Process development plays a critical role in chemical manufacturing, as it involves designing and optimizing the manufacturing process for a specific chemical product.

Process development is an essential step in bringing a new product to market, and it requires a deep understanding of the chemistry involved, as well as the equipment, raw materials, and process controls required to produce the product. In addition, process development must consider the environmental impact of the manufacturing process and work to minimize waste and reduce energy consumption.

In this article, we will explore the role of process development in chemical manufacturing, its importance, and the challenges and best strategies associated with the process. We will also discuss how emerging technologies, such as artificial intelligence and machine learning, are transforming the field of process development and opening up new possibilities for innovation and efficiency.

- What is Chemical Process Development?

- Why is Chemical Process Development Important?

- Goal of Chemical Process Development

- Some Important Considerations for Process Development in Chemical Manufacturing

- Challenges & Solutions of Chemical Process Development

- Quality by Design (QbD) – An Approach Supporting Chemical Process Development

- Process Analytical Technology (PAT)

- Importance of Mixing and Mass Transfer in Chemical Process Development

- How to Improve Process Development in Chemical Processes?

- How ERP can Help in Process Development in Chemical Manufacturing?

- Modern Technologies for Process Development in Chemical Manufacturing

- Skills and Expertise Required for Process Development in Chemical Manufacturing

- Frequently Asked Questions Related to Process Development in Chemical Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

What is Chemical Process Development?

Chemical process development refers to the process of designing, developing, and optimizing chemical processes for the production of a desired product or chemical compound. It involves the integration of chemical and engineering principles to create a safe, efficient, and cost-effective process.

Chemical process development typically involves the following steps:

Research and Development: This involves conducting experiments and analysis to identify the chemical reactions and processes required to produce the desired product.

Process Design: Based on the results of the research and development phase, a process design is created that specifies the equipment and conditions required for the production process.

Pilot Plant Scale-up: The process is then tested at a pilot plant scale to ensure that it can be successfully scaled up to a commercial level.

Optimization: The process is optimized to maximize efficiency, minimize waste, and reduce costs.

Commercialization: Once the process has been fully optimized and tested, it can be commercialized and scaled up for large-scale production.

Chemical process development plays a critical role in a wide range of industries, including pharmaceuticals, petrochemicals, food and beverage, and many others. It enables companies to produce high-quality products efficiently and cost-effectively, while minimizing the environmental impact of their operations.

Why is Chemical Process Development Important?

Chemical Process Development is an essential part of the chemical industry. It is the process of developing the most efficient and cost-effective methods for producing chemicals.

Chemical Process Development involves a variety of disciplines, including chemical engineering, process engineering, and manufacturing engineering. When it comes to chemical production, the process must be as efficient and cost-effective as possible to ensure profitability.

Furthermore, chemical process development can help to make this a reality. It involves identifying and evaluating the best methods for producing chemicals, as well as optimizing processes and equipment to maximize efficiency.

It further can also help to ensure that materials and processes are safe, reliable, and efficient. This is important for protecting the environment, people, and animals, as well as for reducing costs and enhancing the quality of products.

Goals of Chemical Process Development

The goal of process development is to create a safe, efficient, and cost-effective manufacturing process that can produce a high-quality product on a commercial scale. This process involves identifying the critical process parameters, optimizing the process conditions, and ensuring the product meets all quality and safety requirements.

The goals of chemical process development typically include the following:

Developing safe and environmentally sustainable processes: Chemical processes can be hazardous and have an environmental impact, so one of the primary goals of chemical process development is to develop safe and environmentally sustainable processes.

Optimizing the process for efficiency: By optimizing chemical processes, companies can increase efficiency, reduce waste, and reduce costs.

Meeting product quality requirements: Chemical process development must ensure that the product meets the required quality standards, which may involve testing and optimization.

Boosting the process: Chemical process development must ensure that the process can be scaled up to commercial production without sacrificing efficiency, quality, or safety.

