Chemical manufacturers play a crucial role in providing essential products for modern society. However, with this responsibility comes the need to adhere to complex environmental regulations.

As the world becomes increasingly focused on sustainability and protecting the environment, chemical manufacturers must stay informed about these regulations to ensure compliance and minimize their environmental impact.

Importance of Environmental Regulations for Chemical Manufacturers

In this article, we'll explore what every chemical manufacturer needs to know about environmental regulations and how they can stay ahead of the curve.

- Importance of Environmental Regulations for Chemical Manufacturers

- How are Environmental Regulations Enforced?

- Different Types of Environmental Regulations Applying to Chemical Manufacturers

- Role of Regulatory Agencies

- Common Environmental Regulations for Chemical Manufacturers

- Examples of Common Violations and Consequences

- Best Practices for Compliance with Environmental Regulations

- Challenges and Trends in Environmental Regulations

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Importance of Environmental Regulations for Chemical Manufacturers

The chemical industry has the potential to generate significant environmental impacts, including air and water pollution, contamination of soil and ecosystems, and greenhouse gas emissions.

Therefore, ecological regulations are critical for chemical manufacturers because they help ensure that chemical production, use, and disposal do not harm human health or the environment.

Without the regulations, chances of prioritizing profits over responsible practices may occur, potentially leading to significant environmental damage and public health risks. Environmental regulations serve as a check on these activities, setting standards and requirements for the safe production and use of chemicals.

In addition to protecting human health and the environment, environmental regulations can also benefit chemical manufacturers by providing a level playing field and setting industry-wide standards. This can help reduce uncertainty and risk for companies, as they know what is expected of them regarding environmental performance.

Moreover, regulations can also drive innovation in the industry, promoting the development of new, more sustainable and environmentally friendly technologies and practices. In this way, environmental regulations can help chemical manufacturers to become more competitive and prepare for a sustainable future.

Environmental regulations are critical for chemical manufacturers to ensure that their activities are conducted responsibly and sustainably, which protects both the environment and public health.

How are Environmental Regulations Enforced?

Environmental regulations are enforced on chemical manufacturers through a variety of mechanisms at both the federal and state level. The enforcement of environmental regulations is typically carried out by regulatory agencies such as the Environmental Protection Agency (EPA) in the United States.

Inspections

One common way that environmental regulations are enforced is through inspections. Regulatory agencies can conduct inspections of chemical manufacturing facilities to ensure compliance with environmental regulations, such as air and water pollution limits, waste management requirements, and other standards. Inspectors may also review records and documentation to verify that the facility is following regulations.

Permits

Another enforcement mechanism is the issuance of permits. Chemical manufacturers must often obtain permits from regulatory agencies before engaging in certain activities, such as discharging wastewater or emitting air pollutants. These permits may include specific limits on the amount of pollutants that can be released, monitoring and reporting requirements, and other conditions.

Fines and Penalties

In addition to inspections and permits, regulatory agencies may also use enforcement actions such as fines, penalties, or even criminal charges to ensure compliance with environmental regulations. For example, if a chemical manufacturer is found to be in violation of a regulation, they may be fined or required to take corrective action.

Citizen Suits

It's worth noting that environmental regulations can also be enforced through citizen suits. This means that individuals or organizations may bring legal action against a chemical manufacturer if they believe that the company is violating environmental regulations and causing harm to the environment or public health.

Environmental regulations for chemical manufacturers are enforced through various mechanisms designed to ensure compliance and protect human health and the environment.

Different Types of Environmental Regulations Applying to Chemical Manufacturers

There are several types of environmental regulations that apply to chemical manufacturers. Here are some of the most common types:

Air Emissions Regulations

These regulations limit the amount of pollutants that can be released into the air from chemical manufacturing operations. They may set limits on specific pollutants, such as volatile organic compounds (VOCs), particulate matter, and greenhouse gases.

Air emissions regulations are a type of environmental regulation that apply to chemical manufacturers, setting limits on the amount of pollutants that can be released into the air from their operations. These regulations are designed to protect human health and the environment from the negative impacts of air pollution, which can include respiratory problems, acid rain, and other harmful effects.

These regulations may vary depending on the country and region. Still, they typically set limits on the concentration or quantity of specific pollutants that can be released into the air from chemical manufacturing operations. These pollutants may include volatile organic compounds (VOCs), particulate matter, sulfur dioxide, nitrogen oxides, and greenhouse gases such as carbon dioxide.

Chemical manufacturers may need to implement various pollution control measures to comply with air emissions regulations. For example, they may need to install air pollution control equipment such as scrubbers, filters, or other devices to remove or reduce emissions. They may also need to implement practices such as waste reduction, process optimization, and operational changes to reduce emissions.

In addition, chemical manufacturers may need to obtain permits from regulatory agencies to operate their facilities and release pollutants into the air. These permits may include specific emission limits, monitoring and reporting requirements, and other conditions.

Many chemical manufacturers have adopted sustainability goals that include reducing their greenhouse gas emissions, which may involve implementing innovative solutions to reduce their environmental impact while maintaining their competitiveness in the marketplace.

Water Quality Regulations

Water quality regulations apply to chemical manufacturers, governing the discharge of wastewater and other pollutants into bodies of water, including rivers, lakes, and oceans. These regulations are designed to protect human health and the environment from the negative impacts of water pollution, which can include contaminated drinking water, harm to aquatic life, and damage to ecosystems. These pollutants may include heavy metals, nutrients, oils, and other chemicals.

Chemical manufacturers may need to implement various pollution control measures to comply with water quality regulations. For example, they may need to install treatment systems to remove pollutants from their wastewater before it is discharged, or implement processes to minimize the generation of wastewater altogether. In some cases, they may be required to treat their wastewater to a safe reuse level, instead of discharging it to the environment.

Chemical manufacturers may also need to obtain permits from regulatory agencies to discharge wastewater and other pollutants into bodies of water. These permits may include specific discharge limits, monitoring and reporting requirements, and other conditions.

These regulations govern the discharge of wastewater and other pollutants into bodies of water, including rivers, lakes, and oceans. They may set limits on the concentration of specific pollutants, such as heavy metals or nutrients, in the wastewater that can be discharged.

Waste Management Regulations

These regulations govern the management and disposal of hazardous and non-hazardous waste generated by chemical manufacturing operations. They may require the implementation of waste reduction and recycling programs and the safe storage, treatment, and disposal of hazardous waste.

Chemical Substance Regulations

These regulations govern the use and production of chemicals themselves, including the testing and registration of new chemicals, restrictions on the use of certain hazardous chemicals, and requirements for the labeling and communication of chemical hazards.

These regulations are a type of environmental regulation that apply to chemical manufacturers, governing the use and production of chemicals themselves. These are designed to protect human health and the environment from the potential risks posed by chemical substances, such as toxicity, flammability, and reactivity.

Chemical substance regulations may vary, but they typically cover a range of activities related to chemical substances, including the following:

- Testing and registration of new chemicals: Chemical manufacturers may be required to test and register new chemicals with regulatory agencies before they can be marketed or used in commercial products. This may involve submitting data on the chemical's properties, toxicity, and environmental impact.

- Restrictions on the use of certain hazardous chemicals: Chemical manufacturers may be subject to restrictions on the use of certain hazardous chemicals, such as substances that are known to be carcinogenic or bioaccumulative. These restrictions may include bans on the use of the chemical, or limits on the quantity or concentration of the chemical that can be used.

- Labeling and communication of chemical hazards: Chemical manufacturers may be required to label their products with information about the potential hazards posed by the chemicals they contain. This may include information about the chemical's toxicity, flammability, reactivity, and instructions for safe handling and disposal.

- Reporting of chemical releases and spills: Chemical manufacturers may be required to report releases and spills of hazardous chemicals to regulatory agencies and emergency responders. These reports may be used to track the movement of hazardous substances in the environment and to identify potential risks to human health and the environment.

Site Cleanup Regulations

These regulations require the cleanup of sites contaminated with hazardous substances, including those resulting from chemical manufacturing operations. They may establish cleanup standards, require the investigation and reporting of contamination, and specify the responsibilities of responsible parties for cleanup.

Regulations against Hazardous Waste

Hazardous waste regulations generally aim to prevent or minimize the generation of hazardous waste and ensure that it is handled and disposed of in a safe and environmentally sound manner.

Here are some of the key regulations that chemical manufacturers may need to comply with regarding hazardous waste:

- Resource Conservation and Recovery Act (RCRA): This federal law governs the management of hazardous waste from its generation to its final disposal. RCRA requires chemical manufacturers to properly identify, store, transport, and dispose of hazardous waste in accordance with specific regulations.

- Hazardous Waste Generator Regulations: These are federal regulations that set specific requirements for businesses that generate hazardous waste, including chemical manufacturers.

- Occupational Safety and Health Administration (OSHA) regulations: OSHA requires chemical manufacturers to protect workers from exposure to hazardous chemicals and waste, including providing training, protective equipment, and implementing safety procedures.

Workplace Safety Regulations

These regulations are designed to prevent accidents and injuries and reduce the risk of long-term health effects from chemical exposure. Here are some of the key workplace safety regulations that chemical manufacturers must comply with:

- Hazard Communication Standard (HCS): HCS requires chemical manufacturers to provide information about the hazards of chemicals to workers who may be exposed to them. This includes labeling containers, providing safety data sheets, and training employees on the hazards associated with the chemicals they work with.

- Personal Protective Equipment (PPE): Chemical manufacturers must provide workers with appropriate personal protective equipment, such as gloves, goggles, and respirators, to protect them from exposure to hazardous chemicals.

- Emergency Preparedness and Response: Chemical manufacturers must have procedures in place to respond to emergencies, such as spills or fires, to protect workers and the environment. This includes having a written emergency response plan, providing appropriate training, and conducting regular drills.

- Noise Exposure: Chemical manufacturers must comply with OSHA regulations that address exposure to noise in the workplace. This includes establishing a hearing conservation program and providing workers with appropriate hearing protection.

- Ergonomics: These practices are aimed at preventing musculoskeletal disorders. This may include providing training on proper lifting techniques and ergonomically designed workstations.

Role of Regulatory Agencies

The Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) are two examples of regulatory agencies that are responsible for enforcing environmental regulations.

Here are some of the key roles of these agencies:

Development of Regulations

Regulatory agencies like the EPA and OSHA are responsible for developing and promulgating regulations that address environmental and safety hazards in the workplace. These regulations are designed to protect workers, the environment, and the public from potential harm.

Compliance Monitoring

Regulatory agencies conduct inspections and audits of regulated entities to ensure compliance with environmental and safety regulations. Complaints, routine inspections, or other indicators of noncompliance may trigger these inspections.

Enforcement Actions

Regulatory agencies have the authority to take enforcement actions against non-compliant entities. These may include fines, penalties, and legal action, such as injunctions or prosecution.

Technical Assistance

Regulatory agencies provide technical assistance and guidance to regulated entities to help them comply with regulations. This may include training, consultations, and assistance with compliance planning.

Research and Development

Regulatory agencies conduct research and development to support the development of new environmental and safety regulations. This research may involve identifying emerging hazards or developing new technologies to address existing hazards.

Public Education

Regulatory agencies educate the public on environmental and safety hazards and how to protect themselves. This may involve outreach programs, public meetings, and educational materials.

Thus, regulatory agencies like the EPA and OSHA play a critical role in protecting public health and the environment by enforcing environmental regulations. By developing and enforcing regulations, conducting compliance monitoring, and providing technical assistance and public education, these agencies help to prevent environmental and safety hazards and promote safe and healthy workplaces.

Common Environmental Regulations that Chemical Manufacturers Must Comply with

Chemical manufacturers are subject to a range of environmental regulations at the federal, state, and local levels. The specific regulations that apply to a chemical manufacturer depend on the type of chemicals produced, the quantity produced, and the location of the facility. Here are some of the most common environmental regulations that chemical manufacturers need to comply with:

- Clean Air Act: The Clean Air Act regulates air emissions from stationary sources, including chemical manufacturing facilities. Chemical manufacturers may need to obtain permits, install pollution control equipment, and conduct emissions monitoring to comply with the Clean Air Act.

- Clean Water Act: The Clean Water Act regulates discharges of pollutants into surface waters, such as rivers and lakes. Chemical manufacturers may need to obtain permits and implement best management practices to control water pollution from their facilities.

- Resource Conservation and Recovery Act (RCRA): The RCRA regulates the generation, transportation, treatment, storage, and disposal of hazardous waste. Chemical manufacturers may need to obtain permits, implement waste management plans, and conduct hazardous waste determinations to comply with the RCRA.

- Toxic Substances Control Act (TSCA): The TSCA regulates the manufacture, import, processing, and distribution of chemicals in the United States. Chemical manufacturers may need to submit premanufacture notices, develop risk assessments, and comply with restrictions on using and distributing certain chemicals under the TSCA.

- Emergency Planning and Community Right-to-Know Act (EPCRA): The EPCRA requires chemical manufacturers to report releases of hazardous substances to the environment and storage and use of hazardous chemicals at their facilities. Chemical manufacturers may also need to develop and implement emergency response plans under the EPCRA.

- Occupational Safety and Health Administration (OSHA) Standards: OSHA regulates workplace safety, including handling hazardous chemicals. Chemical manufacturers must comply with OSHA standards that are specific to the chemical industry, such as the Process Safety Management Standard, which establishes requirements for the management of highly hazardous chemicals.

Examples of Common Violations and Consequences

Chemical manufacturers who fail to comply with environmental regulations can face serious consequences, including fines, penalties, legal liability, and reputational damage. Here are some examples of common violations and the consequences of noncompliance:

Failure to Obtain Required Permits

Chemical manufacturers who fail to obtain required permits under environmental regulations can face fines, penalties, and legal liability. For example, a chemical manufacturer in Colorado was fined $400,000 for operating without a required air permit, and a chemical manufacturer in Massachusetts was fined $65,000 for operating without a required water permit.

Exceeding Emission Limits

Chemical manufacturers who exceed emission limits under the Clean Air Act or Clean Water Act can face fines, penalties, and legal liability. For example, a chemical manufacturer in Louisiana was fined $1.5 million for violating emission limits under the Clean Air Act, and a chemical manufacturer in West Virginia was fined $600,000 for violating discharge limits under the Clean Water Act.

Hazardous Waste Violations

Chemical manufacturers who fail to properly manage hazardous waste under the Resource Conservation and Recovery Act (RCRA) can face fines, penalties, and legal liability. For example, a chemical manufacturer in Tennessee was fined $3.5 million for illegally disposing of hazardous waste, and a chemical manufacturer in Illinois was fined $525,000 for storing hazardous waste without a permit.

Workplace Safety Violations

Chemical manufacturers who fail to comply with workplace safety regulations under OSHA can face fines, penalties, and legal liability. For example, a chemical manufacturer in Texas was fined $161,000 for failing to provide adequate training and personal protective equipment to workers handling hazardous chemicals, and a chemical manufacturer in Wisconsin was fined $115,000 for exposing workers to hazardous chemicals without proper protective measures.

Failure to Report

Chemical manufacturers who fail to report releases of hazardous substances under the Emergency Planning and Community Right-to-Know Act (EPCRA) can face fines, penalties, and legal liability. For example, a chemical manufacturer in Texas was fined $272,000 for failing to report a release of hazardous chemicals that resulted in a fire, and a chemical manufacturer in New York was fined $11,000 for failing to report a release of ammonia.

Best Practices for Compliance with Environmental Regulations

Compliance with environmental regulations is critical for chemical manufacturers to ensure the safety of their employees, the public, and the environment. Here are some best practices for compliance with environmental regulations for chemical manufacturers:

Stay up-to-date with Regulations

Chemical manufacturers should stay informed about changes in environmental regulations and ensure that they have the latest information on requirements and deadlines.

Develop a Compliance Program

Chemical manufacturers should develop a compliance program that includes policies and procedures for meeting regulatory requirements. The program should be regularly reviewed and updated as needed.

Train Employees

Chemical manufacturers should train their employees on environmental regulations and best practices for compliance. This training should include information on reporting and recordkeeping requirements, emergency response plans, and other compliance-related topics.

Implement pollution prevention measures: Chemical manufacturers should implement pollution prevention measures to reduce their environmental impact. This may include using safer chemicals, reducing waste, and implementing energy-efficient practices.

Maintain Accurate Records

Chemical manufacturers should maintain accurate records of compliance activities, such as emissions monitoring, waste management, and spill response. These records can help demonstrate compliance and provide evidence in case of an audit or investigation.

Conduct Self-audits

Chemical manufacturers should conduct periodic self-audits to identify compliance gaps and address them before they become issues. These audits can help chemical manufacturers proactively address compliance issues and avoid potential penalties and fines.

Work with Regulatory Agencies

Chemical manufacturers should work closely with regulatory agencies and seek guidance when needed. This can help chemical manufacturers better understand regulatory requirements and avoid potential compliance issues.

Challenges and Trends in Environmental Regulations

Here are some of the key challenges and trends in environmental regulations for chemical manufacturers:

Increasingly Stringent Regulations

Environmental regulations are becoming more stringent, with new requirements for emissions reductions, waste reduction, and other environmental impacts. This can be challenging for chemical manufacturers to keep up with, as compliance can be costly and time-consuming.

Global Regulations

Many countries are implementing their own environmental regulations, which can create challenges for chemical manufacturers operating in multiple jurisdictions. Compliance with a range of different regulations can be complex and expensive.

Supply Chain Sustainability

Environmental regulations are increasingly focusing on sustainability throughout the supply chain, requiring chemical manufacturers to consider the environmental impacts of their raw materials, transportation, and other supply chain activities.

