Have you ever wondered why your factory sometimes meets demand effortlessly while at other times it struggles with delays and bottlenecks—even when nothing major has changed? The answer lies in how accurately you understand and evaluate your manufacturing capacity. Manufacturing capacity analysis gives you a clear picture of how much you can produce, under what conditions, and where your true limitations lie. Without this clarity, even well-equipped factories can underperform, leading to missed deadlines, increased costs, and stressed production teams.

Manufacturing capacity analysis is essential for understanding the gap between what your facility can produce versus what it actually produces. It enables manufacturers to plan smarter, allocate resources more efficiently, and respond proactively to demand fluctuations. Whether you're dealing with machine breakdowns, labor shortages, or material constraints, capacity analysis helps you pinpoint inefficiencies early—before they turn into costly operational issues.

In today’s highly competitive manufacturing environment, having precise insights into your production potential is no longer optional; it is a strategic necessity. Modern manufacturers rely on data-driven decision-making to optimize performance, minimize downtime, and improve throughput. By evaluating machine availability, workforce productivity, raw material readiness, and process bottlenecks, capacity analysis lays the foundation for sustainable, scalable, and profitable operations.

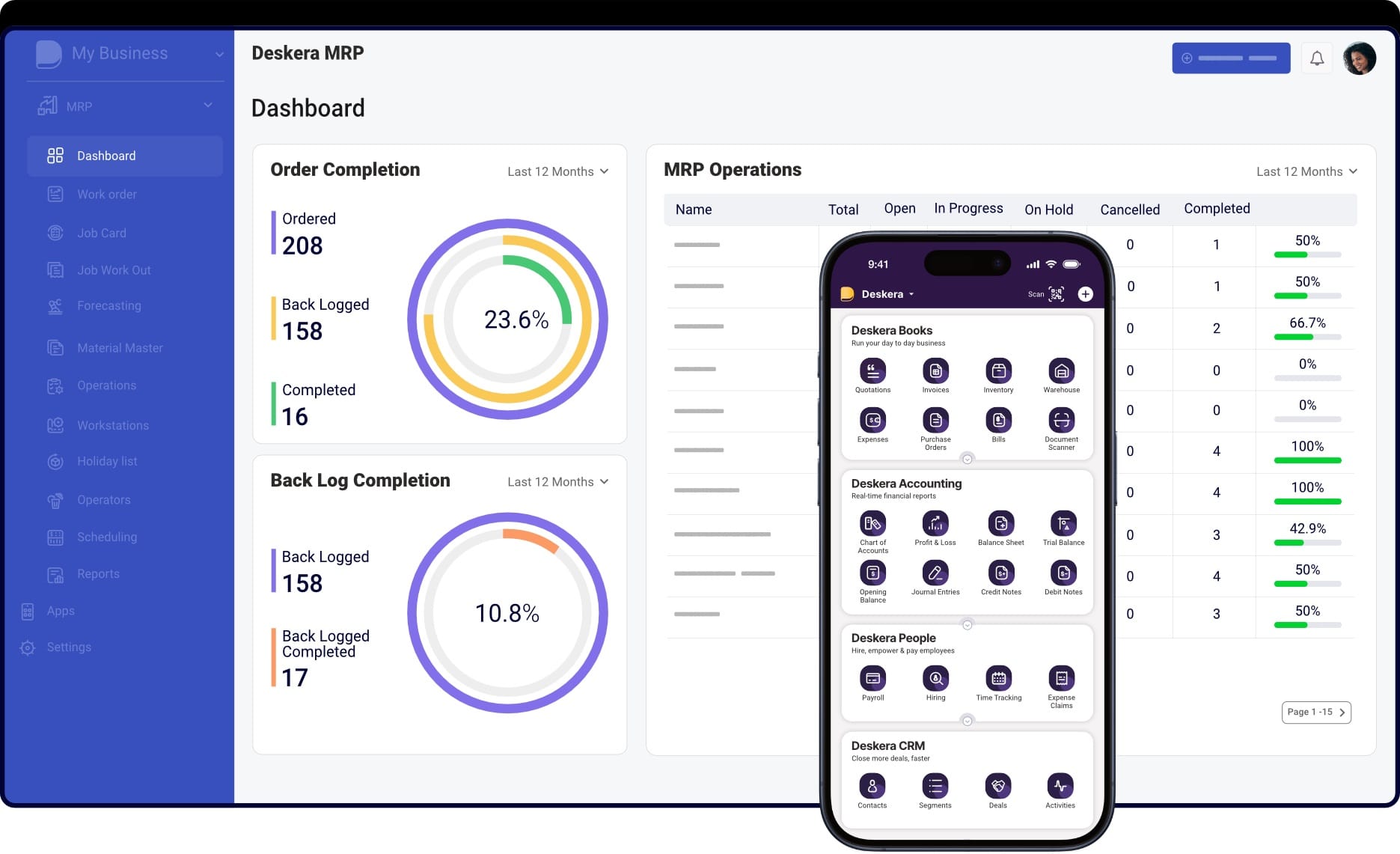

This is where Deskera MRP plays a vital role. With automated production planning, real-time inventory visibility, and smart scheduling tools, Deskera MRP empowers manufacturers to assess and optimize their capacity with greater accuracy. Its demand forecasting capabilities help you match production with market needs, while AI-driven recommendations—powered by Deskera’s intelligent assistant, David—support faster decision-making. The platform also ensures end-to-end clarity across materials, resources, and work orders, making it easier to unlock your factory’s true production potential.

What Is Manufacturing Capacity Analysis?

Manufacturing capacity analysis is the process of assessing how much a production facility can produce compared to what it actually delivers. It examines the gap between ideal production rates and real-world performance by analyzing machine efficiency, labor productivity, material availability, and process reliability. By doing so, manufacturers gain a clearer understanding of where output is being lost—whether due to slower cycles, changeover delays, frequent stoppages, or equipment issues.

