Returns are an unavoidable reality of e-commerce and retail, but their impact goes far beyond a simple refund. According to industry data from Meteor Space, the average return rate for online purchases is approximately 18.1%, with some sectors seeing figures climb as high as 20% to 30%. While customer-friendly return policies may boost buyer confidence, they also introduce significant operational and financial strain for businesses of all sizes.

The hidden costs of returns extend well beyond the initial transaction. Retailers must absorb shipping fees, restocking labor, inventory devaluation, and even customer service overhead. Shopify estimates that the cost to process a single return can be as high as 20% to 65% of the product’s original value—a staggering figure that can quickly erode profit margins, especially during high-volume seasons like holidays or flash sales.

For e-commerce and retail brands, understanding the true cost of returns is not just about minimizing losses—it’s about building a smarter, more sustainable business model. Companies must consider not only the logistics involved but also the customer experience and long-term brand reputation. Return rates can often signal deeper issues, such as inaccurate product descriptions, poor quality control, or insufficient inventory visibility.

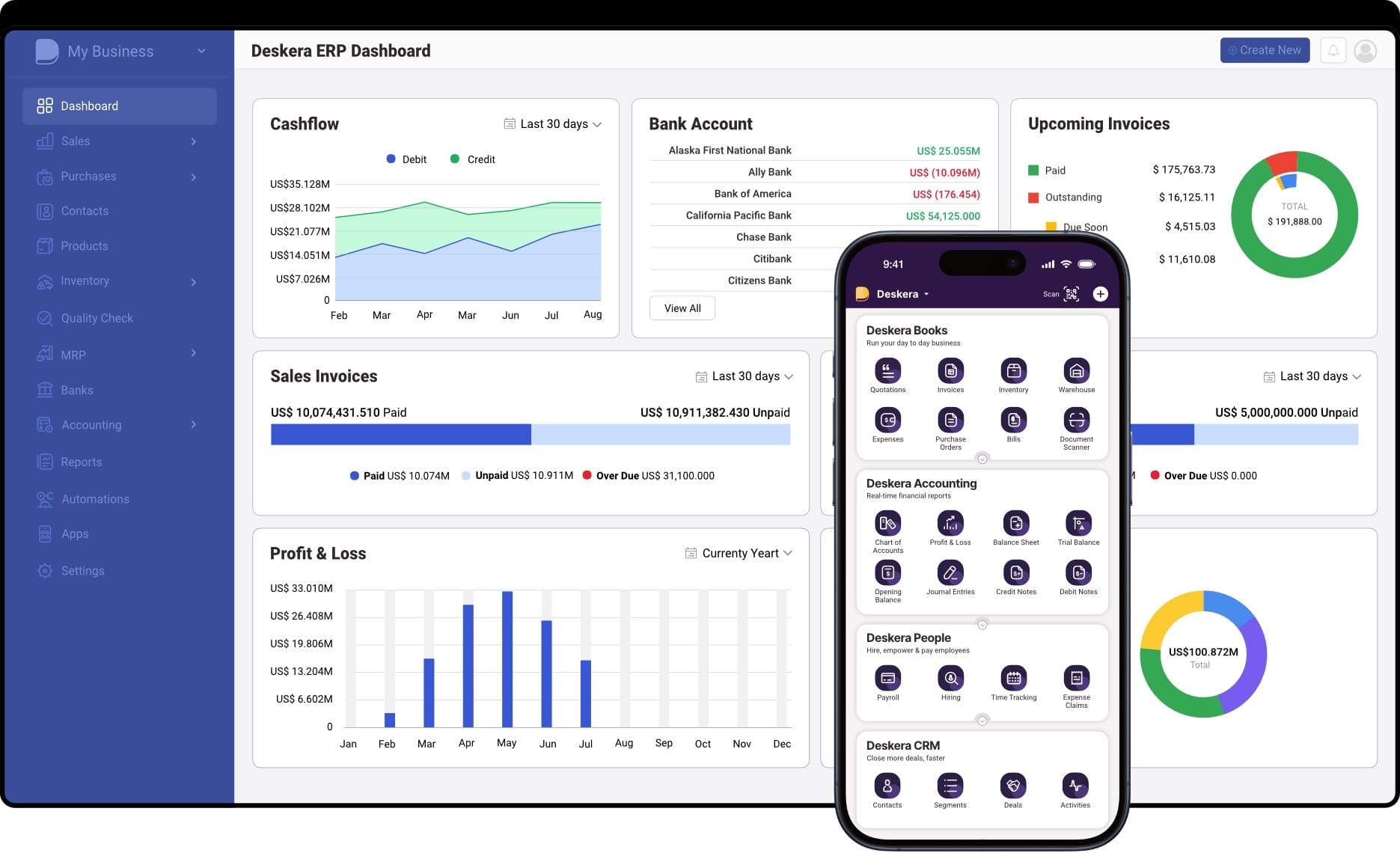

This is where an intelligent solution like Deskera ERP makes a real difference. Deskera offers a comprehensive cloud-based platform that helps businesses streamline inventory management, automate accounting, and gain actionable insights through advanced reporting. Its real-time inventory tracking, integrated financials, and mobile accessibility enable businesses to make quicker, data-driven decisions.

