Furniture production is a complex process that involves the use of various materials and techniques to create beautiful, functional pieces for a home or office. From timber to metal and fabrics, the manufacturing of furniture involves the craftsmanship of skilled artisans, the knowledge of experienced designers, and the use of modern technologies to create pieces that will last for years.

This article covers the following:

- Understanding the Basics of Furniture Production

- Tools & Materials Used in Furniture Production

- Design & Layout for Furniture Production

- Understanding Different Furniture Styles & Types

- Working with Different Wood Types

- Joining Techniques & Hardware for Furniture

- Finishing & Staining Techniques

- Safety Tips for Furniture Production

- Troubleshooting Common Issues in Furniture Production

- Popular Furniture Building Techniques & Trends

Understanding the Basics of Furniture Production

Furniture production is a complex process that requires a great deal of knowledge and skill. From the design and development of a piece to the construction and manufacturing processes, it takes a lot of work and a team of experts to bring a piece of furniture from concept to a finished product.

With that in mind, let’s look at the basics of furniture production to get a better understanding of how it works. The first step in the process is the design and development.

This involves creating a concept for the piece of furniture, deciding on the materials to be used, and the overall dimensions. The designer must also consider the aesthetic, ergonomic, and structural elements of the piece.

Once the concept is finalized, the designer will create sketches and technical drawings of the design, which will be used as a blueprint for the piece’s construction. The next step is the manufacturing process, which involves transforming the design into an actual product.

This process usually starts with cutting the materials to the proper size and shape. The materials may then be assembled using tools such as saws, drills, and screwdrivers. Other techniques, such as joinery, may also be used to hold the pieces together.

Once the pieces are assembled, they are sanded, stained, or painted to give the piece its final look. The final step in the process is the finishing process, which involves adding the final touches to the piece.

This usually involves polishing the wood, adding hardware, and upholstering the piece. The finishing process is the most important step, as it adds the final touches that make the piece look and feel complete.

Furniture production is a complex process that requires a great deal of knowledge and skill. In order to create a quality piece of furniture, it is important to understand the basics of furniture production, from the design and development process to the manufacturing and finishing processes. By understanding the basics, you can ensure that the pieces you create are of the highest quality and will last for years to come.

Tools & Materials Used in Furniture Production

Creating furniture requires a combination of precision, accuracy, and hard work. In order to make high-quality, long-lasting furniture, it’s important to use the right tools and materials.

From saws and drills to wood and glue, these tools and materials are essential for any furniture production process. Tools Table saws: Table saws are essential for woodworking, as they can make straight and accurate cuts with ease.

They’re also used to make bevels, rabbets, and other precise cuts. Circular saws: Circular saws are a type of saw used to make accurate, precise cuts in hard materials such as wood, metal, and concrete.

They are often used to make miter cuts and bevels. Drills: Drills are used to make holes in materials, usually for the purpose of attaching pieces of wood together. They can be powered by electricity, air, or battery, and can make both large and small holes.

Sanders: Sanders are used to smooth out rough surfaces, such as wood, and can be either hand-held or stationary. They use sandpaper to smooth out the surface, and can be used for both large and small projects.

Routers: Routers are used to cut grooves, slots, and other shapes into wood and other materials. They are powered by electricity and can be used to make intricate designs.

Materials Wood: Wood is the most common material used in furniture production, as it is strong, durable, and easy to work with. There are many types of wood available, including oak, maple, and pine.

Metal: Metal is often used for furniture frames and structural components. It is strong and can withstand a lot of wear and tear. Common metals used in furniture production include steel, aluminum, and iron.

Fabric: Fabric is often used to upholster furniture, as it is comfortable, attractive, and easy to clean. Common fabrics used in furniture production include leather, velvet, and canvas.

Glue: Glue is used to attach pieces of wood and other materials together. It is important to use the right type of glue, as some glues may not be strong enough to hold the pieces together. Common types of glue used in furniture production include wood glue, epoxy, and polyurethane.

Hardware: Hardware such as screws, nails, and bolts are used to attach pieces of wood and other materials together. It is important to use the right type and size of hardware to ensure a strong bond.

By using the right tools and materials, furniture producers can create beautiful, high-quality pieces of furniture that will last for years to come. Whether you’re a professional furniture maker or a hobbyist, having the right tools and materials on hand is essential for any furniture production process.

Design & Layout for Furniture Production

When it comes to producing furniture, design and layout are key components. A well-thought-out production plan can help ensure that furniture is made efficiently and to the highest standards. Here’s what you need to know about designing and laying out a production process for furniture manufacturing.

