Leather has been used for centuries for its durability and timeless style. However, in today's highly competitive market, producing leather goods is insufficient. Manufacturers must find innovative ways to differentiate their products to stand out from the crowd.

In the fashion industry specifically, 75% of consumers believe that companies should do more to protect the environment, and 72% are willing to pay more for sustainable products (source: IBM).

This is where innovative manufacturing techniques come into play. By using cutting-edge technology, such as digital printing and laser etching, leather manufacturers can create unique designs and patterns that were once impossible to achieve.

Additionally, sustainable manufacturing techniques, such as using eco-friendly dyes and reducing water waste, can appeal to environmentally conscious consumers. Differentiating leather products through innovative manufacturing sets them apart from the competition and adds value to the brand.

In this article, we will explore the various innovative techniques being used in leather manufacturing, the benefits of differentiation, and the challenges manufacturers may face when implementing these techniques.

- Significance for Leather Manufacturers to Differentiate their Products in a Competitive Market

- Traditional Leather Manufacturing Techniques

- Innovative Leather Manufacturing Techniques

- Benefits of Differentiating Leather Products

- Challenges and Considerations

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Significance for Leather Manufacturers to Differentiate their Products in a Competitive Market

In a highly competitive market, it is essential for leather manufacturers to differentiate their products to stand out from the competition. Here are some reasons why differentiation is significant for leather manufacturers:

Increased Sales: Differentiated products can capture the attention of consumers and make them more likely to purchase. Manufacturers can attract new customers and increase sales by offering unique designs or features that are not available from competitors.

Brand Recognition: Differentiation can also help to build brand recognition and establish a loyal customer base. By offering something unique and memorable, manufacturers can create a strong brand identity that sets them apart from competitors.

Value-Added: Differentiated products can be sold at a higher price point, providing additional value for the manufacturer. Consumers are often willing to pay more for products that are unique or offer additional features or benefits.

Competitive Advantage: Differentiation can provide a competitive advantage in a crowded market. By offering something that competitors cannot, manufacturers can gain a foothold in the market and establish themselves as a leader in the industry.

Overall, differentiation is essential for leather manufacturers to stay relevant and competitive in today's market. By using innovative manufacturing techniques to create unique and high-quality products, manufacturers can set themselves apart and create a loyal customer base.

Traditional Leather Manufacturing Techniques

Leather has been used for thousands of years for its durability and versatility. Traditional leather manufacturing techniques have been passed down for generations and involve a complex process of tanning, dyeing, and finishing animal hides to produce a variety of leather products, including shoes, bags, and upholstery.

The process typically involves treating the animal hides with chemicals to remove hair and flesh, and then tanning them with natural or synthetic agents to preserve and soften the leather. The leather is then dyed and finished with various coatings to achieve the desired texture and appearance.

While traditional leather manufacturing techniques have been refined over time, they can have limitations in terms of differentiating leather products.

In today's market, manufacturers must find innovative ways to differentiate their leather products to stand out. This has led to the development of new and innovative manufacturing techniques that can create unique and high-quality leather products.

Traditional Methods of Leather Manufacturing

The traditional methods of leather manufacturing involve a complex process that has been used for centuries to produce high-quality leather products. Here is a brief overview of the traditional methods of leather manufacturing:

- Pre-treatment: The first step in leather manufacturing is to pre-treat the animal hides to remove hair and flesh. This is typically done using a chemical process that can take several days.

- Tanning: Once the hides have been pre-treated, they are tanned to preserve and soften the leather. Tanning involves treating the hides with natural or synthetic agents, such as vegetable tannins or chromium salts. This process can take several weeks and requires careful monitoring to ensure that the hides are properly tanned.

- Dyeing: Once the leather has been tanned, it can be dyed to achieve the desired color. Dyeing can be done using natural or synthetic dyes, and may involve multiple coats to achieve the desired shade.