With powerful features like demand forecasting, multi-warehouse management, and automated procurement, Deskera empowers retail and e-commerce companies to reduce inefficiencies, optimize operational costs, and enhance the customer experience—all from a single, easy-to-use dashboard.

What is the True Cost of Returns?

The true cost of returns refers to the total expense incurred by retailers when customers send back purchased items. While many businesses view returns as a routine part of the retail cycle, the associated costs can be surprisingly complex and burdensome.

These costs include both direct expenses, such as shipping fees, labor for inspecting and restocking items, and potential markdowns, as well as indirect costs, like customer service resources and loss of customer trust if the return process is mishandled.

Returns have become increasingly common, particularly with the surge in online shopping, where customers can’t physically assess products before purchase. As a result, return rates have climbed, and with them, the financial strain on businesses.

Offering free or flexible return policies may increase conversion rates, but they also elevate operational costs. In fact, every return triggers a reverse logistics chain, which can cost a retailer between 20% to 65% of the item's original value, depending on the industry and product type.

Beyond financial implications, the cost of returns can influence broader aspects of a retailer's business. Poorly managed return processes can negatively affect inventory accuracy, slow down restocking cycles, and create customer dissatisfaction, especially when delays or errors occur.

Conversely, when returns are handled efficiently, they can strengthen customer loyalty, improve brand reputation, and even uncover valuable insights about product quality and buyer expectations.

To reduce the true cost of returns, retailers must adopt a strategic approach—one that includes clear return policies, accurate product listings, proactive customer support, and robust inventory management.

Retailers using advanced ERP solutions like Deskera ERP are better equipped to tackle these challenges, thanks to features like real-time inventory tracking, smart demand forecasting, and seamless integration of order and financial data—all of which contribute to reducing return-related inefficiencies and protecting profit margins.

Key Components of the Cost of Returns

Understanding the key components of return costs is essential for retailers who want to identify areas of improvement and reduce financial losses. Returns are not just a matter of issuing refunds—they involve a complex set of operations that span across logistics, labor, inventory, and customer service.

Here's a breakdown of the major cost components:

1. Shipping and Reverse Logistics

Shipping is one of the most immediate and visible return-related costs. When a customer returns a product, the retailer often bears the cost of return shipping, especially with free return policies.

On top of that, reverse logistics—getting the item from the customer back to the warehouse—requires additional coordination, fuel, handling, and time, all of which incur costs.

2. Labor and Handling

Returned products must be received, inspected, tested, repackaged (if eligible), and restocked. This process involves warehouse staff, quality control teams, and in some cases, specialized technicians. These labor-intensive activities significantly add to the cost of returns, especially in high-volume businesses.

3. Restocking and Warehousing

Not all returned products go directly back to inventory. Some items require repairs or cleaning, while others may be outdated or damaged and no longer sellable. Restocking returned goods demands physical space, inventory management, and sometimes reconditioning—each of which drives up operational costs.

4. Refunds and Revenue Loss

Beyond the physical handling, returns also lead to a direct loss in revenue. Not only does the sale get canceled, but there are also hidden losses in terms of processing fees, discounts, and promotions that can’t be reclaimed. Additionally, frequent returns can disrupt revenue forecasting and sales reporting.

5. Customer Service and Support

Returns often involve customer queries, complaints, and support tickets. The cost of handling return-related communications—via phone, email, or chat—adds to the burden. Each return may require dedicated service hours, return labels, or follow-up to ensure resolution and maintain customer satisfaction.

6. Product Depreciation and Write-Offs

Returned items frequently lose value. Products that are seasonal, perishable, or technologically outdated may not be resold at full price—or at all. In such cases, retailers must mark down or write off the inventory, resulting in direct profit loss.

7. Impact on Inventory Management

Returns disrupt inventory planning and forecasting. Without real-time tracking, stock levels may be inaccurate, leading to overstocking, understocking, or delays in replenishment. This not only inflates holding costs but also impairs sales operations.