Ensuring cost-effectiveness: Chemical process development must ensure that the process is cost-effective, enabling the company to produce products at a competitive price point.

Innovating new chemical products: Chemical process development can also be used to innovate new chemical products and materials, leading to new market opportunities and competitive advantages.

Overall, the goals of chemical process development are to create a safe, efficient, and cost-effective process that produces high-quality products while minimizing environmental impact and providing opportunities for innovation.

Some Important Considerations for Process Development in Chemical Manufacturing

Here are some important considerations for process development in chemical manufacturing:

Scaling up chemical reactions: Process development involves scaling up chemical reactions from the laboratory to the commercial production level. This requires an understanding of the physical and chemical properties of the raw materials, as well as the process variables that affect the yield and quality of the product.

Optimizing the manufacturing process: Process development is responsible for optimizing the manufacturing process to reduce costs, improve efficiency, and enhance the quality of the product. This may involve changes to the process design, equipment selection, or operational procedures.

Ensuring product quality: Process development plays a key role in ensuring the quality of the final product. This involves developing robust quality control procedures, including analytical methods, testing protocols, and process monitoring systems.

Enhancing safety: Process development is responsible for identifying and mitigating safety hazards in the manufacturing process. This includes developing standard operating procedures, risk assessments, and safety protocols to ensure the safety of the people involved in the manufacturing process.

Minimizing environmental impact: Process development also considers the environmental impact of the manufacturing process. This involves developing sustainable and eco-friendly manufacturing processes that minimize waste and reduce energy consumption.

Analyzing process data: Process development involves collecting and analyzing data on the manufacturing process to identify areas for improvement and optimize the process. This requires expertise in data analytics and machine learning.

Collaborating with cross-functional teams: Process development requires collaboration with cross-functional teams, including research and development, quality control, and manufacturing operations, to ensure the success of the process development project.

All in all, process development in chemical manufacturing is a complex and multifaceted discipline that requires a broad range of expertise and considerations to ensure the efficient, safe, and high-quality production of chemical products.

Challenges & Solutions of Chemical Process Development

Chemical process development can be a challenging and complex task. Some of the challenges that can arise during the process include:

Scale-up challenges: Moving from laboratory-scale to commercial-scale production can be challenging, as there are often unanticipated issues that arise when scaling up the process.

Equipment selection and design: The selection and design of equipment can be a challenge, as it must be able to handle the volume and complexity of the manufacturing process, while still meeting safety and regulatory requirements.

Quality control and safety: Ensuring the safety of the process and the quality of the final product is critical and requires a thorough understanding of quality control and safety procedures.

Process variability: Chemical processes are often highly variable and require careful monitoring and control to ensure consistent product quality.

Environmental concerns: Chemical manufacturing can have a significant impact on the environment, and developing sustainable and eco-friendly manufacturing processes is a critical challenge in process development.

Cost management: Process development must balance the need for safety, quality, and efficiency with the need to manage costs, which can be a challenge, especially in highly regulated industries.

Process complexity: Some chemical processes can be very complex, requiring the use of sophisticated equipment and techniques that can be difficult to optimize.

Safety concerns: Chemical processes can be hazardous, and it is critical to ensure that the process is designed to be safe for workers and the environment.

Cost considerations: The development of a chemical process can be expensive, and it is important to balance the cost of development with the potential benefits.

Some of the solutions to these challenges include:

Pilot plant testing: Testing the process at a pilot plant scale can help identify and address scale-up challenges before moving to commercial production.

Advanced modeling and simulation: Advanced modeling and simulation techniques can be used to optimize complex processes and reduce the time and cost of development.

Risk assessment and safety planning: Risk assessment and safety planning can help ensure that the process is designed to be safe and environmentally friendly.

Collaboration and communication: Collaboration between different teams and effective communication can help ensure that the process is developed efficiently and effectively while balancing cost considerations.

In summary, chemical process development can be challenging, but by implementing the right solutions and strategies, companies can overcome these challenges and develop safe, efficient, and cost-effective processes that meet their production goals.

Quality by Design (QbD) – An Approach Supporting Chemical Process Development

Quality by Design (QbD) is an approach that is increasingly being used in chemical process development to help ensure that the final product meets the desired quality standards. QbD is a systematic approach that involves designing quality into the product and process from the outset, rather than trying to test for quality at the end of the process.

QbD is based on the concept that quality is not just a measure of the final product but is also the result of the process used to produce it. QbD involves understanding the critical quality attributes (CQAs) of the product and identifying the critical process parameters (CPPs) that affect these attributes.

By understanding the relationship between CPPs and CQAs, it is possible to design a process that produces a high-quality product consistently.

The QbD approach typically involves the following steps:

- Defining the target product profile (TPP) and the critical quality attributes (CQAs) of the product.

- Identifying the critical process parameters (CPPs) that affect the CQAs.

- Developing a design of experiments (DOE) to identify the optimal range of CPPs.

- Establishing a design space that includes the optimal range of CPPs.

- Implementing a process control strategy to ensure that the process stays within the design space.

- Conducting ongoing process monitoring and analysis to ensure that the process remains in control.

The QbD approach is a valuable tool for chemical process development because it allows companies to design processes that consistently produce high-quality products. By understanding the relationship between CPPs and CQAs, companies can optimize the process to minimize variability and ensure that the product meets the desired quality standards.

The QbD approach also allows companies to identify potential process failures before they occur, which can help reduce the risk of quality issues and production delays. Overall, QbD is a valuable approach that can help support chemical process development by designing quality into the product and process from the outset.

Process Analytical Technology (PAT)

Process Analytical Technology (PAT) is a system for analyzing chemical processes in real-time, allowing for improved control and optimization of the manufacturing process.

Furthermore, PAT involves the use of sensors, process control systems, and data analysis tools to monitor and control the process, and to make adjustments in real-time to optimize the process parameters.

PAT is increasingly being used in chemical manufacturing to improve process efficiency, reduce costs, and ensure product quality. Some of the benefits of PAT include:

Real-time process monitoring: PAT allows for real-time monitoring of critical process parameters, enabling operators to identify and address issues quickly, minimizing the risk of product quality issues or process failures.

Improved process control: By monitoring key process parameters in real-time, PAT can help optimize the process, improving product quality and reducing the risk of waste.

Reduced costs: By minimizing the risk of process failures and optimizing the process, PAT can help reduce production costs, including energy and raw material costs.

Improved product quality: By providing real-time data on the critical process parameters, PAT can help ensure that the final product meets the desired quality specifications.

PAT is used in many different chemical manufacturing processes, including the production of pharmaceuticals, chemicals, and food and beverage products. PAT systems can be customized to meet the specific needs of the manufacturing process and can include a range of sensors and data analysis tools to monitor and control the process.

By using PAT, companies can optimize their manufacturing processes, reduce costs, and ensure the highest levels of product quality.

Importance of Mixing and Mass Transfer in Chemical Process Development

Mixing and mass transfer are important aspects of chemical process development, as they play a critical role in achieving the desired reaction rates, yield, and product quality. Mixing refers to the process of combining two or more substances to form a homogeneous mixture, while mass transfer refers to the process of moving mass from one phase to another.

Mixing is important because it affects the rate of reaction and the distribution of reactants in the reaction mixture. An inefficient mixing process can result in poor product quality, low yields, and prolonged reaction times. In contrast, an optimized mixing process can result in a more homogeneous mixture, leading to more efficient reactions, higher yields, and shorter reaction times.

Mass transfer is important because it affects the rate at which reactants are consumed and products are produced. A slow mass transfer rate can lead to incomplete reactions, while a fast mass transfer rate can result in wasteful overconsumption of reactants. By optimizing the mass transfer rate, the reaction rate can be improved, leading to higher yields and faster reaction times.

In chemical process development, mixing and mass transfer are typically optimized by adjusting the process conditions, such as the temperature, pressure, and agitation rate. Computational fluid dynamics (CFD) modeling can also be used to simulate the mixing and mass transfer behavior of a system, allowing for the optimization of the process conditions without the need for physical experimentation.

Overall, efficient mixing and mass transfer are critical for achieving the desired product quality, yield, and reaction time in chemical process development. By optimizing these processes, companies can improve the efficiency of their manufacturing processes and produce high-quality products at a lower cost.

How to Improve Process Development in Chemical Processes?

Process development in chemical manufacturing can be improved in several ways. Here are some potential strategies:

Collaboration:

Collaboration between research and development, quality control, and manufacturing operations teams can help ensure that process development meets the needs of all stakeholders, and that the process is optimized for efficiency, safety, and quality.

Data Analytics and Machine Learning:

Incorporating data analytics and machine learning into the process development process can help identify areas for improvement, optimize the process, and minimize errors.

Process Modeling and Simulation:

Using process modeling and simulation can help predict and optimize the performance of the manufacturing process, reducing the time and cost required to bring a new product to market.

Continuous Improvement:

Adopting a culture of continuous improvement, where the process is regularly reviewed and optimized, can help identify and correct issues before they become major problems.

Automation:

Incorporating automation into the manufacturing process can help improve efficiency, reduce errors, and minimize the risk of safety incidents.

Environmental Sustainability:

Developing eco-friendly and sustainable manufacturing processes can help reduce the environmental impact of chemical manufacturing, improve the reputation of the company, and ensure compliance with environmental regulations.

Training and Development:

Providing training and development opportunities for employees can help improve their skills and expertise and ensure that they are up to date with the latest technology and best practices in process development.

Ultimately, process development in chemical manufacturing can be improved through a combination of collaboration, data analytics, process modeling and simulation, continuous improvement, automation, environmental sustainability, and training and development. By implementing these strategies, companies can ensure the efficient, safe, and high-quality production of chemical products.

How ERP can Help in Process Development in Chemical Manufacturing?

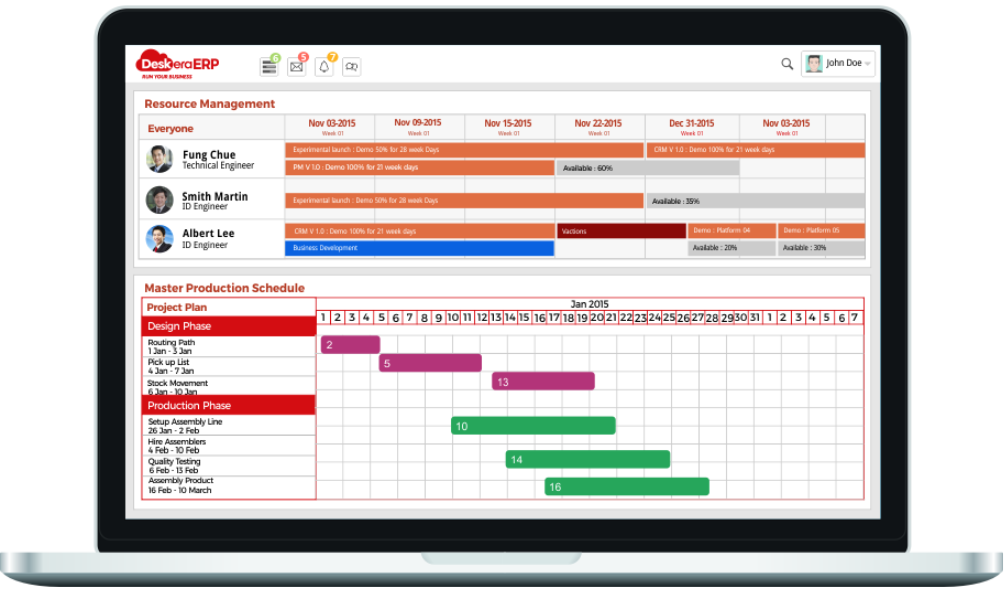

Enterprise resource planning (ERP) systems can play an important role in process development in chemical manufacturing. Here are some ways ERP can help:

Centralized Data Management:

ERP systems provide a centralized platform for managing data related to the manufacturing process, including inventory levels, production schedules, quality control, and compliance with regulatory requirements. This can help improve the efficiency and accuracy of the process development process.