- Finishing: Finally, the leather is finished with various coatings to achieve the desired texture and appearance. This can include buffing, embossing, or adding a protective coating to the surface of the leather.

Limitations of Traditional Methods in Terms of Differentiating Leather Products

The traditional methods of leather manufacturing can have limitations in terms of differentiating leather products. Here are some reasons why:

- Limited Design Options: Traditional leather manufacturing techniques typically produce leather with a limited range of textures, patterns, and colors. This can make it difficult for manufacturers to differentiate their products in a crowded market.

- Similar Appearance: Since traditional leather manufacturing techniques are widely used, many leather products can look very similar, making it hard for consumers to tell them apart. This can be a challenge for manufacturers who want to stand out and create unique products.

- Cost: Traditional leather manufacturing techniques can be time-consuming and labor-intensive, increasing production costs. This can make it challenging for manufacturers to compete with low-cost alternatives and maintain the budget.

- Environmental Concerns: Traditional leather manufacturing techniques can also have negative environmental impacts due to the use of chemicals and water-intensive processes. This can be a concern for consumers who are increasingly looking for sustainable and eco-friendly products.

Given these limitations, manufacturers are increasingly turning to new and innovative manufacturing techniques that can create unique and differentiated leather products. These techniques may include digital printing, laser etching, or sustainable materials like vegetable-tanned leather.

By embracing these new approaches, manufacturers can differentiate their products, meet consumer demand for sustainability, and create new market opportunities.

Innovative Leather Manufacturing Techniques

Innovative leather manufacturing techniques are emerging as a way for manufacturers to differentiate their products in a crowded market. These techniques use advanced technologies and sustainable materials to create unique, high-quality leather products.

Sustainable materials like vegetable-tanned leather are also becoming increasingly popular in innovative leather manufacturing. This approach uses natural tannins extracted from plants to preserve and soften the leather, eliminating the need for harsh chemicals and reducing environmental impacts.

Overall, innovative leather manufacturing techniques are opening up new possibilities for manufacturers to create unique and differentiated leather products. By embracing these new approaches, manufacturers can meet consumer demand for sustainable and eco-friendly products while also creating new market opportunities.

New and Innovative Techniques being used in Leather Manufacturing

In recent years, new and innovative techniques have emerged in leather manufacturing that are changing the industry's landscape. Here are some of the most notable techniques being used today:

- Digital Printing: Digital printing is a technique that allows manufacturers to print detailed designs and patterns directly onto leather. The process involves using a computer-controlled printer to apply ink onto the leather, creating a high-resolution image. Digital printing enables manufacturers to produce custom designs and textures on leather, making it a powerful tool for product differentiation.

- Laser Etching: Laser etching is a technique that uses a laser to create intricate designs and textures on leather. The laser can cut or burn away parts of the leather, creating a three-dimensional effect. This technique can replicate the look of exotic animal skins or create unique patterns on the leather's surface.

- Sustainable Tanning: Traditional tanning methods often involve the use of harsh chemicals that can have negative environmental impacts. However, sustainable tanning methods use natural materials like plant extracts to preserve and soften the leather. Vegetable-tanned leather, for example, is tanned using tannins extracted from plants, making it a more sustainable option for leather manufacturing.

- High-Tech Finishing: Finishing is an essential part of leather manufacturing, as it determines the leather's final appearance and texture. High-tech finishing techniques, such as plasma finishing, use plasma energy to modify the leather's surface at a molecular level. This technique can create unique textures and finishes on the leather, making it stand out in a crowded market.

- Biotechnology: Biotechnology is an emerging field that is beginning to impact leather manufacturing. One example is the use of bio-based materials like mycelium leather, which is made from mushroom roots. This material is eco-friendly, sustainable, and can be produced in a lab without the use of animal products.

Overall, new and innovative techniques are transforming the leather manufacturing industry, enabling manufacturers to create unique and differentiated products that meet the demands of modern consumers. By embracing these techniques, manufacturers can set themselves apart from competitors and create new industry growth opportunities.

How these Techniques can be Used to Differentiate Leather Products

The new and innovative techniques being used in leather manufacturing can be used to differentiate leather products in several ways:

- Customization: Digital printing and laser etching enable manufacturers to produce custom designs and patterns on leather. This allows manufacturers to create unique and personalized products that stand out from competitors.

- Texture and Finish: High-tech finishing techniques and sustainable tanning methods can create unique textures and finishes on leather, giving manufacturers a way to differentiate their products based on appearance and feel.

- Sustainability: Sustainable materials and manufacturing methods are becoming increasingly important to consumers. By using sustainable materials and manufacturing techniques, manufacturers can differentiate their products based on their eco-friendliness.

- Exclusivity: The use of bio-based materials like mycelium leather or rare exotic skins can create a sense of exclusivity around a product, making it more desirable to consumers who want something unique.

By leveraging these techniques, manufacturers can create products that stand out from competitors, meet consumer demands for customization and sustainability, and capture new market opportunities.

10 Benefits of Differentiating Leather Products

Differentiating leather products can offer several benefits to manufacturers and consumers. Differentiating leather products can help manufacturers stand out in a crowded marketplace and offer consumers unique, customized, and sustainable options that meet their specific needs and preferences.

Here is a detailed list of benefits of differentiating leather products:

- Increased Market Share: By differentiating their leather products, manufacturers can tap into new markets and expand their customer base, ultimately increasing their market share and revenue.

- Improved Brand Recognition: Differentiated leather products can help build a brand identity and improve brand recognition, making it easier for consumers to remember and recognize the brand.

- Higher Profit Margins: Unique and customized leather products can command a higher price point, leading to higher profit margins for manufacturers.

- Consumer Satisfaction: Differentiated leather products can meet specific consumer needs and preferences, leading to higher levels of satisfaction and brand loyalty.

- Increased Sales Volume: By offering a range of differentiated leather products, manufacturers can increase sales volume by providing more options for consumers to choose from.

- Competitive Advantage: Differentiating leather products can provide a competitive advantage over other manufacturers in the industry, helping manufacturers stand out in a crowded marketplace.

- Innovation: Developing new and innovative leather products can drive innovation and creativity within the industry, leading to new ideas and approaches to manufacturing.

- Sustainability: By using sustainable manufacturing techniques and materials, manufacturers can differentiate their leather products as environmentally friendly and appeal to consumers who are concerned about sustainability.

- Versatility: Differentiating leather products can provide versatility in the types of products that can be produced, allowing manufacturers to expand their product lines and appeal to a wider range of customers.

- Enhanced Image and Reputation: Differentiating leather products can enhance the image and reputation of a manufacturer as an industry leader, committed to producing high-quality, innovative, and sustainable products.

How Differentiating Leather Products can Increase Sales and Brand Recognition

Differentiating leather products can increase sales and brand recognition in several ways:

- Unique and Customized Products: By differentiating their leather products, manufacturers can offer unique and customized products that meet specific customer needs and preferences. This can help increase sales by offering more options for customers to choose from.

- Higher Perceived Value: Differentiated leather products can have a higher perceived value due to their uniqueness and customization, allowing manufacturers to charge a premium price point. This can increase sales revenue and profit margins.

- Increased Brand Recognition: Differentiated leather products can help build brand recognition by creating a distinctive brand identity and standing out from competitors. This can help increase brand loyalty and attract new customers.

- Targeted Marketing: Differentiated leather products can allow manufacturers to target specific customer segments with tailored marketing campaigns. This can increase brand recognition and sales by reaching customers who are most likely to be interested in the product.

- Competitive Advantage: By differentiating their leather products, manufacturers can gain a competitive advantage over other brands in the industry. This can help increase sales and brand recognition by standing out in a crowded marketplace.

- Innovation: Developing new and innovative leather products can drive innovation within the industry and attract attention from customers who are looking for something new and exciting. This can increase sales and brand recognition by positioning the brand as a leader in the industry.

Examples of Successful Companies

Here are some examples of companies that have successfully differentiated their leather products through innovative manufacturing techniques:

Eccolo: Eccolo is a leather goods company that has successfully differentiated its products through the use of digital printing technology. They use digital printing to create unique patterns and designs on their leather products, such as journals, passport holders, and wallets.

This has allowed them to offer customized products that are different from their competitors and appeal to customers looking for unique leather goods.

Acne Studios: Acne Studios is a fashion brand that has differentiated its leather products through the use of laser etching technology. They use laser etching to create intricate designs and patterns on their leather jackets and bags, giving them a distinctive look and feel. This has helped them stand out in the crowded fashion industry and attract customers looking for high-quality, innovative leather products.

Muul: Muul is a leather goods company that has differentiated its products through the use of sustainable manufacturing techniques. They use eco-friendly materials and manufacturing processes to create their leather products, appealing to customers who are concerned about sustainability.

This has helped them build a reputation as a socially responsible company and attract customers who prioritize environmental sustainability.

Tusting: Tusting is a luxury leather goods company that has differentiated its products through a combination of traditional and innovative manufacturing techniques. They use traditional leatherworking techniques to create high-quality leather bags and accessories, but also incorporate modern technologies like 3D printing and laser cutting to create unique designs and patterns. This has allowed them to appeal to customers who appreciate traditional craftsmanship but also want modern, innovative products.

Stuart & Lau: Stuart & Lau is a men's accessories brand that has differentiated its leather products through a combination of functional and aesthetic design. They use innovative materials and manufacturing techniques to create stylish and functional products, such as their Commuter Briefcase, which is made from a water-resistant fabric and leather trim.

This has allowed them to offer practical and fashionable products, appealing to customers who prioritize both form and function.

Challenges and Considerations

Leather manufacturers may face several challenges when implementing innovative manufacturing techniques, including:

High Cost

Implementing innovative manufacturing techniques can be expensive, requiring significant technological, equipment, and training investment. This can be a barrier for small and medium-sized manufacturers who may not have the financial resources to invest in these technologies.

Limited Availability of Skilled Labor

Some innovative manufacturing techniques may require specialized skills and expertise that are not readily available in the workforce. This can make it challenging for manufacturers to find and hire skilled workers who can operate these technologies effectively.

Complex Production Processes

Innovative manufacturing techniques can be more complex than traditional methods, requiring more steps and processes to produce a finished product. This can increase the risk of errors and quality issues, requiring more resources to manage and maintain quality control.

Regulatory Compliance

Implementing innovative manufacturing techniques may require compliance with new regulations and standards, which can be time-consuming and expensive to implement. This can be particularly challenging for manufacturers who operate in multiple jurisdictions with varying regulations.

Limited Adoption by Customers

While innovative manufacturing techniques can differentiate products and increase sales, they may not always be well-received by customers who prefer traditional leather products. This can limit the market potential for these products, making it more challenging for manufacturers to justify the investment in these technologies.

Overall, leather manufacturers may face several challenges when implementing innovative manufacturing techniques, including high costs, limited availability of skilled labor, complex production processes, regulatory compliance, and limited adoption by customers.

However, with careful planning, investment, and strategic implementation, these challenges can be overcome, allowing manufacturers to differentiate their products and stay competitive in a rapidly evolving market.

Importance of Considering Factors such as Cost, Sustainability, and Consumer Preferences

When choosing manufacturing techniques for leather products, it is important for manufacturers to consider several factors, including cost, sustainability, and consumer preferences. Here's why:

- Cost: Implementing innovative manufacturing techniques can be expensive, and manufacturers must consider the cost of technology, equipment, and training required to implement these techniques. Manufacturers should assess whether the added cost of innovative techniques is worth the potential benefits of differentiation and increased sales.

- Sustainability: Consumers are increasingly concerned about the environmental impact of the products they purchase. Leather manufacturers should consider using sustainable manufacturing techniques that reduce waste, water usage, and carbon emissions. By doing so, manufacturers can appeal to environmentally conscious consumers and demonstrate their commitment to sustainable business practices.

- Consumer preferences: Consumer preferences play a critical role in the success of leather products. Manufacturers should conduct market research to understand the preferences and needs of their target consumers. This includes identifying the materials, styles, and designs that resonate with consumers. By incorporating consumer preferences into the manufacturing process, manufacturers can create products that appeal to their target market and drive sales.

In summary, considering factors such as cost, sustainability, and consumer preferences is crucial when choosing manufacturing techniques for leather products. By carefully evaluating these factors, manufacturers can make informed decisions about the techniques they implement and create products that meet the needs and preferences of their target consumers.

How can Deskera Help You?

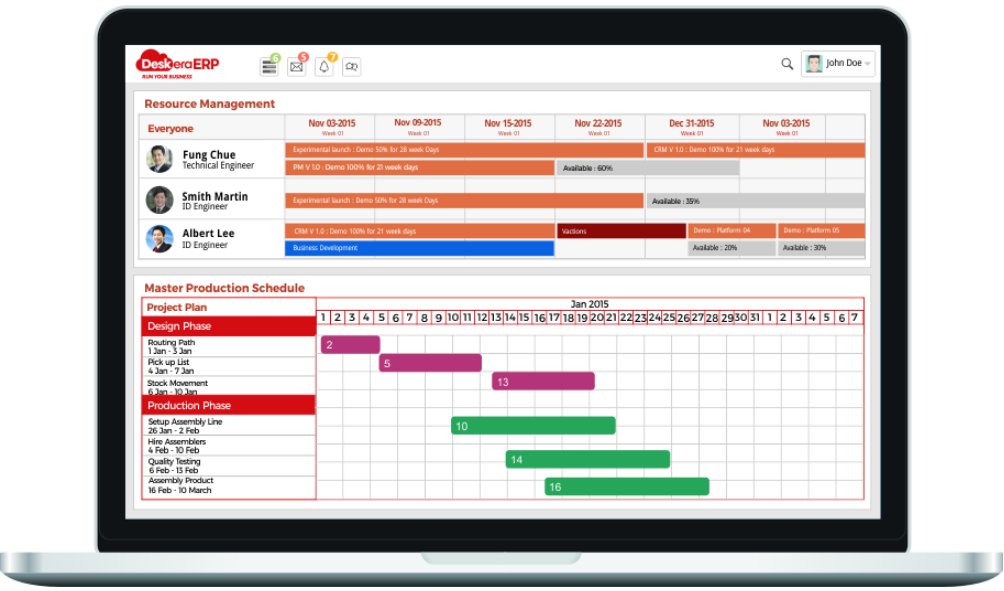

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Traditional leather manufacturing techniques are limited in their ability to differentiate products, leading to a highly competitive market.

- Innovative manufacturing techniques like digital printing and laser etching can differentiate leather products and increase sales.

- Sustainable manufacturing techniques are becoming increasingly important to environmentally conscious consumers.

- Differentiating leather products can lead to increased brand recognition and customer loyalty.

- Consumer preferences should be taken into account when choosing manufacturing techniques.

- Innovative manufacturing techniques can be costly to implement, requiring significant investment in technology, equipment, and training.

- Limited availability of skilled labor can be a challenge for manufacturers implementing innovative techniques.

- Complex production processes can increase the risk of errors and quality issues, requiring more resources to manage and maintain quality control.

- Regulatory compliance can be a challenge when implementing innovative manufacturing techniques.

- Limited adoption by customers may limit the market potential for innovative products.

- Examples of companies successfully differentiating their leather products include Louis Vuitton, Hermès, and ECCO.

- By carefully considering cost, sustainability, and consumer preferences, leather manufacturers can create innovative products that stand out in a competitive market.

Related Articles