Design

Designing furniture requires an understanding of the principles of ergonomics, aesthetics, and functionality. When designing furniture, consider how people will use the piece, how it will look in the space, and how it will fit into the overall room design. It’s also important to consider durability, safety, and the materials that will be used.

Layout

Once a design has been established, it’s time to plan out the layout of the production process. Begin by outlining the overall process and then determine the steps that will be taken to complete each stage.

Consider the resources that will be needed at each step, such as machinery, tools, and personnel. Also, be sure to think about the space requirements of each process and the order in which they should be completed.

Quality Control

Quality control is essential in furniture production. Establishing a system to monitor the quality of each step in the process is critical. Quality control measures should include inspecting raw materials and finished products, assessing the accuracy of measurements, and ensuring that the right processes are being followed.

Production Flow

The production flow is a key element of the furniture production process. It outlines how the process will move from start to finish and helps to ensure that the furniture is made to the highest standards. The production flow should include steps such as cutting, assembly, finishing, and packaging.

By understanding the design and layout considerations for furniture production, you can create an effective and efficient production process. From designing the piece to establishing a quality control system, there are many factors that go into creating a successful furniture production process. With the right plan in place, your furniture production can be a success.

Understanding Different Furniture Styles & Types

Furniture is an essential part of any home, and it’s important to understand the different furniture styles and types that are available. From the traditional to the contemporary, there’s a style to suit any taste and room.

Knowing about the different furniture styles and types will help you make the best decision when it comes to furnishing your home. Traditional Furniture Styles Traditional furniture styles, such as French Provincial and Queen Anne, are timeless and classic.

These styles are characterized by ornate details and intricate craftsmanship. Traditional furniture is often made from wood and features curved lines, carved details, and ornate accents.

Traditional furniture pieces can be found in a variety of colors, from light to dark. Contemporary Furniture Styles Contemporary furniture is modern and on-trend. This style often features sleek lines, minimal details, and neutral colors.

Contemporary furniture pieces are typically made from metal, glass, and plastic. Pieces may be geometric in shape, featuring sharp angles and lines. Mid-Century Modern Furniture Mid-Century Modern furniture is a blend of traditional and contemporary styles.

This style is often characterized by angular shapes, clean lines, and neutral colors. Mid-Century Modern furniture pieces often feature organic curves, simple details, and natural materials.

Rustic Furniture Rustic furniture is inspired by nature and can be found in a variety of styles. Rustic furniture pieces are often made from wood and feature a distressed finish. This style is often characterized by a natural look and feel, with pieces featuring hand-hewn details and natural materials.

Industrial Furniture Industrial furniture is inspired by industrial design and is often characterized by metal accents and exposed hardware. Industrial furniture pieces are often made from metal, wood, or concrete.

This style often features bold lines, chunky details, and a utilitarian aesthetic. Farmhouse Furniture Farmhouse furniture is inspired by the traditional American farmhouse.

This style is often characterized by a cozy and comfortable aesthetic. Farmhouse furniture pieces are often made from wood and feature distressed finishes. This style can be found in a variety of colors, from light to dark.

These are just a few of the different furniture styles and types that are available. Knowing about these styles and types will help you make the best decision when it comes to furnishing your home. From the traditional to the contemporary, there’s a style to suit any taste and room.

Working with Different Wood Types

When it comes to furniture production, wood is one of the most important materials used. It is a versatile material that can be manipulated to create beautiful furniture, but it's important to be aware of the different types of wood and how they will affect the outcome of your project.

Softwoods are generally the most commonly used wood types for furniture production. Softwoods are typically lighter in color and come from coniferous trees such as pine, spruce, fir, and cedar.

These woods are lightweight, easy to work with and are generally less expensive than hardwoods. Softwoods are often used for framing, paneling, and other structural components of furniture.

Hardwoods are typically denser, heavier, and more expensive than softwoods. Hardwoods come from deciduous trees such as oak, cherry, walnut, and ash. These woods are often used for the visible parts of furniture, such as tabletops, legs, and drawer fronts.

Hardwoods are more durable than softwoods and are ideal for creating furniture that will last for years. When working with different wood types, it is important to take into consideration the grain pattern of the wood.

The grain of the wood will affect the look of the furniture and how it will age over time. Some woods, such as oak, have a strong and distinct grain pattern, while other woods, such as cherry, have a more subtle grain pattern.

Understanding the grain patterns of different woods can help you choose the right type of wood for your furniture. Additionally, the type of finish you use on the wood can have a significant impact on the look of the furniture.

