Are you struggling to stick to a routine? Do you feel like your days are all over the place? Have you ever wondered what it would be like if your days were organized in a more systematic way? Forward and backward scheduling may be just the answer for you.

Forward and backward scheduling is a type of daily planning system that helps you keep track of your commitments and tasks. By organizing your day in this way, you can get more accomplished in less time. Forward and backward scheduling can also help to improve work/life balance.

In today’s guide, we’ll thoroughly learn about forward and backward scheduling. Before we delve in, let’s take a look at the table of content:

- What is Production Scheduling?

- Importance of Production Scheduling

- Objective of Production Scheduling

- Production Scheduling Functions

- What is Forward Scheduling?

- What is Backward Scheduling?

- What is the Difference between Forward and Backward Scheduling Strategies?

- Advantages of Forward Scheduling

- Disadvantages of Forward Scheduling

- Advantages of Backward Scheduling

- Disadvantages of Backward Scheduling

- Common Challenges Faced by Modern Businesses with Scheduling

- Which is Better for you: Forward or Backward Scheduling?

- Final Thoughts

- How Deskera Can Assist You?

- Final Takeaways

Let's Start!

What is Production Scheduling?

Organizations utilize scheduling systems to efficiently assign and manage a variety of resources, which aids businesses in understanding the concept of scheduling systems.

These programs cover daily activity management, event planning, staff scheduling, lodging reservations, and calendar upkeep for both internal and external planning of activities.

We should be aware of how essential production planning and scheduling is to the operations of a manufacturing organization. Each business needs to make sure that it is making the most of its resources while completing product deliveries on time.

You must control material resources, time, and production tools to keep costs in check and meet customer expectations. The Operations management schedule specifies which workers should use which resources when a task needs to be performed.

Companies can employ either a forward or a backward scheduling strategy to plan & strategize production, manage resources, and make the needed purchases to fulfill orders.

Importance of Production Scheduling

It is challenging to emphasize how crucial production scheduling is to the efficient operation of a manufacturing organization.

Every business needs to make sure that it uses its resources wisely while completing orders on time. It's crucial to carefully manage material resources, laborers' time, and manufacturing equipment if you want to avoid costs eating away at profits and satisfy customer expectations.

Production scheduling is an important part of the production process. It further helps ensure that products are produced in a timely and efficient manner.

It helps ensure that the resources and machines used in production are efficiently allocated, and that production is completed on time.

Production scheduling also helps to reduce costs associated with production by minimizing downtime and eliminating waste. It can also assist in ensuring that all goods are of the finest quality.

Production schedules are made to specify when particular employees should use particular tools and resources to produce a particular good. Businesses can allocate resources, schedule production, and make the required purchases using either forward or backward scheduling to fulfill customer orders.

Objective of Production Scheduling

Among the objectives of operations management scheduling are the following:

Maximize Resource Usage: One area where a manufacturing cost of a company incurs high costs is the underutilization of all resources.

Reduced Manufacturing Time: If you create a great schedule, you should be able to reduce your overall manufacturing time.

Inventory Minimization: Less work-in-progress (WIP) inventory is typically the result of shorter manufacturing times.

Labor Efficiency: Effective scheduling reduces the number of back and forth, equipment changes, and lead times in operations management.

Increased Customer Care: In addition to the shop floor workers, customer service professionals also benefit from a well-organized production schedule.

Increased Profits: Profits will rise since we can produce more items when our schedule is well-organized.

Production Scheduling Functions

By adopting production scheduling, any company can raise the proportion of on-time deliveries and maintain a competitive edge in the market.

Using an APS (Advanced Planning and Scheduling) system can help you achieve your company's objectives by assisting in the creation of the most efficient production plan.

Manufacturing businesses all across the world utilize APS software to better understand their processes and increase output.

Some of the functions of operations scheduling include:

Allocation of Resources: Allocating resources to each task is the first step in scheduling in the operations management system.

Job Sequence: Identifying the tasks that need to be completed on each resource in what order is the next stage.

Job Start and End Times: Providing the start and finish times for the job comes after the procedures are arranged in the correct order.

Maximum Usage: The available resources are not being used to their utmost potential. When numerous resources sit inactive for an extended period, it can be expensive.

Machine Information: Operations scheduling ensures that you receive the most up-to-date information about machinery and manufactured goods.

Shop floor Control: The best operational schedules ensure that everyone is aware of when tasks should begin and end.

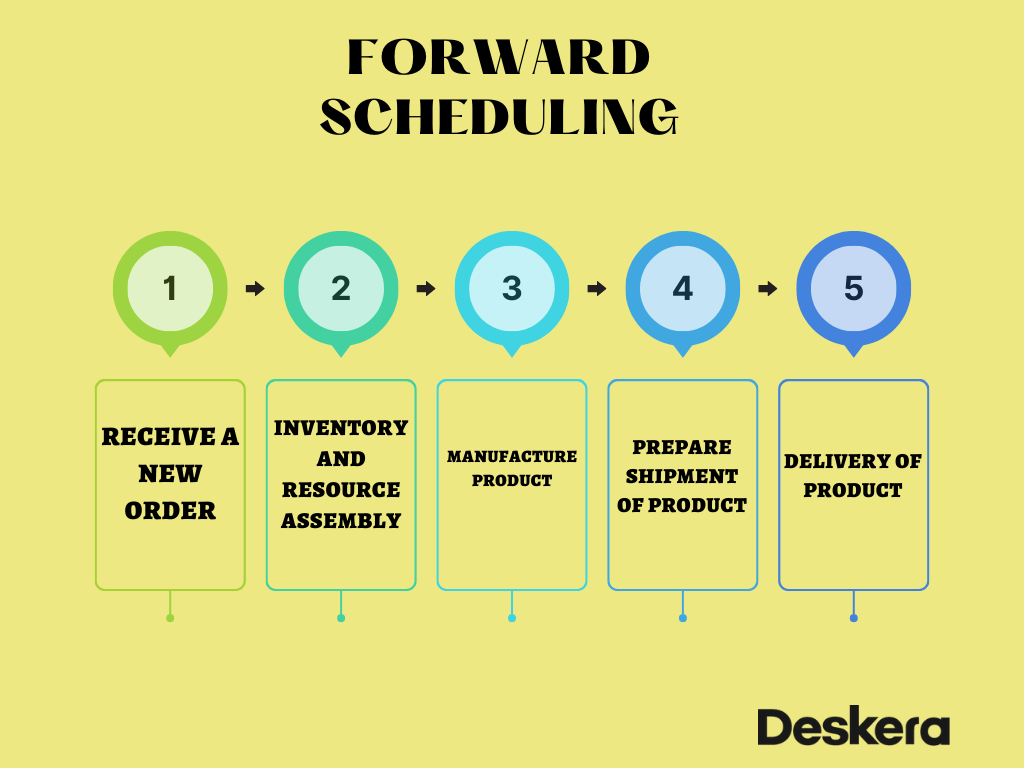

What is Forward Scheduling?

Forward scheduling is a method for organizing and finishing work as quickly as is practical. The aim is to complete a project earlier than expected. Advance scheduling is used by most firms to help teams meet deadlines, improve workflow, and increase revenue.

A simple scheduling method is forward scheduling. Each assignment is given a resource, and it is organized with a clear due date. Production and industrial sectors have the most benefit from this scheduling approach. When resources are accessible, they ensure that every stage of a task is completed correctly and on time.

The availability of resources and capacity are important variables in forward scheduling. For instance, if you have an order for personalized stud earrings, you can begin production.

You can begin creating the earrings right immediately if studs are on hand. Your customers will receive their order once you have produced the goods for them.

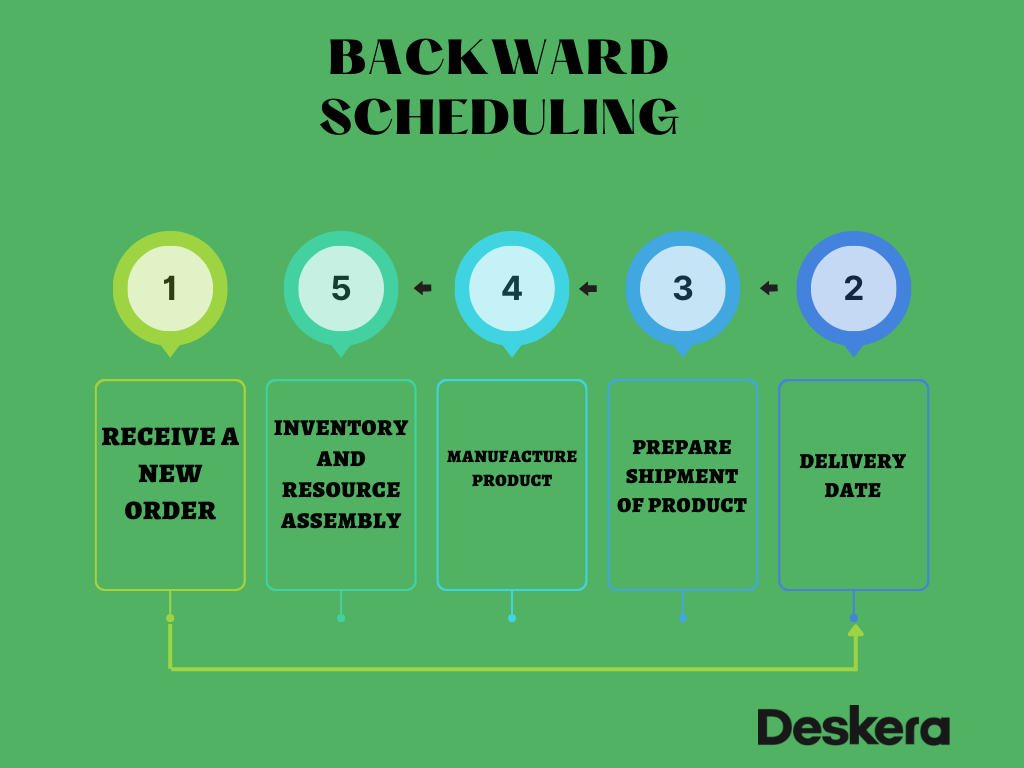

What is Backward Scheduling?

Backward scheduling is subtly different from forward scheduling. "Just-in-time manufacturing" is a common name for it. The proposed production schedule takes your clients' preferred delivery dates into account.

As a result, if a user confirms an order with a deadline, you and your team need to make sure that production is prepared to meet it.

Furthermore, you have more control with backward scheduling, and you can customize or make last-minute changes to orders before distributing them.

What is the Difference between Forward and Backward Scheduling Strategies?

The scheduling methods of backward and forward are distinct from one another. When using forward scheduling, you start at the beginning and move ahead from there. Making arrangements from the anticipated completion date in advance is known as "backward scheduling."

Imagine that a client requests XYZ maintenance from a heating and cooling firm somewhere in the first week of October. By using forward scheduling, a company can reserve an appointment as early as feasible during the week, freeing up other timeslots for potential clients.

As a result of the appointment being scheduled backward, any parts, such as filters, will likely be ordered later than usual, and the appointment will probably be made on the last day of that particular week.

To find out more information about forward and backward scheduling methods. Read further ahead:

If the internal production time is insufficient and the production order's start date is in the future from today's date, the system uses routing to perform backward scheduling. As a consequence, everything is finished by the client's specified delivery date.

On the other hand, if the internal production period is large enough and the start date of the production order is later than today, the system uses routing to do forward scheduling. We choose a delivery date and base it on our decisions.

Advantages of Forward Scheduling

Following, we've discussed several benefits of forward scheduling. Let's learn them:

1. Improved Employee Planning: Forward scheduling helps in improving employee planning. It helps in assigning proper and timely tasks to employees, which in turn leads to improved employee productivity and morale.

2. Enhanced Coordination: Forward scheduling promotes better coordination between team members by keeping everyone informed of upcoming tasks.