At its core, capacity analysis acts as a diagnostic layer within the broader discipline of capacity planning. While capacity planning looks ahead—evaluating the labor, equipment, and space required to meet future demand—capacity analysis focuses on existing operations. It reveals whether current resources are being stretched too thin or underutilized, and it identifies specific constraints that restrict flow. Many of these constraints align with the “six big losses” outlined in Total Productive Maintenance (TPM), which include breakdowns, setup and adjustment losses, reduced speeds, defects, startup losses, and minor stoppages.

This assessment typically begins with detailed data collection across machines, lines, or plants—capturing cycle times, downtime, resource usage, and output trends. Modern manufacturers increasingly rely on digital tools such as MES systems, IoT sensors, or simulation software to convert raw operational data into actionable insights. With these technologies, decision-makers can pinpoint the exact causes of capacity shortfalls rather than relying on assumptions or gut-based estimates. For instance, if a factory discovers that changeovers consume 30% of total downtime, improving setup processes may increase output without adding new machinery or labor.

Understanding capacity also requires distinguishing between three important metrics: design capacity (the theoretical maximum output), maximum effective capacity (the realistic upper limit after accounting for maintenance, breaks, and quality losses), and actual capacity (the current, real-time output level). Actual capacity is almost always the lowest because it reflects the full impact of real-world disruptions such as breakdowns, material shortages, and slower-than-ideal running speeds. Regular capacity analysis helps manufacturers monitor these gaps over time, uncover performance patterns, and adapt quickly to changes in demand, market conditions, or operational challenges.

Key Components of Manufacturing Capacity Analysis

Understanding manufacturing capacity requires a holistic view of all the elements that directly influence how much a facility can produce within a specific timeframe. Capacity is not determined by machines alone—it is shaped by people, materials, processes, and even how the factory floor is organized.

By evaluating each of these components individually, manufacturers gain a clearer picture of their true production potential and the hidden constraints that may be limiting output.

Below are the core building blocks of a thorough manufacturing capacity analysis.

Machine Capacity

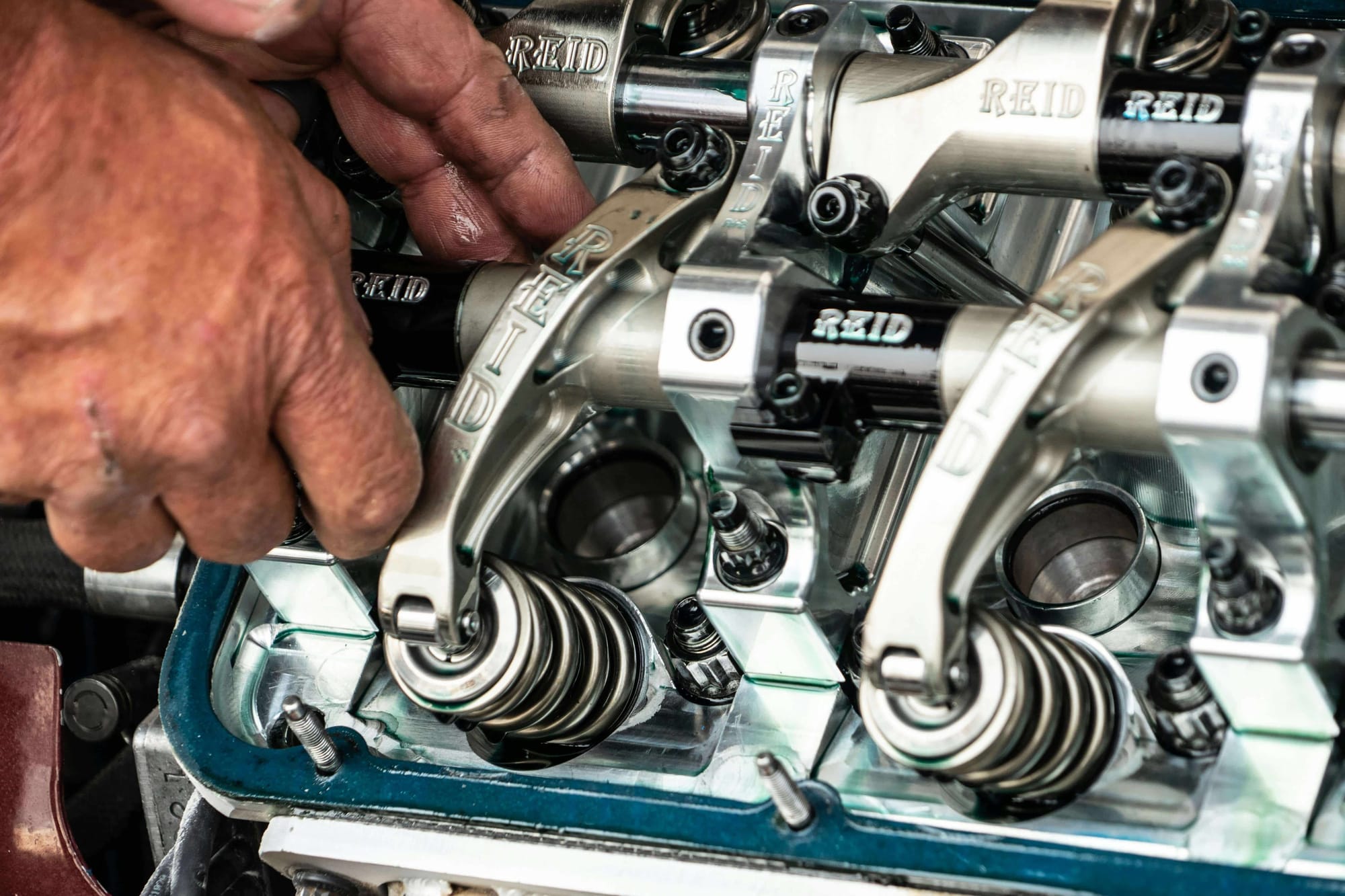

Machine capacity reflects the capability of equipment to operate at its optimal speed and efficiency. It considers machine availability, uptime, downtime events, and maintenance cycles. Frequent breakdowns, slow-running equipment, or long repair intervals can significantly reduce output.

Measuring Overall Equipment Effectiveness (OEE), analyzing failure patterns, and tracking maintenance history help manufacturers understand how well their machines support production goals. Industries with high automation especially rely on consistent machine performance to stabilize capacity.

Labor Capacity

Labor capacity evaluates the human element that drives manufacturing operations. It includes workforce skills, staffing levels, training quality, shift schedules, and labor productivity metrics. Any gaps in skillsets, absenteeism, inefficient shift rotations, or poor task allocation can hinder output.

A well-trained workforce that follows standardized procedures often performs faster, handles changeovers more efficiently, and reduces process variations—all of which contribute to higher production capacity.

Material Capacity

Material capacity focuses on whether raw materials and components required for production are available at the right time and in the right quantity. It considers inventory levels, supplier reliability, lead times, and material flow across the shop floor.

Shortages, inconsistent supply quality, or delays can stall entire production lines. A strong material management system ensures smooth replenishment, minimizes buffer stock requirements, and aligns material availability with demand forecasts.

Process Capacity

Process capacity measures how efficiently production processes convert resources into finished goods. It encompasses process speed, bottlenecks, cycle times, takt time alignment, and the level of standardization.

A single bottleneck process can limit output across an entire line, regardless of how well other steps perform. By analyzing constraints, eliminating unnecessary motions, and reducing process variability, manufacturers can enhance overall throughput without additional investments.

Plant Layout and Space Utilization

Plant layout and space utilization determine how effectively physical space is used to support production flow. Poor workstation arrangement, long travel distances, or a cluttered floor can slow material movement and increase process time.

A well-designed layout ensures that equipment, people, and materials move seamlessly, reducing wait times and improving line balancing. Lean manufacturing principles such as 5S, cellular layouts, and value stream mapping are often used to optimize space and enhance capacity.

Types of Manufacturing Capacity Analysis

Manufacturing capacity isn’t measured through a single metric—different capacity models help manufacturers understand their ideal performance, realistic output, and current limitations.

Each type serves a specific purpose within production planning, budgeting, and decision-making. By evaluating design, effective, and actual capacity, manufacturers can pinpoint where they stand today and what improvements are required to achieve higher throughput.

Below are the three primary capacity types used across manufacturing environments.

Design Capacity

Design capacity represents the theoretical maximum output a facility can achieve under perfect, uninterrupted conditions. It assumes machines run at full speed, operators work at peak productivity, and there are no changeovers, inspections, breakdowns, or quality losses.

In reality, design capacity is rarely attainable long term—but it offers a useful benchmark for understanding the upper limit of what the system was originally engineered to produce. Manufacturers often compare actual performance against design capacity to measure how much potential is being left untapped.

Effective Capacity

Effective capacity reflects the maximum sustainable output under normal, expected operating conditions. It accounts for planned downtime such as maintenance schedules, shift changes, inspections, cleaning, and mandatory breaks.

Unlike design capacity, effective capacity represents a realistic target for day-to-day operations. It helps manufacturers set achievable production plans, allocate resources more efficiently, and understand how much output can be generated without overburdening people or machines.

Actual Capacity

Actual capacity shows the real output produced, considering all unplanned losses that occur during production. These include unexpected machine breakdowns, rework due to defects, slower cycle times, material shortages, operator errors, waiting periods, and minor stoppages.

Actual capacity is almost always lower than both design and effective capacity because it reflects real-world imperfections. This metric is the most valuable for continuous improvement, as it highlights where capacity is leaking and where operational changes can create the greatest impact.

Why Manufacturing Capacity Analysis Matters

Manufacturing capacity analysis is more than an operational exercise—it's a strategic tool that enables manufacturers to understand their true production potential.

By uncovering how well current systems, machines, and teams perform, businesses can make smarter decisions about resource allocation, cost control, and future planning.

Even modest improvements in capacity can dramatically increase throughput, reduce operational waste, and boost profitability without large capital investments.

Below are the key reasons why capacity analysis plays a critical role in modern manufacturing.

Identifies Bottlenecks and Production Constraints

Capacity analysis helps manufacturers pinpoint where delays and inefficiencies originate—whether from underperforming machines, skill gaps in the workforce, inconsistent material supply, or process imbalances.

By identifying the true bottleneck in each production line, businesses can focus improvement efforts where they will make the greatest impact. Eliminating a constraint at the bottleneck often results in immediate throughput gains across the entire system.

Sets Clear and Realistic Productivity Benchmarks

Evaluating capacity provides objective performance baselines for every machine, process, and line. These benchmarks help manufacturers set achievable production targets, compare performance across departments or facilities, and monitor seasonal fluctuations. Over time, capacity benchmarks help track the effectiveness of improvement efforts and guide continuous optimization initiatives.

Improves Resource Allocation and Utilization

With an accurate understanding of capacity, manufacturers can allocate labor, machines, materials, and equipment more effectively. It prevents scenarios where workers sit idle, machines remain underutilized, or materials are stockpiled unnecessarily. Capacity analysis also supports decisions about when to add extra shifts, redistribute tasks, invest in new equipment, or reduce excess resources if they are no longer needed.

Increases Output Without Major Investments

One of the greatest advantages of capacity analysis is its ability to boost production without requiring expensive capital upgrades. Simple changes—such as streamlining layouts, reducing changeover time, balancing workflows, or implementing predictive maintenance—can significantly increase throughput. These improvements reduce lead times, enhance customer satisfaction, and elevate overall profitability.

