Sustainably produced leather is becoming an important aspect of the fashion industry. There are many benefits to using sustainable leather, including improving the environment and contributing to ethical practices.

Leather has been used for centuries as a material for clothing and accessories. At its most basic, leather is a mixture of water, collagen, and other fibrous substances. The process of making leather requires a lot of energy and resources, which is why it's often considered to be environmentally harmful.

There are many different types of sustainable leather production methods available, each with its own set of benefits. In today’s guide, we’ll understand and discuss thoroughly about advancements in sustainable leather manufacturing. Let’s take a look at the table of content:

- What is Sustainable Leather Manufacturing?

- Importance of Sustainability in Leather Manufacturing

- Advancements in Sustainable Leather Manufacturing

- Traditional Leather Manufacturing Process

- Alternative Materials

- Water-Intensive Process of Leather Tanning

- Chemical Reduction

- Circular Economy

- Frequently Asked Questions (FAQs) Associated with Advancements in Sustainable Leather Manufacturing

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

What is Sustainable Leather Manufacturing?

Sustainable leather manufacturing refers to the production of leather using methods that minimize negative impacts on the environment and prioritize ethical and social responsibility.

This can include reducing water consumption, minimizing the use of harmful chemicals, and recycling or repurposing waste. Sustainable leather manufacturing also emphasizes the humane treatment of animals, fair labor practices, and transparency in the supply chain.

The goal of sustainable leather manufacturing is to create a more responsible and environmentally friendly leather industry.

Importance of Sustainability in Leather Manufacturing

Sustainability in leather manufacturing is of great importance due to its significant impact on the environment and society. Leather production is a complex process that involves the use of various chemicals and resources, including water, energy, and raw materials.

The traditional leather manufacturing process is known to cause several environmental problems, such as air pollution, water pollution, and deforestation, which can have adverse effects on biodiversity and climate change.

In recent years, there has been an increasing awareness of the need to adopt sustainable practices in the leather manufacturing industry to reduce its impact on the environment and promote social responsibility.

Furthermore, sustainable leather manufacturing involves adopting eco-friendly practices that minimize the use of chemicals, reduce energy consumption, and use fewer resources.

One of the key benefits of sustainable leather manufacturing is the reduction of pollution. Eco-friendly leather manufacturing processes involve using natural and biodegradable materials, such as vegetable tanning, which reduces the use of harmful chemicals that can pollute the environment. This not only helps to protect the environment but also ensures that the leather produced is of high quality and safe for use.

Sustainable leather manufacturing also promotes social responsibility by ensuring that workers are treated fairly, and their working conditions are safe and healthy. It promotes the use of ethical practices that take into consideration the well-being of workers, animals, and the environment.

Consequently, the importance of sustainability in leather manufacturing cannot be overemphasized. By adopting sustainable practices, leather manufacturers can reduce their impact on the environment, promote social responsibility, and produce high-quality and safe leather products.

Advancements in Sustainable Leather Manufacturing

In recent years, there have been significant advancements in sustainable leather manufacturing aimed at reducing the industry's impact on the environment and promoting social responsibility. Some of the notable advancements include:

Use of Eco-Friendly Materials:

The use of natural and biodegradable materials, such as vegetable tanning, reduces the use of harmful chemicals and promotes sustainable practices.

Adoption of Renewable Energy:

The use of renewable energy sources, such as solar and wind power, helps to reduce carbon emissions and promote sustainability.

Recycling and Waste Reduction:

The adoption of recycling and waste reduction techniques helps to minimize the amount of waste generated during the leather manufacturing process.

Traceability and Transparency:

The implementation of traceability systems helps to ensure that the raw materials used in the leather manufacturing process are sourced responsibly, and the products are manufactured ethically and sustainably.

Use of Alternative Leather Materials:

The development of alternative leather materials, such as pineapple leather, mushroom leather, and apple leather, offers sustainable options that reduce the environmental impact of traditional leather manufacturing.

Overall, these advancements in sustainable leather manufacturing are significant steps towards a more sustainable and responsible leather industry that benefits both the environment and society.

Traditional Leather Manufacturing Process

The traditional leather manufacturing process involves several stages, including:

- Pre-treatment: The hides or skins are cleaned and soaked in water to remove impurities and prepare them for further processing.

- Tanning: This is the process of turning the hides or skins into leather by treating them with chemicals. The most common tanning methods include chrome tanning, vegetable tanning, and synthetic tanning.

- Dyeing: The leather is dyed to give it color and improve its appearance.

- Finishing: The leather is finished by applying coatings, embossing, and polishing to enhance its properties and make it suitable for use in various products.

Alternative Materials

There are several alternative materials that can be used for leather manufacturing. One popular option is synthetic leather, which is made from polyurethane or polyvinyl chloride.