3. Increased Visibility: It helps in providing a better insight into the progress of the project and allows team members to plan accordingly.

4. Improved Efficiency: Forward scheduling helps in ensuring efficiency by ensuring that the right tasks are given to the right people at the right time.

5. Greater Accountability: Forward scheduling helps in increasing accountability among team members as deadlines are set in advance.

6. Reduced Stress: Forward scheduling can help reduce stress among team members by allowing them to plan in advance and by allowing them to anticipate upcoming tasks.

Disadvantages of Forward Scheduling

Following we've discussed several disadvantages of backward scheduling. Let's learn them:

1. Poor Visibility: Backward scheduling does not always provide an accurate view of the project and tasks, as it does not provide an overall view of the project timeline.

2. Difficult to Adjust: It is difficult to make changes and adjust the project timeline once the project has been scheduled in reverse.

3. Loss of Focus: Backward scheduling can lead to a loss of focus on the project objectives, as attention is given to completing the last task first.

4. Difficult to Monitor Progress: It can be difficult to track progress with backward scheduling, as tasks are completed in reverse, and the overall project timeline is unclear.

5. Unclear Milestones: Milestones are not as clear in backward scheduling as the timeline is reversed, and milestones may be missed or not identified.

Advantages of Backward Scheduling

Following, we've discussed several advantages of backward scheduling for manufacturers. Let's discuss them:

1. Resources and materials will be used as needed. Additionally, they shouldn't have any products on hand since production will stop on the due date (although storing some safety stock never hurts). This suggests that the carrying cost will be modest or nonexistent.

2. Backward scheduling helps to identify the critical path of a project.

3. It helps to reduce the risk of missing project deadlines by maintaining a realistic timeline.

4. It helps to identify potential problems and conflicts in the project timeline.

5. It helps to ensure the required resources are available on time.

6. It helps to identify the tasks that are dependent on the completion of other tasks.

7. It helps to prioritize tasks and focus on the most important tasks first.

8. It helps to provide a better estimation of the project cost.

9. It helps to create a better understanding of the project timeline by all the stakeholders.

10. It helps to identify the tasks that can be executed in parallel.

11. It helps to create a more efficient project with less time and resources.

12. Lower risk. Since resources and materials haven't been committed to a project yet, you'll have them available if production speeds need to be increased or decreased.

Disadvantages of Backward Scheduling

Following, we've discussed several disadvantages of backward scheduling. Let's discuss:

1. Backward scheduling can be difficult to plan and adjust, as the end date for a project must be established prior to scheduling.

2. There is a lack of visibility into the project's timeline, as the whole process must be completed before the start date can be established.

3. It is time-consuming, as the entire process must be completed before the start date can be determined.

4. It is difficult to predict potential problems or delays in the project due to the lack of visibility into the timeline.

5. It requires accurate forecasting of the project's completion time, which can be difficult to achieve.

6. It can be difficult to manage multiple projects at the same time with backward scheduling.

7. It can be difficult to accommodate changes or unexpected delays in the project.

Common Challenges Faced by Modern Businesses with Scheduling

By using forward and backward planning, many of the common scheduling issues that contemporary businesses have can be avoided.

You may increase process and production efficiency, ensure that delivery dates will be fulfilled, balance employee workloads (and reduce employee burnout), and allow yourself the flexibility to handle order revisions by using these scheduling approaches.

Following, we've discussed some common challenges that are faced by modern businesses with scheduling. Let's learn them:

Meeting Important Due Dates and Deadlines

Teams can use backward scheduling and forward scheduling to avoid missing appointments and meet important deadlines (or early).

One advantage of forward scheduling is its capacity to offer goods pickup and delivery services where there is more room to accept more requests. Furthermore, these open times could then be used by the product pickup and delivery services to make deliveries earlier than expected and exceed client expectations.

With recurrent monthly or quarterly service appointments, backward scheduling aids maintenance and repair organizations in balancing their calendars to meet a variety of deadlines.