Provides Direction for Continuous Improvement Efforts

Capacity analysis reveals exactly where improvement efforts will deliver the highest returns. Whether it's increasing uptime, improving first-pass yield, or reducing setup time, focusing on the bottleneck produces system-wide gains. This aligns directly with lean principles and the Theory of Constraints, both of which emphasize targeted, high-impact improvements.

Helps Establish Realistic Production Lead Times

A clear understanding of capacity ensures that lead times promised to customers are accurate and achievable. This supports better scheduling, improves delivery reliability, and enhances cash flow management. It also helps prevent overloading the system—one of the root causes of delays and quality issues.

Offers a High-Level Productivity Metric for Decision-Making

Capacity utilization—the gap between actual output and maximum effective capacity—serves as an essential productivity indicator. It helps leaders evaluate how well assets are being used and whether additional investments are necessary. While OEE provides machine-level visibility, capacity analysis delivers a broader operational perspective that supports strategic decision-making.

Common Challenges in Manufacturing Capacity Analysis

Manufacturing capacity analysis is essential for accurate planning, but it is often difficult to execute effectively. Many manufacturers struggle with fragmented data, unpredictable resource availability, and operational complexities that make it hard to determine true capacity. These challenges can lead to inaccurate forecasts, wasted resources, and production disruptions.

Below are some of the most common obstacles businesses face when conducting capacity analysis.

Inaccurate or Incomplete Data Collection

Capacity analysis depends heavily on reliable data from machines, labor, and processes. When data is scattered across spreadsheets, manual logs, or disconnected systems, it becomes difficult to calculate accurate cycle times, downtime, or utilization rates. Poor data quality leads to misleading insights and incorrect production planning.

Unpredictable Downtime and Equipment Failures

Unexpected machine breakdowns, maintenance delays, and slow-running equipment can drastically alter capacity calculations. Since many of these events are unplanned, manufacturers often struggle to estimate how much output they can realistically achieve on a daily or weekly basis.

Variability in Workforce Skills and Availability

Labor is one of the most dynamic elements of capacity. Absenteeism, inconsistent skill levels, inadequate training, or misaligned shift schedules can significantly reduce effective capacity. If workforce performance fluctuates, capacity analysis becomes harder to standardize and predict.

Material Shortages and Supply Chain Disruptions

Even if machines and labor operate at full efficiency, production capacity drops when materials arrive late, in insufficient quantities, or with quality issues. Long or variable lead times create bottlenecks that distort both effective and actual capacity.

Hidden Bottlenecks in Complex Processes

Manufacturing lines often include multiple interdependent operations, making it difficult to identify the true bottleneck. A minor constraint in one process can ripple across the entire line, limiting output even when other steps run smoothly. Many manufacturers only discover these hidden constraints after prolonged analysis or system-wide slowdowns.

Outdated Factory Layouts and Inefficient Space Utilization

Poor facility layouts—long travel distances, congested aisles, or poorly positioned equipment—slow down movement and increase cycle times. These spatial inefficiencies reduce capacity but are often overlooked during routine analysis.

Overestimating Theoretical Capacity

Some companies mistakenly rely on design capacity (theoretical maximum) when planning production. This leads to unrealistic expectations, frequent schedule delays, and overloaded systems. Without factoring in maintenance, quality losses, or operator pace, capacity projections become overly optimistic.

Limited Digital Tools and Automation

Manufacturers that rely solely on manual analysis struggle to capture real-time data or identify capacity patterns accurately. Without automation, it becomes difficult to track subtle performance losses, compare trends over time, or simulate “what-if” capacity scenarios.

How to Analyze Manufacturing Capacity

Analyzing manufacturing capacity involves more than calculating machine speeds or counting labor hours—it requires a comprehensive view of how equipment, people, materials, workflows, and demand interact. A structured capacity analysis helps manufacturers uncover hidden inefficiencies, identify constraints, and make accurate production decisions.

Below is an expanded, modern framework that captures all major components required for an effective capacity analysis.