These materials can be made to look and feel like real leather but are generally less expensive and easier to maintain. Another option is natural fabrics, such as cotton or hemp, which can be treated to mimic the texture and appearance of leather.

Additionally, some companies are exploring the use of innovative materials like mushrooms, pineapple leaves, and even lab-grown animal skin as sustainable alternatives to traditional leather.

A. Introduction

In recent years, there has been an increasing interest in developing alternative materials to traditional leather that are more sustainable and eco-friendlier. Some of the popular alternative materials include:

Plant-based leather: Plant-based leather is made from plant materials, such as pineapple leaves, apple peels, and cactus. The production process involves extracting cellulose fibers from the plants and combining them with natural resins to create a leather-like material.

Mushroom leather: Mushroom leather is made from the mycelium, which is the vegetative part of the fungus. The mycelium is grown in a controlled environment using agricultural waste as a substrate, and the resulting material is processed to create a leather-like material.

B. Benefits and Drawbacks of Alternative Materials:

Benefits of alternative materials:

- Sustainability: Alternative materials are more sustainable and eco-friendlier compared to traditional leather because they use fewer resources and have a lower environmental impact.

- Versatility: Alternative materials can be customized to suit various applications and can be designed to have different textures, colors, and properties.

- Animal welfare: Alternative materials do not involve the use of animal products, which promotes animal welfare.

Drawbacks of alternative materials:

- Cost: Alternative materials are often more expensive to produce than traditional leather, which may make them less accessible to consumers.

- Durability: Some alternative materials may not be as durable as traditional leather, which may affect their lifespan and performance.

C. Examples of Companies Using Alternative Materials in Their Products:

- Piñatex: Piñatex is a plant-based leather made from pineapple leaves. It is used by companies such as Hugo Boss and H&M in their products.

- MycoWorks: MycoWorks produces mushroom leather, which is used by companies such as Hermès and Lululemon in their products.

- Desserto: Desserto produces cactus leather, which is used by companies such as Kering and Tesla in their products.

Ultimately, alternative materials such as plant-based leather and mushroom leather offer a more sustainable and eco-friendly option compared to traditional leather. While they may have some drawbacks, they provide companies with the opportunity to create innovative and sustainable products that benefit both the environment and society.

Water-Intensive Process of Leather Tanning:

The leather tanning process is water-intensive, with large amounts of water required for soaking, washing, and rinsing. The water is also used for chemical processing, such as tanning, dyeing, and finishing.

The wastewater generated from the tanning process contains high levels of pollutants, including organic matter, heavy metals, and salts, which can have a significant impact on the environment if not managed properly.

A. Introduction of Water-Saving Techniques:

To address the water-intensive nature of leather tanning and the associated environmental impact, various water-saving techniques have been developed, including:

Closed-loop systems: Closed-loop systems are designed to recycle water used in the tanning process. The water is treated and reused, reducing the amount of fresh water required for the process.

Wastewater treatment: Wastewater treatment systems are used to treat the wastewater generated from the tanning process before it is discharged. The treatment removes pollutants and reduces the environmental impact of the discharge.

Water-efficient technologies: Water-efficient technologies, such as low-water-use equipment and process optimization, can reduce the overall water consumption of the tanning process.

B. Benefits and Drawbacks of Water-Saving Techniques:

Benefits of water-saving techniques:

Environmental protection: Water-saving techniques reduce the amount of water required for the tanning process, reducing the impact on freshwater resources and minimizing the amount of wastewater discharged into the environment.

Cost savings: Water-saving techniques can reduce the overall cost of the tanning process by reducing the amount of water required and the associated costs of water treatment and disposal.

Drawbacks of water-saving techniques:

Initial cost: The initial cost of implementing water-saving techniques can be high, requiring significant capital investment.

Technical expertise: The implementation of water-saving techniques requires technical expertise, which may not be readily available in some companies.

C. Examples of Companies Implementing Water-Saving Techniques

Here are some examples of companies implementing water-saving techniques in sustainable leather manufacturing:

- BLC Leather Technology Centre: BLC Leather Technology Centre is a UK-based company that provides technical services to the leather industry. The company has developed a water-saving technology called the "Zero Discharge of Hazardous Chemicals" (ZDHC) program, which aims to reduce the amount of water used in leather production and eliminate the discharge of hazardous chemicals into the environment.

- ECCO Leather: ECCO Leather is a Danish leather manufacturer that has implemented a water-saving technique called the "Water Recycling System." This system uses reverse osmosis to purify and recycle water, reducing the amount of fresh water needed for leather production.

- ISA TanTec: ISA TanTec is a global leather manufacturer that has implemented a water-saving technique called "Rainwater Harvesting." This technique involves collecting rainwater and using it for leather production, reducing the amount of freshwater needed.

