the way. Here are some of the biggest challenges that manufacturers face when producing plastic components.

Design Complexity

Plastic components often require complex designs, which can make them difficult to produce. Design complexity can lead to errors and delays in production, as well as higher costs.

Quality Control

Quality control is a key challenge in plastic manufacturing. Quality control is the process of ensuring that the finished product meets a certain level of quality. Quality control can be difficult to maintain in plastic manufacturing due to variations in the manufacturing process.

Tooling

Tooling is a crucial part of plastic manufacturing as it is used to shape and form plastic components. Tooling can be expensive and time-consuming, and if it is not properly maintained it can affect the quality of the finished product.

Tolerances

Tolerances refer to the allowable amount of variation from the design specification in the finished product. If tolerances are not properly maintained, it can lead to quality issues and defects in the finished product.

Waste

Waste can be a major issue in plastic manufacturing as it can lead to higher costs and wasted materials. Waste is often caused by errors in the manufacturing process or by faulty tooling.

Cost

The cost of plastic manufacturing can be a major challenge as it involves many factors including raw materials, tooling, waste, and labor. Finding ways to reduce costs without sacrificing quality can be difficult.

These are some of the biggest challenges that manufacturers face when producing plastic components. By understanding the challenges and taking steps to address them, manufacturers can ensure that their plastic components are produced to a high standard.

Benefits of Plastic Manufacturing

Plastic is one of the most widely used materials in the world, and the plastic manufacturing industry plays an important role in global markets. From packaging to automotive parts, plastic is used in virtually every industry and has become a key component of modern life. But what are the benefits of plastic manufacturing? Let’s take a look.

Cost-Effective

One of the major benefits of plastic manufacturing is its cost-effectiveness. Compared to other materials, such as metal or wood, plastic is often cheaper to produce and can be molded into any shape or size, making it an ideal choice for many applications.

Durability

Plastic is known for its durability and can often withstand extreme temperatures and wear and tear for long periods of time. This makes it an ideal choice for products that need to be designed to last.

Lightweight

Plastic is much lighter than other materials, such as metal or wood, making it easier to transport and handle. This makes it perfect for products that need to be moved around often or for large projects, such as construction.

Versatility

Plastic can be molded into virtually any shape or size, making it perfect for custom applications. This makes it easier to design and manufacture complex products, such as medical devices or automotive parts.

Low Maintenance

Plastic products are often low maintenance and require little cleaning or upkeep. This makes them a great choice for products that need to be used frequently and without much hassle.

The plastic manufacturing industry has revolutionized the way products are designed and manufactured. From cost-effectiveness to its versatility, plastic offers a number of benefits that make it one of the most popular materials used in the world today.

Opportunities in the plastic manufacturing industry

The plastic manufacturing industry has seen a lot of growth over the past few decades. It is a booming industry that offers a number of opportunities for entrepreneurs looking to get into the business.

Plastic manufacturing is a process of transforming raw materials such as polymers, resins and additives into finished products. These products can be either plastic products or components that are used in the manufacturing of other products.

The possibilities are virtually endless when it comes to plastic manufacturing. The plastic manufacturing industry is an ideal sector for entrepreneurs who are looking to launch their own businesses.

It requires relatively low start-up costs and minimal technical expertise, making it an attractive option for those just starting. Additionally, the industry is relatively flexible, allowing entrepreneurs to specialize in a particular type of plastic product or process.

One of the most attractive aspects of the plastic manufacturing industry is the fact that it is largely recession-proof. Demand for plastic products tends to remain relatively steady regardless of economic conditions, as it is used in a wide variety of industries.

This makes the industry a great option for entrepreneurs who want to take advantage of potential profit opportunities without having to worry about market fluctuations. The plastic manufacturing industry is also a great sector for those looking to expand their business.

As the industry continues to grow, more people are looking to get involved in the manufacturing process. This means that there are plenty of opportunities for those looking to get involved in the industry.

Finally, plastic manufacturing is a great way to diversify one’s portfolio. It is a relatively low-risk sector, and it provides entrepreneurs with the ability to create a number of different products.

This makes it an ideal investment for those looking to diversify their portfolio and reduce risk. Overall, the plastic manufacturing industry is a great opportunity for entrepreneurs looking to get involved in a booming industry.

With relatively low start-up costs and minimal technical expertise required, it is a great option for those looking to get into the business. Additionally, it is largely recession-proof and provides entrepreneurs with the ability to create a number of different products.

Finally, it is a great way to diversify one’s portfolio and reduce risk. All in all, the plastic manufacturing industry is an attractive option for entrepreneurs looking to get into the business.

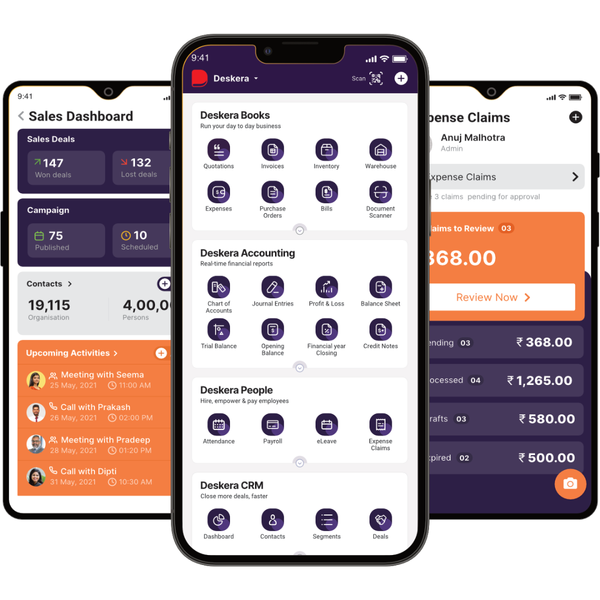

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Plastic components often require complex designs, which can make them difficult to produce.

- The possibilities are virtually endless when it comes to plastic manufacturing.

- Quality control is the process of ensuring that the finished product meets a certain level of quality.

- Plastic is known for its durability and can often withstand extreme temperatures and wear and tear for long periods of time.

- Plastic can be molded into virtually any shape or size, making it perfect for custom applications.

Related Articles: