Wood is one of the most popular materials used in manufacturing. From furniture to flooring to building materials, wood is a resource that is not only versatile but also renewable. As a result, many companies are turning to recycling wood in their production processes to both reduce their environmental impact and conserve resources.

This article covers the following:

- Benefits of Wood Manufacturing

- Wood Manufacturing Process

- Wood Manufacturing Tools and Techniques

- Different Types of Wood Manufacturing

- Regulations and Guidelines for Wood Manufacturing

- Sustainability in Wood Manufacturing

- Recycling of Wood

- Advantages of Recycling Wood

- Disadvantages of Recycling Wood

- Steps to Recycle Wood

- Reusing and Refurbishing Wood

- Wood Waste Management Strategies

- Innovations in Wood Manufacturing and Recycling

- Wood Manufacturing and Recycling Around the World

- Future of Wood Manufacturing and Recycling

Benefits of Wood Manufacturing

Wood manufacturing is a process that involves the transformation of raw materials into usable and versatile products. It is an essential part of many industries, and the benefits of wood manufacturing are far-reaching. From furniture to construction materials, wood is an integral part of our lives. Here are some of the benefits of wood manufacturing:

Eco-Friendly

Wood is a renewable resource, and its manufacturing process is relatively eco-friendly. Wood production does not produce pollutants or generate greenhouse gases. It is also a sustainable material, meaning that it can be used over and over again without depleting natural resources.

Cost-Effective

Wood is an affordable material when compared to other materials like metal or plastic. This makes it a great choice for those looking to save money on manufacturing costs.

Versatility

Wood is one of the most versatile materials out there. With its natural strength and malleability, wood can be used to create a variety of products, from furniture to flooring.

Durability

Wood is a strong and durable material, making it ideal for use in high-wear applications like flooring and furniture.

Aesthetics

Wood has a natural beauty, making it a great choice for a variety of applications. It can be stained or painted to create a wide range of aesthetic looks. Wood manufacturing is a great choice for those looking to create products with an eco-friendly, cost-effective, versatile, durable, and aesthetically pleasing material.

Wood is an integral part of many industries, and its manufacturing process has many benefits. From furniture to construction materials, wood is an essential part of our lives.

Wood Manufacturing Process

Wood manufacturing is a process of transforming raw timber into a variety of products, such as furniture, cabinets, doors, windows, and other wooden items. It involves a variety of steps, from selecting the right type of wood to the final product.

The first step in the wood manufacturing process is to select the right kind of wood. Depending on the type of product being created, different kinds of wood can be used.

Hardwoods such as oak, maple, and cherry are commonly used for furniture and cabinets, while softwoods such as pine, cedar, and fir are better suited for doors and windows.

Once the proper wood has been selected, the wood needs to be cut into the desired shape. This is typically done using a saw or other cutting tool. The wood is then planed, which means that it is sanded down to a smoother surface.

This step helps to create a smoother finish and makes the wood easier to work with. Once the wood has been planned, it is ready for staining or painting. This is done to give the wood a desired color and finish.

Staining is often used to give the wood a darker color, while painting is used to give the wood a brighter, more vibrant look. Once the wood has been stained or painted, it is ready for assembly. This is done by fastening the pieces together with screws, nails, or other fastening materials. The pieces of wood are then glued together to form the desired product.

The final step in the wood manufacturing process is finishing. This is done to give the product a smooth, professional look. The finishing process can involve sanding, staining, and varnishing the wood.

Once the product is finished, it is ready for sale. Wood manufacturing is an intricate process that requires skill and precision. By following these steps, manufacturers can create high-quality products that are attractive, durable, and long-lasting. With the right tools and materials, anyone can become a successful wood manufacturer.

Wood Manufacturing Tools and Techniques

Wood manufacturing is a craft that has been around for centuries and continues to be used today. Whether you’re a professional woodworker or a hobbyist, having the right tools and techniques can help you create beautiful and durable pieces of furniture, sculptures, and other products.

When it comes to wood manufacturing, there are a variety of tools and techniques available for use. The most important tool for wood manufacturing is the saw. There are a variety of saws available, from the traditional hand saw to the more modern power saws.

Each saw has its own unique uses and applications, so it’s important to understand the different types of saws and how to use them properly. Another important tool for wood manufacturing is the chisel.

A chisel is used to shape and carve the wood into different shapes and sizes. Chisels come in a variety of sizes, so it’s important to know how to use each one correctly. Additionally, chisels should always be sharpened regularly to ensure they are working properly.

In addition to saws and chisels, other tools used in wood manufacturing include routers, drills, sanders, and planers. Routers are used to create grooves and shapes in the wood, while drills are used to create holes.

Sanders is used to smoothing the wood’s surface, and planers are used to create even surfaces. Each of these tools requires a specific set of skills and knowledge to use properly, so it’s important to understand how to use them before attempting any woodworking projects.

Finally, there are a variety of techniques and methods for wood manufacturing. A popular technique is called joinery, which is the process of joining two pieces of wood together using nails, screws, or glue.

Joinery is a very important technique for woodworking because it allows for stronger, longer-lasting wood pieces. Wood manufacturing is a craft that requires patience, skill, and knowledge.

With the right tools and techniques, it’s possible to create beautiful and durable pieces of furniture and sculptures. Whether you’re an experienced woodworker or just getting started, it’s important to take the time to learn the different tools and techniques available so you can create the best piece of furniture or sculpture possible.

Different Types of Wood Manufacturing

Wood manufacturing is an industry that has been around for centuries. It involves the production of products from wood, such as lumber, furniture, and other products. The different types of wood manufacturing processes depend on the type of product being created and the desired outcome.

One of the most common types of wood manufacturing is sawmilling. This is the process of cutting logs into boards, planks, and other shapes. Sawmills use circular saws, band saws, and other cutting tools to create their products.

Sawmills can create a variety of products, from construction lumber to furniture. Another type of wood manufacturing is woodworking. This involves the shaping of wood into furniture, cabinets, and other products.

It typically requires the use of hand tools, such as chisels, planes, and saws. Woodworking can also involve the use of power tools, such as routers, sanders, and drills. A third type of wood manufacturing is veneering.

This involves the application of thin sheets of wood onto other pieces of wood. Veneering can be used to create a variety of products, such as furniture, cabinets, and paneling.

Veneers can also be used to enhance the appearance and quality of wood products. Finally, wood finishing is the process of coating wood products with a finish to protect it from damage. Finishes can include paint, varnish, lacquer, and others.

The type of finish chosen depends on the product and the desired outcome. Wood manufacturing is a broad industry with a variety of processes used to create products from wood.

The different types of wood manufacturing processes are determined by the type of product being created and the desired outcome. Sawmills, woodworking, veneering, and wood finishing are all processes used in the wood manufacturing industry.

Regulations and Guidelines for Wood Manufacturing

Wood is a natural resource that has been used in manufacturing for centuries. It is a versatile material that can be used to make furniture, construction materials, and even musical instruments.

As with any industry, there are regulations and guidelines that must be followed to ensure the safety and quality of wood products. Understanding and adhering to these regulations can help wood manufacturers stay compliant and produce the highest quality products for their customers.

Wood Manufacturing Regulations

When it comes to wood manufacturing, manufacturers must adhere to regulations set forth by their local, state, and federal governments. These regulations vary depending on the type of product being made, where it is being made, and who will be using it. Some of the most common wood manufacturing regulations include:

Fire Safety

Fire safety regulations vary from jurisdiction to jurisdiction, but they are all designed to ensure the safety of the public and the factory workers. Fire safety regulations often include requirements for fire extinguishers, fire doors, and fire suppression systems.

Air Quality

Wood manufacturing factories must meet certain air quality standards in order to protect workers and the public from hazardous emissions. Regulations may include requirements for air filtration systems, ventilation systems, and other measures to reduce the amount of dust, smoke, and other pollutants emitted into the air.

Chemical Safety

Many wood manufacturing processes involve the use of hazardous chemicals. Regulations may include requirements for proper storage, labeling, and disposal of these chemicals.

Environmental Protection

Wood manufacturing often involves the use of hazardous materials and processes, so it is important that manufacturers take steps to reduce their environmental impact. Regulations may include requirements for waste management, pollution control, and energy efficiency.

Guidelines for Wood Manufacturing

In addition to regulations, there are also a number of industry guidelines that wood manufacturers should follow in order to produce the highest quality products. These guidelines include:

Quality Control

Quality control is essential for producing high-quality wood products. Manufacturers should have a system in place to ensure that all products meet their specifications and are of the highest quality.

Design

Design is a key factor in producing wood products that are both functional and aesthetically pleasing. Manufacturers should take into account the design elements that will best meet their customers’ needs.

Material Selection

The type of wood used in a product can have a major impact on its quality and durability. Manufacturers should carefully select the materials they use in order to ensure the best possible outcome.

Process Control

Process control is essential for ensuring that the production process is efficient and cost-effective. Manufacturers should have a system in place to track and monitor the production process in order to identify any potential issues.

Adhering to the regulations and guidelines for wood manufacturing is essential for producing quality products that meet the needs of customers and comply with safety standards.

By understanding and following these regulations and guidelines, wood manufacturers can ensure that they are producing the highest quality products in the most efficient and cost-effective manner.

Sustainability in Wood Manufacturing

Sustainability is becoming increasingly important in the world of wood manufacturing. As our planet’s resources become more scarce, manufacturers are looking for ways to reduce their environmental impact and create products with a lower carbon footprint.

In this blog post, we’ll take a look at the importance of sustainability in wood manufacturing, as well as some of the ways that manufacturers are addressing this issue.

The first step in making wood products more sustainable is to source raw materials responsibly. This means that companies should only use wood from responsibly managed forests, ensuring that the wood is harvested sustainably and in a way that preserves the environment.

By doing so, these companies are supporting the health of the forests and reducing the need for additional land to be cleared for the purpose of harvesting. In addition to sourcing responsibly, many companies are also looking for ways to reduce the amount of energy and water used during the manufacturing process.

By utilizing energy-efficient equipment and reducing waste, companies can reduce their environmental impact and create greener products. Finally, many companies are also looking for ways to make their products more durable and longer-lasting.

By sourcing higher-quality materials and utilizing advanced manufacturing techniques, companies can create products that are designed to last. This reduces the need for new materials and energy to produce replacements, ultimately making the products more sustainable.

These are just a few of the ways that wood manufacturing companies are making their products more sustainable. By sourcing responsibly, reducing energy and water use, and creating longer-lasting products, manufacturers can reduce their environmental impact and create products that are more sustainable. As more companies commit to sustainability, wood manufacturing can be a great way to create products that are both beautiful and eco-friendly.

Recycling of Wood

Wood is one of the most widely used materials in the world, and it’s no surprise that it’s also one of the most commonly recycled materials. Recycling wood has become increasingly important in recent years as the demand for wood has grown rapidly and the supply of natural resources has become limited.

Wood recycling helps to conserve natural resources and reduce the production of harmful emissions that can cause air pollution. The process of wood recycling begins with the collection of wood waste.

This can be done through a variety of methods, including wood curbside pickup, wood drop-off centers, or wood waste collection from sawmills and woodworking shops. The wood is then sorted and separated according to material type and size.

The sorted wood is then taken to a recycling center where it is ground into small pieces and used as fuel or mulch. Wood recycling has many environmental benefits. It helps to reduce the amount of waste that is sent to landfills, thereby reducing the amount of space used by landfills.

It also helps to reduce the amount of energy required to produce wood products, as the wood does not need to be heated or treated with chemicals to make it suitable for use. Additionally, wood recycling helps to reduce the amount of air pollution caused by the burning of wood in the production of energy. Wood recycling also has economic benefits.

By recycling wood, manufacturers can reduce their costs of production and create lower-cost products. Additionally, recycled wood can be used for a variety of purposes, such as creating furniture, flooring, and even construction materials.

Overall, wood recycling is an important part of the effort to conserve natural resources and reduce air pollution. By making use of recycled wood, manufacturers can save money while reducing their environmental impact. Additionally, by using recycled wood, consumers can help to reduce the amount of waste that goes to landfills and help to create a more sustainable future.

Advantages of Recycling Wood

Recycling wood is an important way to conserve natural resources and reduce waste. Not only does it save trees from being cut down, but it also reduces the amount of wood that is sent to landfills or incinerators.

Additionally, recycled wood can be used to create a variety of products that are both practical and beautiful. Here are some of the advantages of recycling wood. 1.

Environmental Benefits

Recycling wood conserves natural resources like trees, reduces air and water pollution, and helps to reduce the number of greenhouse gases that are released into the atmosphere. Additionally, using recycled wood can reduce the demand for virgin wood, ensuring that our forests will remain healthy and thriving.

Cost Savings

Using recycled wood can help to save money in a variety of ways. For example, recycled wood can be used to create furniture, cabinetry, and other products that are much less expensive than their counterparts made from new materials. Additionally, using recycled wood can reduce the need for expensive disposal and transportation costs, which can add up quickly.

Unique Characteristics

Recycled wood often has unique characteristics that make it desirable for use in furniture, cabinetry, and other products. For example, it may have a unique patina that cannot be replicated with new wood. Additionally, the wood may have markings or imperfections that give it a unique look and feel.

Sustainability

Using recycled wood helps to ensure that our forests will remain healthy and sustainable. Additionally, recycling wood helps to preserve the natural beauty of our forests, allowing future generations to enjoy the same stunning views that we do today.

Recycling wood is a great way to conserve natural resources, save money, and create unique and beautiful products. By using recycled wood, we can all do our part to ensure that our forests remain healthy and sustainable for generations to come.

Disadvantages of Recycling Wood

Recycling wood is a great way to reduce waste and conserve resources, but there are a few potential disadvantages to consider before you decide to recycle wood. The first disadvantage is that recycled wood is often not as strong or durable as new wood.

This is because recycling wood involves breaking down existing wood and reassembling it rather than creating completely new wood from scratch. As a result, recycled wood may not be as structurally sound as new wood, which could be a problem if it is to be used for furniture or other items that need to be strong and reliable.

Another disadvantage of recycling wood is that the cost may be higher than buying new wood. This is because recycling wood is a labor-intensive process that requires specialized equipment and expertise.

This added cost may be enough to make it not worth the effort for some people. Finally, there is the risk of contamination when recycling wood. Since recycled wood has been previously used, there is a possibility that it could be contaminated with hazardous materials like lead paint, asbestos, or formaldehyde.

These materials can be dangerous if inhaled or touched, so it is important to make sure that any recycled wood is properly tested and treated to ensure it is safe to use. Overall, recycling wood has its benefits, but it also has some potential drawbacks. It is important to weigh these factors carefully before deciding if recycling wood is the best choice for your project.

Steps to Recycle Wood

Recycling wood is an important part of sustainable manufacturing, helping to reduce the environmental impact of manufacturing products from new sources of wood. There are several steps that can be taken to ensure that wood is recycled in an efficient, effective way.

Source Wood Responsibly

The first step in the recycling process is to source wood responsibly. This means avoiding wood that has been treated with chemicals, such as those used for pressure-treating wood, as well as wood that has been sourced from unsustainable sources, such as old-growth forests. Responsible sourcing also means avoiding wood from sources that have been illegally logged.

Sort and Separate

Once you have sourced the wood, it needs to be sorted and separated. This involves separating different types of wood, such as softwood and hardwood, as well as separating different types of wood products, such as sawdust, chips, and logs.

Salvage and Reuse

Once the wood has been sorted and separated, it can be salvaged and reused. This includes salvaging usable lumber and boards, as well as salvaging smaller pieces and sawdust for reuse in other projects.

Repurpose and Upcycle

After salvaging and reusing wood, it can be repurposed and upcycled. This includes creating new products from salvaged wood pieces, such as furniture and home decor items.

Dispose of Waste Properly

After salvaging and upcycling, the remaining waste should be disposed of properly. This includes taking the waste to a recycling center or other facility that can properly handle the waste.

Recycling wood is an important part of sustainable manufacturing and helps to reduce the environmental impact of producing products from new sources of wood. By following these steps, manufacturers can ensure that their wood is recycled in an efficient, effective way.

Reusing and Refurbishing Wood

Reusing and refurbishing wood is a great way to reduce waste and conserve natural resources. With the right tools and techniques, it’s possible to make an old piece of wood look new or even better than it originally did.

Wood is an incredibly versatile material that can be recycled, reused, and refurbished in a variety of ways. Refurbishing wood is a great way to give old furniture and other wood items a new life.

The process can involve anything from a simple sanding and painting job to a complete overhaul and reinvention of an item. The first step in refurbishing wood is to assess the condition of the item.

Depending on the item’s condition, it may need to be sanded, stained, or treated with a sealant. Once the item is cleaned and prepped, it’s time for the fun part – giving the item a new look.

This can be done by painting, staining, or even using a wood-burning tool to create a unique design. When refurbishing wood, it’s important to use the right tools and techniques.

Make sure to use sandpaper that’s appropriate for the item’s surface, and use a quality paintbrush or roller to get the best results. When staining wood, use a quality stain and ensure that the wood is completely dry before applying the stain. To protect the wood, a sealant can be applied.

With the right tools, techniques, and a bit of creativity, it’s possible to give old wood items a new lease on life. Reusing and refurbishing wood is a great way to reduce waste and help conserve natural resources. Not only does it save money, it can also give a unique and creative touch to any home.

Wood Waste Management Strategies

Wood waste is a significant environmental issue, as it not only affects the environment, but can also cause health and safety issues. To ensure the safe and efficient management of wood waste, it is important to understand the different types of wood waste, the best methods for managing it, and the potential health and safety risks associated with its improper disposal.

Types of Wood Waste

Wood waste can come from a variety of sources, including sawmills, woodworking shops, furniture manufacturers, and construction sites. It can range from small chips and sawdust to large pieces of wood.

Sawdust is the most common type of wood waste, as it is the byproduct of cutting and shaping wood. This can be used for mulch, animal bedding, and fuel for wood-burning stoves.

Wood Waste Management Strategies

The first step in managing wood waste is to reduce the amount generated. This can be done through woodworking techniques that reduce the amount of sawdust produced, such as using a jointer or planer rather than a saw.

Additionally, reusing or recycling wood waste can help to reduce the amount of waste that needs to be disposed of. One of the best ways to manage wood waste is through composting.

Composting wood waste can turn it into a useful soil amendment, helping to improve soil fertility and reduce soil erosion. Composting can also help to reduce the amount of wood waste that needs to be disposed of, as it breaks down the wood into smaller pieces that are easier to dispose of.

When it comes to disposing of wood waste, it is important to use the right method. Burning wood waste can create air pollution and should only be done in an enclosed, approved burner.

Landfilling is another option, but it can be costly and can take up valuable space. It’s important to check with local regulations before disposing of wood waste in this manner. Health and Safety Risks Wood waste can pose a variety of health and safety risks. Sawdust is the most common type of wood waste, and it can cause respiratory irritation and allergic reactions in some people.

Additionally, wood waste can contain hazardous chemicals, such as heavy metals and formaldehyde. If these chemicals are not disposed of properly, they can contaminate the air and water, creating a health hazard.

It’s also important to be aware of the potential fire risks associated with wood waste. Wood waste can easily catch fire, and if not managed properly, it can cause a serious fire hazard.

It’s important to ensure that wood waste is kept away from any sources of ignition, such as matches, lighters, and cigarettes. Wood waste management is essential for the safe and efficient disposal of wood waste.

By understanding the different types of wood waste, the best methods for managing it, and the potential health and safety risks associated with its improper disposal, it is possible to ensure that wood waste is managed in an environmentally responsible way.

Innovations in Wood Manufacturing and Recycling

Innovation in wood manufacturing and recycling is becoming increasingly important for businesses to stay competitive in the ever-changing market. With the rising demand for sustainable materials, wood has become a popular choice for many companies.

As environmental awareness increases, so too does the need for innovative wood manufacturing and recycling processes. Wood is a renewable resource, making it an ideal choice for businesses looking to reduce their carbon footprint.

It is also one of the most versatile materials, with the ability to be crafted into a variety of products. From furniture to flooring, wood is a popular choice for many consumers. One of the most innovative wood manufacturing processes is wood pelletization.

This process turns wood chips and sawdust into a small, uniform pellet that can be used in a variety of applications. This process not only reduces the amount of waste from wood manufacturing but also reduces the cost of production since the pellets are ready to use.

Printing on wood is another innovative process used in wood manufacturing. This process utilizes digital printing technology to create intricate designs and patterns on wood surfaces.

This process is not only used for decorative purposes, but it can also be used to create labels, tags, and other promotional materials. Finally, wood recycling is becoming increasingly popular among businesses.

This process is designed to reduce the amount of wood waste by recycling it into usable products. Companies are able to use reclaimed wood to create furniture, flooring, and other products.

This process helps to reduce the amount of wood waste going into the trash and helps to conserve natural resources. Innovation in wood manufacturing and recycling is essential for businesses to stay competitive in the ever-changing market.

With the growing demand for sustainable materials, wood is becoming an increasingly popular choice for many businesses. By taking advantage of innovative processes like wood pelletization, digital printing, and wood recycling, businesses can reduce their carbon footprint while creating a range of quality products

Wood Manufacturing and Recycling Around the World

Wood manufacturing has been around for centuries and is one of the oldest industries in the world. It is an important part of the global economy and provides a variety of products and services that are used in everyday life.

Wood is a renewable resource and can be harvested sustainably if managed properly. In addition, wood manufacturing is an important source of jobs and economic activity in many parts of the world.

The process of wood manufacturing involves the cutting, shaping, and finishing of wood to create various objects and products. This is done by using various tools and techniques, such as saws, planers, and lathes.

The materials used in wood manufacturing can include both hardwoods and softwoods, which come from different species of trees. Hardwoods, such as oak and walnut, are generally more expensive and are typically used to make furniture or cabinets.

Softwoods, such as pine, are usually less expensive and are used to make items such as doors, windows, and flooring. The wood manufacturing industry has come a long way in terms of sustainability and recycling.

In many countries, wood manufacturers are required to follow certain regulations and standards that ensure the wood they use is harvested and processed in an environmentally responsible manner.

Many manufacturers also recycle their wood waste, which helps to reduce the amount of wood that ends up in landfills. In addition to wood manufacturing, wood recycling is becoming increasingly popular around the world.

This is because wood recycling helps to reduce the amount of wood that is wasted, which helps to reduce the amount of greenhouse gas emissions from the burning of wood.

Wood recycling also helps to conserve resources and reduce the amount of energy that is used to produce new wood products. Wood manufacturing and recycling are important parts of the global economy and are essential for the sustainability of our planet.

It is important for everyone to be aware of the importance of preserving our forests and to understand the importance of recycling and reusing wood products. This is why it is important to support companies that are committed to sustainable wood manufacturing and recycling practices.

Future of Wood Manufacturing and Recycling

The future of wood manufacturing and recycling is an intriguing topic, and one that will have a major impact on the environment in years to come. With the world’s population growing exponentially, it is essential that sustainable practices are put in place in order to preserve the world’s natural resources.

One way to do this is through wood manufacturing and recycling. Wood manufacturing involves the process of creating products from wood. This includes everything from furniture to flooring and even building materials.

Wood manufacturers use a variety of techniques to make wood products that are both durable and aesthetically pleasing. In addition to these traditional methods, wood manufacturers are now also exploring the use of 3D printing and other new technologies in order to create unique products.

The recycling of wood is also becoming increasingly popular. This involves taking old wood products and reusing them for new purposes. The advantage of this is that it helps to reduce the amount of waste going into landfills, as well as reducing the need to harvest new wood.

In addition, many companies are now using recycled wood in their products, which helps to reduce the amount of energy used in the manufacturing process. The future of wood manufacturing and recycling looks promising.

As technology advances, new methods are being developed that will allow for the creation of even more unique and sustainable products. In addition, many companies are now focusing on using sustainable materials in their production processes, which will help to reduce the environmental impact of wood manufacturing.

Finally, with the growing awareness of the importance of sustainability, more and more people are looking for ways to incorporate sustainable practices into their lives. This means that wood manufacturing and recycling could soon become a major part of the future of our planet.

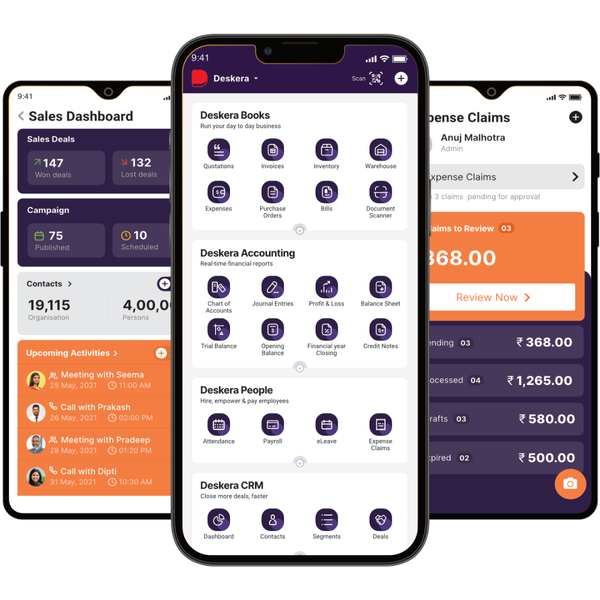

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Wood manufacturing is a process that involves the transformation of raw materials into usable and versatile products.

- It’s important to ensure that wood waste is kept away from any sources of ignition, such as matches, lighters, and cigarettes.

- Wood manufacturing has been around for centuries and is one of the oldest industries in the world.

- With the growing demand for sustainable materials, wood is becoming an increasingly popular choice for many businesses.

- The first step in managing wood waste is to reduce the amount generated. This can be done through woodworking techniques that reduce the amount of sawdust produced, such as using a jointer or planer rather than a saw.

Related Articles: