Procurement is often viewed as a back-office function, but in reality, it plays a defining role in how efficiently a business operates. One of the most critical metrics within this process is procurement lead time—the total time taken from identifying a purchasing need to receiving the goods or services. When this timeline stretches, it doesn’t just delay procurement; it disrupts production schedules, inflates inventory costs, and weakens customer commitments across the supply chain.

The significance of procurement lead time becomes clearer when you look at its share in the broader supply chain cycle. Studies indicate that procurement activities can represent nearly 80% of the overall supply chain operation cycle, making it one of the largest contributors to operational efficiency—or inefficiency. Even small delays at the procurement stage can cascade into missed deadlines, excess safety stock, and reduced business agility.

Despite its impact, procurement remains heavily reliant on manual processes. In fact, 83% of procurement professionals report that less than half of their processes are automated, a gap that directly contributes to longer approval cycles, fragmented communication, and avoidable delays. Compounding this challenge is limited visibility—69% of organizations lack complete oversight across their supply chains, making it difficult to anticipate disruptions or manage procurement lead time proactively.

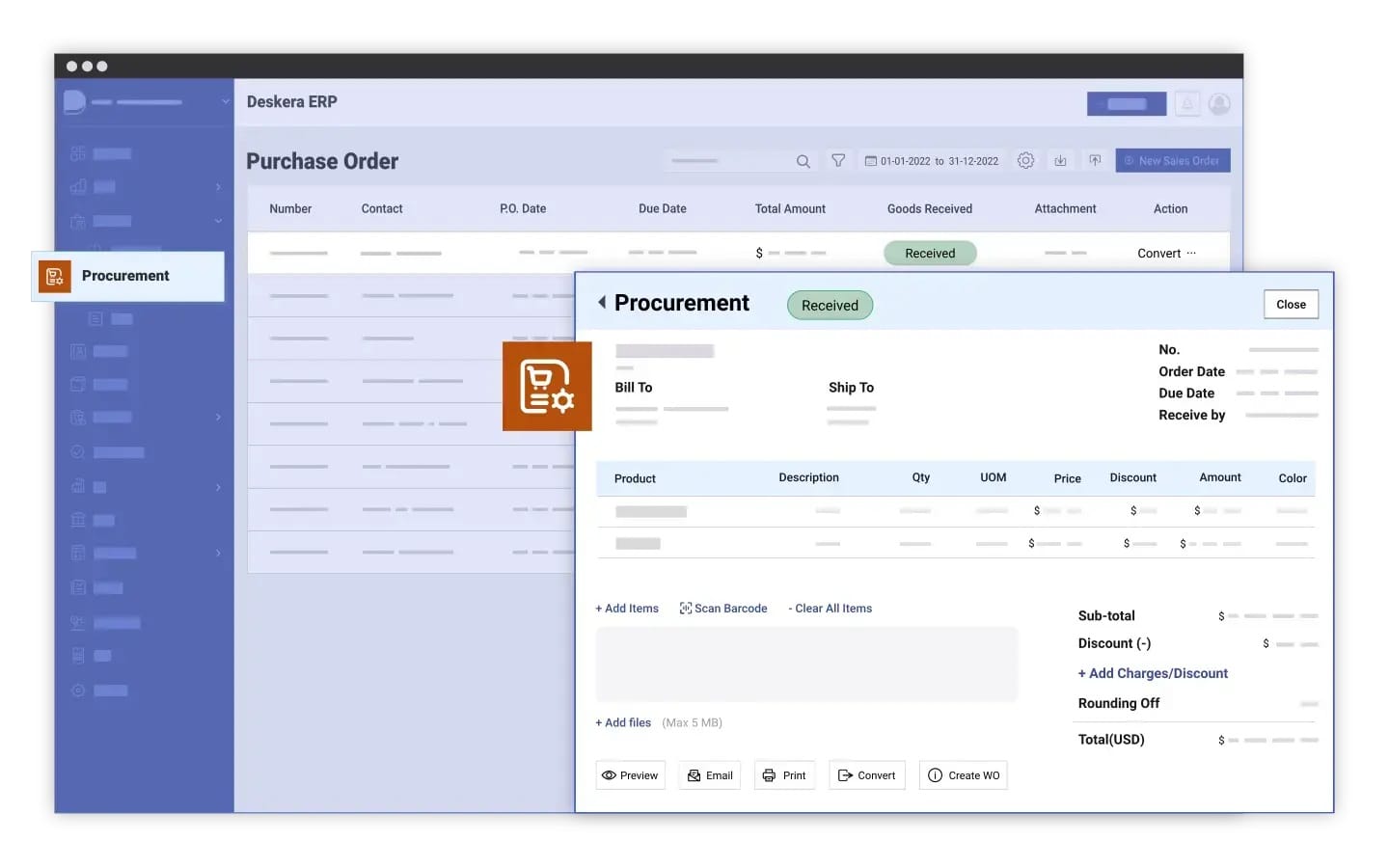

This is where modern ERP solutions like Deskera ERP make a measurable difference. Deskera centralizes procurement, inventory, and finance data on a single platform, enabling real-time visibility into every stage of the procurement cycle. With automated workflows, faster approvals, and actionable insights, Deskera ERP helps businesses shorten procurement lead times, improve coordination with suppliers, and build a more resilient, responsive supply chain.

What Is Procurement Lead Time?

Procurement lead time refers to the total time taken from identifying the need for goods or services to their final delivery and acceptance by the business. It covers every stage of the procurement cycle—from internal approvals and purchase requisitions to supplier coordination, production, shipping, inspection, and receipt of goods. Typically measured in days or weeks, procurement lead time is a critical supply chain KPI that directly influences how effectively an organization can plan, operate, and respond to demand.

More specifically, procurement lead time begins when an order is initiated and ends when the ordered items arrive at the designated location and are ready for use. This timeframe includes multiple interconnected activities such as supplier research and negotiations, production planning, raw material sourcing, manufacturing, quality inspections, packaging and labeling, logistics, customs clearance, and final delivery. Each of these stages contributes to the overall lead time and introduces potential delays if not managed carefully.

Because of its broad scope, procurement lead time has a direct impact on inventory management, production continuity, and cash flow. Businesses with long or unpredictable procurement lead times often struggle with stockouts, missed sales opportunities, or excess inventory that ties up working capital. Conversely, when procurement lead time is actively monitored and optimized, companies can reduce operating costs, improve supplier relationships, and respond more quickly to market changes and customer needs.

Ultimately, procurement lead time is about predicting, measuring, and controlling the timelines involved in sourcing materials from suppliers to buyers. Accurate lead time forecasting helps organizations strike the right balance between availability and cost—avoiding both shortages and overstocking. By understanding and managing procurement lead time effectively, businesses gain better control over their procurement systems, minimize operational disruptions, enhance customer satisfaction, and strengthen overall financial performance.

Key Components of Procurement Lead Time

Procurement lead time is not a single activity but a combination of multiple stages that occur from the moment a need is identified until the goods are ready for use. Understanding these components helps businesses pinpoint delays, improve planning accuracy, and optimize the overall procurement process.

Purchase Requisition and Internal Approvals

This stage begins when a department raises a purchase request and moves through internal reviews and approvals. Delays often occur due to manual workflows, unclear approval hierarchies, or incomplete requisition details.

Supplier Identification and Communication

Once the request is approved, procurement teams evaluate suppliers, request quotations, negotiate terms, and confirm availability. The efficiency of supplier communication and the reliability of vendors significantly influence lead time at this stage.

Purchase Order Creation and Confirmation

After selecting a supplier, a purchase order is created, approved, and sent for confirmation. Errors, rework, or slow approval cycles can extend this component of the procurement lead time.

Supplier Production or Order Processing

This phase includes the supplier’s time to source raw materials, schedule production, or prepare the order. Customization requirements, production capacity, and supplier efficiency directly affect how long this stage takes.

Quality Inspection and Packaging

Before shipment, goods may undergo quality checks, testing, packaging, and labeling. While essential for maintaining standards, inadequate coordination or rework can add unexpected delays.

Shipping, Logistics, and Customs Clearance

Transportation time, mode of shipping, customs procedures, and external disruptions such as weather or regulatory checks all contribute to procurement lead time. International sourcing often increases variability at this stage.

Goods Receipt and Final Inspection

The final component involves receiving the goods, inspecting them for quality and quantity, and updating inventory records. Delays here can occur if documentation is incomplete or discrepancies are found.

By breaking procurement lead time into these components, organizations can better identify bottlenecks, reduce variability, and implement targeted improvements that lead to faster, more reliable procurement cycles.

Why Procurement Lead Time Is Important

Procurement lead time plays a critical role in determining how smoothly a business operates. It directly influences inventory availability, production schedules, costs, and customer satisfaction.

When procurement lead time is predictable and well-managed, organizations can plan with confidence, minimize disruptions, and respond faster to market changes.

Impact on Inventory Management

Procurement lead time determines how much inventory a business needs to hold. Longer or inconsistent lead times often force companies to maintain higher safety stock, increasing carrying costs and the risk of obsolescence. Optimized lead times help maintain the right inventory balance—reducing both stockouts and excess inventory.

Influence on Production Planning

Reliable procurement lead times ensure that raw materials and components are available when needed. Delays can halt production lines, cause missed deadlines, and disrupt downstream operations. Shorter, predictable lead times enable smoother production schedules and better resource utilization.

Effect on Cash Flow and Working Capital

Procurement lead time has a direct impact on cash flow. Extended lead times tie up capital in inventory for longer periods, reducing liquidity. By shortening procurement cycles, businesses can free up working capital and improve overall financial flexibility.

Role in Meeting Customer Demand

Customer expectations for faster delivery continue to rise. Uncertain procurement lead times make it difficult to commit to accurate delivery dates, leading to dissatisfaction and lost trust. Efficient lead time management allows businesses to fulfill orders on time and improve service levels.

Contribution to Cost Control and Efficiency

Long procurement lead times often result in higher operational costs, including expedited shipping, emergency sourcing, and production downtime. Streamlining procurement lead time reduces these inefficiencies and supports more cost-effective operations.

Support for Business Agility and Competitiveness

In dynamic markets, the ability to respond quickly to changes in demand or supply conditions is a competitive advantage. Optimized procurement lead times enable businesses to adapt faster, launch products sooner, and stay ahead of competitors.

The Role of Procurement Lead Time in the Supply Chain

Procurement lead time serves as a critical performance indicator (KPI) that reflects how efficiently an organization sources goods and materials. It directly influences supply chain stability, cost control, and service levels. When procurement lead time is accurately measured and well-managed, businesses can align procurement activities with operational and strategic goals more effectively.

Inventory Planning and Optimization

Procurement lead time plays a key role in determining how much inventory a business should hold. Accurate lead time calculations help maintain optimal stock levels, reducing the risk of overstocking or stockouts while minimizing inventory carrying and storage costs.

Cash Flow and Working Capital Management

Shorter and more predictable procurement lead times reduce the need for large safety stock buffers. This frees up working capital, improves cash flow, and allows businesses to allocate resources to growth-focused initiatives.

Production Continuity and Operational Stability

Reliable procurement lead times ensure that raw materials and components are available when needed. This keeps production lines running smoothly, prevents costly downtime, and supports on-time order fulfillment.

Customer Satisfaction and Retention

Consistent procurement lead times enable businesses to meet delivery commitments and provide accurate timelines to customers. This reliability builds trust, reduces order cancellations, and strengthens long-term customer relationships.

Cost Efficiency Across the Supply Chain

Optimized procurement lead times help lower logistics costs, reduce emergency sourcing expenses, and limit excess warehousing needs. Over time, this leads to improved operational efficiency and reduced total supply chain costs.

Supplier Relationship Management

Strong supplier relationships contribute to faster response times and more reliable deliveries. Effective collaboration with suppliers helps reduce delays and ensures priority support during peak demand periods.

Risk Mitigation and Supply Chain Resilience

Well-managed procurement lead times reduce the impact of disruptions such as supplier delays, transportation issues, or regulatory challenges. This improves overall supply chain resilience and business continuity.