Different finishes such as stains, paints, and varnishes can be used to enhance the natural beauty of the wood or to give the furniture a unique look. When it comes to furniture production, understanding the different types of wood and how they will affect the outcome of your project is key. Taking the time to familiarize yourself with different wood types and finishes can help you create beautiful furniture that will last for years.

Joining Techniques & Hardware for Furniture

When it comes to furniture production, joining techniques and hardware are essential components of the process. Without them, you wouldn’t be able to build strong, sturdy pieces that are designed to last.

One of the most common joining techniques is doweling. This involves drilling two pieces of wood and inserting a third piece of wood, known as a dowel, into the holes to create a joint.

Dowels are typically made from hardwood, but steel dowels can also be used. Doweling is a great option for creating strong joints that won’t come apart easily. Another popular joining technique is biscuit joining.

This technique uses small round pieces of wood, known as biscuits, which are inserted into slots cut into the two pieces of wood. The biscuits are then glued in place to create a joint. Biscuit joining is great for creating strong joints that are easy to assemble and disassemble if needed.

The final joining technique we’ll discuss is mortise and tenon joints. This requires cutting a small hole, known as a mortise, into one piece of wood and a matching projection, known as a tenon, into the other.

The two pieces are then joined together using glue and possibly a dowel for extra strength. Mortise and tenon joints are great for creating strong, durable furniture pieces. When it comes to hardware, there are a few options to choose from.

The most common type is screws and bolts, which are used to hold two pieces of wood together. Nails are also commonly used in furniture production, but they don’t provide as much strength as screws and bolts.

Other types of hardware include cam locks, which are used to secure drawers and shelves, and corner brackets, which are used to join two pieces of wood at right angles. In summary, there are several joining techniques and hardware options available for furniture production.

Doweling, biscuit joining, and mortise and tenon joints are all popular joining techniques, while screws, bolts, nails, cam locks, and corner brackets are all common hardware options. With the right combination of these components, you can create strong, sturdy furniture pieces that will last for years to come.

Finishing & Staining Techniques

When it comes to furniture production, the finishing and staining of the pieces is one of the most important steps. Not only does it give the piece a finished look, but it also helps to protect the furniture from wear and tear.

While there are many different techniques available for finishing and staining furniture, there are a few that are more popular than others. The first technique is called French polishing.

This method is one of the oldest and most traditional methods of furniture finishing. It involves applying a series of layers of shellac, varnish and wax to the surface of the piece.

These layers are applied with a rubbing pad and left to dry. The result is a deep, rich shine that is both elegant and durable. Another popular technique is staining. Staining involves applying a colored, semi-transparent stain to the wood to give the piece a unique look.

The range of colors available for staining is nearly endless, so you can choose the perfect shade to complement your furniture. Staining is often combined with other techniques such as distressing or glazing for a more unique look.

The last technique is called glazing. Glazing involves applying a thin layer of colored glaze to the surface of the furniture. This is usually done over a stained surface, and the glaze adds depth and highlights certain areas of the piece.

Glazing is a great way to add a bit of extra character to a piece of furniture, and it can also help to protect the piece from wear and tear. No matter what technique you choose for finishing and staining furniture, the results can be stunning.

With a little bit of practice and patience, you can create beautiful furniture that will last for years. Be sure to do your research and decide which technique is best for you and your furniture. With the right technique, you can create a piece of furniture that looks just as good as it does in the showroom.

Safety Tips for Furniture Production

Safety is an important part of any furniture production process. Ensuring that the furniture is produced in a safe manner is essential for protecting workers, customers, and the environment. Here are some safety tips to keep in mind while producing furniture:

Wear protective gear:

Goggles, gloves, and other protective gear should be worn when handling furniture during the production process. This will help to protect workers from any injury or contamination.

Maintain cleanliness:

Dust and other debris should be removed from the workspace prior to beginning any production. This will help to reduce the risk of contamination or injury from hazardous materials.

Use proper tools:

Using the proper tools for the job is important for both safety and quality. Make sure that all tools and equipment used in production are in good working order.

Follow safety procedures:

Establish safety procedures for the production process and make sure that all employees are aware of them. This will help to ensure that everyone is following the same protocol.

Monitor the workspace:

Regularly inspect the workspace to make sure that all safety protocols are being followed. Any potential hazards should be addressed immediately. By following these safety tips, furniture producers can help to ensure that the production process is done safely and efficiently. This will help to create a safe working environment and ensure that quality furniture is produced.

Troubleshooting Common Issues in Furniture Production

Troubleshooting common issues in furniture production can be a daunting task. Furniture production is a complex process involving a variety of different materials, tools, and techniques.

From cutting, sanding, and assembly, to finishing and packaging, there are several steps involved in creating quality furniture. Unfortunately, some issues can arise during the production process.

To minimize downtime, it’s important to understand and address common issues in furniture production. One of the most common issues in furniture production is improper cutting.

When cuts are too deep, too shallow, or not straight, they can cause problems with the overall design of the piece. To avoid this issue, use the correct cutting tools and techniques.

Double-check the measurements, and use a ruler or template to make sure the cuts are precise and the edges are straight. Another common issue is wood splintering or chipping.

This can occur when wood is too dry or too wet, or when the wrong cutting tools are used. To prevent this issue, use a sharp blade and make sure the wood is properly conditioned before cutting.

Additionally, keep the surface clean and free of debris to prevent the blade from catching as it moves across the wood. Incorrect sanding is another issue that can arise during the furniture production process.

Sanding too aggressively can cause the wood to become uneven or splinter. To avoid this, use the correct grit of sandpaper and sand in the direction of the wood grain. Additionally, use a vacuum to remove any sawdust or debris from the surface.

Finally, assembly errors can be a major issue in furniture production. To ensure that pieces fit together properly, use the correct tools and techniques. Additionally, double-check measurements and use clamps to secure pieces while assembling them.

Troubleshooting common issues in furniture production can be a challenge. By understanding the common issues and how to prevent them, you can ensure that your furniture production process runs smoothly and efficiently. With the right tools and techniques, you can produce quality furniture and keep your production line running smoothly.

Popular Furniture Building Techniques & Trends

Furniture production has come a long way since the days of cobbling together crude chairs and tables in the home. Today’s furniture makers employ a variety of different building techniques and materials to create beautiful, functional furnishings.

First, let’s look at the most common furniture building techniques. Carpentry is the most traditional style of furniture building, and involves cutting, shaping, and joining wood to create a variety of items, from chairs and tables to bedframes and cabinets.

Upholstery is another popular technique, where fabric is cut, stitched, and applied to furniture frames to create comfortable seating. Metalworking is also popular, where metal is formed and combined to create items like desks, tables, and chairs.

Now, let’s take a look at the latest furniture trends. Live edge furniture is a popular choice for those wanting a more rustic look. Live edge furniture is made from slabs of wood that are sanded and finished to preserve their natural shape, creating a unique and eye-catching piece.

Mid-century modern furniture is also gaining in popularity, with its iconic clean lines and minimalistic aesthetic. Finally, there’s the increasing use of sustainable materials, such as bamboo and reclaimed wood, in furniture production.

These are just some of the popular furniture building techniques and trends in the industry today. By understanding the different techniques and materials available, you can make an informed decision when choosing the perfect piece of furniture for your home.

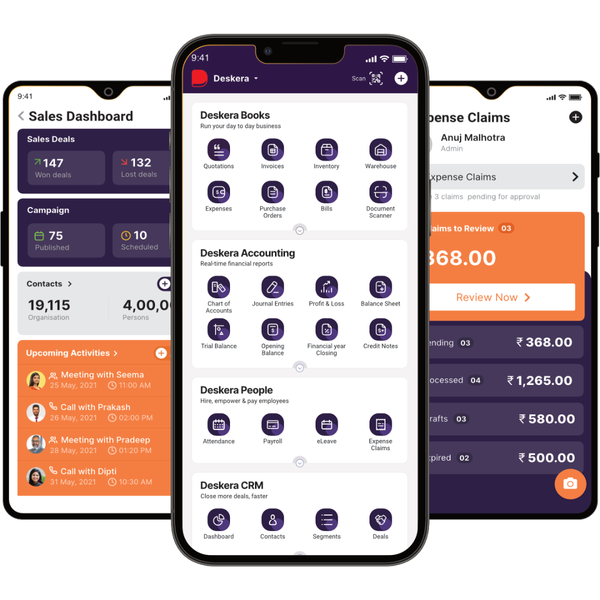

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Sustainable wood is becoming increasingly popular as people become more conscious of the environment and their impact on it.

- Sustainable wood is a great choice for furniture and home décor, as it helps reduce our impact on the environment.

- When it comes to sustainability, wood is one of the most abundant and renewable resources available to us.

- With the increasing concern about global warming and deforestation, it's important to make sure the wood we buy is sourced from sustainable sources.

- Many companies are now labeling their wood with labels that indicate where the wood was sourced and how it was harvested. Look for labels that say FSC-certified, SFI-certified, or PEFC-certified.

Related Articles: