The traditional practices that once governed this vital aspect of production are now being reshaped by a wave of advanced technologies, giving rise to the era of "Smarter Procurement." In this article, we embark on a journey to explore how the adoption of cutting-edge technologies is revolutionizing manufacturing procurement processes, ushering in an era of unprecedented efficiency, cost-effectiveness, and innovation.

Manufacturing procurement, the heart of supply chain management, has long been marked by intricate negotiations, voluminous paperwork, and unpredictable inventory management. However, the status quo is rapidly evolving, driven by a confluence of factors.

The integration of artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and blockchain technologies has propelled manufacturing procurement into a new dimension.

These technologies empower manufacturers to make data-driven decisions, optimize supply chains, and foster stronger partnerships with suppliers.

As we delve deeper into this transformative landscape, we will dissect the key technologies at play and their applications in manufacturing procurement. We will unravel the myriad benefits these innovations bestow upon manufacturers, from reducing operational costs and enhancing supplier relationships to fortifying compliance and risk management.

in the pages that follow, we will outline practical steps for manufacturers to embark on their journey towards Smarter Procurement, providing insights into assessment, technology selection, implementation strategies, and ongoing optimization. We will also peer into the future, glimpsing at upcoming trends that promise further revolution within this domain.

Join us as we embark on this enlightening expedition into the world of manufacturing procurement's technological evolution, and discover the boundless possibilities that await those who dare to embrace change.

- What is Procurement?

- What is Smart Procurement?

- Why is it Important for Manufacturing Companies to Adopt Advanced Technologies in Procurement?

- Benefits of Adopting Advanced Technologies in Manufacturing Procurement

- Examples of Advanced Technologies Used in Manufacturing Procurement

- Challenges of Adopting Advanced Technologies in Manufacturing Procurement

- Steps to Adopt Advanced Technologies in Manufacturing Procurement

- Conclusion

- Key Takeaways

- Related Articles

What is Procurement?

Procurement is the process of acquiring goods and services from suppliers. It includes activities such as sourcing, negotiating, ordering, receiving, and paying for goods and services. Procurement is an important function in any organization, as it can have a significant impact on costs, efficiency, and compliance.

There are two main types of procurement: direct procurement and indirect procurement. Direct procurement refers to the acquisition of goods and services that are directly used in the production of a product or service. Indirect procurement refers to the acquisition of goods and services that are used to support the business, such as office supplies and IT services.

The procurement process can be divided into several stages:

- Sourcing: This is the process of identifying potential suppliers and obtaining quotes.

- Negotiation: This is the process of negotiating the terms of the purchase, such as price, delivery, and payment terms.

- Order placement: This is the process of placing an order with the supplier.

- Receiving: This is the process of receiving the goods or services from the supplier.

- Payment: This is the process of paying the supplier for the goods or services.

The procurement process can be complex and time-consuming, but it is an important function that can help organizations save money, improve efficiency, and comply with regulations.

Here are some of the key benefits of effective procurement:

- Reduced costs: Effective procurement can help organizations to reduce costs by negotiating better prices, identifying discounts and rebates, and managing supplier relationships.

- Improved efficiency: Effective procurement can help organizations to improve efficiency by streamlining the procurement process, automating tasks, and using technology to track spending and identify trends.

- Increased visibility: Effective procurement can help organizations to gain greater visibility into their spending by tracking supplier performance, managing contracts, and ensuring compliance with regulations.

- Enhanced risk management: Effective procurement can help organizations to mitigate risks by assessing supplier risk, managing compliance, and tracking counterfeit goods.

- Improved sustainability: Effective procurement can help organizations to improve their sustainability by sourcing sustainable materials, reducing waste, and minimizing their environmental impact.

What is Smart Procurement?

Smart procurement is the use of technology to automate and streamline the procurement process. It can help organizations to reduce costs, improve efficiency, and gain greater visibility into their spending.

Smart procurement uses a variety of technologies, including:

- Artificial intelligence (AI): AI can be used to automate tasks such as sourcing, negotiating, and ordering. AI can also be used to identify and reduce procurement risks.

- Machine learning: Machine learning can be used to analyze historical data to identify patterns and trends. This information can be used to make better procurement decisions, such as predicting future demand or identifying potential suppliers.

- Blockchain: Blockchain can be used to create a secure and transparent record of procurement transactions. This can help to reduce fraud and errors.

- 3D printing: 3D printing can be used to produce parts and components on-demand. This can help to reduce inventory costs and improve agility.

- The Internet of Things (IoT): The IoT can be used to collect data from sensors and other devices throughout the procurement process. This data can be used to improve efficiency, optimize inventory levels, and identify potential problems.

Smart procurement can be implemented in a variety of ways, depending on the specific needs of the organization. Some organizations may choose to implement a comprehensive smart procurement solution, while others may choose to implement a more gradual approach.

The benefits of smart procurement include:

- Reduced costs: Smart procurement can help organizations to reduce costs by automating tasks, negotiating better prices, and identifying discounts and rebates.

- Improved efficiency: Smart procurement can help organizations to improve efficiency by streamlining the procurement process, automating tasks, and using technology to track spending and identify trends.

- Increased visibility: Smart procurement can help organizations to gain greater visibility into their spending by tracking supplier performance, managing contracts, and ensuring compliance with regulations.

- Enhanced risk management: Smart procurement can help organizations to mitigate risks by assessing supplier risk, managing compliance, and tracking counterfeit goods.

- Improved sustainability: Smart procurement can help organizations to improve their sustainability by sourcing sustainable materials, reducing waste, and minimizing their environmental impact.

If you are considering implementing smart procurement, there are a few things you need to keep in mind:

- The cost of implementation: Smart procurement can be a significant investment, so it is important to carefully consider the costs and benefits before you implement it.

- The need for change management: Smart procurement requires a change in the way that procurement is done. This can be a challenge, so it is important to have a plan for managing change.

- The need for data: Smart procurement relies on data. You need to make sure that you have the data that you need to make informed decisions.

If you are willing to invest in the implementation and change management, smart procurement can be a valuable tool for improving your organization's procurement process.

Why is it Important for Manufacturing Companies to Adopt Advanced Technologies in Procurement?

Manufacturing companies are increasingly adopting advanced technologies in procurement to improve their efficiency, reduce costs, and gain a competitive edge.

Here are some of the reasons why it is important for manufacturing companies to adopt advanced technologies in procurement:

- Enhanced sustainability: Advanced technologies can help to make the procurement process more sustainable. For example, they can be used to track the environmental impact of procurement decisions, source sustainable materials, and reduce waste.

- Artificial intelligence (AI): AI is being used to automate tasks such as sourcing, negotiating, and ordering. AI can also be used to identify and reduce procurement risks. For example, AI can be used to analyze historical data to identify patterns and trends in supplier performance. This information can be used to identify suppliers that are at risk of defaulting on their contracts.

- Machine learning: Machine learning is being used to analyze historical data to identify patterns and trends. This information can be used to make better procurement decisions, such as predicting future demand or identifying potential suppliers. For example, machine learning can be used to analyze historical data on demand for raw materials to predict future demand. This information can then be used to negotiate better prices with suppliers.

- Blockchain: Blockchain is being used to create a secure and transparent record of procurement transactions. This can help to reduce fraud and errors. For example, blockchain can be used to track the movement of goods and materials throughout the supply chain. This information can be used to verify the authenticity of goods and materials and to prevent counterfeiting.

- 3D printing: 3D printing is being used to produce parts and components on-demand. This can help to reduce inventory costs and improve agility. For example, 3D printing can be used to produce spare parts for manufacturing equipment. This can help to reduce the time and cost of repairing equipment downtime.

- The Internet of Things (IoT): The IoT is being used to collect data from sensors and other devices throughout the procurement process. This data can be used to improve efficiency, optimize inventory levels, and identify potential problems. For example, the IoT can be used to track the temperature and humidity of goods in storage. This information can be used to prevent damage to goods and to ensure that goods are stored in the correct conditions.

Benefits of Adopting Advanced Technologies in Manufacturing Procurement

Here are some specific examples of how advanced technologies are being used in manufacturing procurement:

- Improved efficiency and productivity: Advanced technologies can help to automate and streamline many of the manual tasks involved in procurement, such as sourcing, negotiating, and ordering. This can free up procurement professionals to focus on more strategic tasks, such as developing supplier relationships and managing risk.

- Reduced costs: Advanced technologies can help to identify and reduce procurement costs in a number of ways. For example, they can be used to compare prices from multiple suppliers, identify discounts and rebates, and negotiate better terms.

- Increased visibility and control: Advanced technologies can provide greater visibility into the procurement process, from identifying demand to tracking orders and payments. This can help to improve decision-making and ensure that procurement is aligned with the overall business goals.

- Improved risk management: Advanced technologies can help to identify and mitigate risks in the procurement process. For example, they can be used to assess supplier risk, manage compliance, and track counterfeit goods.

- Enhanced sustainability: Advanced technologies can help to make the procurement process more sustainable. For example, they can be used to track the environmental impact of procurement decisions, source sustainable materials, and reduce waste.

These are just a few of the ways that advanced technologies are being used in manufacturing procurement. As these technologies continue to develop, we can expect to see even more innovation in this area.

Examples of Advanced Technologies Used in Manufacturing Procurement

Apart from Artificial Intelligence, block chain, and machine learning, there are various other examples of advanced technologies that can enhance manufacturing procurement. Let’s learn about them:

- 3D printing: This can help to reduce inventory costs and improve agility. For example, 3D printing can be used to produce spare parts for manufacturing equipment. This can help to reduce the time and cost of repairing equipment downtime.

- Robotics: This can help to improve efficiency and reduce costs. For example, robots can be used to pick up and pack orders in warehouses. This can help to free up human workers to focus on other tasks, such as customer service.

- Augmented reality (AR): AR is being used to help procurement professionals make better decisions. For example, AR can be used to visualize how a new piece of equipment will fit into a manufacturing plant. This can help procurement professionals to make better decisions about which equipment to purchase.

- Virtual reality (VR): VR is being used to train procurement professionals on new procurement processes and procedures. For example, VR can be used to simulate the experience of sourcing and negotiating with a supplier. This can help procurement professionals gain the skills they need to be successful in their role.

These are just a few of the advanced technologies that are being used in manufacturing procurement. As these technologies continue to develop, we can expect to see even more innovation in this area.

Challenges of Adopting Advanced Technologies in Manufacturing Procurement

Here are some tips for overcoming the challenges of adopting advanced technologies in manufacturing procurement:

- Cost: Advanced technologies can be expensive to implement and maintain.

- Lack of expertise: There may be a lack of expertise in-house to implement and use advanced technologies.

- Resistance to change: Some employees may be resistant to change and may not be willing to adopt new technologies.

- Data security and privacy: Advanced technologies often collect and store large amounts of data. This data must be protected from security breaches and privacy violations.

- Integration: Advanced technologies often need to be integrated with existing systems and processes. This can be a complex and time-consuming process.

- Vendor lock-in: Once a manufacturer adopts a particular technology, they may become locked into that vendor's ecosystem. This can make it difficult to switch to a different technology if needed.

Despite these challenges, the benefits of adopting advanced technologies in manufacturing procurement can be significant. By automating and streamlining the procurement process, reducing costs, improving visibility and control, and managing risk, advanced technologies can help manufacturing companies improve their bottom line and gain a competitive edge.

- Start small: Don't try to implement too many technologies at once. Start with a small project that you can manage and then scale up as you gain experience.

- Get buy-in from stakeholders: Make sure that all stakeholders are on board with the adoption of new technologies. This includes employees, management, and suppliers.

- Provide training: Employees need to be trained on how to use new technologies. This training should be ongoing to ensure that employees are up-to-date on the latest features and functionality.

- Choose the right technologies: Not all technologies are created equal. Choose technologies that are right for your specific needs and budget.

- Plan for integration: Make sure that you have a plan for integrating new technologies with your existing systems and processes.

- Manage risk: Understand the risks associated with adopting new technologies and put measures in place to mitigate those risks.

By following these tips, you can overcome the challenges of adopting advanced technologies in manufacturing procurement and reap the benefits of these technologies.

Steps to Adopt Advanced Technologies in Manufacturing Procurement

here are the steps to adopt advanced technologies in manufacturing procurement, explained in terms of the following:

A. Assess current procurement processes: This step involves understanding the current procurement process, including the goals, objectives, pain points, and opportunities for improvement. This information can be gathered through interviews, surveys, and process mapping.

B. Identify suitable technologies: Once the current procurement process has been assessed, the next step is to identify suitable technologies. There are a variety of technologies that can be used in manufacturing procurement, including artificial intelligence (AI), machine learning, blockchain, and 3D printing. The specific technologies that are selected will depend on the specific needs of the organization.

C. Create a roadmap for implementation: Once suitable technologies have been identified, the next step is to create a roadmap for implementation. This roadmap should include a timeline, budget, and resource plan. It should also identify the challenges that may be encountered during implementation and how these challenges will be addressed.

D. Invest in training and change management: The successful adoption of advanced technologies requires training and change management. Employees need to be trained on how to use the new technologies, and they need to be prepared for the changes that these technologies will bring. Change management is also important to ensure that the organization is ready for the changes that come with the adoption of new technologies.

E. Monitor and continuously optimize: Once the new technologies have been implemented, it is important to monitor their performance and make continuous improvements. This can be done by collecting data and using it to identify areas for improvement.

By following these steps, organizations can successfully adopt advanced technologies in manufacturing procurement and reap the benefits of these technologies.

Here are some additional tips for adopting advanced technologies in manufacturing procurement:

- Start small and scale up as you go. Don't try to implement too many technologies at once.

- Get buy-in from stakeholders. Make sure that everyone who will be affected by the changes is on board.

- Provide training and support. Employees need to be trained on how to use the new technologies and they need to be supported as they transition to using these technologies.

- Be patient and persistent. It takes time to adopt new technologies and to see the benefits.

- By following these tips, organizations can increase their chances of success in adopting advanced technologies in manufacturing procurement.

Conclusion

In conclusion, advanced technologies can be a valuable tool for improving the procurement process in manufacturing. By automating and streamlining tasks, reducing costs, improving visibility and control, and managing risk, advanced technologies can help manufacturers to improve their bottom line and gain a competitive edge.

However, there are also challenges associated with adopting advanced technologies. These challenges include cost, lack of expertise, resistance to change, data security and privacy, integration, and vendor lock-in.

Despite these challenges, the benefits of adopting advanced technologies can be significant. By carefully considering the challenges and benefits, manufacturers can make informed decisions about whether or not to adopt advanced technologies in their procurement process.

Here are some additional thoughts on the future of smart procurement in manufacturing:

- We can expect to see even more innovation in the use of advanced technologies in manufacturing procurement.

- As these technologies become more affordable and accessible, more manufacturers will adopt them.

- Smart procurement will become an essential part of the manufacturing process, helping manufacturers to improve their efficiency, sustainability, and profitability.

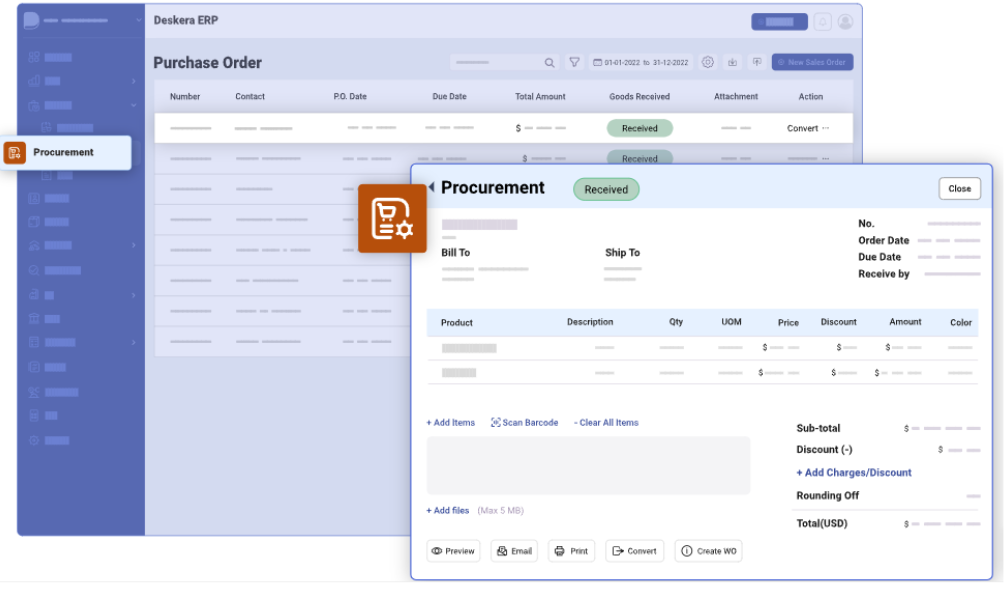

How Can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Here are some ways Deskera ERP's Procurement functionality can assist you:

- Create Requisitions and RFQs

- Generate Vendor Quotations

- Set up Vendor Scorecards

- Manage Preferred Suppliers

- Scan Purchase Invoices

- Create Purchase Orders

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways

Advanced technologies can help manufacturing companies to improve their procurement process in a number of ways, including:

- Improving efficiency and productivity: Advanced technologies can help to automate and streamline many of the manual tasks involved in procurement, such as sourcing, negotiating, and ordering. This can free up procurement professionals to focus on more strategic tasks, such as developing supplier relationships and managing risk.

- Reducing costs: Advanced technologies can help to identify and reduce procurement costs in a number of ways. For example, they can be used to compare prices from multiple suppliers, identify discounts and rebates, and negotiate better terms.

- Increased visibility and control: Advanced technologies can provide greater visibility into the procurement process, from identifying demand to tracking orders and payments. This can help to improve decision-making and ensure that procurement is aligned with the overall business goals.

- Improved risk management: Advanced technologies can help to identify and mitigate risks in the procurement process. For example, they can be used to assess supplier risk, manage compliance, and track counterfeit goods.

- Enhanced sustainability: Advanced technologies can help to make the procurement process more sustainable. For example, they can be used to track the environmental impact of procurement decisions, source sustainable materials, and reduce waste.

- Some of the advanced technologies that are being used in manufacturing procurement include:

- Artificial intelligence (AI): AI is being used to automate tasks such as sourcing, negotiating, and ordering. AI can also be used to identify and reduce procurement risks.

- Machine learning: Machine learning is being used to analyze historical data to identify patterns and trends. This information can be used to make better procurement decisions, such as predicting future demand or identifying potential suppliers.

- Blockchain: Blockchain is being used to create a secure and transparent record of procurement transactions. This can help to reduce fraud and errors.

- 3D printing: 3D printing is being used to produce parts and components on-demand. This can help to reduce inventory costs and improve agility.

- The Internet of Things (IoT): The IoT is being used to collect data from sensors and other devices throughout the procurement process. This data can be used to improve efficiency, optimize inventory levels, and identify potential problems.

7. There are a number of challenges associated with adopting advanced technologies in manufacturing procurement, including:

- Cost: Advanced technologies can be expensive to implement and maintain.

- Lack of expertise: There may be a lack of expertise in-house to implement and use advanced technologies.

- Resistance to change: Some employees may be resistant to change and may not be willing to adopt new technologies.

- Data security and privacy: Advanced technologies often collect and store large amounts of data. This data must be protected from security breaches and privacy violations.

- Integration: Advanced technologies often need to be integrated with existing systems and processes. This can be a complex and time-consuming process.

- Vendor lock-in: Once a manufacturer adopts a particular technology, they may become locked into that vendor's ecosystem. This can make it difficult to switch to a different technology if needed.

8. Despite the challenges, the benefits of adopting advanced technologies in manufacturing procurement can be significant. By automating and streamlining the procurement process, reducing costs, improving visibility and control, and managing risk, advanced technologies can help manufacturing companies to improve their bottom line and gain a competitive edge.

9. Here are some tips for overcoming the challenges of adopting advanced technologies in manufacturing procurement:

- Start small: Don't try to implement too many technologies at once. Start with a small project that you can manage and then scale up as you gain experience.

- Get buy-in from stakeholders: Make sure that all stakeholders are on board with the adoption of new technologies. This includes employees, management, and suppliers.

10. The future of smart procurement in manufacturing is bright. We can expect to see even more innovation in the use of advanced technologies in manufacturing procurement. As these technologies become more affordable and accessible, more manufacturers will adopt them.

Related Articles