1. Define the Scope of the Analysis

Start by clearly defining which part of your operations you want to evaluate—whether it’s a single machine, process step, assembly line, or the entire facility. Within this scope, identify:

- All machines, workstations, and tools involved

- Available labor, shift patterns, and operator roles

- Material inputs, flow paths, and internal logistics

- Data sources such as MES, ERP, IoT sensors, and manual logs

A well-defined scope ensures the analysis is accurate, relevant, and aligned with strategic goals such as reducing lead times, preparing for higher demand, or improving cost efficiency.

2. Determine the Output Rate of Each Machine or Workstation

Calculate the design capacity—each machine’s maximum theoretical output under ideal conditions. Use consistent units such as:

- Units per hour

- Cycles per minute

- Units per shift

Also assess quality considerations. Some machines achieve higher speeds but generate more defects when pushed at maximum output. Recording both productivity and quality accuracy ensures you don’t overestimate true operating capability.

3. Identify All Nonproductive Hours

List every factor that reduces the time a machine or operator can work at full capacity. This includes:

Planned downtime:

- Preventive maintenance

- Safety checks

- Changeovers

- Cleaning and setup

Unplanned downtime:

- Breakdowns

- Quality issues and rework

- Material shortages

- Operator delays

Tracking downtime over several weeks helps identify patterns and recurring losses, enabling targeted improvement plans.

4. Subtract Downtime to Determine Productive Hours

Subtract total nonproductive hours from total available hours to calculate productive time. This gives you a realistic view of machine availability—not the theoretical uptime often assumed.

Many manufacturers believe machines run at 90% capacity, when actual productive hours may be closer to 60–75%. This step prevents overloading schedules and ensures more accurate planning.

5. Calculate the Actual Capacity of Each Machine

Actual capacity can be calculated using:

Actual Capacity = Output Rate × Productive Hours × Efficiency

This figure represents the true, real-world capacity and shows how closely actual performance approaches effective capacity.

Document this for every machine or workstation in the workflow. Differences often reveal imbalances that restrict overall throughput.

6. Identify Bottlenecks Across the Production Flow

Compare actual capacity across all steps to identify the workstation or machine with the lowest output—the bottleneck. This constraint dictates the maximum production capacity of the entire line.

Bottlenecks may shift based on product mix, equipment condition, or labor availability, so they must be monitored continuously. Improvements anywhere except at the bottleneck will not increase total throughput, making this step essential for effective optimization.

7. Incorporate Demand Forecasting Into Capacity Decisions

Align capacity analysis with expected market demand using:

- Historical sales patterns

- Seasonal variations

- Customer order forecasts

- New product introductions

This ensures capacity decisions support both short-term scheduling and long-term strategic planning. If projected demand exceeds capacity, actions like overtime, outsourcing, or equipment upgrades may be required.

8. Evaluate Workforce Capacity and Skill Constraints

Labor plays a crucial role in determining true capacity. Assess:

- Operator skill levels

- Availability and absenteeism

- Training gaps

- Shift structures and overtime limits

Even if machines are capable, a lack of skilled operators can significantly restrict output.

9. Analyze Material Flow and Supply Chain Constraints

Material availability can immediately reduce capacity. Review:

- Supplier reliability and delivery performance

- Inventory levels and reorder points

- Internal logistics, material queues, and transfer times

A machine may be fully operational but still underperform due to delayed or inconsistent material supply.

10. Conduct Scenario Analysis (Best, Expected, Worst Cases)

Simulate different operating conditions to understand system flexibility, such as:

- Demand surges

- Equipment failures

- Staffing shortages

- Adding/removing shifts

- Introducing new product variants

Scenario analysis supports better decision-making under uncertainty.

11. Track Utilization and Performance Trends Over Time

Capacity analysis should consider long-term patterns, not just a single measurement. Monitor:

- Monthly capacity utilization trends

- OEE changes

- Seasonal variations

- Aging equipment performance

Trend insights help forecast maintenance needs and anticipate future bottlenecks.

12. Analyze WIP Levels and Flow Imbalances

Work-in-progress (WIP) accumulation is one of the strongest indicators of hidden inefficiencies. Assess:

- Buffer sizes

- Queue times

- Uneven flow between processes

High WIP often reveals poor line balancing or upstream delays that restrict capacity.

13. Benchmark Against Industry Standards

Compare your machine and line performance with industry benchmarks, such as:

- OEE world-class benchmark of 85%

- Typical changeover times for your industry

- Average cycle time expectations

Benchmarking helps determine whether performance gaps require process improvements or investments.