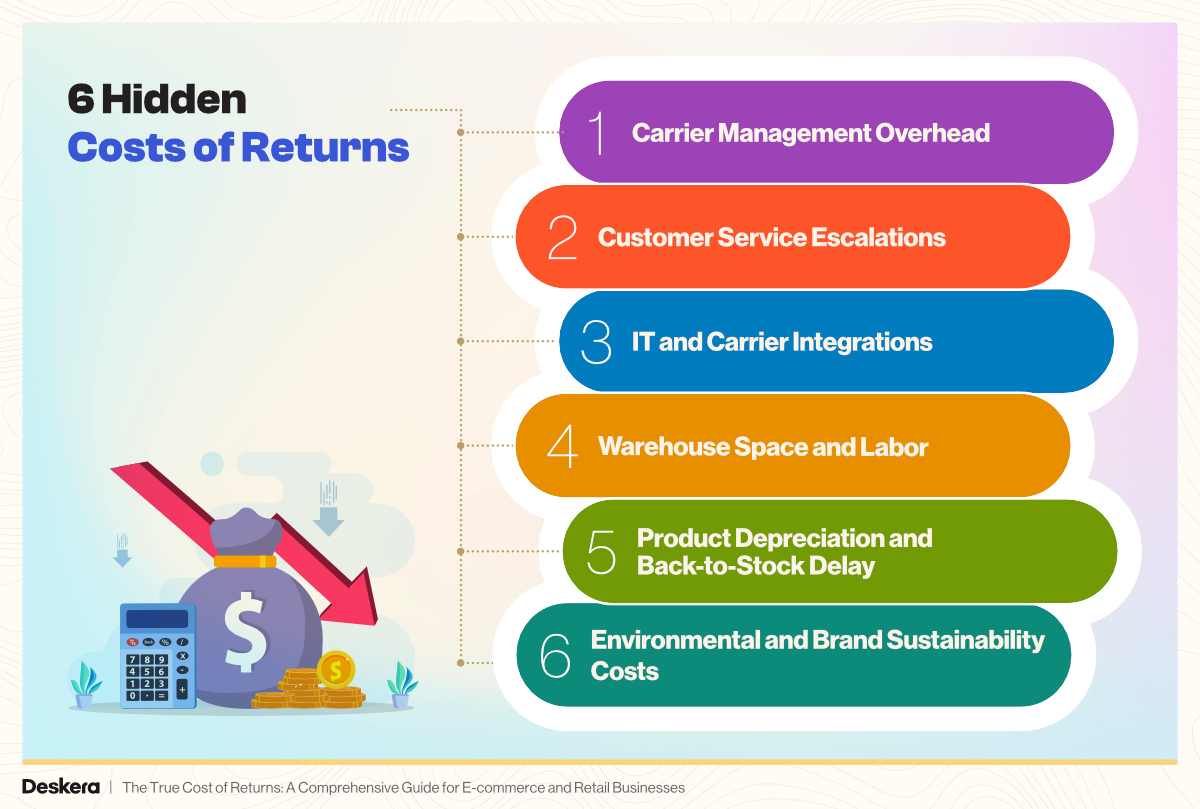

6 Hidden Costs of Returns

While the direct costs of product returns—like shipping and restocking—are well-documented, there are several hidden costs that silently erode a retailer’s margins. These costs are operational, financial, and reputational, and understanding them is key to building a more efficient and customer-centric return management process.

1. Carrier Management Overhead

Retailers frequently partner with multiple logistics carriers to handle returns across regions and countries. However, managing these relationships is resource-intensive.

Teams must track lost packages, handle service-level agreement (SLA) issues, reduce lead times, and resolve other carrier-related concerns. The time spent manually coordinating and updating spreadsheets with carrier data adds up, representing a significant operational drag that rarely gets measured.

2. Customer Service Escalations

Every return has the potential to trigger a call or email to customer service. When refunds are delayed or return tracking is opaque, customers reach out—driving up support costs. Depending on complexity, each support ticket can cost anywhere from $3 to $15.

Additionally, poor experiences in this area negatively impact retention: 80% of customers say they would switch to a competitor after multiple bad support interactions. Efficient communication and data transparency are critical to avoid this unnecessary cost.

3. IT and Carrier Integrations

To ensure customers can track their return shipments, retailers must integrate data from multiple carriers—each with its own system and format. Developing and maintaining these integrations is technically challenging and costly.

Without proper syncing, returns remain a “black box,” which only fuels more customer complaints and delays. As brands expand internationally, the cost and complexity of managing these systems multiply.

4. Warehouse Space and Labor

Returned products don’t process themselves—they require dedicated warehouse space, scanning, inspection, cleaning, and often repackaging. During peak seasons, like holidays, the volume can overwhelm existing facilities.

Each returned package represents a compound cost: not just the physical space but also the additional staff hours needed to handle inbound logistics alongside outbound order fulfillment.

5. Product Depreciation and Back-to-Stock Delay

Returns are rarely instant. Delays in getting products back on shelves—especially in fast-moving sectors like fashion—mean significant loss of value. A returned item stuck in transit or waiting in a processing queue might miss its seasonal window.

Even a short delay in return processing can make an item unsellable at full price. Retailers end up discounting these items or, worse, writing them off entirely.

6. Environmental and Brand Sustainability Costs

Returns contribute to environmental waste through unused return labels, repackaging, and CO₂ emissions from additional shipping. Many returned items, especially in fashion or electronics, end up in landfills if they can’t be resold quickly.

These environmental impacts carry brand risks. Consumers are increasingly eco-conscious, and excessive returns can damage a brand’s reputation if not addressed with sustainable solutions.

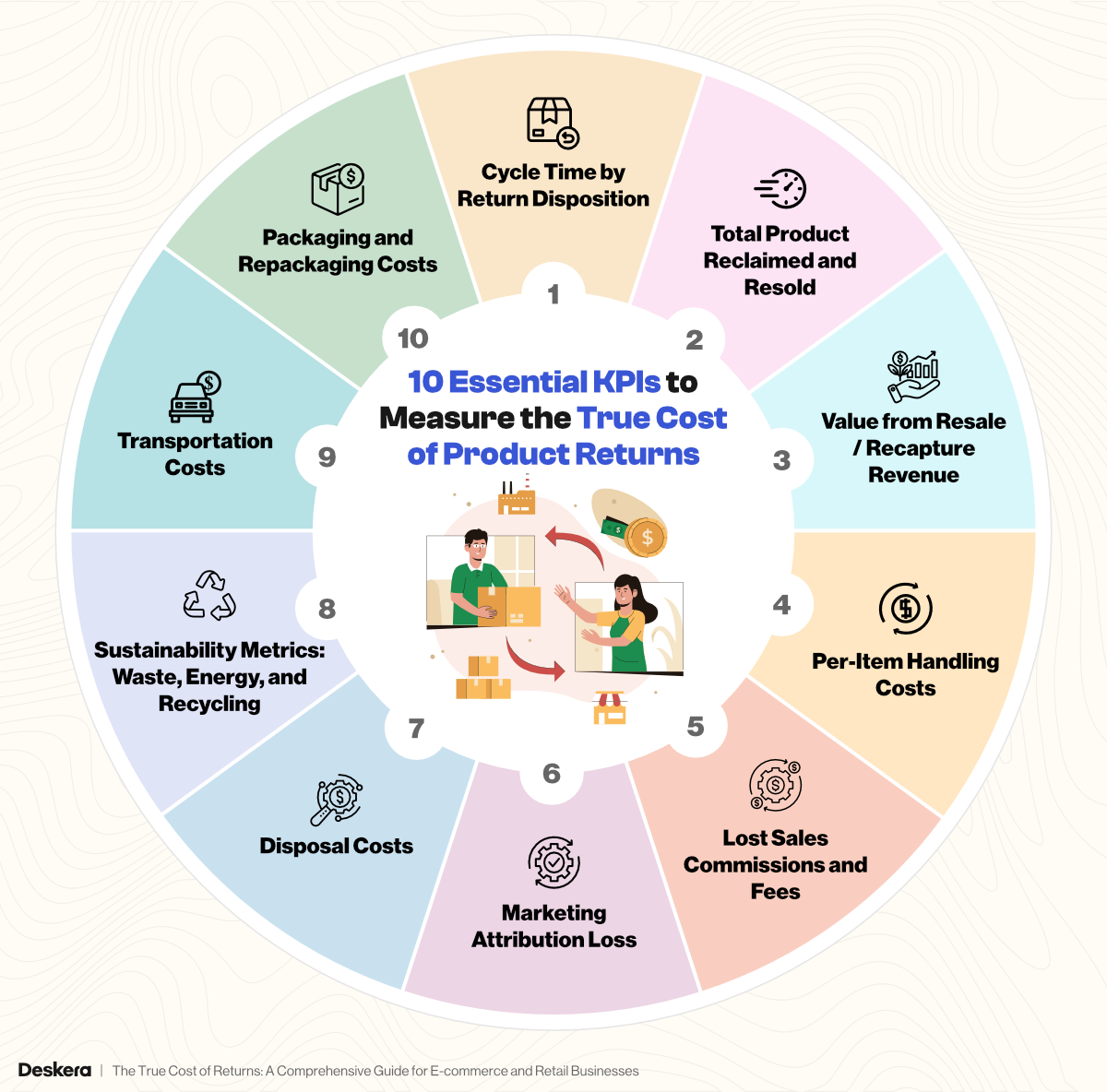

10 Essential KPIs to Measure the True Cost of Product Returns

Returns don’t just impact revenue—they erode profits through operational, environmental, and reputational costs. To fully understand the business impact of returns, companies must track key performance indicators (KPIs) that go beyond surface-level logistics.

Here are 10 essential KPIs to help you quantify, analyze, and optimize your returns process:

1. Cycle Time by Return Disposition

Measure how long it takes for an item to complete the returns process based on its final outcome: resale, vendor return, recycling, or disposal. A long cycle time means delayed inventory recovery and higher operational costs. Track this to pinpoint inefficiencies in your reverse logistics pipeline.

2. Total Product Reclaimed and Resold

This KPI reveals how much returned inventory is successfully resold, either as-is or after refurbishment. A high reclaim rate means you’re recovering more of your cost of goods sold (COGS) and minimizing write-offs.

3. Value from Resale / Recapture Revenue

Track the actual revenue generated from reselling returned items, minus refurbishment or repackaging costs. This metric helps assess the profitability of resale channels and informs decisions on whether to restock, liquidate, or dispose of returned goods.

4. Per-Item Handling Costs

Returns require multiple touchpoints—unpacking, inspection, restocking, etc. Calculate the average handling cost per item and break it down by department, product category, or facility. Identifying where labor costs spike will help prioritize automation or training investments.

5. Lost Sales Commissions and Fees

If you sell on marketplaces (like Amazon or eBay), returned products often lead to lost commissions, platform fees, or even ad spend. Quantifying these costs per return gives a clearer picture of the full revenue impact.

6. Marketing Attribution Loss

When a returned product was acquired through paid advertising or promotional campaigns, that spend becomes a sunk cost. Tie returns data back to campaign performance to gauge the efficiency and risk of different channels.

7. Disposal Costs

Not all items can be resold or returned to the vendor. For products that end up in landfills or are incinerated, track the disposal fees, transportation, storage, and labor required to manage them.

8. Sustainability Metrics: Waste, Energy, and Recycling

Capture how much waste is generated through returns—packaging, product, and energy usage. Track what percentage of returned items are recycled versus discarded. These metrics support both ESG reporting and sustainability goal setting.

9. Transportation Costs

Returns incur fuel, driver wages, vehicle maintenance, and route optimization challenges. Measure the average cost per return shipment, especially if you offer prepaid return labels or manage return pickups.

10. Packaging and Repackaging Costs

Evaluate the costs associated with discarded packaging and repackaging for resale or exchange. Inefficient packaging sizes or materials increase labor and environmental costs.

By factoring in these KPIs, you can calculate:

- Per-Item Return Cost: The average cost to process a single return, broken down by product type, channel, or facility.

- Total Product Return Cost: A comprehensive view that includes COGS, marketing spend, shipping (both ways), handling, and disposition costs—offset by any recapture value.

Understanding these metrics allows you to make smarter decisions on return policies, partner selection, packaging design, and post-purchase customer experience.

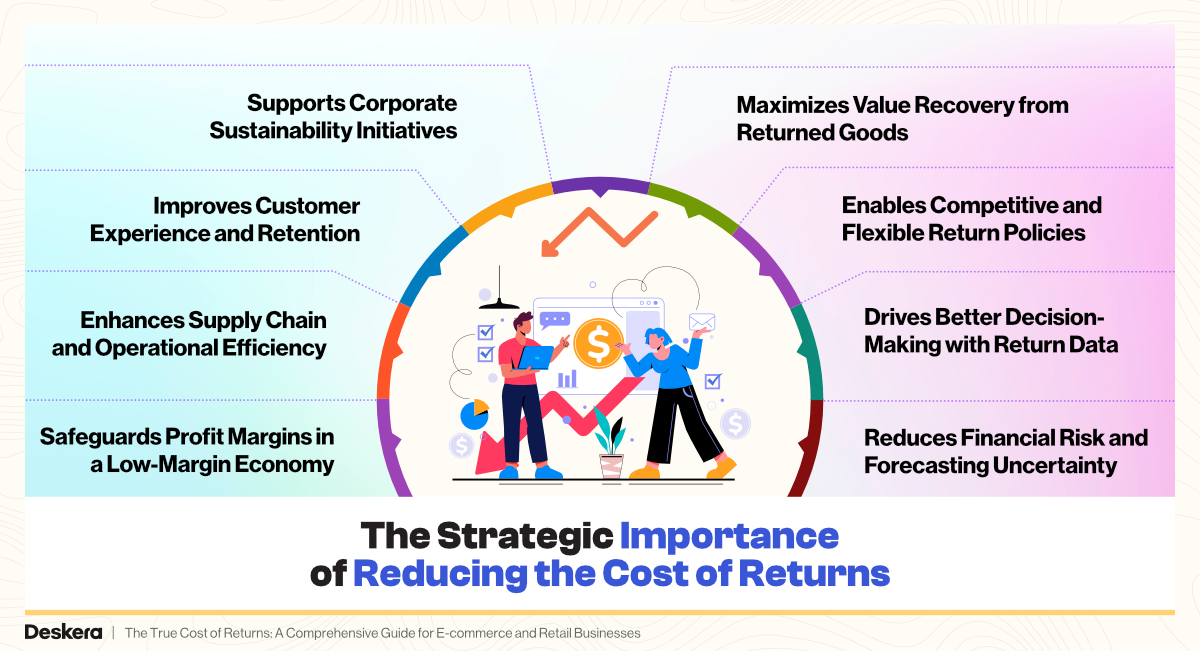

The Strategic Importance of Reducing the Cost of Returns

In an increasingly competitive and customer-centric retail landscape, product returns are no longer just a cost of doing business—they are a critical operational and financial concern. While some level of returns is inevitable, managing and reducing the associated costs can deliver significant value across every layer of your organization.

Here's why it's vital to prioritize return cost reduction:

1. Safeguards Profit Margins in a Low-Margin Economy

Returned products directly cut into your margins—not just through refunds, but through a cascade of hidden costs. These include reverse logistics, customer service time, warehouse labor, depreciation in item value, repackaging, and even the cost of disposal.

For example, if a $100 product with a $30 margin is returned and incurs $20 in return processing costs, the business actually loses money on the transaction. Reducing these costs helps you preserve profitability, especially when margins are thin.

2. Enhances Supply Chain and Operational Efficiency

Returns often clog supply chains, particularly during peak seasons. Unprocessed returns take up valuable warehouse space, demand manual labor for inspection and sorting, and can delay restocking of sellable items.

By optimizing your returns process—automating repetitive tasks, introducing intelligent return routing, or leveraging AI-based restocking decisions—you streamline operations. This improves throughput, reduces bottlenecks, and frees up resources to focus on forward-moving inventory.

3. Improves Customer Experience and Retention

Consumers today expect a hassle-free return process. In fact, surveys consistently show that a poor return experience significantly lowers the likelihood of repeat purchases. Delays in refunds, lack of tracking visibility, and unresponsive support contribute to negative brand perception.

On the other hand, a fast, transparent, and low-friction return process—enabled by cost-efficient systems—can enhance customer satisfaction and build loyalty. This translates into higher lifetime value and lower churn.

4. Supports Corporate Sustainability Initiatives

Every return generates environmental impact: additional packaging waste, reverse transportation emissions, energy for warehouse processing, and, in many cases, the disposal of unsellable products.

Reducing the number of returns and optimizing the handling of necessary returns helps companies minimize landfill contributions and CO₂ emissions.

In a market where consumers and investors alike are placing greater emphasis on sustainability, this can also strengthen your ESG reporting and corporate reputation.

5. Maximizes Value Recovery from Returned Goods

The longer an item sits in the return process, the more it depreciates—especially in fast-moving categories like fashion, electronics, and seasonal goods. Reducing the time and cost involved in inspecting, refurbishing, and restocking returns helps businesses resell them at a higher margin or quickly return them to the vendor for credit. This not only cuts losses but also improves inventory turnover and reduces dead stock accumulation.

6. Enables Competitive and Flexible Return Policies

Many retailers are pressured to offer generous return windows and free returns to remain competitive, especially in ecommerce. While these policies boost conversions, they can backfire if return costs are high. By optimizing return costs internally, businesses can afford to offer customer-friendly policies without compromising profitability—turning returns into a competitive advantage rather than a liability.

7. Drives Better Decision-Making with Return Data

Reducing return costs requires businesses to dig deep into their return analytics—understanding what products are returned, why, and at what cost. This insight fuels smarter product development, better inventory forecasting, improved quality control, and even targeted marketing strategies that reduce returns proactively. In essence, managing return costs becomes a strategic lever for continuous improvement across the value chain.

8. Reduces Financial Risk and Forecasting Uncertainty

Uncontrolled return costs can lead to unpredictable expenses, complicating budgeting and forecasting efforts. By creating a well-managed returns program and incorporating cost-recovery strategies (like return-to-vendor programs, restocking fees, or refurbished resale), businesses gain greater control over their financials and are better equipped to forecast and mitigate future return-related risks.

Reducing the cost of returns is not just about saving money—it's about unlocking operational resilience, enhancing customer experience, and building a future-ready business model in a world where consumer expectations and environmental concerns are rapidly evolving.

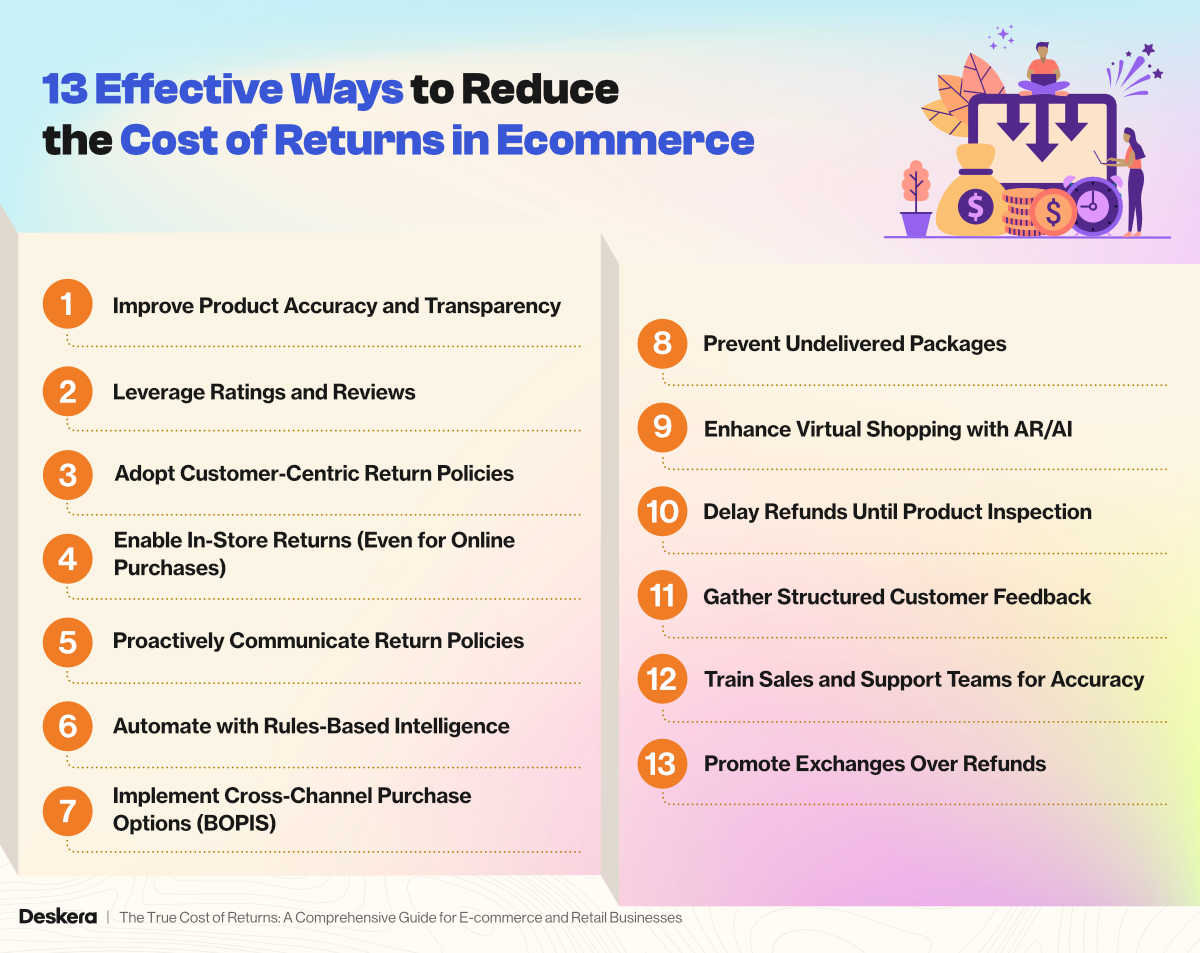

13 Effective Ways to Reduce the Cost of Returns in Ecommerce

Returns are an inevitable part of ecommerce—but they don’t have to be a financial drain. According to industry reports, inefficient return processes cost retailers billions each year in lost revenue, damaged brand loyalty, and wasted logistics.

But with the right strategies, businesses can significantly reduce return rates and the cost of handling them, all while enhancing customer satisfaction.

Here are twelve impactful ways to lower return-related costs:

1. Improve Product Accuracy and Transparency

One of the leading causes of returns is mismatched expectations—when the product received doesn’t match what was advertised.

How to improve:

- Use high-resolution images from multiple angles with zoom capability.

- Include detailed product descriptions with materials, dimensions, fit, and function.

- Add video demonstrations or AR try-on tools for a richer shopping experience.

- Provide personalized sizing tools (e.g., body type input for clothing or spatial visualization for furniture).

- Enable a product Q&A section for real-time shopper engagement.

Impact: Reduces "not as described" and size-related returns, builds trust pre-purchase.

2. Leverage Ratings and Reviews

Social proof is powerful. Reviews provide potential buyers with a peer-based understanding of the product.

Implementation tips:

- Prompt verified customers to leave detailed feedback.

- Allow reviewers to add images and specific use cases.

- Enable filtering reviews by product use, size, or preferences.

- Highlight “most helpful” reviews and common themes.

Impact: Shoppers make more confident purchases, reducing buyer’s remorse and return likelihood.

3. Adopt Customer-Centric Return Policies

Restrictive policies can increase cart abandonment, while overly generous ones can invite abuse.

Best practices:

- Offer 45–90 day return windows to increase retention and reduce rushed decisions.

- Clearly state which items are non-returnable and under what conditions.

- Introduce tiered return eligibility (e.g., store credit vs. full refund based on usage or time elapsed).

- Monitor and flag serial returners with pattern recognition tools.

Impact: Balances customer satisfaction with protection against policy exploitation.

4. Enable In-Store Returns (Even for Online Purchases)

Omnichannel return options give customers flexibility and reduce logistical burdens on your fulfillment network.

Benefits of in-store returns:

- Eliminates return shipping costs.

- Accelerates restocking and resale.

- Drives in-store foot traffic and potential upselling.

- Provides personalized assistance and issue resolution.

Impact: Streamlines reverse logistics and turns returns into new revenue opportunities.

5. Proactively Communicate Return Policies

Many returns result from a lack of policy awareness.

How to communicate effectively:

- Add return policy links to product pages, checkout screens, and order emails.

- Use plain language and visual guides.

- Include reminder prompts near the return window expiration.

- Offer chatbot support to answer policy questions in real-time.

Impact: Reduces confusion, preempts customer service issues, and lowers friction.

6. Automate with Rules-Based Intelligence

Manual return processing is costly and error-prone.

Technology to deploy:

- Use AI-driven return management systems to classify return reasons.

- Automate routing rules (e.g., restock vs. liquidation vs. recycle).

- Integrate with inventory and accounting systems to track losses and recovery.

Impact: Cuts labor costs, improves turnaround time, and maximizes resale value.

7. Implement Cross-Channel Purchase Options (BOPIS)

“Buy Online, Pick Up In Store” (BOPIS) gives customers a preview of their purchase and allows on-the-spot evaluation.

Advantages:

- Reduces returns due to sizing or mismatch.

- Eliminates last-mile delivery errors.

- Enhances cross-selling during pickup.

Impact: Lower return rates, higher operational efficiency, and better customer satisfaction.

8. Prevent Undelivered Packages

Failed deliveries are a hidden return cost. Retailers lose on shipping fees and damage customer trust.

Preventative steps:

- Avoid P.O. boxes for valuable shipments.

- Use real-time tracking updates with delivery timeframes.

- Offer delivery photos or signatures to confirm receipt.

- Enable address validation tools at checkout.

Impact: Prevents revenue loss, ensures better delivery outcomes, and reduces “item never received” claims.

