Why do the same problems keep resurfacing in manufacturing, even after quick fixes? The answer lies in addressing symptoms instead of the actual cause. Root Cause Analysis (RCA) is a systematic method that helps manufacturers dig deeper into problems, uncover their origins, and implement solutions that last. Rather than patching up recurring issues, RCA ensures that businesses eliminate them at the source.

In today’s competitive manufacturing environment, downtime, quality defects, and inefficiencies directly affect profitability and customer satisfaction. RCA not only helps resolve these challenges but also strengthens overall operations by enhancing reliability and reducing waste. By focusing on the “why” behind every issue, manufacturers can transform reactive problem-solving into proactive improvement.

From techniques like the 5 Whys and Fishbone Diagram to advanced methods such as FMEA, RCA equips manufacturers with the tools they need to tackle production bottlenecks, improve quality, and maintain safety standards. Real-world applications further highlight how RCA can prevent costly breakdowns, streamline supply chains, and foster continuous improvement across operations.

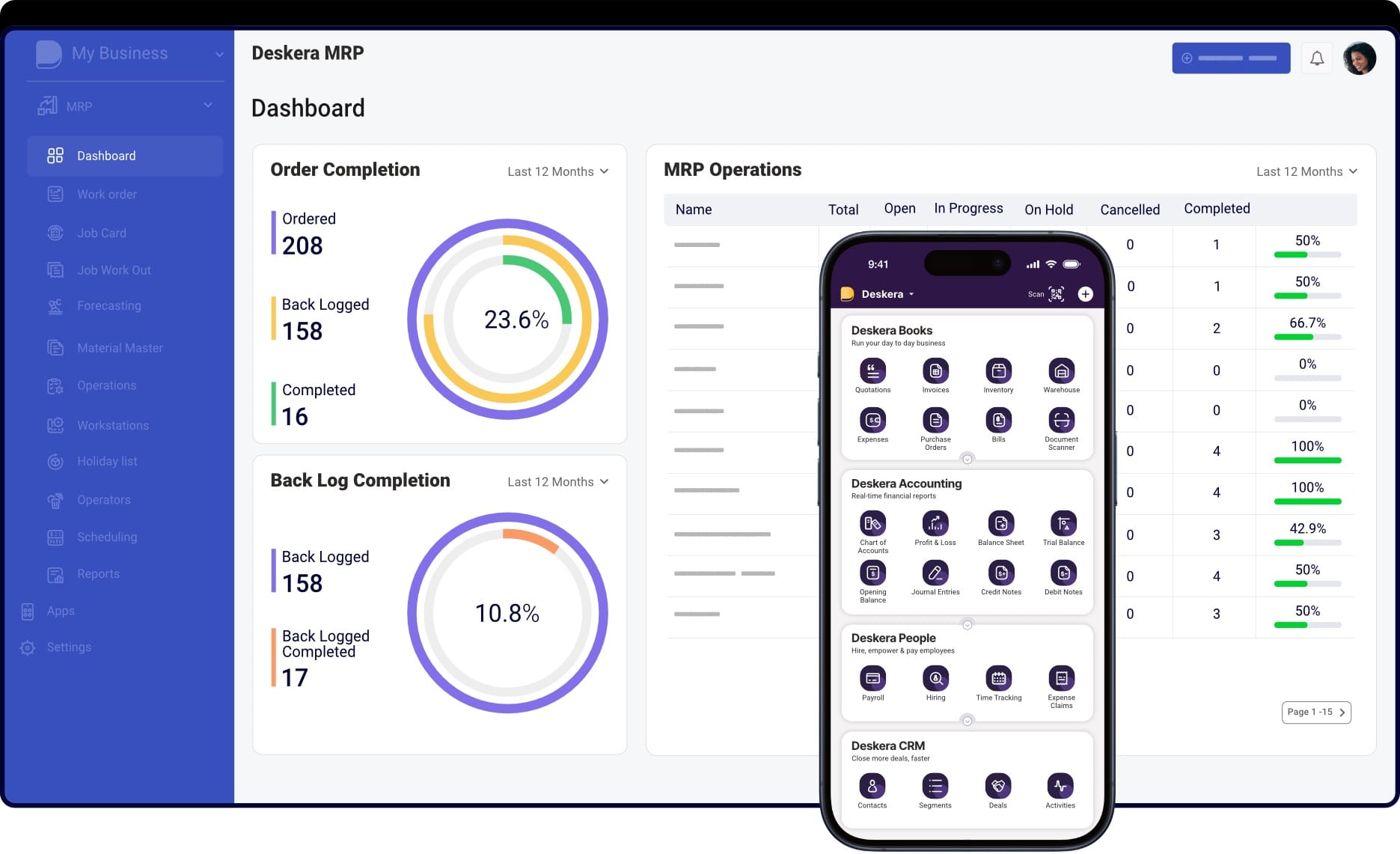

This is where digital solutions like Deskera Manufacturing ERP become invaluable. With real-time data tracking, AI-driven insights, and integrated production planning, Deskera helps manufacturers quickly identify problem areas and streamline RCA efforts. Its advanced reporting, mobile accessibility, and built-in MRP features empower teams to not just detect issues but resolve them efficiently, ensuring long-term operational excellence.

What is Root Cause Analysis in Manufacturing?

Root Cause Analysis (RCA) is a systematic process used to identify the fundamental reason behind a problem, rather than just addressing its symptoms.

In manufacturing, RCA plays a critical role in uncovering the true origins of product defects, equipment failures, production slowdowns, or recurring operational issues. The ultimate goal of RCA is not simply to fix a problem temporarily but to eliminate its source entirely, ensuring that the same issue does not resurface.

By implementing RCA, manufacturers can improve product quality, enhance production reliability, reduce waste, and safeguard customer satisfaction. For example, instead of continuously repairing a faulty machine that disrupts production, RCA would trace the breakdown back to its root—whether it’s poor maintenance practices, operator errors, or design flaws—and guide the business to a sustainable solution.

Manufacturers typically initiate RCA when faced with issues such as:

- Shop floor disruptions – Unexpected bottlenecks, stoppages, or inefficiencies.

- Product defects – Failures during quality checks, customer complaints, or recalls.

- Machinery breakdowns – Equipment failures leading to downtime or costly maintenance.

- Safety concerns – Accidents or compliance risks affecting workplace safety.

- Recurring problems – Persistent issues that signal previous fixes were incomplete.

A standardized RCA approach not only addresses these issues but also helps develop long-term prevention strategies, such as process redesign, enhanced employee training, or equipment upgrades.

Because of its structured methodology, RCA is recognized as a key element in continuous improvement frameworks like Lean Manufacturing and Six Sigma. By making RCA a core competency, manufacturers can resolve problems faster, prevent recurrences, and build a more resilient production system.

How to Perform a Root Cause Analysis in Manufacturing

Any manufacturing firm that wants to reduce downtime, improve product quality, boost safety, and minimize costs must understand how to perform a Root Cause Analysis (RCA).

While the specific tools and level of detail may vary depending on the industry, company size, or problem type, the core RCA process typically follows the same framework.

Here’s how it works step by step:

Step 1: Define the Problem Clearly

The process begins with accurately describing the problem. Go beyond vague statements like “the machine broke down” and instead capture specifics such as: what happened, when and where it occurred, who was involved, and the impact on production or quality. The goal is to create a fact-based problem statement that all stakeholders can agree on. This clarity prevents the analysis from drifting into assumptions or misinterpretations later.

Step 2: Gather the Right Data

Once the problem is defined, the next step is to collect all relevant information. This may include maintenance logs, operator reports, sensor readings, inspection data, and environmental conditions. In some cases, interviewing employees who were directly involved can provide valuable insights. The quality of the RCA is only as good as the data feeding it—so ensuring accuracy and completeness is critical.

Step 3: Identify Possible Causes

With the data in place, assemble a cross-functional team to brainstorm potential causes. Diverse perspectives—from operators and engineers to quality managers—help avoid tunnel vision. At this stage, it’s normal to generate multiple possible causes without jumping to a conclusion. Structured brainstorming tools, such as Fishbone Diagrams or Affinity Diagrams, can help organize ideas systematically.

Step 4: Analyze Each Cause

Now it’s time to dig deeper. Investigate each possible cause with structured techniques like the 5 Whys, Fault Tree Analysis, or Pareto Analysis. This step is about testing the validity of each hypothesis against the evidence. Be cautious of biases, such as only focusing on convenient explanations or ignoring data that challenges initial assumptions. The goal is to methodically rule out weaker causes and zero in on the most likely drivers.

Step 5: Pinpoint the True Root Cause

After a thorough analysis, the team should be able to identify the primary underlying cause—or sometimes multiple causes—that triggered the issue. For example, instead of simply blaming “machine failure,” RCA might uncover that poor preventive maintenance scheduling or inadequate operator training was the true reason behind the breakdown. Pinpointing the root cause ensures that future corrective actions will stop the problem at its source.

Step 6: Develop Corrective Actions

With the root cause identified, the next step is to design a corrective action plan. This plan should be specific, actionable, and realistic, addressing the root cause directly rather than applying a temporary fix. It may involve changing a process, updating training protocols, adjusting maintenance schedules, or investing in better equipment. Involving all key stakeholders at this stage increases the chances of adoption and long-term success.

Step 7: Implement the Solution

Execution is just as important as planning. The corrective actions should be implemented systematically, with clear ownership, sufficient resources, and effective communication across teams. This prevents confusion, duplication of effort, or incomplete adoption. Changes should also be well-documented so they can be standardized across the organization.

Step 8: Track and Validate Results

Finally, no RCA is complete without follow-up. Manufacturers should monitor key performance indicators (KPIs), such as downtime reduction, defect rates, or cost savings, to confirm that the corrective actions have worked. Periodic audits and reviews help ensure that the problem has been permanently resolved.

Leading organizations also measure the effectiveness of their RCA programs overall—tracking metrics such as the number of RCAs performed, success rates of corrective actions, and long-term improvements in efficiency.

Root Cause Analysis Techniques and Methods

Most manufacturers standardize Root Cause Analysis (RCA) using structured techniques and methods designed to identify, analyze, and eliminate the underlying causes of production problems.

Choosing the right methodology ensures that investigations are evidence-based and effective, ultimately reducing downtime, improving quality, and supporting continuous improvement.

Below are some of the most widely used RCA techniques in manufacturing:

Five Whys

The Five Whys method involves asking “why?” repeatedly—usually at least five times—until the team uncovers the root cause. Each answer forms the basis for the next “why,” moving beyond surface-level symptoms.

For example, if a laser-cutting machine stops working:

- Why did the machine stop? → An overload blew a fuse.

- Why was there an overload? → The bearing was not lubricated.

- Why was it not lubricated? → The pump was not working properly.

- Why was the pump not working? → Its shaft was worn.

- Why was the shaft worn? → The strainer was missing, letting metal scraps in.

This technique works best for simple problems or when narrowing down after other methods. The key is basing every “why” on evidence, not assumptions.

Fishbone Diagram (Ishikawa Diagram)

The Fishbone Diagram visually categorizes potential causes of a problem into branches such as methods, machines, materials, manpower, measurement, and environment.

For instance, in analyzing equipment failure, teams can brainstorm all possible factors under each branch—like operator error under manpower, or humidity under environment.

This method is especially useful for complex issues with many contributing factors, encouraging cross-functional collaboration and thorough investigation.

Fault Tree Analysis

Fault Tree Analysis (FTA) is a top-down visual method that starts with the undesired event (e.g., equipment failure) and breaks it down into possible causes using logical “AND” and “OR” gates.

Example: Equipment failure might result from mechanical failure, electrical issues, operator error, or environmental conditions. The tree structure shows how these failures interact—whether one alone is enough to cause the issue, or multiple must occur simultaneously.

FTA is particularly valuable in complex manufacturing environments where one failure could ripple across the system. Some manufacturers also use it proactively in product design to anticipate potential issues before they occur.

Is/Is Not Analysis

The Is/Is Not Analysis narrows the scope of an investigation by distinguishing what the problem is versus what it is not.

For example, if a plant experiences frequent equipment failures:

- Is: Machines A and B, during night shifts, while cutting material X.

- Is Not: Machines C and D, during day shifts, while processing material Y.

By clarifying these distinctions, teams can spot patterns and anomalies that point toward the root cause. This approach works well when the problem is unclear or has fuzzy boundaries, helping teams avoid chasing irrelevant issues.

Pareto Analysis

Based on the 80/20 rule, Pareto Analysis helps teams focus on the “vital few” causes that contribute to most of the problems.

For instance, a smartphone manufacturer facing weight variability might find:

- Human error: 40%

- Equipment issues: 20%

- Process issues: 5%

- Environmental issues: 2%

Instead of spreading resources thin, the company can focus on human error and equipment, which together account for 60% of issues. Pareto charts make this prioritization visual and data-driven, helping teams direct corrective efforts where they’ll have the most impact.

Failure Modes and Effects Analysis (FMEA)

FMEA is a structured method for identifying potential failure modes, analyzing their effects, and prioritizing them based on severity, occurrence, and detectability.

Though often used proactively during design and process planning, FMEA also plays a key role in RCA. If failures occur despite preventive measures, revisiting the FMEA helps teams determine whether critical risks were overlooked or controls need to be updated.

By proactively identifying vulnerabilities, manufacturers can reduce risks before they escalate and improve the resilience of their processes.

Together, these RCA methods provide manufacturers with a toolbox of strategies to match the complexity and urgency of each problem. In practice, many teams combine techniques—for example, using a Fishbone Diagram to brainstorm possible causes and then applying the Five Whys to drill down further.

Benefits of Performing Root Cause Analysis in Manufacturing

Performing Root Cause Analysis (RCA) is not just about solving problems—it’s about preventing them from recurring and creating a more reliable, efficient, and competitive manufacturing operation.

By digging deeper into the underlying issues rather than applying surface-level fixes, manufacturers can unlock a wide range of benefits that directly impact cost savings, productivity, safety, and customer satisfaction.

1. Cost Optimization and Waste Reduction

Manufacturing is often characterized by tight profit margins, and recurring defects, recalls, and unplanned downtime can cut deeply into profitability. According to a 2024 Hexagon/ETQ survey, nearly three-quarters of manufacturers experienced a product recall in the past five years, costing millions of dollars each time.

RCA helps reduce these risks by eliminating inefficient processes, unnecessary rework, scrap, and bottlenecks, ultimately driving higher cost efficiency. By solving the true source of problems, manufacturers can significantly improve profitability and resource utilization.

2. Improved Processes and Efficiency

One of the greatest advantages of RCA is its ability to enhance workflows and streamline processes. When underlying inefficiencies are uncovered and resolved, manufacturers see improvements in consistency, cycle times, and overall throughput.

Instead of repeatedly dealing with the same disruptions, teams can focus on continuous improvement and smoother, more predictable production lines. This not only supports operational excellence but also increases resilience in the face of market and demand fluctuations.

3. Reduced Downtime and Increased Reliability

Unplanned downtime is one of the most expensive problems for any manufacturer. Equipment breakdowns, supply chain disruptions, or process failures can halt production and cause significant losses. RCA helps by targeting the root causes of downtime—whether mechanical, process-related, or workforce-driven.

For example, a 2024 survey by L2L found that 81% of manufacturers experienced disruptions due to high employee turnover. By using RCA, companies can prevent repeat stoppages and make their systems more reliable, minimizing costly interruptions.

4. Stronger Safety Standards

Workplace accidents or near-misses often stem from deeper systemic issues. RCA enables manufacturers to identify these fundamental causes of safety incidents—such as poorly maintained equipment, insufficient training, or flawed processes—and implement long-term solutions.

This not only reduces the likelihood of injuries and compliance issues but also fosters a culture of safety. Employees who feel safe and valued are more engaged, contributing to both productivity and morale on the shop floor.

5. Enhanced Productivity and Output

When RCA is integrated into daily operations, manufacturers are better able to eradicate recurring inefficiencies that slow down production.

Machines run more consistently, teams work more effectively, and the shop floor achieves peak capacity utilization.

The cumulative effect is higher productivity, better on-time delivery performance, and stronger competitiveness in the marketplace.

6. A Proactive and Continuous Improvement Culture

RCA shifts the mindset of manufacturing teams from reactive firefighting to proactive problem-solving. Instead of waiting for issues to escalate, employees begin to anticipate and address risks before they become costly problems.

Over time, this fosters a culture of continuous improvement where data-driven decision-making, collaboration, and innovation thrive. Manufacturers who embed RCA into their culture position themselves for long-term operational excellence and sustainable growth.

7. Data-Driven Insights and Better Decision-Making

Because RCA relies heavily on data collection and analysis, it enables leaders to base decisions on evidence rather than assumptions. Tracking patterns, identifying recurring failure points, and analyzing trends provide actionable insights that can be used to optimize processes, guide investments, and prioritize improvement initiatives. In the age of smart factories and Industry 4.0, data-driven RCA is an essential enabler of intelligent manufacturing.

In summary, Root Cause Analysis doesn’t just solve problems—it creates a foundation for efficiency, reliability, safety, and continuous improvement in manufacturing. Companies that consistently apply RCA not only reduce costs and downtime but also build stronger, safer, and more customer-focused operations.

Challenges of Performing Root Cause Analysis in Manufacturing and How to Overcome Them

While root cause analysis (RCA) offers manufacturers a powerful framework for problem-solving and continuous improvement, it isn’t without its challenges.

Many organizations stumble during implementation, leading to incomplete investigations, misdiagnosed problems, or recurring issues.

Below are some of the most common challenges manufacturers face when performing RCA—and strategies to overcome them.

1. Confirmation Bias

Challenge: Teams may unconsciously filter out evidence that contradicts their initial assumptions, focusing only on information that validates their preexisting beliefs. This skews the RCA and often leads to incomplete or incorrect conclusions.

Solution: Encourage a culture of open-minded investigation. Use cross-functional teams to bring diverse perspectives, and rely on structured tools like the 5 Whys or Fishbone Diagram to systematically evaluate evidence rather than jumping to conclusions.

2. Confusing Contributing Factors with Root Causes

Challenge: Teams often mistake contributing factors (conditions influencing the problem) for the true root cause. For example, frequent CNC machine breakdowns might be linked to operator errors or material inconsistencies, but the deeper issue could be insufficient investment in preventive maintenance.

Solution: Train teams to distinguish between contributing factors and root causes. Encourage deeper questioning beyond surface-level observations until a systemic issue is uncovered.

3. Data Gaps and Inaccuracies

Challenge: RCA is only as strong as the data behind it. Missing, incomplete, or inaccurate data forces teams to rely on hunches, leading to flawed solutions.

Solution: Invest in reliable data collection systems, such as IoT sensors and ERP software, to capture real-time operational data. Deskera Manufacturing ERP, for instance, centralizes production and maintenance data, ensuring that RCA investigations are based on accurate and comprehensive insights.

4. Assigning Individual Blame

Challenge: When investigations turn into fault-finding exercises, individuals feel threatened, and collaboration breaks down. This not only derails RCA efforts but also damages workplace culture.

Solution: Emphasize that RCA is about fixing processes, not people. Reinforce a culture of continuous improvement, where the focus is on preventing recurrence rather than penalizing mistakes.

5. Lack of Follow-Up

Challenge: Implementing corrective actions is only half the battle. Without follow-up, there’s no way to measure whether solutions are effective—or whether new issues have emerged.

Solution: Establish clear monitoring mechanisms. Use KPIs and periodic reviews to track progress. Incorporate follow-up steps directly into standard operating procedures so they become part of routine operations.

6. Limited RCA Skills and Training

Challenge: Not every employee is equipped with the right analytical or problem-solving skills to perform effective RCA. Without proper training, investigations may stall or miss critical insights.

Solution: Invest in regular RCA training programs. Provide hands-on practice with tools like Fault Tree Analysis, Pareto Charts, and Failure Mode and Effects Analysis (FMEA). Empower employees with both technical and problem-solving skills to make RCA part of everyday operations.

Best Practices for Performing Root Cause Analysis in Manufacturing

Performing root cause analysis (RCA) effectively requires more than just following a checklist—it demands discipline, structure, and the right mindset. A poorly executed RCA can result in wasted time, incorrect conclusions, or temporary fixes that allow problems to resurface.

By adopting best practices, manufacturers can maximize the impact of RCA and embed it into their continuous improvement culture.

1. Focus on Improving Systems, Not Assigning Blame

The ultimate goal of RCA is to improve processes and systems, not to penalize individuals. Focusing on “who caused the problem” discourages honesty and prevents accurate analysis. Instead, RCA should seek to answer the “how” and “why” questions behind an issue.

- Build cross-functional RCA teams to broaden perspectives.

- Foster a culture of psychological safety, where employees feel comfortable reporting problems and sharing insights.

- Ensure corrective actions target system improvements such as updated processes, better training, or new technology.

2. Look Beyond Symptoms to Identify True Causes

It’s tempting to address the most visible symptoms of a problem—for example, replacing a broken machine part—without asking why the failure happened in the first place. This approach only provides short-term relief.

- Encourage teams to use tools like the 5 Whys or Fishbone Diagram to dig deeper.

- Collect complete, accurate data to distinguish between symptoms, contributing factors, and root causes.

- Push investigations until systemic issues are identified, ensuring long-term solutions.

3. Keep Solutions Practical and Sustainable

Corrective actions must be realistic and aligned with organizational resources. Overly complex, costly, or disruptive solutions are unlikely to be implemented fully—or at all.

- Involve all relevant stakeholders in brainstorming and evaluating corrective actions.

- Pilot test solutions on a small scale before rolling them out across the organization.

- Balance cost, feasibility, and long-term impact when deciding on corrective measures.

4. Validate Corrective Actions Through Monitoring

The work doesn’t end once a solution is implemented. Continuous monitoring ensures corrective actions are applied correctly and are delivering the intended results.

- Define KPIs or quality metrics to measure the effectiveness of corrective actions.

- Assign responsibility for follow-up monitoring to avoid oversight.

- Conduct regular reviews and audits to ensure corrective measures become embedded in standard processes.

5. Share Lessons and Prevent Recurrence

A successful RCA not only fixes a single issue but also prevents similar problems from arising elsewhere. Knowledge gained should be documented and shared widely.

- Record findings, corrective actions, and outcomes in a central repository.

- Update training programs, standard operating procedures (SOPs), and maintenance schedules.

- Share best practices across teams and departments to encourage organization-wide improvements.

6. Leverage Technology to Strengthen RCA

Modern manufacturing generates enormous amounts of data, and technology can make RCA both faster and more accurate. Tools like Manufacturing ERP systems consolidate information and provide insights that might otherwise be missed.

- Use ERP platforms like Deskera Manufacturing ERP to centralize production, quality, and maintenance data.

- Leverage dashboards, AI analytics, and automated alerts to identify trends and spot problems early.

- Automate data collection and reporting to reduce manual errors and ensure timely insights.

7. Monitoring Results and Continuous Improvement Cycles

RCA is not a one-time process—it thrives on continuous improvement.

- Monitoring post-implementation results ensures that corrective measures are effective and sustainable.

- Regular feedback loops and continuous monitoring foster a culture of learning, helping manufacturers refine processes and build long-term resilience.

Real-World Applications of RCA in Manufacturing

Root Cause Analysis isn’t just a theoretical framework—it’s a practical problem-solving tool that has transformed manufacturing operations across industries.

By identifying the “why” behind persistent challenges, companies have been able to cut costs, boost efficiency, and deliver consistent product quality.

Here are some real-world applications of RCA in manufacturing:

- Minimizing Machine Downtime: A leading automotive manufacturer used the Fishbone Diagram and 5 Whys method to uncover that frequent machine breakdowns were caused not by operator errors but by irregular preventive maintenance schedules. By addressing this root cause, they reduced downtime by 25% in one year.

- Improving Product Quality: In the food processing industry, a company faced recurring packaging defects. RCA revealed that the root cause wasn’t equipment malfunction but a mismatch between packaging material specifications and supplier-provided stock. After switching suppliers, defect rates dropped by 40%.

- Enhancing Safety Standards: A chemical plant used Failure Mode and Effects Analysis (FMEA) to analyze recurring safety incidents. The analysis traced issues back to inadequate employee training. Implementing a structured training program reduced incident frequency by over 50%.

- Boosting Customer Satisfaction: An electronics manufacturer dealt with repeated customer complaints about faulty circuit boards. RCA uncovered that improper temperature settings during soldering were the main issue. Adjusting the process led to a 30% reduction in product returns within six months.

- Optimizing Supply Chain Efficiency: A textile manufacturer applied RCA to frequent delivery delays. The analysis identified inaccurate demand forecasting as the root cause, which was leading to stockouts. By implementing ERP-driven forecasting tools, they streamlined inventory and improved delivery performance.

How Can Deskera Manufacturing ERP Help You?

Deskera Manufacturing ERP makes root cause analysis easier, faster, and more effective by combining real-time data, advanced analytics, and process automation. Instead of relying on guesswork or incomplete information, manufacturers can identify issues, track corrective actions, and build a culture of continuous improvement.

Here’s how Deskera ERP supports you in root cause analysis:

- Centralized Data Management – Ensures complete and reliable information across production processes, reducing data gaps and assumptions.

- Advanced Reporting & Analytics – Highlights anomalies, recurring issues, and trends, making it easier to identify true root causes.

- Visual Dashboards – Provides at-a-glance tracking of corrective actions and improvements in progress.

- AI-Driven Insights – Reduces confirmation bias by offering data-backed decision-making support.

- Automated Workflows – Streamlines corrective action processes and follow-ups to maintain long-term improvements.

- Mobile Accessibility – Enables teams to monitor processes and RCA progress anytime, anywhere.

- Collaboration Tools – Fosters cross-functional teamwork and accountability without placing blame on individuals.

By integrating these features, Deskera Manufacturing ERP helps businesses shift from reactive firefighting to proactive problem-solving, driving efficiency and continuous growth.

Key Takeaways

- Root cause analysis (RCA) goes beyond surface-level fixes and uncovers the true source of recurring manufacturing issues, enabling long-term solutions.

- RCA reduces downtime, prevents costly rework, and improves product quality, making it a vital practice for efficiency and profitability.

- Techniques like the 5 Whys, Fishbone Diagram, and Failure Mode and Effects Analysis (FMEA) provide structured methods to identify and solve problems effectively.

- Combining qualitative and quantitative approaches—such as Pareto analysis, fault tree analysis, and statistical methods—helps teams pinpoint issues with precision.

- Case examples highlight how RCA has been successfully applied to reduce machine breakdowns, improve process efficiency, and enhance customer satisfaction.

- Manufacturers often face obstacles such as limited data, time constraints, and resistance to change, which can undermine RCA’s effectiveness.

- Adopting a culture of continuous improvement, encouraging collaboration, and documenting corrective actions are essential to achieving sustainable results.

- Deskera Manufacturing ERP simplifies RCA with centralized data, AI-driven insights, automated workflows, and real-time reporting to drive proactive problem-solving.

Related Articles