In today's competitive manufacturing landscape, the ability to accurately predict customer demand is a critical factor for success. Demand forecasting plays a pivotal role in effective supply chain management, enabling manufacturers to align their operations with market needs, optimize resources, and drive overall business performance.

By leveraging historical data, market trends, and predictive analytics, manufacturers can gain valuable insights into future demand patterns and make informed decisions that impact production planning, inventory management, procurement, and distribution.

The dynamic nature of customer demand requires manufacturers to stay agile and responsive. Demand forecasting provides a roadmap for manufacturers to anticipate and adapt to changing market conditions, minimize risks, and seize opportunities. It serves as a foundation for efficient supply chain operations, enabling manufacturers to meet customer expectations, reduce costs, and gain a competitive edge.

This article explores why demand forecasting is critical for effective supply chain management in the manufacturing sector.

Let’s look at the table of content we’ll cover in this guide:

- Meaning of Demand Forecasting in Supply Chain Management in Manufacturing

- Importance of Demand Forecasting in Optimizing Supply Chain Operations

- Benefits of Demand Forecasting in Manufacturing for Effective Supply Chain

- What Internal and External Factors Drive Demand Most Significantly?

- Integration of Demand Forecasting into Supply Chain Management

- Challenges and Mitigation Strategies

- Case Studies and Best Practices

- Future Trends and Innovations in Demand Forecasting for Manufacturing

- Frequently Asked Questions (FAQs) Associated with Demand Forecasting for Supply Chain in Manufacturing

- Wrapping Up

- How Can Deskera Assist You?

Let's get started!

Meaning of Demand Forecasting in Supply Chain Management in Manufacturing

Demand forecasting in supply chain management in manufacturing refers to the process of predicting future customer demand for a product or service. It involves analyzing historical data, market trends, customer behavior, and other relevant factors to estimate the quantity and timing of future demand.

The primary goal of demand forecasting is to provide accurate and timely information to guide various supply chain activities, such as production planning, inventory management, procurement, and distribution.

By understanding and forecasting demand patterns, manufacturers can optimize their operations, allocate resources effectively, minimize costs, and meet customer requirements efficiently.

Importance of Demand Forecasting in Optimizing Supply Chain Operations

Demand forecasting plays a crucial role in optimizing supply chain operations in manufacturing. Here are some key reasons why demand forecasting is important:

Efficient Production Planning:

Demand forecasting enables manufacturers to anticipate customer demand and plan their production activities accordingly. By aligning production levels with anticipated demand, manufacturers can optimize their resources, minimize waste, and ensure optimal utilization of production capacities. This helps in avoiding underproduction or overproduction scenarios, leading to cost savings and improved operational efficiency.

Inventory Management:

Accurate demand forecasting allows manufacturers to maintain optimal inventory levels. By predicting future demand, manufacturers can determine the right quantity of raw materials, components, and finished goods to have in stock. This prevents excessive inventory carrying costs and reduces the risk of stockouts or shortages, ensuring smooth production and fulfillment processes.

Supplier Management and Procurement:

Demand forecasting helps in effective supplier management and procurement. By accurately estimating future demand, manufacturers can negotiate better contracts with suppliers, plan their procurement activities, and ensure a timely and sufficient supply of materials. This enables manufacturers to optimize their purchasing decisions, reduce lead times, and minimize supply chain disruptions.

Customer Satisfaction:

Meeting customer demand is crucial for maintaining customer satisfaction. Demand forecasting allows manufacturers to understand customer needs and preferences, enabling them to fulfill orders promptly and accurately. By aligning production and supply chain operations with anticipated demand, manufacturers can avoid delays, backorders, and other issues that can negatively impact customer satisfaction.

Cost Reduction:

Demand forecasting helps in optimizing costs throughout the supply chain. By accurately predicting demand, manufacturers can minimize inventory holding costs, reduce wastage and obsolescence, optimize transportation and logistics activities, and improve overall supply chain efficiency. This leads to cost savings and increased profitability.

In summary, demand forecasting is critical for optimizing supply chain operations in manufacturing by facilitating efficient production planning, inventory management, procurement, enhancing customer satisfaction, and reducing costs. It enables manufacturers to make informed decisions, align their operations with market demand, and stay competitive in the dynamic business environment.