- PrimeAsia Leather Corporation: PrimeAsia Leather Corporation is a leather manufacturer based in Hong Kong that has implemented a water-saving technique called "Chrome Recovery." This technique involves recovering and recycling chromium used in leather tanning, reducing the amount of water needed for the process.

These are just a few examples of companies implementing water-saving techniques in sustainable leather manufacturing. Many other companies are also exploring innovative ways to reduce their water usage and minimize their environmental impact.

Chemical Reduction

In leather manufacturing, chemical reduction is a process used to reduce the chromium that is often used in tanning processes.

Chromium is a common tanning agent that produces a durable and long-lasting leather, but it can also have negative environmental impacts if not properly managed. Furthermore, chemical reduction involves the use of reducing agents, such as sodium hydrosulfite, to reduce the amount of chromium in the leather.

This process not only helps to reduce the environmental impact of leather manufacturing but also produces a softer and more pliable leather that is more suitable for certain applications.

However, it is important to note that chemical reduction is not always used in leather manufacturing and other methods, such as vegetable tanning, may be used as more sustainable alternatives.

A. Explanation of the Use of Hazardous Chemicals in Leather Tanning:

Leather tanning is the process of converting animal hides or skins into leather, which involves treating the material with chemicals to prevent decomposition and stabilize the material.

Traditionally, the most commonly used tanning agents are heavy metals such as chromium, which is known to be a hazardous chemical that can have negative impacts on human health and the environment.

Chromium is a known carcinogen and can cause respiratory problems, skin irritation, and other health issues. The use of chromium and other hazardous chemicals in leather tanning has led to pollution of water sources and soil and poses a significant risk to the health of workers in the industry.

B. Introduction of Chemical-Free or Low-Chemical Tanning Methods:

To address the negative impact of hazardous chemicals in leather tanning, several chemical-free or low-chemical tanning methods have been developed.

One such method is vegetable tanning, which uses natural tannins found in plants to tan leather. Vegetable tanning is considered to be a more sustainable and environmentally friendly alternative to chromium tanning.

Another method is the use of enzymes, which are naturally occurring proteins that can break down proteins in hides and skins to produce leather. Furthermore, enzyme-based tanning methods are considered to be low-chemical and more environmentally friendly than traditional tanning methods.

C. Benefits and Drawbacks of Chemical-Free Tanning Methods:

Following, we've discussed crucial benefits and drawbacks of chemical-free tanning methods. Let's learn:

Environmental sustainability: Chemical-free tanning methods reduce the use of hazardous chemicals, which helps to reduce the pollution of water sources and soil.

Health and safety: Chemical-free tanning methods are safer for workers in the industry, as they are not exposed to hazardous chemicals.

Higher quality leather: Chemical-free tanning methods can produce high-quality leather that is more natural-looking and has a unique texture.

Drawbacks:

Cost: Chemical-free tanning methods can be more expensive due to the cost of natural ingredients and the longer time required for the tanning process.

Limited availability: Chemical-free tanning methods are not widely used in the leather industry, so finding products made from chemically-free leather can be challenging.

Longer production time: Chemical-free tanning methods require a longer time for the tanning process, which can slow down the production of leather goods.

D. Examples of Companies Implementing Chemical-Free Tanning Methods:

There are a few companies that have implemented chemical-free tanning methods. Here are some examples:

Ecodermis: Ecodermis is a tanning company that uses a vegetable-tanning process to create leather products. This process uses natural materials like tree bark, leaves, and fruit to create tannins that can be used to tan leather.

Wickett & Craig: Wickett & Craig is a leather tannery that has been using vegetable tanning methods since 1867. They use a combination of natural materials and time-honored techniques to create leather products that are both durable and beautiful.

The Genuine Company: The Genuine Company is a tannery that uses a unique tanning process called "Wickett & Craig Re-tan." This process involves re-tanning leather that has already been tanned using vegetable methods, resulting in an even more durable and eco-friendly product.

Muirhead: Muirhead is a Scottish leather manufacturer that uses a combination of vegetable tanning and water-based finishing techniques to create high-quality leather products without using harsh chemicals.

D'Arçy & Everest: D'Arçy & Everest is a British tannery that specializes in vegetable tanning. They use a blend of natural materials like chestnut, quebracho, and mimosa to create tannins that are gentle on the environment and produce high-quality leather products.

Circular Economy

Circular Economy is an economic model that aims to minimize waste and promote the sustainable use of resources by keeping them in the system for as long as possible. In this model, products are designed to be reused, repaired, and recycled, rather than disposed of after a single use.

This approach not only reduces the environmental impact of our economic activities but also creates new economic opportunities, such as the development of new recycling technologies and the growth of circular supply chains.

The Circular Economy is seen as a key strategy for achieving long-term sustainability and addressing the challenges of climate change and resource depletion.