Product Stewardship

Chemical manufacturers are increasingly responsible for the entire lifecycle of their products, from production to disposal. This requires chemical manufacturers to consider the environmental impacts of their products throughout their entire lifecycle.

Technology Innovations

As technology evolves, new solutions are emerging to help chemical manufacturers meet environmental regulations. For example, advancements in digital technologies, such as the Internet of Things (IoT), can help chemical manufacturers monitor their environmental impacts more effectively.

Public pressure

Consumers and other stakeholders are increasingly aware of the environmental impacts of chemical manufacturing, and are putting pressure on chemical manufacturers to improve their environmental performance. This can lead to new regulations and requirements, as well as reputational risks for non-compliance.

Conclusion

In conclusion, compliance with environmental regulations is critical for chemical manufacturers to ensure the safety of their employees, the public, and the environment. Chemical manufacturers must stay up-to-date with regulations, develop a compliance program, train employees, implement pollution prevention measures, maintain accurate records, conduct self-audits, and work closely with regulatory agencies.

They must also be aware of the challenges and trends in environmental regulations, such as increasing stringency, global regulations, supply chain sustainability, product stewardship, technology innovations, and public pressure. By following best practices and staying ahead of these challenges, chemical manufacturers can meet environmental regulations and ensure a safer, healthier future for all.

How can Deskera Help You?

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera MRP enables real-time monitoring of the manufacturing process. The solution assists you in staying on top of your game and maintaining your company's competitive edge, from the bill of materials to the production planning features.

Deskera Books can help you automate your accounting and reduce business risks. Deskera simplifies the creation of invoices by automating many other procedures, reducing the administrative workload of your team.

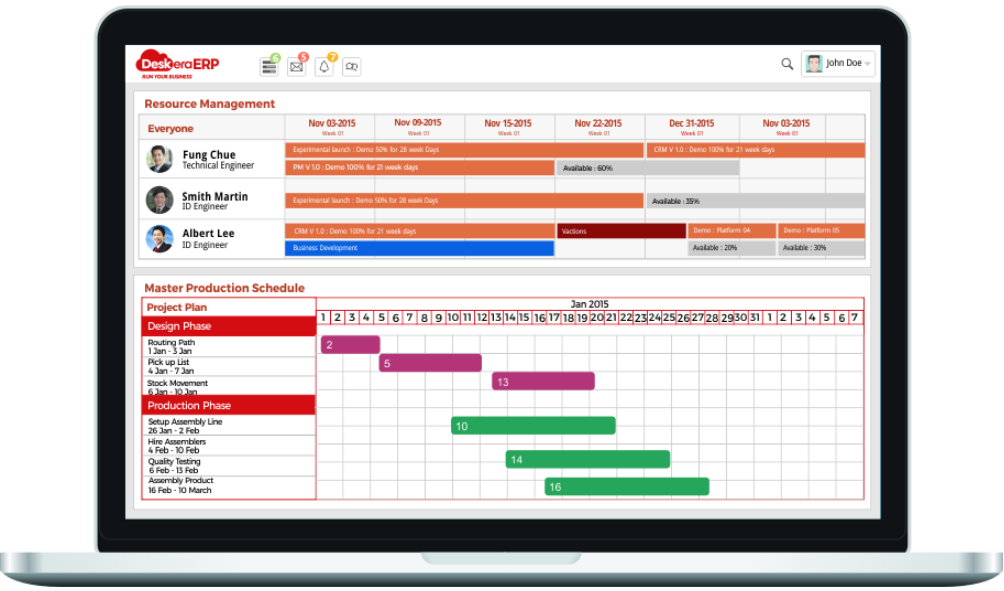

Deskera also provides integrated applications to assist businesses with financial, inventory, and operations management. Other business aspects include HR (Deskera People), CRM (Deskera CRM), and Deskera ERP.

Key Takeaways

- Environmental regulations are critical for chemical manufacturers to ensure that their activities are conducted in a responsible and sustainable way that protects both the environment and public health.

- Without the regulations, chances of prioritizing profits over responsible practices may occur, potentially leading to significant environmental damage and public health risks.

- Inspections, permits, fines, and citizen suits are some of the ways in which the regulations may be enforced.

- Air emissions, water quality, and waste management regulations are some of the types of environmental regulations that apply to chemical manufacturers.

- Regulatory agencies like EPA and OSHA take care of enforcing the regulations.

- Chemical manufacturers can stay updated about the regulations and can educate their staff about them to abide by the compliances.

Related Articles