Benefits of Demand Forecasting in Manufacturing for Effective Supply Chain

Demand forecasting in manufacturing offers several benefits for effective supply chain management. Here are some key advantages:

Improved Inventory Management: Accurate demand forecasting helps manufacturers optimize their inventory levels. By forecasting future demand, manufacturers can determine the right quantity of raw materials, components, and finished goods to have in stock. This prevents excessive inventory carrying costs, reduces the risk of stockouts or shortages, and ensures efficient use of warehouse space.

Enhanced Production Planning and Scheduling: Demand forecasting provides manufacturers with insights into anticipated customer demand. This information enables them to plan and schedule production activities more effectively.

Furthermore, manufacturers can align their production capacities, labor, and equipment with forecasted demand, avoiding underutilization or overburdening of resources. This leads to optimized production efficiency and minimized production costs.

Efficient Resource Allocation and Procurement: Accurate demand forecasting enables manufacturers to allocate their resources efficiently. By knowing the expected demand, they can allocate labor, equipment, and other resources in a way that maximizes productivity and minimizes waste.

Additionally, manufacturers can plan their procurement activities based on forecasted demand, ensuring timely and adequate availability of materials while avoiding excess inventory and associated costs.

Minimized Stockouts and Improved Customer Satisfaction: Demand forecasting helps manufacturers avoid stockouts, which occur when customer demand exceeds available inventory.

By accurately predicting demand, manufacturers can ensure they have sufficient stock to meet customer requirements. This reduces the risk of delayed deliveries and backorders, enhancing customer satisfaction and loyalty.

Optimal Pricing and Promotions: Demand forecasting aids manufacturers in setting optimal pricing strategies and planning promotional activities. By understanding customer demand patterns, manufacturers can determine the right pricing levels and identify opportunities for promotional campaigns. This helps in maximizing revenue and profit margins while staying competitive in the market.

Supply Chain Optimization: Demand forecasting plays a vital role in optimizing the entire supply chain. By providing insights into expected demand, manufacturers can collaborate with suppliers, logistics providers, and other stakeholders to synchronize their activities.

Furthermore, this coordination leads to improved supply chain visibility, reduced lead times, enhanced responsiveness, and ultimately, a more efficient and effective supply chain.

In summary, demand forecasting in manufacturing offers benefits such as improved inventory management, enhanced production planning, efficient resource allocation and procurement, minimized stockouts, improved customer satisfaction, optimal pricing and promotions, and overall supply chain optimization. It enables manufacturers to make data-driven decisions, reduce costs, enhance operational efficiency, and meet customer demands effectively.

What Internal and External Factors Drive Demand Most Significantly?

Several internal and external factors can have a significant impact on demand. The relative importance of these factors may vary depending on the industry, market conditions, and specific products or services. Here are some key factors that commonly influence demand:

Internal Factors:

Following, we've discussed some major internal factors. Let's learn:

Pricing Strategy: Pricing plays a crucial role in shaping customer demand. The price of a product or service can significantly impact consumer behavior and purchasing decisions. Price reductions, discounts, and promotional offers can stimulate demand, while higher prices may reduce demand.

Product Quality and Features: The quality, features, and performance of a product directly influence customer demand. Customers are more likely to purchase products that meet their needs, provide superior functionality, and offer a positive user experience. Continuous product improvement and innovation can drive increased demand.

Brand Image and Reputation: Strong brand image and positive reputation can significantly impact demand. Well-established brands that are trusted by consumers often enjoy higher demand due to factors such as perceived quality, reliability, and customer loyalty. Branding and marketing efforts can influence customer perceptions and preferences.

Marketing and Advertising: Effective marketing and advertising campaigns can create awareness, generate interest, and stimulate demand for products or services. Strategies such as targeted advertising, social media campaigns, endorsements, and influencer marketing can all influence customer demand.

External Factors:

Following, we've discussed some major external factors. Let's learn:

Economic Conditions: Economic factors, such as overall economic growth, inflation, interest rates, and consumer confidence, can have a substantial impact on demand. During periods of economic expansion, consumers tend to have higher purchasing power and increased demand. Conversely, during economic downturns, demand may decline as consumers tighten their spending.

Market Competition: Competition within the market can influence demand. The presence of substitute products or services, the number of competitors, and their pricing strategies can all impact customer choices. Intense competition may lead to price wars, aggressive marketing, and product differentiation to attract and retain customers.

Consumer Preferences and Trends: Consumer preferences, tastes, and trends significantly affect demand. Changes in consumer behavior, lifestyle choices, cultural influences, and evolving trends can create shifts in demand for certain products or services. Keeping up with consumer preferences through market research and customer insights is crucial for understanding and predicting demand.

Regulatory and Legal Factors: Regulatory and legal requirements can influence demand in certain industries. Government regulations, standards, certifications, and environmental considerations can impact customer preferences and demand. Compliance with regulations and adapting to changing legal requirements can influence product demand.

Technological Advancements: Technological advancements can both create and disrupt demand. Innovations and technological breakthroughs can introduce new products, services, and market opportunities, driving demand. On the other hand, emerging technologies can render certain products or services obsolete, leading to a decline in demand.

It's important to note that these factors are interrelated and can collectively shape demand. Manufacturers need to monitor and analyze these factors to accurately forecast demand and adjust their strategies accordingly.

Integration of Demand Forecasting into Supply Chain Management

Integration of demand forecasting into supply chain management is essential for optimizing operations and improving overall efficiency. Demand forecasting provides valuable insights into anticipated customer demand, enabling manufacturers to make informed decisions and align their supply chain activities accordingly.

Here are some key aspects of integrating demand forecasting into supply chain management:

Production Planning: Demand forecasting helps in determining the production levels required to meet anticipated customer demand. Manufacturers can adjust their production schedules, capacities, and labor requirements based on the forecasted demand. This ensures that production resources are allocated efficiently and helps avoid underutilization or overburdening of production capabilities.

Inventory Management: Accurate demand forecasting allows manufacturers to optimize their inventory levels. By forecasting future demand, manufacturers can determine the appropriate stock levels of raw materials, components, and finished goods. This helps in reducing inventory carrying costs, minimizing stockouts, and avoiding excessive inventory levels.

Procurement and Supplier Management: Demand forecasting influences procurement decisions and supplier management strategies. Manufacturers can plan their procurement activities based on forecasted demand to ensure a timely and sufficient supply of materials. This helps in maintaining smooth production processes and reducing the risk of supply chain disruptions. Additionally, demand forecasting helps in negotiating better contracts with suppliers, optimizing lead times, and managing supplier relationships effectively.

Distribution and Logistics: Demand forecasting aids in optimizing distribution and logistics operations. By accurately predicting demand, manufacturers can plan their distribution networks, transportation modes, and delivery schedules. This ensures that products are delivered to customers efficiently, minimizing lead times and transportation costs. Demand forecasting also helps in warehousing management and distribution center operations by aligning them with expected demand.

Financial Planning and Budgeting: Demand forecasting provides valuable inputs for financial planning and budgeting. Manufacturers can estimate their sales revenues, expenses, and cash flow projections based on the forecasted demand. This helps in setting realistic financial goals, allocating resources effectively, and making informed investment decisions.

New Product Development and Market Expansion: Demand forecasting supports decision-making regarding new product development and market expansion. By analyzing demand trends and customer preferences, manufacturers can identify potential market opportunities and assess the feasibility of introducing new products or expanding into new markets. This helps in minimizing risks and optimizing resource allocation for new ventures.

Data Sharing and Collaboration: Integration requires close collaboration and information sharing between demand forecasting teams and other supply chain functions. Demand forecasting teams should collaborate with sales, marketing, production planning, inventory management, and procurement teams to exchange data, insights, and expertise. This collaboration ensures that demand forecasts are based on accurate and comprehensive information from across the supply chain.

Demand-Driven Planning: Integration involves making supply chain plans and decisions based on demand forecasts. Production planning, inventory management, and procurement activities should be aligned with forecasted demand levels to avoid overproduction or stockouts. Demand-driven planning ensures that supply chain resources and capacities are optimally utilized, reducing waste and improving operational efficiency.

Continuous Monitoring and Adjustment: Integrated demand forecasting requires ongoing monitoring and adjustment. Demand forecasts should be regularly reviewed and updated based on changing market conditions, customer behavior, and other relevant factors. By continuously monitoring actual demand versus forecasted demand, supply chain teams can identify any deviations and make necessary adjustments to planning and execution.

Technology and Analytics: Integrating demand forecasting into supply chain management often involves leveraging technology and analytics tools. Advanced forecasting software, data analytics platforms, and predictive modeling techniques can enhance the accuracy and efficiency of demand forecasting. By utilizing these tools, supply chain teams can analyze historical data, market trends, and other factors to generate more accurate demand forecasts.

Performance Metrics and KPIs: Integration requires defining performance metrics and key performance indicators (KPIs) related to demand forecasting and supply chain operations.

Furthermore, these metrics could include forecast accuracy, fill rate, inventory turnover, on-time delivery, and customer satisfaction. Monitoring and measuring these metrics provide insights into the effectiveness of demand forecasting integration and overall supply chain performance.

Collaboration with External Partners: Integration extends beyond internal supply chain functions. Collaboration with external partners, such as suppliers and distributors, is crucial for effective demand forecasting and supply chain management. Sharing forecasted demand information with external partners enables them to align their operations, production capacities, and delivery schedules to meet anticipated demand.

In summary, demand forecasting plays a critical role in supply chain decision-making. It enables manufacturers to make informed decisions regarding production planning, inventory management, procurement, distribution, financial planning, and strategic expansion. By leveraging demand forecasting insights, manufacturers can optimize their supply chain operations, reduce costs, improve customer satisfaction, and gain a competitive edge in the market.

Challenges and Mitigation Strategies

Common Challenges in Demand Forecasting for Manufacturing:

Uncertain and Volatile Market Conditions: Manufacturing companies often face challenges in accurately forecasting demand due to uncertain and volatile market conditions. Factors such as economic fluctuations, changing customer preferences, and competitive dynamics can make it difficult to predict future demand accurately.

Limited Historical Data: New product launches, market expansions, or changes in customer behavior may result in limited historical data for forecasting. Insufficient historical data can lead to forecast inaccuracies and increase the risk of errors.

Seasonality and Trends: Demand patterns influenced by seasonality or trends pose challenges for forecasting. Fluctuations in demand during specific periods or the emergence of new trends can make it challenging to accurately capture the underlying patterns and predict future demand.

Lack of Collaboration and Information Sharing: Inadequate collaboration and information sharing between different functions within the organization can hinder accurate demand forecasting. Insufficient communication between sales, marketing, production, and supply chain teams can lead to incomplete or biased information, affecting the quality of demand forecasts.

Strategies to Overcome Forecast Errors and Variability:

Following, we've thoroughly discussed some important strategies to overcome forecast errors and variability. Let's learn:

Utilize Multiple Forecasting Techniques: Employing a combination of forecasting techniques, such as quantitative methods (e.g., time series analysis, regression) and qualitative methods (e.g., expert opinions, market surveys), can help mitigate forecast errors. Using multiple techniques provides a more comprehensive view of demand patterns and helps compensate for the limitations of individual methods.

Incorporate External Factors: Consider external factors such as economic indicators, market trends, and competitor activities in the forecasting process. Analyzing industry reports, market research, and customer insights can provide valuable inputs for demand forecasting and improve forecast accuracy.

Collaborative Forecasting: Foster collaboration and information sharing among various departments involved in the demand forecasting process. Sales, marketing, production, and supply chain teams should regularly exchange information, insights, and feedback to ensure a holistic and accurate understanding of demand drivers.

Continuous Improvement and Learning: Implement a feedback loop to continuously evaluate forecast accuracy and identify areas for improvement. Analyze forecast errors, track performance metrics, and solicit input from stakeholders to learn from past forecasting mistakes and make necessary adjustments.

Importance of Continuous Monitoring and Adjustment:

Continuous monitoring and adjustment are critical to demand forecasting for manufacturing due to the dynamic nature of markets and changing customer behaviors. Here's why it's important:

Adaptation to Market Changes: Markets evolve, and demand patterns can change over time. Continuous monitoring allows manufacturers to stay informed about market trends, shifts in customer preferences, and emerging opportunities or threats. By adjusting the forecast based on new information, manufacturers can proactively respond to market changes.

Mitigation of Forecast Errors: Continuous monitoring helps identify forecast errors and variances between predicted and actual demand. By monitoring performance metrics and comparing forecasts to actual outcomes, manufacturers can identify patterns, root causes of errors, and areas for improvement. This allows for the refinement of forecasting models and techniques to reduce errors over time.

Agility and Responsiveness: Continuous monitoring and adjustment enable manufacturers to be agile and responsive to demand fluctuations. When deviations from the forecast occur, adjustments can be made promptly to align production, inventory, and procurement decisions with the updated demand outlook. This helps prevent stockouts, minimize excess inventory, and maintain high customer service levels.

Optimization of Resources and Costs: By continuously monitoring and adjusting demand forecasts, manufacturers can optimize resource allocation and cost management. Accurate forecasts help in efficient production planning, inventory management, and procurement, ensuring optimal utilization of resources and minimizing costs associated with underutilized capacity or excess inventory.

In summary, continuous monitoring and adjustment in demand forecasting are crucial for adapting to market changes, mitigating forecast errors, maintaining agility, and optimizing resources. By employing effective strategies and leveraging data-driven insights, manufacturers can improve their forecast accuracy and make more informed supply chain decisions.

Case Studies and Best Practices

Following, we’ve discussed some important case studies and best practices. Let’s learn:

Case Studies of Successful Demand Forecasting Implementation in Manufacturing:

Procter & Gamble (P&G): P&G, a multinational consumer goods company, implemented a demand-driven forecasting approach called "Collaborative Planning, Forecasting, and Replenishment" (CPFR).

By collaborating closely with retail partners and sharing real-time sales data, P&G improved its demand forecasting accuracy and reduced inventory costs. The collaborative approach helped P&G better align its production and distribution with actual customer demand.

Amazon: As a global e-commerce giant, Amazon leverages advanced demand forecasting techniques and data analytics to optimize its supply chain operations. Through a combination of historical sales data, customer behavior analysis, and machine learning algorithms, Amazon achieves accurate demand forecasts at both the macro and micro levels. This enables the company to efficiently manage inventory, minimize stockouts, and provide fast and reliable deliveries.

Best Practices for Effective Demand Forecasting:

Utilize a Combination of Methods: Employ a mix of quantitative and qualitative forecasting methods to capture different aspects of demand. Combining statistical models, market research, expert opinions, and customer feedback enhances the accuracy and reliability of forecasts.

Data-Driven Approach: Leverage historical sales data, market data, customer insights, and other relevant data sources to inform demand forecasts. Utilize advanced analytics and forecasting tools to analyze data, identify patterns, and generate accurate predictions.

Collaborate and Share Information: Foster collaboration and information sharing between different teams and functions involved in demand forecasting, such as sales, marketing, operations, and supply chain. Regularly exchange insights, market intelligence, and feedback to enhance the accuracy and relevance of forecasts.

Continuous Improvement and Feedback Loop: Establish a feedback loop to evaluate forecast accuracy and make necessary adjustments. Regularly review forecast performance, identify areas for improvement, and incorporate feedback from stakeholders to refine forecasting models and processes.

Monitor Leading Indicators: Identify and monitor leading indicators that can provide early signals of demand changes. These indicators may include market trends, economic indicators, social media sentiment, and customer behavior patterns. Monitoring leading indicators can help anticipate shifts in demand and adjust forecasts accordingly.

Lessons Learned and Recommendations for Manufacturers:

Invest in Technology and Analytics: Embrace advanced forecasting tools, data analytics, and machine learning algorithms to enhance forecast accuracy and automation. Investing in technology and analytics capabilities can significantly improve forecasting efficiency and provide valuable insights for decision-making.

Collaborate with Partners: Engage in collaborative forecasting with key partners in the supply chain, such as suppliers, distributors, and retailers. Sharing demand forecasts and collaborating on planning and inventory management can improve supply chain visibility, responsiveness, and overall performance.

Embrace Flexibility and Agility: Recognize that demand forecasting is an iterative process. Stay adaptable and responsive to changing market conditions, emerging trends, and customer preferences. Embrace flexibility in production, inventory, and distribution strategies to align with evolving demand patterns.

Continuous Learning and Adaptation: Demand forecasting is a continuous learning process. Learn from past forecasting errors, monitor forecast accuracy, and continuously refine forecasting models and techniques. Regularly evaluate and update forecasting practices based on feedback and new insights.

By implementing these best practices, manufacturers can enhance their demand forecasting capabilities, optimize supply chain operations, reduce costs, and better meet customer demand.

Future Trends and Innovations in Demand Forecasting for Manufacturing:

Following, we've discussed future trends and innovation in demand forecasting for manufacturing. Let's discuss:

1.Emerging Technologies Shaping Demand Forecasting:

Let's learn the emerging technologies that would help to shape demand forecasting for manufacturing.

a. Internet of Things (IoT): IoT sensors and devices provide real-time data on product usage, performance, and customer behavior. This data can be leveraged for more accurate demand forecasting by capturing real-time demand signals and improving visibility into supply chain operations.

b. Big Data and Advanced Analytics: The growing availability of large volumes of data and advanced analytics techniques enable manufacturers to analyze complex data sets and extract valuable insights for demand forecasting. Machine learning algorithms and predictive analytics help identify patterns, trends, and demand drivers, leading to more accurate forecasts.

c. Predictive Analytics and Prescriptive Analytics: Predictive analytics uses historical data and statistical models to predict future demand patterns. Prescriptive analytics goes a step further by providing recommendations on actions to take based on forecasted demand, enabling manufacturers to proactively optimize their supply chain operations.

2. Integration of Artificial Intelligence (AI) and Machine Learning (ML):

AI and ML technologies play a significant role in demand forecasting by analyzing vast amounts of data, learning from patterns and trends, and improving forecast accuracy. AI and ML algorithms can automatically adjust and refine forecasting models based on changing market conditions and customer behavior, leading to more accurate and dynamic demand forecasts.

3. Potential Impact of Industry 4.0 on Demand Forecasting:

Industry 4.0, characterized by the integration of digital technologies and automation in manufacturing, is expected to have a significant impact on demand forecasting. Key areas of impact include:

a. Enhanced Data Connectivity: Industry 4.0 technologies facilitate seamless data connectivity across the supply chain, enabling real-time data sharing and collaboration. This improves the availability and accuracy of data inputs for demand forecasting.

b. Smart Manufacturing and Real-time Monitoring: Smart manufacturing systems equipped with sensors and IoT devices enable real-time monitoring of production processes, inventory levels, and customer demand. This real-time data integration allows for more accurate and timely demand forecasting.

c. Supply Chain Digitization and Automation: Digitization and automation of supply chain processes enable more efficient data collection, analysis, and decision-making. Automated demand forecasting algorithms can leverage real-time data and insights from various sources to generate more accurate and timely forecasts.

d. Demand-Driven Supply Chains: Industry 4.0 enables demand-driven supply chains, where customer demand signals are captured in real-time, and production, inventory, and logistics are dynamically adjusted to meet customer needs. Demand forecasting plays a crucial role in enabling this responsiveness and agility.

Overall, these emerging technologies and the integration of AI, ML, and Industry 4.0 concepts in demand forecasting have the potential to revolutionize manufacturing operations by enabling more accurate, dynamic, and responsive demand forecasting, leading to improved supply chain efficiency, customer satisfaction, and competitive advantage.

Frequently Asked Questions (FAQs) Associated with Demand Forecasting for Supply Chain in Manufacturing

Following, we’ve discussed some important frequently asked questions associated with demand forecasting in manufacturing linked with the supply chain. Let’s learn:

Q1: How does demand forecasting impact production planning and inventory management in manufacturing?

A1: Demand forecasting provides insights into the expected demand levels, allowing manufacturers to plan their production activities accordingly. It helps determine the required production capacity, schedule production orders, and allocate resources effectively.

In terms of inventory management, demand forecasting aids in maintaining optimal inventory levels, reducing the risk of stockouts or excess inventory, and improving overall inventory turnover.

Q2: What are the key benefits of demand forecasting for manufacturers in supply chain management?

A2: Demand forecasting offers several benefits for manufacturers in supply chain management, including:

- Improved production planning and resource allocation

- Enhanced inventory management and reduced carrying costs

- Minimized stockouts and improved customer service levels

- More accurate procurement and supplier management

- Optimal utilization of manufacturing facilities and equipment

- Cost reduction through efficient resource utilization

- Enhanced agility and responsiveness to market changes

Q3: How does demand forecasting help in reducing costs and improving operational efficiency?

A4: Demand forecasting helps manufacturers reduce costs and improve operational efficiency by ensuring that production and inventory levels are aligned with customer demand. Moreover, it minimizes overproduction and excess inventory, which reduces storage costs and the risk of obsolescence.

By accurately forecasting demand, manufacturers can optimize their supply chain processes, reduce lead times, eliminate bottlenecks, and streamline operations, leading to cost savings and improved overall efficiency.

Q4: What challenges do manufacturers face in demand forecasting, and how can they be overcome?

A4: Manufacturers often face challenges such as uncertain market conditions, limited historical data, seasonality, and the need for collaboration among different functions.

These challenges can be overcome by employing strategies like utilizing multiple forecasting techniques, incorporating external factors, fostering collaboration and information sharing, and continuously monitoring and adjusting forecasts based on feedback and market insights.

Q5: How does demand forecasting support decision-making in procurement and supplier management?

A5: Demand forecasting provides valuable information for procurement and supplier management decisions. By accurately predicting demand, manufacturers can plan their procurement activities, negotiate contracts with suppliers, and ensure timely availability of raw materials or components.

Furthermore, it helps optimize inventory levels, reduce stockouts, and align procurement activities with expected demand, resulting in efficient supplier management and cost-effective procurement practices.

Q6: Can demand forecasting help manufacturers in optimizing customer service levels and meeting market demand?

A6: Yes, demand forecasting plays a crucial role in optimizing customer service levels and meeting market demand. By accurately forecasting demand, manufacturers can ensure product availability, minimize stockouts, and meet customer expectations in terms of delivery times and product availability. This leads to improved customer satisfaction, repeat business, and a competitive advantage in the marketplace.

Q7: What role does collaboration between demand forecasting and other supply chain functions play in manufacturing?

A7: Collaboration between demand forecasting and other supply chain functions, such as sales, marketing, production, and logistics, is essential for accurate and effective forecasting. Close collaboration ensures the exchange of information, market insights, and feedback, enabling a holistic understanding of demand drivers.

It helps align supply chain activities, improve forecast accuracy, and facilitates coordinated decision-making across the organization.

Q8: How does demand forecasting help manufacturers in adapting to market changes and reducing lead times?

A8: Demand forecasting enables manufacturers to anticipate and adapt to market changes by providing early visibility into shifts in customer demand patterns. By continuously monitoring demand and adjusting forecasts accordingly, manufacturers can quickly respond to changing market conditions, reduce lead times, and proactively manage their supply chain operations. This adaptability helps manufacturers stay competitive and responsive in dynamic markets.

Q9: Are there any industry-specific considerations or best practices for demand forecasting in manufacturing?

A9: Yes, demand forecasting practices may vary across industries due to specific factors such as seasonality, product lifecycles, market trends, and customer behavior.

Industry-specific considerations and best practices include understanding industry dynamics, incorporating industry-specific data sources, analyzing market trends and competitors, and aligning forecasting models with industry-specific factors. It is important for manufacturers to tailor their demand forecasting approaches to the unique characteristics of their industry for optimal results.

Q10: How does demand forecasting contribute to strategic decision-making in manufacturing?

A10: Demand forecasting provides valuable insights for strategic decision-making in manufacturing. Accurate demand forecasts inform decisions related to capacity planning, expansion or contraction of production facilities, investment in new products or markets, and resource allocation.

By having a clear understanding of future demand, manufacturers can align their strategic initiatives with market opportunities, mitigate risks, and make informed decisions to drive business growth and competitiveness.

Q11: What are the long-term benefits of implementing effective demand forecasting in manufacturing?

A11: Implementing effective demand forecasting in manufacturing brings several long-term benefits. These include improved customer satisfaction, reduced inventory carrying costs, optimized production planning, better resource utilization, enhanced supply chain responsiveness, increased operational efficiency, and competitive advantage.

By accurately predicting demand and aligning their operations accordingly, manufacturers can establish a strong foundation for sustainable growth, profitability, and success in the marketplace.

Q12: Can demand forecasting help manufacturers optimize their supply chain performance?

A12: Yes, demand forecasting plays a crucial role in optimizing supply chain performance for manufacturers. By accurately forecasting demand, manufacturers can align their supply chain activities, such as production, inventory management, procurement, and distribution, with expected demand levels.

This alignment leads to improved operational efficiency, reduced costs, minimized stockouts, optimized inventory levels, and enhanced customer service levels. Demand forecasting helps manufacturers make data-driven decisions that contribute to the overall optimization of the supply chain.

Wrapping Up

Demand forecasting plays a critical role in effective supply chain management for manufacturing companies. By accurately predicting future demand, manufacturers can optimize their production planning, inventory management, procurement, and distribution processes. The integration of demand forecasting throughout the supply chain enables proactive decision-making, resource optimization, and improved customer service levels.

Through demand forecasting, manufacturers can anticipate changes in market demand, adapt their operations accordingly, and minimize the risk of stockouts or excess inventory. It helps in aligning supply chain activities with customer demand, reducing costs, and improving operational efficiency.

However, demand forecasting is not without its challenges. Uncertain market conditions, limited historical data, seasonality, and the need for collaboration across various functions can pose hurdles. Manufacturers need to employ strategies such as utilizing multiple forecasting techniques, incorporating external factors, fostering collaboration, and continuously monitoring and adjusting forecasts to overcome these challenges.

The future of demand forecasting in manufacturing is promising, with emerging technologies such as IoT, big data analytics, AI, and Industry 4.0 driving advancements. These technologies enable real-time data analysis, automation, and improved forecast accuracy, leading to more efficient supply chain operations and better decision-making.

In conclusion, demand forecasting is a critical component of effective supply chain management in manufacturing. By embracing best practices, leveraging technology, and adopting a collaborative approach, manufacturers can optimize their supply chain operations, reduce costs, enhance customer satisfaction, and gain a competitive edge in the dynamic marketplace.

How Can Deskera Assist You?

