What happens when a critical machine suddenly stops working—and production comes to a halt? The answer, more often than not, lies in corrective maintenance. Every organization, regardless of how robust its systems are, faces unexpected equipment failures. Corrective maintenance focuses on addressing these breakdowns after they occur, restoring assets to their normal operating condition and ensuring continuity in operations.

In simple terms, corrective maintenance is the action taken to fix equipment once a fault has been identified. Unlike preventive or predictive approaches that aim to avoid failures, corrective maintenance responds to them. While it may sound reactive, it plays a crucial role in maintenance management—especially for non-critical assets or situations where continuous monitoring isn’t economically viable.

For many businesses, corrective maintenance is not a choice but a necessity. Unplanned failures can lead to downtime, safety risks, and financial losses if not handled efficiently. Having a structured corrective maintenance process helps maintenance teams respond faster, prioritize tasks effectively, and reduce the overall impact of equipment breakdowns on operations.

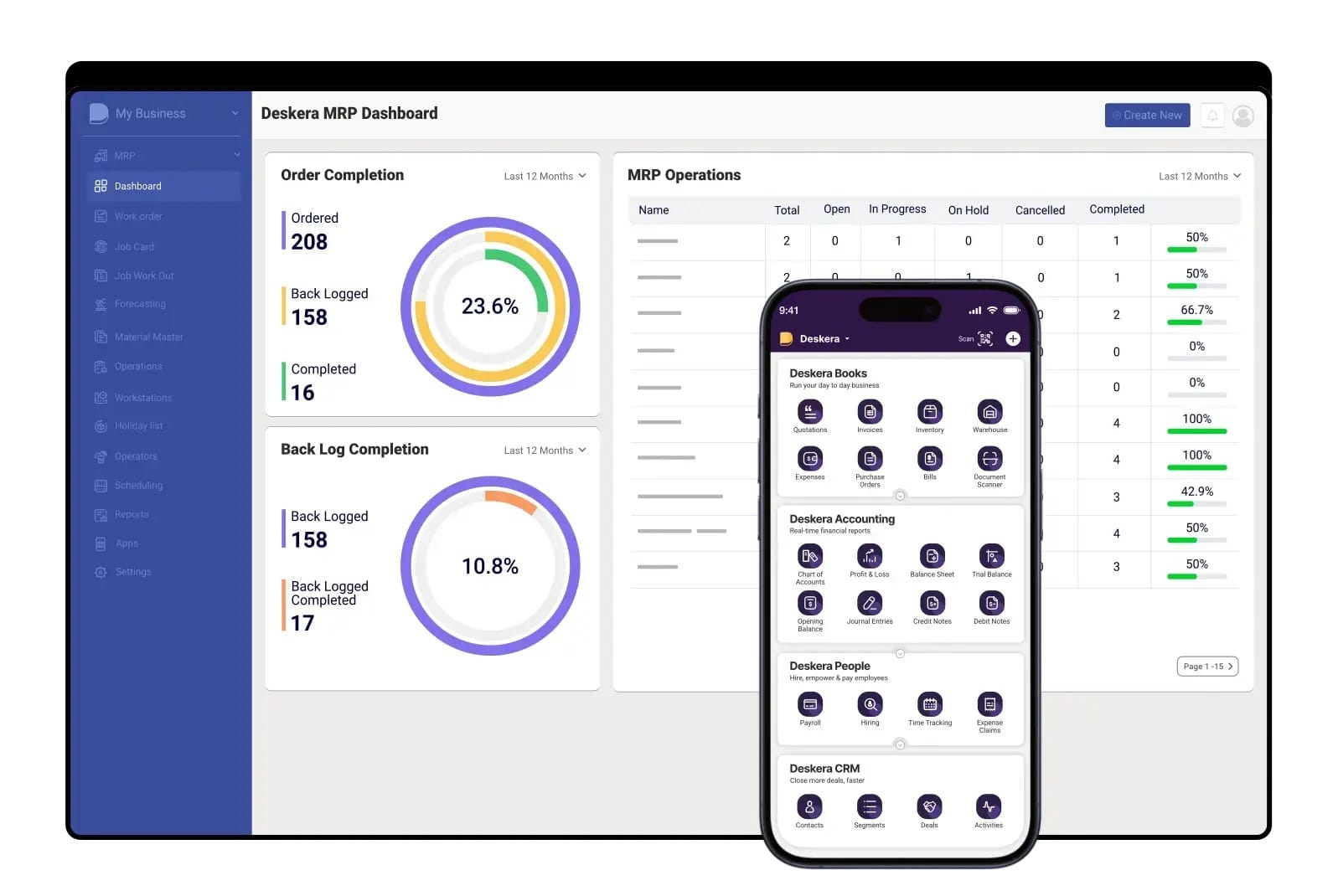

This is where digital solutions like Deskera MRP add significant value. Deskera MRP helps organizations streamline corrective maintenance by enabling quick issue reporting, centralized tracking of maintenance tasks, and better visibility into asset performance. With real-time data, automated workflows, and integrated inventory management for spare parts, Deskera MRP ensures that corrective maintenance is not just reactive—but controlled, documented, and optimized for long-term efficiency.

What Is Corrective Maintenance?

Corrective maintenance is a category of maintenance activities carried out to repair, restore, or replace equipment, systems, or components after a failure has occurred. Its primary objective is to bring an asset back to its normal working condition once a fault, breakdown, or malfunction is identified. Because it is performed after an issue arises, corrective maintenance is often referred to as reactive maintenance or breakdown maintenance.