Balancing Workload

In order to equally share the labor among groups of employees or drivers, backward and forward scheduling might be used. Moreover, to ensure that each driver receives the same number of deliveries, for instance, a company that delivers groceries can start with delivery windows and arrange routes backward.

Forward scheduling would therefore enable the packing crew to put together orders as soon as they had the chance. As a result, workloads are balanced. Limiting underworked workers will reduce needless spending while ensuring that your team isn't overworked.

Accommodation Adjustments

Backward scheduling is a helpful tool for some types of production planning since it enables you to account for time for order revisions. This is especially helpful for companies that produce customized goods and have experience with production planning.

Let's check:

Consider the scenario where your business produces custom windows. Despite the fact that the manufacturing of a window takes 15 days, you guarantee delivery within 30 days.

In order to start production eight days after receiving a new order, you can arrange your production schedule backward, starting at the 30-day point and allowing seven days for shipment or delivery.

You would then have the flexibility you require for the first week following the placement of an order.

Planning in Advance

Both backward and forward scheduling can help you create more thorough plans. It would further provide you a precise idea of your expected income and point out any process inefficiencies that need to be fixed.

Which is Better for you: Forward or Backward Scheduling?

Both scheduling strategies, as we've seen, each schedule has its own benefits. But the question arises which one should you choose?

Although, it all depends on the products and processes you make. Backward scheduling is an alternative for manufacturers who make-to-order, while forward scheduling is often utilized by manufacturers who make-to-stock (as well as those who make-to-stock in accordance with a sales projection).

Learn more about Make-to-order Vs Make-to-Stock here.

However, combining these two scheduling techniques is also an option. Businesses can use a range of strategies in a variety of situations.

For instance, you can use backward scheduling to organize orders according to their due dates when many orders come at once. You can use advance scheduling once more to maximize your production capacity and available resources once orders start coming in again.

The best way to comprehend scheduling is to use MRP software. With an MRP or manufacturing ERP system, you may use both techniques at once to guarantee the best scheduling possible at all times. The tool maintains track of all the moving parts of the process for you and provides you with precise lead times and intricate schedules.

Final Thoughts

There are benefits to both forward and reverse schedules. Although each has advantages and disadvantages, neither is superior to the other, and certain logistics coordinators may even gain from combining the two approaches.

You should take into account two primary elements when deciding which technique will work best for your company: the type of business or delivery service you run and your preferred method of scheduling.

To complete your tasks, you may combine forward and backward scheduling to return to the weekend to-do list example. If you're prepared, you could do all of your yard work on Saturday morning and put off cleaning your car until Sunday (using backward scheduling).

In this manner, even if it poured on Saturday night, you would still be able to drive to your meeting on Monday morning, knowing that most of your obligations were satisfied.

How Deskera Can Assist You?