Strategic Sourcing and Flexibility

Diversifying suppliers and sourcing regions reduces dependency on a single vendor. This flexibility minimizes lead time variability and helps businesses adapt quickly to changing market conditions.

Demand Forecasting and Planning Accuracy

Accurate demand forecasting aligned with procurement lead times ensures materials are available when required. This reduces the need for emergency purchases and supports smoother production and fulfillment planning.

In a competitive business environment, procurement lead time directly affects how agile and responsive a supply chain can be. Organizations that actively manage and optimize this metric are better positioned to control costs, meet customer expectations, and gain a sustainable competitive advantage.

Factors That Affect Procurement Lead Time

Procurement lead time is influenced by a wide range of internal and external factors. From supplier performance to logistics and internal workflows, each element can either accelerate or delay the procurement cycle. Understanding these factors allows businesses to identify bottlenecks, reduce uncertainty, and improve procurement efficiency.

Supplier Reliability and Management

Reliable suppliers play a major role in reducing procurement lead time. Consistent delivery performance, strong quality control, and clear communication help avoid rework and delays. Building long-term relationships and actively managing supplier performance lowers procurement risks.

Geographic Location of Suppliers

The physical distance between buyers and suppliers directly affects transit time. Local or regional suppliers typically offer faster and more predictable deliveries, while overseas sourcing may introduce longer lead times due to shipping and border processes.

Shipping and Transportation Logistics

Efficient logistics, including route planning, freight management, and real-time shipment tracking, are essential for maintaining predictable lead times. Poor coordination or unreliable carriers can quickly extend procurement timelines.

Customs Regulations and Compliance

For international procurement, customs procedures and regulatory requirements can significantly impact lead time. Incomplete documentation or non-compliance often results in clearance delays, making regulatory awareness and preparation critical.

Order Size and Complexity

Large-volume or highly customized orders usually require longer production and inspection cycles. In contrast, standard or repeat orders move faster through the procurement process with fewer delays.

Inventory Management and Stock Levels

Inaccurate inventory data or frequent stockouts can delay procurement decisions and order fulfillment. Effective forecasting and real-time stock visibility help ensure materials are available when needed.

Supplier Production Capacity and Workload

Suppliers operating at or near full capacity may struggle to meet delivery timelines, especially during peak demand periods. Verifying production capacity in advance helps prevent unexpected delays.

Supplier Financial Stability

Financially unstable suppliers are more likely to experience labor shortages, production disruptions, or material constraints. Partnering with financially sound suppliers improves delivery reliability and reduces lead time risks.

Technology and Communication Systems

Digital procurement tools and integrated communication systems speed up order processing, approvals, and shipment tracking. Technology-enabled suppliers and buyers can significantly shorten procurement cycles.

Demand Fluctuations and Seasonality

Sudden spikes in demand or seasonal peaks often increase procurement lead times due to capacity constraints and logistics congestion. Proactive planning and forecasting help mitigate these challenges.

Internal Processes and Approvals

Slow or manual internal approval workflows can delay procurement before orders even reach suppliers. Streamlining approvals and improving cross-functional coordination accelerates the entire procurement process.

3 Critical Stages of Procurement Lead Time

Procurement lead time can be broadly divided into three critical stages. Each stage plays a distinct role in determining how quickly and efficiently goods move from suppliers to your business. Breaking procurement lead time into these phases makes it easier to identify delays and optimize the end-to-end procurement lifecycle.

1. Pre-Processing Stage: Sourcing and Approvals

This stage occurs before an order is placed and often sets the pace for the entire procurement cycle.

- Supplier selection and vetting: Evaluating vendors based on cost, quality standards, reliability, and delivery capability

- Negotiation and contract approvals: Finalizing pricing, payment terms, service-level agreements, and compliance requirements

- Internal purchase approvals: Securing authorization from procurement, finance, or management teams

Delays at this stage are commonly caused by manual approval workflows, extended contract negotiations, or limited supplier availability.

2. Processing Stage: Order Placement and Fulfillment

Once approvals are in place, the procurement process moves into execution.