Process Automation:

ERP systems can automate many of the routine tasks associated with process development, such as creating and tracking work orders, generating production reports, and managing quality control data. This can help reduce errors and improve the efficiency of the process.

Real-Time Monitoring and Reporting:

ERP systems can provide real-time data on the manufacturing process, allowing managers and operators to monitor the process and identify areas for improvement. This can help facilitate continuous improvement in the process development process.

Supply Chain Management:

ERP systems can help manage the entire supply chain, from raw material sourcing to product delivery, ensuring that the manufacturing process is efficient and cost-effective.

Financial Management:

ERP systems can provide financial data related to the manufacturing process, including cost data, revenue data, and profit margins. This can help managers make informed decisions about the manufacturing process and identify areas for cost savings.

Regulatory Compliance:

ERP systems can help ensure regulatory compliance by tracking and managing data related to safety, quality control, and environmental sustainability. This can help companies avoid regulatory fines and improve their reputation.

Modern Technologies for Process Development in Chemical Manufacturing

There are several modern technologies that are transforming process development in chemical manufacturing. Following, we've discussed few examples:

Process Simulation Software

Process simulation software, such as Aspen Plus, can be used to model and optimize chemical processes in a virtual environment, allowing engineers to test and refine the process before it is implemented in a production environment. This can help reduce the time and cost associated with process development and enable engineers to explore a range of process options.

High-Throughput Experimentation:

High-throughput experimentation involves automating the process of conducting experiments, using robots and other technologies to rapidly test a large number of variables. This approach can accelerate the process development process, allowing engineers to quickly identify the optimal process conditions and materials.

Artificial Intelligence and Machine Learning:

Artificial intelligence (AI) and machine learning (ML) technologies can be used to analyze large amounts of data and identify patterns and correlations that can help optimize the manufacturing process. For example, AI and ML can be used to identify the optimal process conditions, predict equipment failures, and optimize energy consumption.

Process Analytical Technology:

Process analytical technology (PAT) involves using sensors and other monitoring tools to measure key process parameters in real-time, providing engineers with instant feedback on the performance of the manufacturing process. This can help identify process deviations and allow engineers to quickly adjust the process to maintain quality and efficiency.

Additive Manufacturing:

Additive manufacturing, or 3D printing, is increasingly being used in chemical manufacturing to produce complex geometries, create custom components, and reduce waste. This technology can also accelerate the process development process by allowing engineers to quickly produce prototypes and test new materials.

Skills and Expertise Required for Process Development in Chemical Manufacturing

Process development in chemical manufacturing requires a broad range of skills and expertise, including:

Chemical engineering: A strong foundation in chemical engineering is essential for process development, as it provides an understanding of chemical reactions, process design, equipment selection, and process optimization.

Process optimization: Process development requires expertise in process optimization, including statistical analysis, experimental design, and modeling. This involves analyzing data, identifying process variables that affect the yield and quality of the product, and optimizing the process accordingly.

Quality control: A strong understanding of quality control is essential for process development, as it involves developing quality control procedures, testing protocols, and process monitoring systems to ensure the quality of the final product.

Safety: Process development requires a strong focus on safety, as it involves identifying and mitigating safety hazards in the manufacturing process. This requires knowledge of safety protocols, risk assessments, and standard operating procedures.

Sustainability: Process development also requires a focus on sustainability, as it involves developing eco-friendly and sustainable manufacturing processes that minimize waste and reduce energy consumption.

Data analytics and machine learning: Process development involves collecting and analyzing data on the manufacturing process to identify areas for improvement and optimize the process. This requires expertise in data analytics and machine learning.