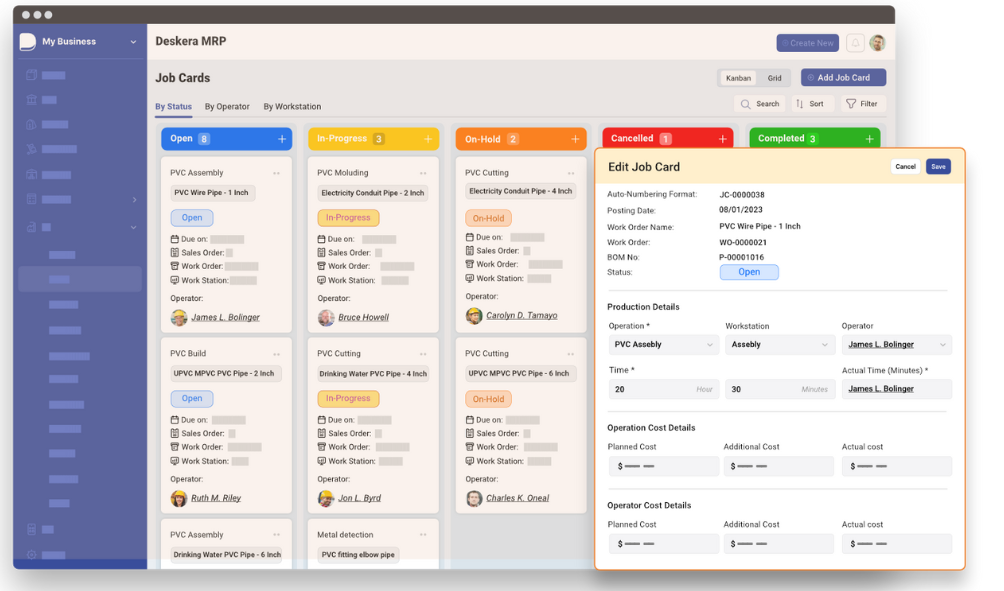

Deskera ERP and MRP systems help you to keep your business units organized. The system's key features of demand forecasting with Deskera include as follows:

- Establish Demand Forecasting Process

- Automate Data Collection

- Monitor Market Trends

- Analyze Historical Data

- Estimate Future Demand

- Adjust Production Levels

- Manage Supply Chain...and much more!

- Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

- Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

- Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

- Deskera People is a straightforward tool for centralizing your human resource management functions.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Demand forecasting in supply chain management in manufacturing refers to the process of predicting future customer demand for a product or service. It involves analyzing historical data, market trends, customer behavior, and other relevant factors to estimate the quantity and timing of future demand.

- Accurate demand forecasting helps manufacturers optimize their inventory levels. By forecasting future demand, manufacturers can determine the right quantity of raw materials, components, and finished goods to have in stock. This prevents excessive inventory carrying costs, reduces the risk of stockouts or shortages, and ensures efficient use of warehouse space.

- Meeting customer demand is crucial for maintaining customer satisfaction. Demand forecasting allows manufacturers to understand customer needs and preferences, enabling them to fulfill orders promptly and accurately. By aligning production and supply chain operations with anticipated demand, manufacturers can avoid delays, backorders, and other issues that can negatively impact customer satisfaction.

- Strong brand image and positive reputation can significantly impact demand. Well-established brands that are trusted by consumers often enjoy higher demand due to factors such as perceived quality, reliability, and customer loyalty. Branding and marketing efforts can influence customer perceptions and preferences.

- Integration requires close collaboration and information sharing between demand forecasting teams and other supply chain functions. Demand forecasting teams should collaborate with sales, marketing, production planning, inventory management, and procurement teams to exchange data, insights, and expertise.

- Employing a combination of forecasting techniques, such as quantitative methods (e.g., time series analysis, regression) and qualitative methods (e.g., expert opinions, market surveys), can help mitigate forecast errors. Using multiple techniques provides a more comprehensive view of demand patterns and helps compensate for the limitations of individual methods.

- Collaboration between demand forecasting and other supply chain functions, such as sales, marketing, production, and logistics, is essential for accurate and effective forecasting. Close collaboration ensures the exchange of information, market insights, and feedback, enabling a holistic understanding of demand drivers.

- Markets evolve, and demand patterns can change over time. Continuous monitoring allows manufacturers to stay informed about market trends, shifts in customer preferences, and emerging opportunities or threats. By adjusting the forecast based on new information, manufacturers can proactively respond to market changes.

Related Articles