14. Use Digital Twins and Simulation Tools

Manufacturers with advanced digital capabilities can create a digital twin of their production line to virtually:

- Model capacity changes

- Test layout modifications

- Simulate different product mixes

- Identify ideal machine settings

This allows safe experimentation without disrupting real operations.

15. Connect Capacity Analysis to Financial Impact

Quantify the financial impact of capacity improvements by calculating:

- Cost of downtime

- Cost of bottlenecks

- Savings from productivity gains

- ROI of equipment upgrades or process changes

This elevates capacity analysis from operational planning to strategic decision-making.

16. Implement Continuous Monitoring and Optimization

Capacity analysis is not a one-time task. Use ERP, MES, and IoT-enabled dashboards to continuously monitor:

- Real-time machine performance

- Downtime events

- OEE

- Line balancing

- Throughput

This creates an ongoing improvement loop that keeps operations responsive, resilient, and efficient.

How Deskera MRP Helps Improve Manufacturing Capacity

Improving manufacturing capacity requires real-time visibility, accurate planning, streamlined workflows, and data-driven decisions. Deskera MRP brings all these elements together through an integrated, automation-first platform designed for manufacturing excellence.

Here’s how Deskera helps manufacturers optimize every layer of their capacity strategy:

Real-Time Production Visibility

- Provides a unified dashboard to track Work Orders, machine utilization, labor availability, and production status in real time.

- Helps manufacturers spot bottlenecks immediately and reallocate resources before delays escalate.

- Ensures decision-makers have accurate, live insights to adjust production schedules quickly.

Smart MRP (Material Requirements Planning)

- Automates material planning based on BOMs, demand forecasts, and production plans.

- Eliminates stockouts and overstocking by ensuring materials are available exactly when needed.

- Helps maintain optimal inventory levels, reducing unnecessary production stoppages.

Automated Work Order Management

- Creates, assigns, and tracks work orders seamlessly.

- Offers clear visibility into job progress, workstation load, and completion timelines.

- Reduces manual errors and speeds up the entire production cycle.

Accurate Demand Forecasting

- Uses historical data and predictive analytics to forecast customer demand.

- Enables manufacturers to plan capacity more accurately and avoid overproduction or underproduction.

- Aligns production capabilities with future market needs.

Capacity Planning and Scheduling Tools

- Provides advanced scheduling features like finite and infinite capacity planning.

- Helps adjust workloads based on machine availability, labor capacity, and material readiness.

- Enhances overall throughput with smarter scheduling decisions.

Integrated Inventory & Warehouse Management

- Syncs real-time inventory levels with production schedules to prevent material shortages.

- Tracks raw materials, WIP, and finished goods with complete accuracy.

- Improves warehouse efficiency, supporting uninterrupted production workflows.

Automated Reporting and Analytics

- Generates detailed reports on production efficiency, downtime, utilization, and capacity gaps.

- Helps leaders identify performance constraints and improve operational efficiency.

- Offers built-in templates for faster and more reliable decision-making.

Mobile Accessibility with Deskera App

- Allows managers and shop-floor teams to access production data anytime, anywhere.

- Supports faster approvals, quick updates, and proactive issue resolution.

- Enhances operational responsiveness and on-the-go decision-making.

AI Assistant “David” for Smart Insights

- Provides recommendations for optimizing schedules, reducing waste, and improving capacity utilization.

- Automates routine tasks and enhances productivity with AI-driven support.

- Helps streamline complex MRP and manufacturing workflows effortlessly.

Key Takeaways

- Effective manufacturing capacity planning begins with understanding your true production potential, identifying hidden constraints, and using data to make smarter, faster decisions.

- A strong capacity analysis depends on accurately assessing machine capabilities, labor availability, process efficiency, and material supply to build a complete and realistic picture of production potential.

- Understanding design capacity, effective capacity, and actual capacity helps manufacturers evaluate the gap between theoretical output and real-world performance, enabling better planning and optimization.

- Capacity analysis matters because it identifies bottlenecks, establishes productivity benchmarks, improves resource allocation, and increases output without requiring major capital investment.

- Data inconsistencies, unplanned downtime, fluctuating demand, inefficient workflows, and lack of visibility often make it difficult for manufacturers to evaluate capacity accurately and act on insights.

- Conducting capacity analysis involves gathering accurate production data, evaluating cycle times, identifying constraints, comparing actual vs. effective capacity, and applying continuous improvement to boost throughput.

Related Articles