In practice, corrective maintenance is initiated when a problem is discovered—either due to a complete equipment failure or during other maintenance activities. For example, a technician may identify an additional fault while performing an emergency repair, routine inspection, or preventive maintenance task. This newly identified issue then becomes a corrective maintenance order, which can be planned and scheduled for execution at an appropriate time. During this process, the asset may be repaired, adjusted, or replaced depending on the severity of the issue.

Corrective maintenance focuses on fault identification and decision-making. Once a failure occurs, the root cause is analyzed to determine whether the equipment requires repair or full replacement. The aim is not just to fix the immediate issue, but to ensure the asset can safely and effectively resume operations. This makes corrective maintenance a critical component of overall asset management, especially for assets that are not mission-critical or where preventive measures may not be cost-effective.

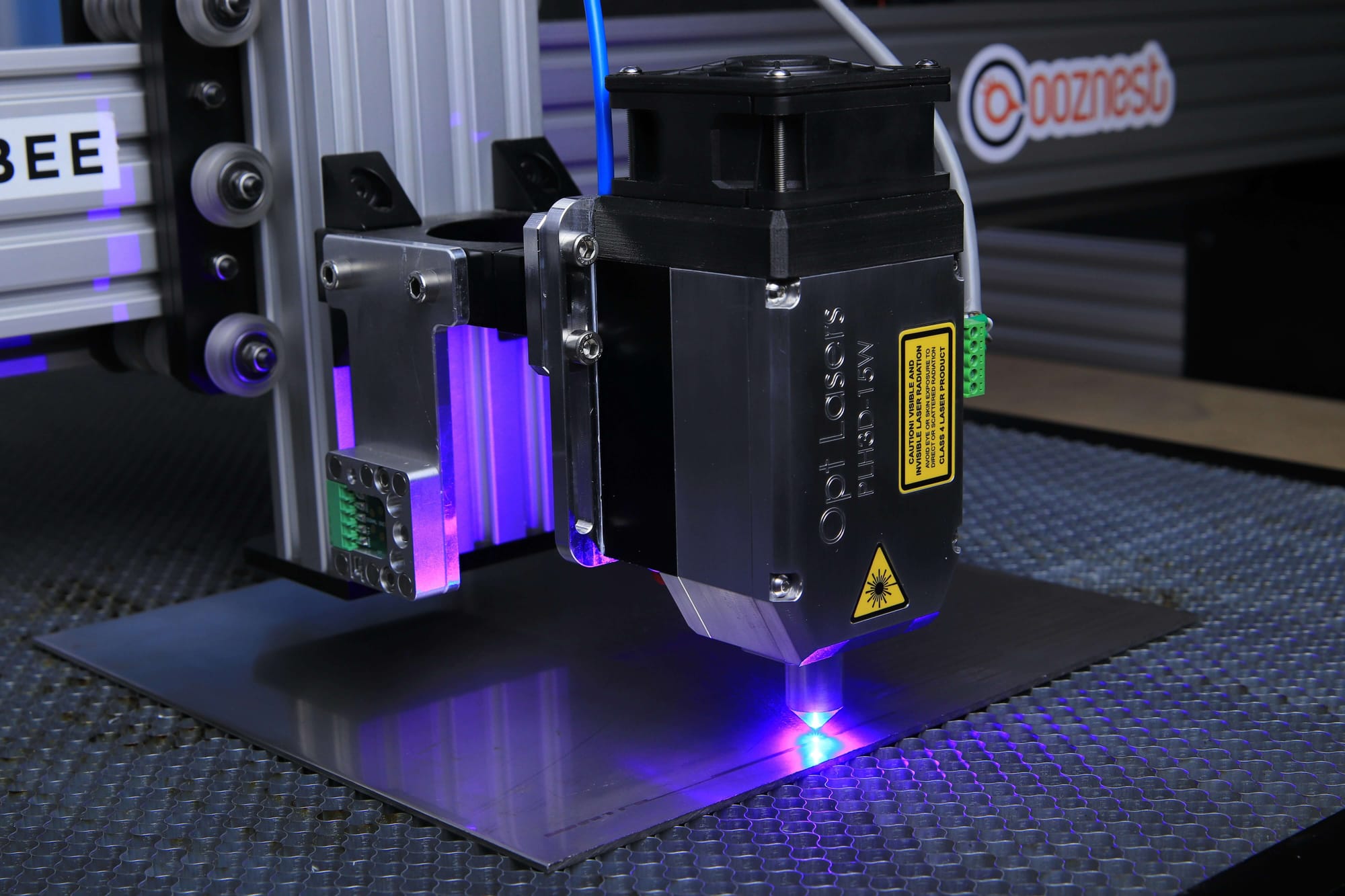

This maintenance approach is commonly applied across industries—including manufacturing, facilities, IT, and data centers. In IT and software environments, corrective maintenance involves fixing bugs, repairing hardware, replacing failed components, or restoring systems after outages. While corrective maintenance alone is not sufficient as a long-term strategy, it plays a vital role when integrated with preventive and predictive maintenance to create a balanced and resilient maintenance framework.

When Is Corrective Maintenance Needed?

Corrective maintenance is required when assets deviate from their normal operating condition due to failures, faults, or performance issues. It is typically triggered by unplanned events that disrupt operations or pose safety and reliability risks. Understanding when corrective maintenance is needed helps organizations respond quickly, minimize downtime, and prevent minor issues from escalating into major failures.

Equipment Failure

Corrective maintenance becomes essential when a machine, system, or device stops functioning as intended. This may include scenarios such as a motor failing, a production machine shutting down unexpectedly, or an IT system crashing. In such cases, immediate action is required to restore the equipment to operational status.

Malfunctioning Components

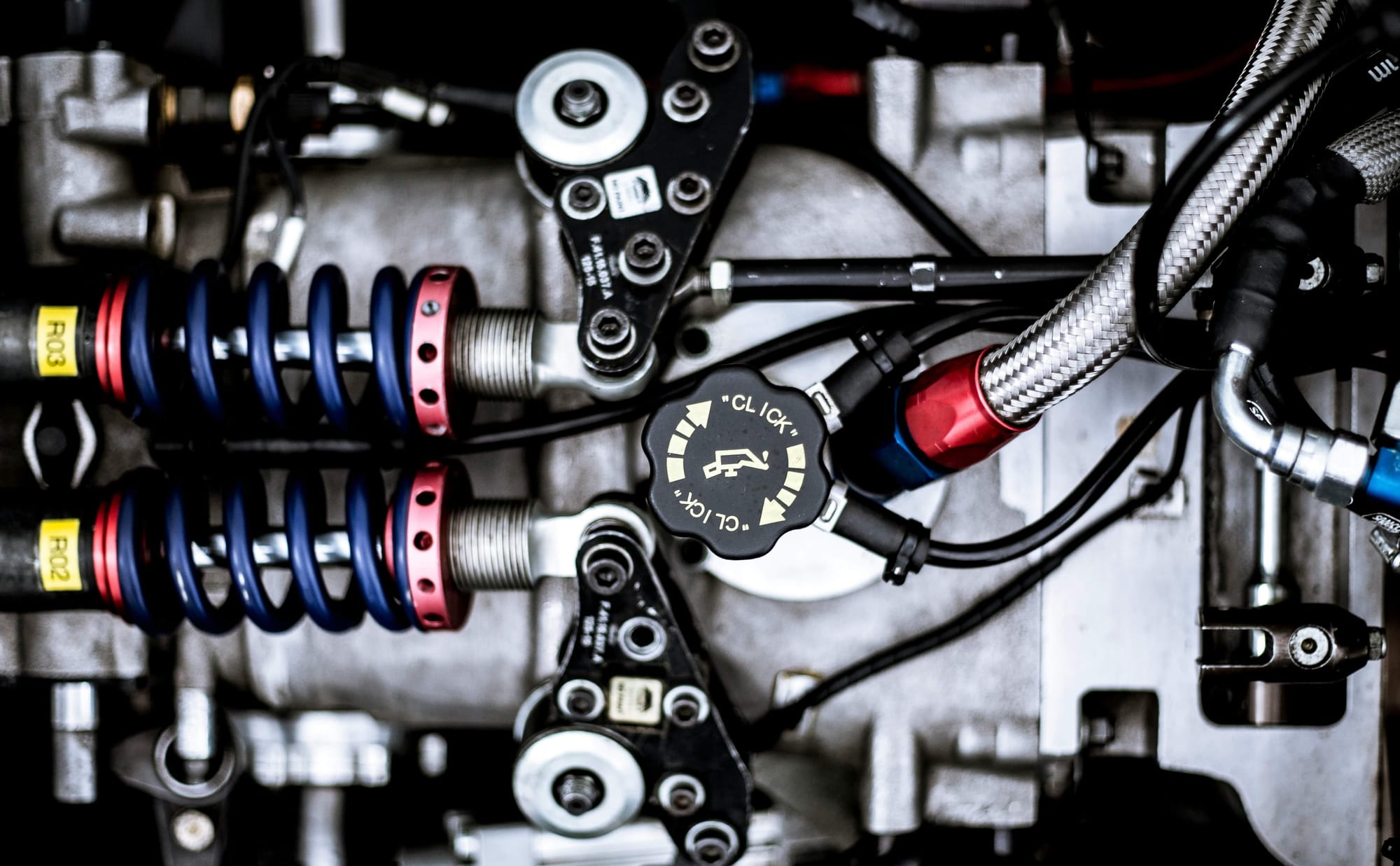

Even if the overall system is still running, failure of individual components can impact performance or reliability. Faulty sensors, leaking valves, worn-out bearings, or damaged electrical parts often require corrective maintenance to repair or replace the affected component and ensure the system operates correctly.

Safety Concerns

When equipment failures create safety hazards, corrective maintenance is critical and often urgent. Issues such as exposed electrical wiring, malfunctioning fire suppression systems, or unstable machinery must be addressed immediately to protect employees, facilities, and assets from potential harm.

Performance Degradation

Corrective maintenance may also be needed when equipment shows signs of declining performance. Reduced efficiency, unusual noise, slower processing speeds, or decreased accuracy are early indicators of underlying issues. Addressing these problems promptly can help prevent complete breakdowns in the future.

Unplanned Downtime

Any unexpected interruption to operations—such as a halted production line or a system outage—calls for corrective maintenance. The primary goal in these situations is to quickly identify the cause of the failure and restore functionality to reduce operational and financial losses.

Breakdowns During Preventive Maintenance

Despite regular inspections and preventive maintenance, unforeseen issues can still occur. If a fault is discovered or a breakdown happens during a scheduled maintenance activity, corrective maintenance is required to resolve the problem before normal operations can resume.

While corrective maintenance focuses on fixing issues after they occur, it is most effective when combined with preventive and predictive maintenance strategies. This balanced approach helps organizations improve asset reliability, reduce recurring failures, and enhance overall operational efficiency.

Types of Corrective Maintenance

Corrective maintenance is not a one-size-fits-all approach. Depending on the urgency of the issue, the criticality of the asset, and operational constraints, organizations apply different types of corrective maintenance.

Each type serves a specific purpose—from handling sudden breakdowns to addressing known issues in a planned manner.

Emergency Corrective Maintenance

Emergency corrective maintenance is carried out when a critical and unexpected failure occurs that demands immediate action. These situations often pose serious risks to safety, operations, or compliance, such as a production line stopping abruptly or a safety system malfunctioning. The primary goal is to restore functionality as quickly as possible, even if it requires overtime labor, expedited spare parts, or temporary fixes.

Deferred Corrective Maintenance

Deferred corrective maintenance involves postponing repairs when a failure does not immediately affect safety or operations. This approach is usually applied to non-critical assets where short-term delays are acceptable. While deferral helps manage budgets and resources, it must be carefully evaluated, as prolonged delays can lead to higher costs, performance degradation, or safety risks over time.

Scheduled Corrective Maintenance

Scheduled corrective maintenance addresses identified faults by planning repairs during predefined maintenance windows. Issues detected during inspections or routine checks are logged and resolved at a time that minimizes operational disruption. This approach allows better resource planning, reduces unplanned downtime, and helps maintenance teams work more efficiently.

Planned Corrective Maintenance

Planned corrective maintenance is similar to scheduled maintenance but focuses on early detection of problems before total failure. Once warning signs are identified through inspections or monitoring, repairs are planned using standard procedures and documentation. While it still responds to existing issues, this method reduces surprises and improves coordination across teams.

Unplanned Corrective Maintenance

Unplanned corrective maintenance occurs when equipment fails without warning, requiring immediate response. These breakdowns often disrupt operations, increase downtime, and raise repair costs due to urgency. While unavoidable in some cases, frequent unplanned corrective maintenance usually indicates gaps in monitoring or preventive practices.

Reactive Corrective Maintenance

Reactive corrective maintenance is performed after a failure has already occurred, focusing solely on restoring functionality. Technicians diagnose the issue, replace or repair the faulty component, and bring the asset back online. Although necessary for unforeseen failures, overreliance on reactive maintenance can lead to higher long-term costs and reduced asset reliability.

Condition-Based Corrective Maintenance

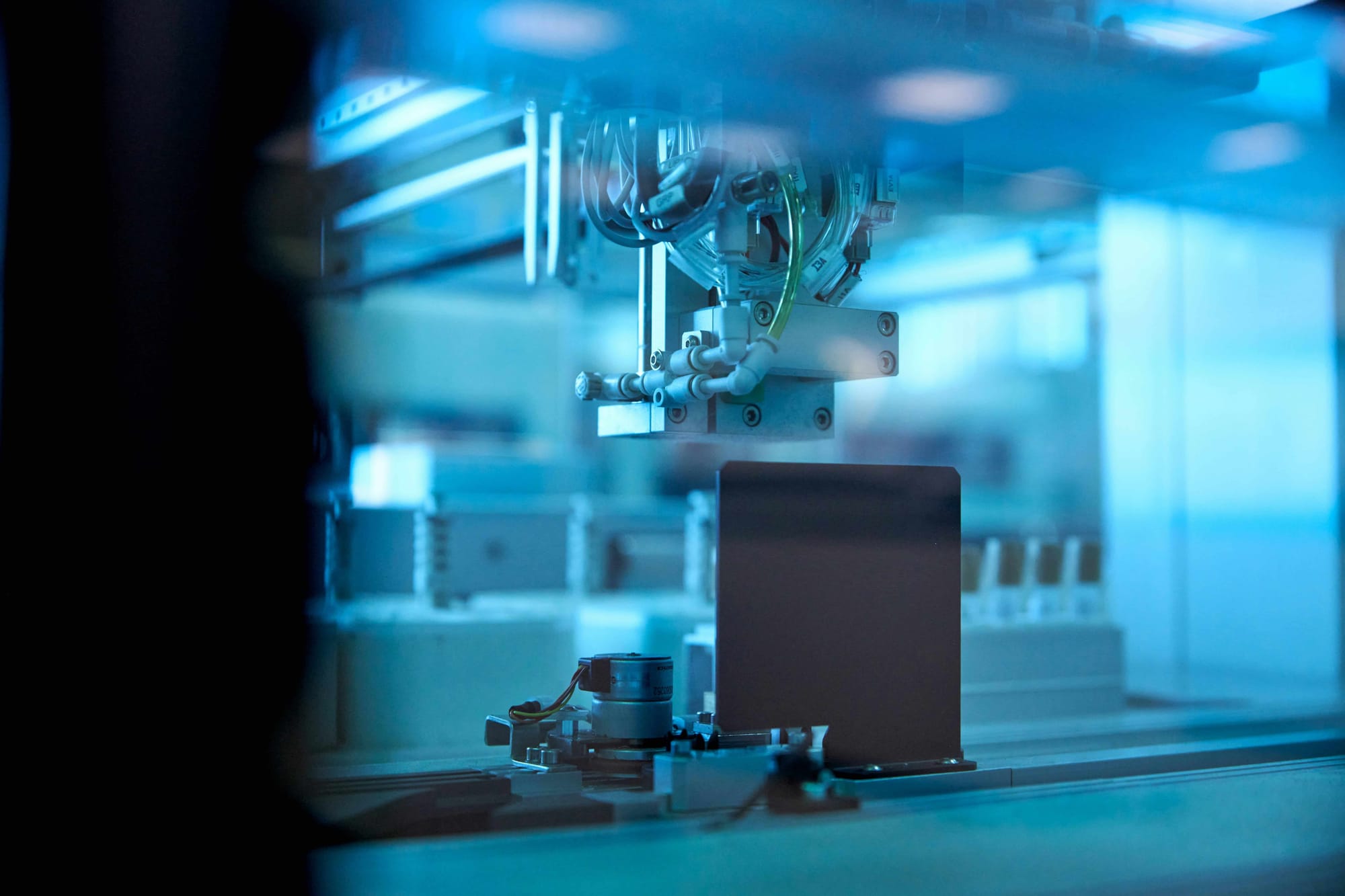

Condition-based corrective maintenance relies on real-time data and condition monitoring to trigger corrective actions only when asset health indicators cross acceptable thresholds. By tracking parameters such as vibration, temperature, or pressure, maintenance teams can intervene at the right time—preventing sudden failures while avoiding unnecessary repairs.

Run-to-Failure Corrective Maintenance

Run-to-failure maintenance allows equipment to operate until it breaks down, after which corrective maintenance is performed. This approach is suitable for low-cost, non-critical assets that are easy to replace. While it reduces planning efforts, it can lead to unexpected downtime if applied to important equipment.

Understanding these types of corrective maintenance helps organizations choose the right approach for different assets. The most effective maintenance strategies combine corrective methods with preventive and predictive practices to balance cost, reliability, and operational efficiency.

Steps Involved in the Corrective Maintenance Process

A well-defined corrective maintenance process helps organizations restore equipment efficiently while minimizing downtime, safety risks, and repeat failures. Following a structured set of steps ensures that issues are not only fixed but properly documented and validated before assets are returned to service.

Identify the Equipment Failure

The process begins when a malfunction or breakdown is detected. This may occur through condition monitoring systems, automated alerts, operator reports, or visible performance issues. Technicians first confirm whether a fault actually exists before proceeding with corrective actions.

Localize and Diagnose the Fault

Once a failure is confirmed, the next step is to isolate the problem to a specific piece of equipment and then to the affected component. Diagnostic tools, system logs, built-in test features, or manual inspections are used to identify the root cause of the failure and avoid treating only surface-level symptoms.

Plan the Corrective Action

After diagnosis, the maintenance team plans the intervention. This includes deciding whether the component should be repaired or replaced, identifying required tools and spare parts, estimating downtime, and scheduling the work to reduce operational disruption.

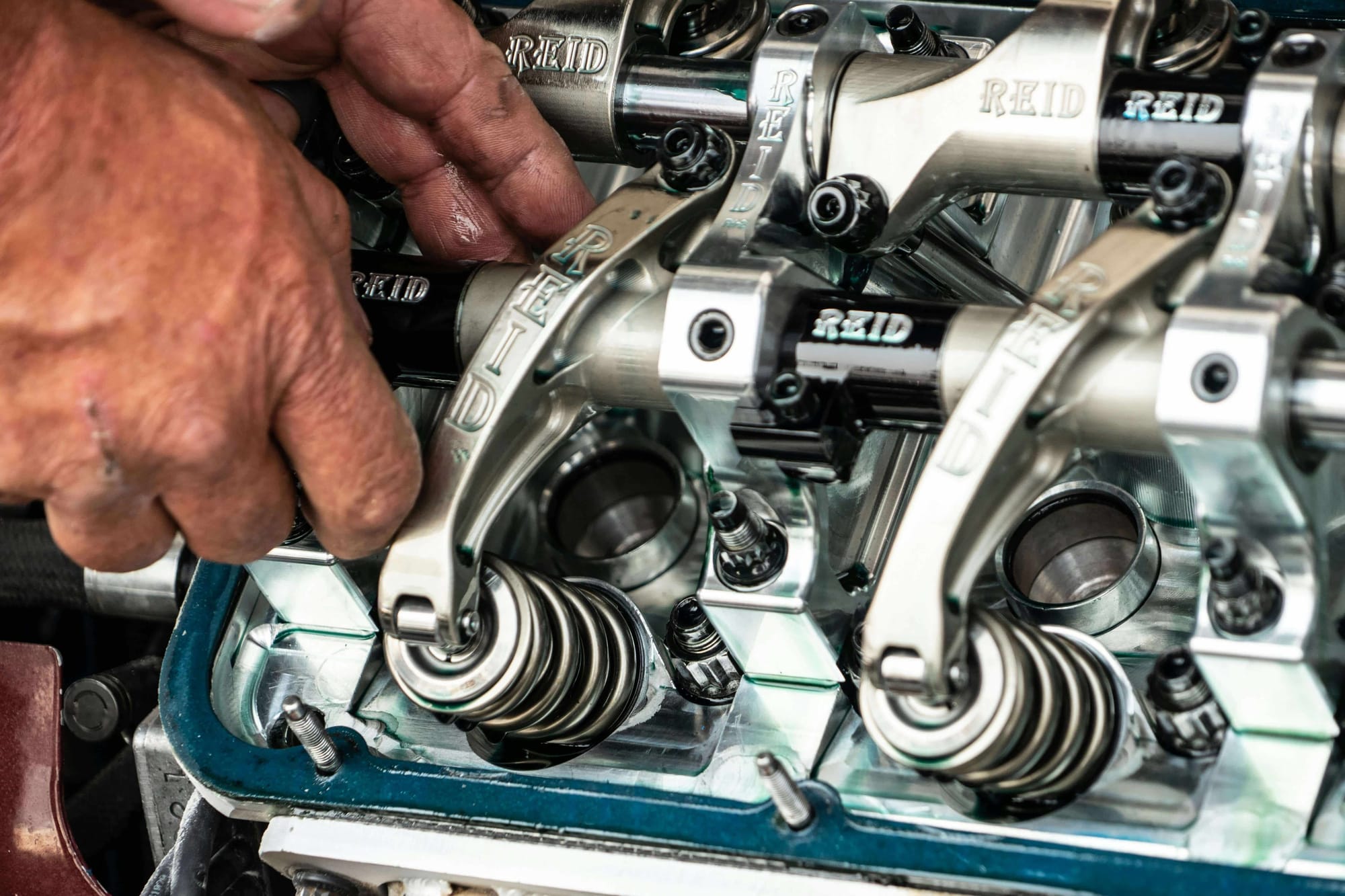

Repair or Replace the Faulty Component

The actual corrective work is carried out during this stage. Technicians repair the defective part or replace it with a new or refurbished component, depending on severity, availability, and cost considerations. This step restores the core functionality of the equipment.

Align, Calibrate, and Restore Settings

Following repair or replacement, alignment and calibration are performed to ensure the equipment operates within specified standards. Proper adjustments are critical to remove deviations and ensure accurate, stable performance.

Clean and Lubricate the Equipment

Cleaning and lubrication are often performed to support long-term reliability. Removing contaminants and applying the correct type and amount of lubricant helps reduce friction, prevent premature wear, and improve overall equipment performance.

Test and Validate Performance

Before returning the asset to service, thorough testing is conducted to confirm that the issue has been fully resolved. Performance, safety, and operational checks are documented to verify that the equipment meets required standards.

Close Out and Document the Maintenance Activity

The final step involves recording the failure, corrective actions taken, parts used, and test results. Proper documentation supports future troubleshooting, improves maintenance planning, and helps prevent recurring failures.

By following these steps, corrective maintenance becomes more controlled, efficient, and reliable—reducing operational risks while supporting long-term asset performance.

Benefits of Corrective Maintenance

Corrective maintenance focuses on restoring assets to proper working condition after a fault or failure occurs. When applied strategically—often alongside preventive maintenance—it offers several operational, financial, and safety-related advantages across manufacturing, facilities, IT, and software environments.

Reduced Emergency Maintenance Costs

Timely execution of corrective maintenance helps reduce the need for costly emergency repairs. When issues identified during inspections or routine work are addressed before escalating, organizations can avoid last-minute interventions that require overtime labor, expedited parts, or external support.

Improved Employee and Workplace Safety

Corrective maintenance plays a vital role in mitigating safety risks. Faulty equipment, exposed electrical components, or malfunctioning systems can pose serious hazards if left unresolved. Addressing these issues promptly helps protect employees, facilities, and assets from accidents and compliance violations.

Lower Downtime and Fewer Service Interruptions

By identifying and resolving issues before they lead to complete failure, corrective maintenance can significantly reduce downtime. Scheduling corrective work in advance allows maintenance teams to restore functionality without disrupting production or critical services.

Extended Asset and System Lifespan

Corrective maintenance, especially when combined with preventive practices, helps prevent minor issues from damaging other components. Early repairs reduce wear and tear, preserve equipment integrity, and extend the usable life of assets and systems.

Cost Efficiency for Non-Critical Assets

For non-essential or low-risk equipment, corrective maintenance can be more cost-effective than preventive strategies. Resources are spent only when failures occur, avoiding unnecessary inspections, monitoring, and routine servicing costs.

Simplified Maintenance Planning

Because corrective maintenance is reactive by nature, it requires less upfront planning and administrative effort. This simplified approach reduces operational overhead and allows teams to focus on core business activities until maintenance is actually needed.

Optimized Resource Allocation

Corrective maintenance tasks are logged, prioritized, and scheduled based on actual need. This enables better use of labor, spare parts, and budgets, ensuring that resources are directed where they deliver the most value.

Faster Problem Resolution

Corrective maintenance enables quick response to failures, helping teams isolate issues, implement fixes, and restore operations efficiently. Rapid recovery minimizes productivity losses and supports business continuity.

Inspection and Learning Opportunities

Each corrective maintenance activity provides insights into failure modes and asset behavior. These learnings can be used to improve maintenance strategies, refine preventive plans, and reduce the likelihood of recurring issues.

Improved Software and System Reliability

In IT and software environments, corrective maintenance improves system stability by fixing bugs, errors, and defects after detection. This enhances user experience, increases reliability, and reduces the risk of repeated outages.

While corrective maintenance offers clear benefits, relying on it alone can increase operational risk. The greatest value is achieved when corrective maintenance is integrated into a balanced maintenance strategy that includes preventive and predictive approaches.

Disadvantages of Corrective Maintenance

While corrective maintenance is necessary in many situations, relying on it as a primary or sole maintenance strategy can create significant operational, financial, and safety challenges. Because it is reactive by nature, corrective maintenance often addresses problems only after damage has already occurred.

Increased Downtime and Production Interruptions

Corrective maintenance is typically performed after a failure, which can result in unplanned downtime. If critical equipment breaks down unexpectedly, entire production lines or essential services may come to a halt, leading to lost productivity and missed deadlines.

Higher Repair and Operational Costs

Repairs carried out under pressure often cost more than planned maintenance. Emergency labor, overtime wages, expedited spare parts, and external service support can significantly increase maintenance expenses—especially when failures involve critical assets.

Unpredictability and Poor Planning

Since corrective maintenance depends on when failures occur, it is difficult to plan budgets, schedules, and resource allocation. This unpredictability makes it challenging for maintenance teams and management to optimize workloads or forecast maintenance costs accurately.

Shortened Asset Lifespan

Only repairing equipment after it breaks can accelerate wear and tear on other components. Without early intervention, minor issues can spread and cause more extensive damage, ultimately reducing the overall lifespan of assets.

Increased Safety Risks

Unexpected equipment failures can create hazardous working conditions. Malfunctioning machinery, electrical faults, or sudden shutdowns may put employees at risk, particularly in safety-critical environments such as manufacturing plants or data centers.

Risk of Recurring Failures

Corrective maintenance often focuses on restoring functionality rather than addressing root causes. If underlying issues are not identified and resolved, the same failures may occur repeatedly, leading to frequent breakdowns and higher long-term costs.

Resource Allocation Challenges

Urgent corrective maintenance tasks can disrupt planned activities and strain maintenance teams. Technicians may need to abandon scheduled work to respond to emergencies, reducing overall maintenance efficiency.

Reduced Operational Reliability

When corrective maintenance becomes the dominant approach, equipment reliability declines over time. Frequent breakdowns erode confidence in systems, affect service quality, and can negatively impact customer satisfaction and business reputation.

While corrective maintenance has its place—especially for non-critical assets—it is most effective when used alongside preventive and predictive maintenance strategies. This balanced approach helps reduce risks, control costs, and improve long-term asset reliability.

Best Practices to Reduce and Manage Corrective Maintenance Effectively

While corrective maintenance cannot be eliminated entirely, organizations can significantly reduce its frequency and impact by adopting structured processes, skilled teams, and the right technology. These best practices help shift maintenance efforts from reactive firefighting to controlled, efficient interventions.

Invest in Preventive and Predictive Maintenance

One of the most effective ways to reduce corrective maintenance is by strengthening preventive and predictive maintenance programs. Regular inspections, lubrication, calibration, and condition monitoring help detect early warning signs before failures occur. Predictive tools such as vibration analysis or thermal imaging further reduce unexpected breakdowns.

Use MRP Software with an Integrated Maintenance Management Module

Instead of relying on standalone tools, organizations can benefit from MRP software that includes a built-in maintenance management module. Such systems centralize asset data, work orders, spare parts, and maintenance schedules within a single platform.

By linking maintenance activities directly with production planning and inventory, teams can respond to breakdowns faster, reduce downtime, and ensure that corrective maintenance does not disrupt manufacturing operations.

Prioritize Corrective Tasks Based on Asset Criticality

Not all failures require the same level of urgency. Ranking assets based on their impact on safety, production, and compliance helps teams focus on high-priority equipment first while scheduling non-critical repairs appropriately.

Perform Root Cause Analysis

Corrective maintenance should go beyond fixing symptoms. Conducting root cause analysis after failures helps identify underlying issues—such as design flaws, operating conditions, or human error—and prevents recurring breakdowns.

Train and Empower Maintenance Teams

Well-trained technicians are better equipped to diagnose issues accurately and complete repairs efficiently. Ongoing training in equipment diagnostics, safety practices, and technology usage improves response time and repair quality.

Standardize Maintenance Procedures

Clear standard operating procedures (SOPs), checklists, and job plans reduce variability in repair work. Consistent processes ensure that corrective maintenance tasks are performed safely, correctly, and efficiently every time.

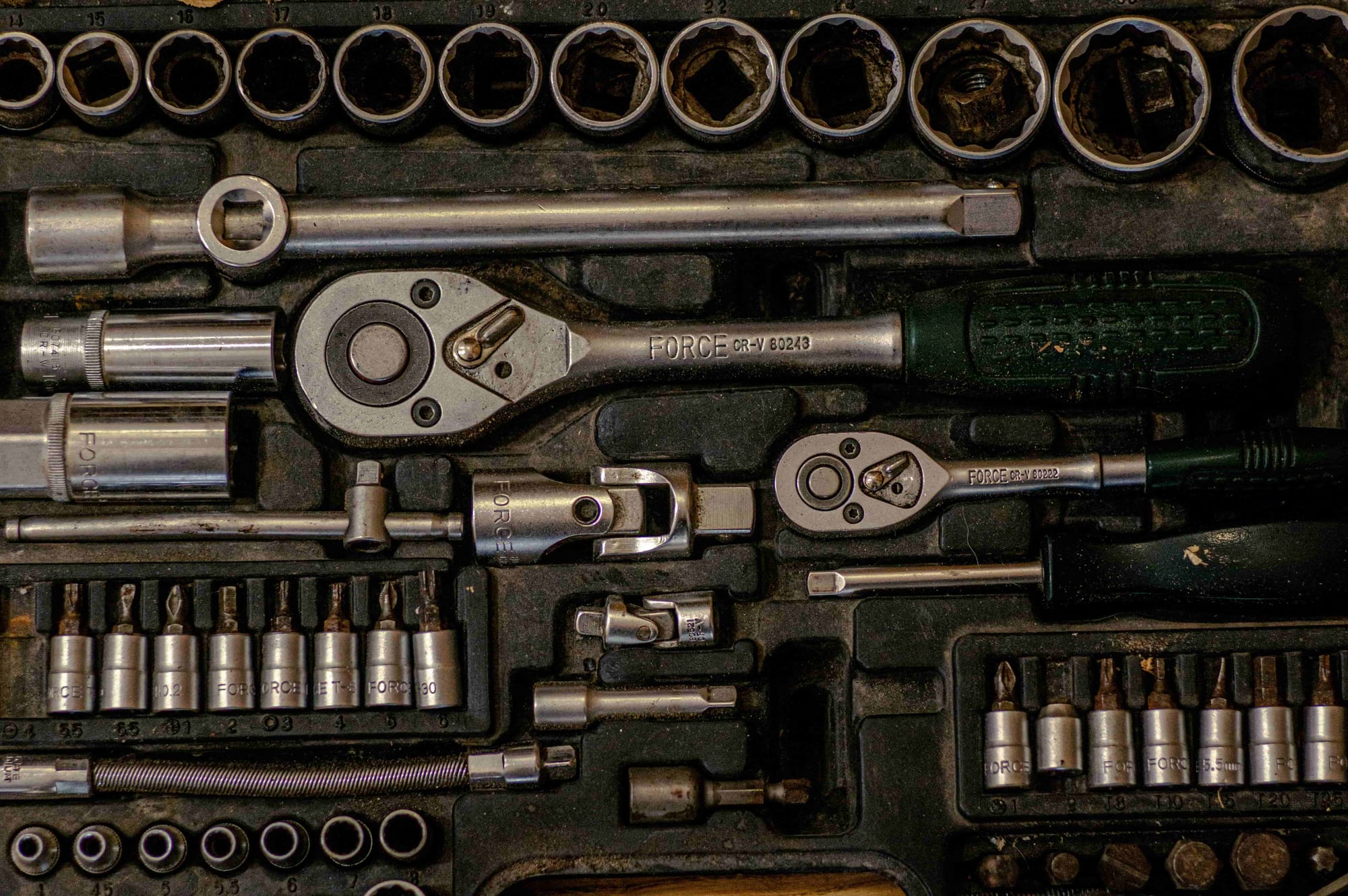

Maintain a Ready Spare Parts Inventory

Delays in sourcing spare parts can extend downtime. Maintaining an organized inventory of frequently used components ensures faster repairs and smoother corrective maintenance execution.

Automate Work Order Assignment and Scheduling

Automation reduces delays and manual effort. Assigning corrective work orders automatically to the right technicians based on skills and availability improves response time and reduces administrative overhead.

Capture and Analyze Maintenance Data

Tracking metrics such as mean time to repair (MTTR), downtime frequency, and failure patterns provides insights into equipment reliability. Data-driven decisions help refine maintenance strategies and reduce future corrective work.

Leverage Inspection Opportunities

Every corrective maintenance activity should include a quick inspection for related or emerging issues. This proactive mindset allows technicians to log additional concerns and prevent future failures.

By following these best practices, organizations can reduce reliance on corrective maintenance, improve asset reliability, control costs, and create a more resilient and efficient maintenance strategy that balances reactive and proactive approaches.

How Deskera MRP Helps Streamline Corrective Maintenance

Effective corrective maintenance requires more than quick fixes—it needs visibility, coordination, and control across assets, inventory, and production. Deskera MRP supports this by integrating maintenance management directly into manufacturing and inventory workflows. This ensures breakdowns are addressed faster, repairs are better planned, and operations return to normal with minimal disruption.

Centralized Maintenance and Work Order Management

Deskera MRP allows teams to create, assign, and track maintenance work orders from a single system. When a breakdown occurs, maintenance tasks can be logged immediately, ensuring accountability and clear tracking from issue identification to closure.

Faster Breakdown Response with Real-Time Visibility

By providing real-time access to machine status, maintenance history, and open work orders, Deskera MRP helps maintenance teams respond quickly to equipment failures. This reduces diagnostic delays and shortens overall corrective maintenance time.

Integrated Spare Parts and Inventory Control

Corrective maintenance often gets delayed due to unavailable spare parts. Deskera MRP links maintenance activities with inventory data, helping teams check part availability instantly, trigger replenishment, and avoid extended downtime caused by stockouts.

Better Planning with Production and Maintenance Alignment

Deskera MRP connects maintenance schedules with production planning. This allows teams to plan corrective actions with minimal impact on manufacturing output, especially when repairs require planned stoppages or extended intervention.

Key Takeaways

- Corrective Maintenance Overview: Corrective maintenance focuses on restoring equipment functionality after a failure, making it essential for addressing unplanned breakdowns and minimizing prolonged operational disruption.

- Importance of Corrective Maintenance: A well-defined corrective maintenance approach helps organizations reduce downtime, control repair costs, and maintain safety and operational reliability even during unexpected failures.

- Steps of Corrective Maintenance: Following a structured process—from fault identification and diagnosis to repair, testing, and validation—ensures repairs are effective and prevents recurring equipment issues.

- Root Cause Analysis: Identifying the underlying cause of failures during corrective maintenance helps organizations move beyond temporary fixes and improve long-term asset performance.

- Repair and Replacement Activities: Timely repair or replacement of faulty components is critical to restoring equipment efficiency and avoiding cascading failures across connected systems.

- Testing, Calibration, and Validation: Post-repair testing and calibration confirm that corrective actions have fully restored the equipment to required performance and safety standards.

- Documentation and Follow-Up: Recording corrective maintenance activities builds a valuable maintenance history that supports continuous improvement, compliance, and better decision-making.

- Challenges of Corrective Maintenance: While necessary, corrective maintenance can increase downtime and costs if poorly planned, highlighting the need for coordination, visibility, and proper tools.

- Role of MRP Software in Corrective Maintenance: MRP software with an integrated maintenance management module streamlines corrective actions by connecting maintenance, inventory, and production planning.

- How Deskera MRP Helps: Deskera MRP centralizes work orders, asset data, spare parts, and maintenance history, enabling faster response to breakdowns and more controlled, efficient corrective maintenance execution.

Related Articles