Cross-functional collaboration: Process development requires collaboration with cross-functional teams, including research and development, quality control, and manufacturing operations, to ensure the success of the process development project.

Overall, process development in chemical manufacturing requires a diverse skill set and a deep understanding of the chemical manufacturing process to ensure the efficient, safe, and high-quality production of chemical products.

Frequently Asked Questions Related to Process Development in Chemical Manufacturing

Here are some frequently asked questions related to process development in chemical manufacturing:

Que 1: What is process development in chemical manufacturing?

Ans: Process development in chemical manufacturing involves transforming laboratory-scale processes into large-scale commercial processes to optimize efficiency, reduce costs, and ensure product and process safety.

Que 2: What are the key goals of process development in chemical manufacturing?

Ans: The key goals of process development in chemical manufacturing include improving efficiency, reducing costs, ensuring product and process safety, optimizing quality, and minimizing environmental impact.

Que 3: Process Development Vs Process Design in Chemical Manufacturing

Ans: Process development and process design are two distinct stages in chemical manufacturing, although they are closely related. The main difference between them is as follows:

Process Development: Process development involves transforming laboratory-scale processes into large-scale commercial processes to optimize efficiency, reduce costs, and ensure product and process safety. The focus is on improving the efficiency and safety of an existing manufacturing process.

Process Design: Process design involves creating a new manufacturing process from scratch. It involves designing the chemical reaction, selecting the equipment, and developing the operational procedures to produce a new product. The focus is on creating a new manufacturing process that can produce a new product with the desired quality and quantity.

In essence, process development focuses on optimizing an existing manufacturing process, whereas process design focuses on creating a new manufacturing process from scratch.

While both stages involve optimizing the manufacturing process for efficiency and safety, process development builds upon an existing process, whereas process design creates a new process. The success of both stages is critical for ensuring the efficient, safe, and high-quality production of chemical products.

Que 4: Selection of the Synthesis Route in Chemical Process Development

Ans: The selection of the synthesis route in chemical process development is a critical step, as it can have a significant impact on the efficiency, safety, and cost of the process.

The following factors should be considered when selecting a synthesis route:

Chemical properties of starting materials and products: The chemical properties of the starting materials and products will impact the choice of the synthesis route, as some reactions may not be compatible with certain materials or may produce unwanted byproducts.

Availability and cost of raw materials: The availability and cost of raw materials should also be considered, as some synthesis routes may require expensive or hard-to-source materials.

Efficiency of the reaction: The efficiency of the reaction is a critical factor, as it can impact the cost and yield of the process. Factors such as reaction rate, yield, and selectivity should be considered when selecting a synthesis route.

Environmental impact: The environmental impact of the synthesis route should also be considered, as some routes may produce hazardous byproducts or require the use of hazardous chemicals.

Safety considerations: Safety is a critical factor in chemical process development, and the synthesis route should be designed with safety in mind, including the safe handling and disposal of chemicals.

Intellectual property: Intellectual property considerations, such as the availability of patents and potential infringement issues, may also influence the choice of the synthesis route.

Furthermore, the selection of the synthesis route should be based on a thorough analysis of these factors, as well as other relevant considerations specific to the product and the production process.

Ultimately, the chosen synthesis route should be safe, efficient, cost-effective, and environmentally sustainable, while meeting the quality and yield requirements of the product.

Que 5: Meaning of Chemical Process Optimization

Ans: Chemical process optimization involves improving the efficiency, cost-effectiveness, and sustainability of chemical processes. The goal of process optimization is to improve the productivity of the process, while minimizing the use of energy, raw materials, and other resources.

Chemical process optimization can be achieved by implementing a range of strategies, including:

Minimizing waste and emissions: By minimizing waste and emissions, companies can reduce their environmental impact, while also reducing their costs. This can be achieved by implementing cleaner production processes, optimizing the use of raw materials, and using energy-efficient equipment.

Increasing process efficiency: By optimizing the process conditions, companies can increase the efficiency of the process, reducing the cost of production and improving product quality. This can be achieved by optimizing mixing and mass transfer, controlling reaction conditions, and using process analytical technology (PAT) to monitor and control the process.

Improving process control: By implementing advanced process control (APC) systems, companies can optimize the process in real-time, making adjustments to process parameters as needed to ensure that the process remains within the desired operating range.

Automating the process: By automating the process, companies can improve process efficiency and reduce the risk of errors. Automation can be achieved through the use of programmable logic controllers (PLCs), distributed control systems (DCS), and other advanced control technologies.

Overall, chemical process optimization is critical for achieving the desired product quality, reducing costs, and improving the sustainability of chemical manufacturing processes.

By implementing a range of strategies to optimize the process, companies can improve their competitiveness in the market, while also reducing their environmental impact and enhancing their reputation for sustainability.

Que 6: Factors Affecting Process Development in Chemical Manufacturing

Process development in chemical manufacturing is influenced by several factors, including:

Raw materials: The properties of raw materials used in chemical manufacturing, such as purity, consistency, and quality, can have a significant impact on the development of the manufacturing process.

Chemical reactions: The complexity of chemical reactions and their sensitivity to process conditions can make process development challenging.

Equipment: The selection and design of equipment used in chemical manufacturing can have a significant impact on the efficiency, safety, and quality of the process.

Quality control and safety: Ensuring the safety of the process and the quality of the final product is critical and requires a thorough understanding of quality control and safety procedures.

Environmental regulations: Chemical manufacturing is subject to a range of environmental regulations, which can impact the development of the manufacturing process, and require companies to adopt eco-friendly and sustainable manufacturing practices.

Market demand: The demand for a particular product can influence the development of the manufacturing process, as companies need to optimize the process to meet the market demand for the product.

Cost management: The cost of manufacturing a product can impact the development of the manufacturing process, and require companies to balance the need for safety, quality, and efficiency with the need to manage costs.

Wrapping Up

Process development in chemical manufacturing is essential for the successful production of chemicals in a safe and cost-effective manner. It involves the development of safe and efficient processes for the production of chemicals through the selection, design, and optimization of unit operations and support systems.

Moreover, it ensures that the chemicals are produced with the highest quality and in the most efficient manner, while minimizing waste, energy consumption, and environmental impact.

Furthermore, process development also helps to reduce the overall cost of production, allowing for the manufacture of chemicals at competitive prices.

Ultimately, process development is therefore an integral part of any chemical manufacturing operation and should be taken into consideration when planning and implementing any new or existing process.

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Chemical process development refers to the process of designing, developing, and optimizing chemical processes for the production of a desired product or chemical compound. It involves the integration of chemical and engineering principles to create a safe, efficient, and cost-effective process.

- Developing safe and environmentally sustainable processes: Chemical processes can be hazardous and have an environmental impact, so one of the primary goals of chemical process development is to develop safe and environmentally sustainable processes.

- Optimizing the manufacturing process: Process development is responsible for optimizing the manufacturing process to reduce costs, improve efficiency, and enhance the quality of the product. This may involve changes to the process design, equipment selection, or operational procedures.

- Process development involves collecting and analyzing data on the manufacturing process to identify areas for improvement and optimize the process. This requires expertise in data analytics and machine learning.

- Quality by Design (QbD) is an approach that is increasingly being used in chemical process development to help ensure that the final product meets the desired quality standards. QbD is a systematic approach that involves designing quality into the product and process from the outset, rather than trying to test for quality at the end of the process.

- Process Analytical Technology (PAT) is a system for analyzing chemical processes in real-time, allowing for improved control and optimization of the manufacturing process. PAT involves the use of sensors, process control systems, and data analysis tools to monitor and control the process.

- Mixing and mass transfer are important aspects of chemical process development, as they play a critical role in achieving the desired reaction rates, yield, and product quality. Mixing refers to the process of combining two or more substances to form a homogeneous mixture, while mass transfer refers to the process of moving mass from one phase to another.

Related Articles