9. Enhance Virtual Shopping with AR/AI

Give online customers tools to simulate real-world experiences.

Technology options:

- Augmented Reality (AR): Let shoppers “place” furniture in their home via smartphone.

- Virtual Fitting Rooms: Help users try on clothes using AI body mapping.

- Interactive videos: Highlight product scale, usability, and features.

Impact: Enhances confidence in purchase decisions and reduces buyer uncertainty.

10. Delay Refunds Until Product Inspection

Immediate refunds can be risky if items are damaged or unusable.

Recommended approach:

- Establish a clear return inspection process before issuing refunds.

- Create a “keep it” rule for low-cost items when return cost exceeds item value.

- Use partial refunds for items that are opened, used, or no longer in original condition.

Impact: Protects business margins while maintaining a fair customer experience.

11. Gather Structured Customer Feedback

Data from returns can guide product development and merchandising.

Collection methods:

- Offer return reason drop-downs or open-text fields.

- Use exit surveys during the return process.

- Analyze feedback by product category, SKU, or supplier.

Impact: Identifies high-return-rate products or vendors, reduces systemic issues, and boosts retention.

12. Train Sales and Support Teams for Accuracy

Miscommunication during the sale can lead to unnecessary returns.

Training focus:

- Align product messaging with customer expectations.

- Train on use cases, limitations, and target audiences for each product.

- Ensure third-party partners and resellers are trained with consistent information.

Impact: Reduces mismatched expectations, enhances brand reputation, and cuts down on return volume.

13. Promote Exchanges Over Refunds

Encouraging customers to exchange items rather than request refunds helps retain revenue and maintain customer loyalty.

How to implement:

- Make the exchange process as easy and seamless as returns—ideally with just a few clicks.

- Highlight the exchange option prominently on your return page and throughout the post-purchase journey.

- Offer incentives such as free shipping or a discount on the exchanged item to encourage switching over refunding.

- Use automation tools (like ERP-integrated returns management) to recommend similar or alternative products during the return process.

- Provide real-time inventory updates to ensure availability of replacement items.

Impact: Shifts the outcome from a lost sale to a retained customer relationship, reducing revenue leakage and operational costs associated with restocking and refund processing.

Return management isn't just a cost center—it's a strategic opportunity. By proactively investing in customer education, automation, and flexible fulfillment processes, businesses can significantly reduce the financial and operational burden of returns.

In doing so, they can not only cut costs but also build loyalty and stand out in an increasingly competitive ecommerce landscape.

How Deskera ERP Helps You Simplify Returns and Minimize Costs

Deskera ERP is designed to help businesses streamline their operations, and that includes making the returns process smoother, faster, and more cost-effective. Here's how Deskera ERP can help:

- Real-Time Inventory and Product Visibility: With Deskera's real-time inventory tracking, businesses can ensure product listings are always up to date. This reduces errors in product availability and descriptions that often lead to returns.

- Integrated Sales and Returns Workflow: Deskera ERP unifies sales, returns, and accounting in one platform. This enables seamless handling of return requests and ensures that every return is automatically reflected in your inventory and financial records.

- Automated Return Approvals and Restocking: You can set rules to automate return approvals and restocking processes. This not only saves time but also reduces the chance of manual errors.

- Customer Communication and Transparency: Through integrated CRM and email tools, Deskera allows businesses to keep customers informed at every step — from order dispatch to return confirmation — leading to better customer experiences and fewer disputes.

- Multi-Channel Sales and Returns Support: Whether you're selling through an online store, a marketplace, or directly to customers, Deskera ERP ensures consistent return policies and procedures across all channels.

- Detailed Reporting and Return Analytics: Deskera provides comprehensive reports and dashboards that help businesses track return rates, identify common return reasons, and make data-driven decisions to reduce return frequency.

- Logistics and Fulfillment Integration: Deskera integrates with shipping providers, enabling businesses to manage return shipping labels, track packages, and ensure smooth reverse logistics.

By using Deskera ERP, businesses can reduce the complexity of returns, improve customer satisfaction, and protect their bottom line through smarter inventory and sales management.

Key Takeaways

- The true cost of returns is often underestimated; it affects not only profits but also logistics, operations, and customer trust. For every $100 in returned items, retailers lose approximately $10.40 due to associated return expenses.

- Return costs consist of several components, including reverse shipping, product inspection, repackaging, restocking, and loss of product value. Each element contributes to the overall burden on the business.

- Hidden costs—such as employee time, reduced resale value, damaged packaging, lost inventory, and environmental impact—further erode profitability and are often not captured in surface-level financials.

- Monitoring key performance indicators like return rates, cost per return, refund vs. exchange ratios, reasons for returns, and customer feedback is crucial to understanding and controlling return-related losses.

- Reducing the cost of returns is essential for sustaining growth, improving margins, maintaining customer satisfaction, and supporting operational efficiency in both e-commerce and retail environments.

- Twelve practical strategies—ranging from enhancing product pages and offering detailed size guides to leveraging ERP tools like Deskera and promoting exchanges—can significantly reduce return rates and related costs.

Related Articles