- Purchase order placement: Issuing accurate purchase orders with confirmed quantities, prices, and delivery timelines

- Order confirmation from suppliers: Validating order details to avoid discrepancies or rework

- Manufacturing or order fulfillment: Accounting for production time, especially for customized or made-to-order items

Inefficiencies such as miscommunication, slow supplier responses, or production bottlenecks can significantly extend lead times during this stage.

3. Post-Processing Stage: Shipping and Receiving

The final stage focuses on moving goods to the buyer and making them ready for use.

- Shipping and logistics coordination: Managing transportation, carrier performance, and customs clearance for international shipments

- Receiving and inspection: Verifying quantity and quality before goods are accepted into inventory

- Inventory updates: Recording received items accurately to ensure stock visibility

Unpredictable logistics disruptions, customs delays, or delivery errors can slow this phase. Using reliable logistics partners and real-time tracking systems helps reduce risks and improve delivery accuracy.

Understanding these three stages allows businesses to pinpoint bottlenecks, streamline workflows, and reduce procurement lead time for more efficient and resilient supply chain operations.

How to Calculate Procurement Lead Time

Calculating procurement lead time allows businesses to plan purchases accurately, avoid production disruptions, and reduce the risk of stockouts or excess inventory. By breaking the process into clear stages and evaluating each component carefully, organizations can gain better control over their procurement timelines.

Procurement lead time is calculated by adding the time spent across all three stages of the procurement cycle:

Procurement Lead Time = Pre-Processing Time + Processing Time + Post-Processing Time

This formula represents the complete journey from internal planning and approvals to supplier fulfillment and final delivery. External factors such as customs delays or logistics disruptions may extend the total lead time.

Identifying Required Products and Materials

Start by creating a detailed list of all materials and products needed. Define quantities, technical specifications, and quality requirements, and prioritize items based on their urgency and importance to production or operations.

Determining Purchase Periods and Safety Margins

Evaluate how long it typically takes to receive items after placing an order. Add safety margins to account for supplier delays, demand fluctuations, or unexpected disruptions, especially for critical materials.

Segregating Items with Longer Lead Times

Identify items that have historically longer lead times or play a critical role in production. These items should be ordered earlier and monitored more closely to prevent downstream delays.

Calculating Production, Processing, and Waiting Times

Include supplier production or order fulfillment time, internal processing delays, shipping duration, and customs clearance. Capturing all waiting periods ensures a more accurate lead time calculation.

Reviewing Supplier Lead Times Regularly

Supplier lead times can change due to capacity constraints, location, or shipping methods. Regular reviews and open communication with suppliers help keep lead time data accurate and actionable.

Accounting for Transportation and Logistics Variability

Factor in potential delays caused by weather, port congestion, customs inspections, or carrier availability. Building buffer time is especially important for international procurement.

Assessing Inventory Levels and Buffer Stock

Conduct regular inventory checks and maintain buffer stock for high-risk or high-demand items. Inventory management methods such as FIFO or LIFO help reduce waste and improve material flow.

Leveraging Procurement Automation and Software

Use procurement and ERP software to track orders in real time, analyze historical data, and monitor supplier performance. Automation improves accuracy and reduces manual delays in lead time calculations.

Analyzing Historical Data and Performance Metrics

Review past procurement cycles to identify patterns, recurring delays, and supplier reliability issues. These insights help refine lead time estimates and improve future planning.

Strengthening Supplier Relationships

Strong supplier relationships enable better communication, flexibility, and faster issue resolution. Trusted suppliers are more likely to support shorter and more reliable procurement lead times.

Procurement Lead Time Calculation Examples

In a standard procurement scenario, internal approvals may take 3 days, order processing 7 days, and shipping and receiving 5 days—resulting in a total lead time of 15 days. In a manufacturing scenario involving custom production and international shipping, pre-processing may take 5 days, processing 14 days, and post-processing 10 days—resulting in a total procurement lead time of 29 days.

This structured approach helps businesses calculate procurement lead time more accurately, reduce uncertainty, and improve overall supply chain efficiency.

Best Practices to Reduce Procurement Lead Time

Reducing procurement lead time is essential for improving operational efficiency, strengthening cash flow, and maintaining a competitive edge. Delays in procurement can lead to stockouts, production stoppages, and dissatisfied customers. By combining strategic supplier management, streamlined internal processes, and technology-driven automation, businesses can significantly shorten procurement cycles and improve supply chain performance.

Optimize Supplier Relationships

Strong supplier relationships are the foundation of shorter procurement lead times. Collaborative partnerships improve responsiveness, reliability, and coordination across the supply chain.

- Develop strong partnerships: Maintain regular communication, share demand forecasts, and proactively address potential issues with key suppliers.

- Implement Vendor Managed Inventory (VMI): Allow suppliers to manage inventory levels and replenishment, reducing ordering delays and administrative effort.

- Negotiate better contract terms: Secure faster turnaround times, priority processing, clear delivery schedules, and penalties for delays within supplier agreements.

Streamline Internal Procurement Processes

Internal inefficiencies often cause avoidable delays before orders even reach suppliers. Simplifying and standardizing workflows can significantly reduce lead time.

- Automate procurement systems: Use procurement or ERP software to automate purchase orders, approvals, invoicing, and tracking.

- Standardize procedures: Implement uniform approval workflows, order templates, and supplier evaluation criteria to reduce variability and confusion.

- Enhance cross-functional communication: Ensure procurement, finance, and operations teams are aligned to prevent bottlenecks and rework.

Improve Demand Forecasting and Planning

Accurate forecasting reduces last-minute orders and allows suppliers to plan production and logistics more effectively.

- Leverage data analytics: Use historical data, seasonal trends, and market insights to predict demand more accurately.

- Adopt Just-In-Time (JIT) practices: Order materials only when needed, supported by reliable forecasts and strong supplier coordination.

- Share forecasts with suppliers: Providing visibility into future demand helps suppliers prepare capacity and shorten response times.

Enhance Order and Inventory Management

Efficient order handling and inventory planning help eliminate unnecessary delays and excess costs.

- Simplify ordering processes: Use electronic purchase orders and digital approvals to reduce administrative time and errors.

- Apply Economic Order Quantity (EOQ): Balance order size and holding costs to avoid overstocking or frequent rush orders.

- Maintain optimal buffer stock: Hold safety stock for critical or volatile items to reduce emergency procurement.

Leverage Technology and Automation

Technology plays a critical role in accelerating procurement workflows and improving visibility.

- Use ERP and procurement software: Enable real-time order tracking, supplier monitoring, and automated approvals.

- Implement supplier portals: Allow suppliers to view orders, confirm timelines, and update shipment status in real time.

- Apply AI and analytics: Improve demand prediction, identify bottlenecks, and continuously optimize lead times.

Diversify and Strategically Manage Suppliers

Over-reliance on a single supplier increases risk and lead time variability.

- Adopt multiple sourcing strategies: Maintain backup suppliers and source from different regions to reduce disruption risk.

- Prequalify suppliers: Create an approved vendor list to avoid repeated vetting and speed up reordering.

- Monitor supplier performance: Use scorecards and KPIs to evaluate delivery reliability, quality, and responsiveness.

Monitor Performance and Drive Continuous Improvement

Reducing procurement lead time is an ongoing effort that requires regular evaluation and adjustment.

- Track key procurement KPIs: Monitor order cycle time, supplier response time, and delivery accuracy.

- Conduct regular reviews: Identify bottlenecks, assess improvement initiatives, and refine strategies based on performance data.

- Strengthen long-term partnerships: Strategic supplier relationships often lead to priority handling, faster deliveries, and greater flexibility.

By implementing these best practices, businesses can shorten procurement lead times, reduce costs, improve agility, and ensure a more resilient and responsive supply chain.

Strategic Value of Shorter Procurement Lead Times

Shorter procurement lead times deliver more than just operational improvements—they create long-term strategic advantages that directly impact customer satisfaction, cost efficiency, and financial performance. Organizations that consistently reduce procurement lead times are better positioned to compete, adapt, and grow in dynamic markets.