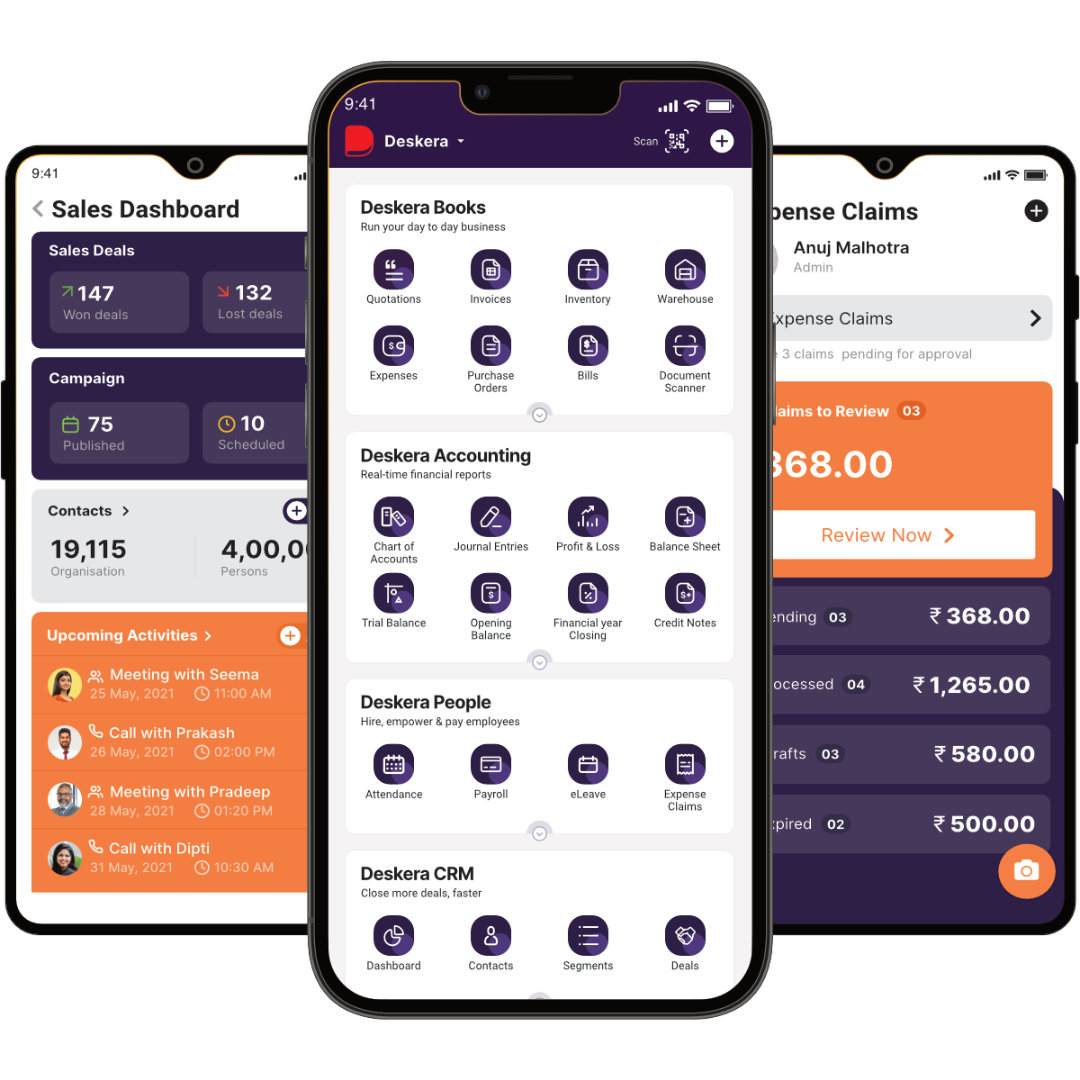

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Every business needs to make sure that it uses its resources wisely while completing orders on time. It's crucial to carefully manage material resources, laborer's time, and manufacturing equipment if you want to avoid costs eating away at profits and satisfy customer expectations.

- Using an APS (Advanced Planning and Scheduling) system can help you achieve your company's objectives by assisting in the creation of the most efficient production plan.

- Forward scheduling is a method for organizing and finishing work as quickly as is practical. The aim is to complete a project earlier than expected. Advance scheduling is used by most firms to help teams meet deadlines, improve workflow, and increase revenue.

- Backward scheduling is subtly different from forward scheduling. "Just-in-time manufacturing" is a common name for it. The proposed production schedule takes your clients' preferred delivery dates into account.

- Backward scheduling is a helpful tool for some types of production planning since it enables you to account for time for order revisions. This is especially helpful for companies that produce customized goods and have experience with production planning.

- You may increase process and production efficiency, ensure that delivery dates will be fulfilled, balance employee workloads (and reduce employee burnout), and allow yourself the flexibility to handle order revisions by using these scheduling approaches.

- Forward scheduling helps in improving employee planning. It helps in assigning proper and timely tasks to employees, which in turn leads to improved employee productivity and morale.

- The best way to comprehend scheduling is to use MRP software. With an MRP or manufacturing ERP system, you may use both techniques at once to guarantee the best scheduling possible at all times.

- The tool maintains track of all the moving parts of the process for you and provides you with precise lead times and intricate schedules.

Related Articles