Creating Happier and More Loyal Customers

Faster procurement lead times enable quicker order fulfillment and more reliable delivery commitments. When customers receive products on time—or sooner than expected—it builds trust and strengthens brand loyalty. In competitive markets where speed is a differentiator, shorter lead times help improve customer retention and increase overall customer lifetime value.

Reduced Risk of Inventory Obsolescence

Shorter lead times allow businesses to bring products to market faster, ensuring offerings remain relevant and aligned with current demand. This is especially critical in fast-changing industries where product lifecycles are short. By reducing the time inventory sits in the supply chain, companies lower the risk of obsolescence, markdowns, and waste while staying agile in response to shifting customer preferences.

Lower Labor and Operational Costs

Streamlined procurement processes reduce the manual effort required to manage sourcing, ordering, and inventory. Fewer delays mean less time spent on follow-ups, expediting, and issue resolution. Automation of tasks such as purchase order creation, approvals, and invoice processing further cuts labor costs while improving productivity and accuracy.

More Efficient Capital Utilization

Reducing procurement lead time accelerates the conversion of raw materials into finished goods and revenue. Faster procurement cycles free up working capital sooner, reduce inventory holding periods, and improve cash flow. This allows businesses to reinvest capital into growth initiatives, innovation, or market expansion.

In summary, shorter procurement lead times strengthen customer relationships, reduce financial and operational risk, lower costs, and improve capital efficiency—making them a powerful strategic lever for sustainable business success.

How Deskera ERP Simplifies Procurement Lead Time Management

Managing procurement lead time effectively requires eliminating internal delays, improving supplier coordination, and ensuring inventory decisions are data-driven. Deskera ERP simplifies procurement lead time management by bringing purchasing, inventory, and finance together on a single, integrated platform.

Streamlined Purchase Requisitions and Orders

Deskera ERP automates purchase requisitions and purchase order creation, reducing manual effort and approval delays. Centralized procurement workflows ensure requests move faster from initiation to order placement, helping shorten internal processing time.

Automated Approval Workflows

Built-in approval hierarchies allow procurement requests to be reviewed and approved quickly without back-and-forth communication. Automated workflows minimize bottlenecks, ensuring procurement activities progress smoothly and on schedule.

Centralized Supplier and RFQ Management

Deskera enables businesses to manage supplier information, quotations, and purchase history in one place. Easy access to supplier data improves coordination, speeds up vendor selection, and reduces delays caused by fragmented communication.

Real-Time Inventory Visibility

By integrating procurement with inventory management, Deskera provides real-time visibility into stock levels. This helps businesses place orders at the right time, avoid emergency purchases, and reduce delays caused by stockouts or over-ordering.

Integrated Finance and Cost Control

Procurement activities in Deskera are directly linked with accounting and budgeting. This integration ensures faster financial approvals, accurate cost tracking, and fewer delays caused by budget mismatches or manual reconciliations.

Actionable Procurement Insights

Deskera offers built-in reports and dashboards that help track procurement activity, order status, and supplier performance at a practical level. These insights help teams identify recurring delays and improve procurement planning over time.

Key Takeaways

- Procurement lead time represents the total duration from identifying a purchasing need to receiving goods, making it a critical metric for operational planning.

- Breaking procurement lead time into pre-processing, processing, and post-processing stages helps businesses pinpoint delays and improve efficiency.

- Accurate procurement lead time ensures smoother operations, prevents production disruptions, and supports better inventory and cash flow management.

- Procurement lead time is calculated by adding pre-processing, processing, and post-processing times, providing a clear view of sourcing timelines.

- Well-managed procurement lead time strengthens supply chain resilience, enhances customer satisfaction, and improves cost control.

- Supplier delays, demand variability, manual processes, and logistics uncertainties are common obstacles that increase procurement lead time.

- Shorter procurement lead times drive customer loyalty, reduce obsolescence risk, lower operational costs, and improve capital utilization.

- Deskera ERP streamlines procurement workflows, improves inventory visibility, and integrates finance and purchasing to reduce internal delays.

Related Articles