A. Concept of Circular Economy in Leather Manufacturing

The concept of circular economy can be applied to the leather manufacturing industry in various ways. Leather production involves the use of animal hides, which are a natural resource that can be sustainably managed through a circular economy approach.

Following, we've discussed some examples of how circular economy principles can be applied to leather manufacturing:

Sustainable sourcing: In a circular economy, the raw materials used in manufacturing are sourced sustainably. In the leather industry, this means using hides from animals that are raised for their meat rather than sourcing from illegal or unsustainable hunting.

By using hides from animals that would have been slaughtered for meat anyway, the industry can reduce waste and promote sustainable land use.

Resource efficiency: Leather production requires significant amounts of water, energy, and chemicals. In a circular economy, these resources are used efficiently and recycled whenever possible.

For example, water can be treated and reused in the tanning process, reducing the amount of fresh water needed. Energy can be generated from renewable sources, and chemicals can be reused or recycled, reducing the environmental impact of the leather production process.

Product design: Circular economy principles can also be applied to the design of leather products. Products can be designed to be durable and long-lasting, and made with materials that can be easily repaired, reused, or recycled.

For example, leather products can be designed with modular components that can be easily replaced, reducing the need to replace the entire product.

Recycling: In a circular economy, materials are recycled and reused rather than being disposed of after use. Leather waste can be recycled into new leather products or other products, such as shoes, belts, and wallets. Leather scraps can also be used as a source of fuel or turned into compost.

By applying circular economy principles to leather manufacturing, the industry can reduce waste, conserve resources, and promote sustainable practices. This approach not only benefits the environment but also creates new economic opportunities and helps to ensure the long-term viability of the leather industry.

B. Circular Practices

Circular practices such as recycling and upcycling are important components of the circular economy, as they help to minimize waste and extend the life cycle of products and materials. Here's a detailed explanation of both recycling and upcycling:

Recycling:

Recycling is the process of converting waste materials into new products or materials. This can be done through a variety of methods, including mechanical recycling, chemical recycling, and thermal recycling.

Mechanical recycling involves collecting and processing waste materials such as plastic, paper, or metal, and breaking them down into smaller pieces that can be used to make new products.

On the other hand, chemical recycling involves breaking down waste materials at a molecular level and using them as a source of energy or to create new materials. Thermal recycling involves using heat to convert waste materials into energy or materials that can be used for fuel.

Additionally, recycling has numerous environmental benefits, such as reducing the amount of waste sent to landfills and conserving natural resources. It also has economic benefits, as it can create new jobs and reduce the cost of raw materials.

Upcycling:

Upcycling is the process of transforming waste materials or unwanted products into new products of better quality or higher value.

Unlike recycling, which involves breaking down materials and remaking them into new products, upcycling involves using existing materials to create something new and different.

Upcycling involves creativity and ingenuity, as it often requires finding new uses for materials that were originally intended for something else. For example, a discarded tire can be upcycled into a unique planter, or an old T-shirt can be transformed into a reusable shopping bag.

Furthermore, upcycling has several benefits, including reducing waste, conserving resources, and promoting creativity and innovation. It also has economic benefits, as it can create new business opportunities and generate revenue from products that would otherwise have been discarded.

Consequently, recycling and upcycling are both important circular practices that can help to minimize waste, conserve resources, and promote sustainability. By incorporating these practices into our daily lives, we can reduce our environmental impact and contribute to a more sustainable future.

Recycling involves converting waste materials into new products, which can help to conserve resources and reduce the amount of waste sent to landfills. Upcycling, on the other hand, involves creatively repurposing existing materials to give them a new life and prevent them from becoming waste.

Both recycling and upcycling can help to reduce the number of raw materials and energy required to produce new products, as well as reduce greenhouse gas emissions and other environmental pollutants associated with the manufacturing process. Additionally, these practices can create new economic opportunities and promote job growth in the recycling and upcycling industries.

C. Benefits and drawbacks of circular practices

Circular practices refer to a system of resource management that seeks to minimize waste and maximize resource efficiency.

The main objective of circular practices is to create a closed-loop system in which materials and resources are reused, repurposed, and recycled to minimize waste and reduce environmental impact.

Following, we've discussed some benefits and drawbacks of circular practices:

Benefits:

Reduced waste: Circular practices can significantly reduce waste by ensuring that materials are reused and recycled instead of being discarded.

Resource efficiency: Circular practices aim to maximize the use of resources, which can help reduce costs and conserve resources.

Environmental benefits: By reducing waste and conserving resources, circular practices can help reduce environmental impact, such as greenhouse gas emissions, air and water pollution, and deforestation.

Business opportunities: Circular practices can create new business opportunities in the form of circular supply chains, circular business models, and innovative products and services.

Drawbacks:

High implementation costs: Implementing circular practices can be expensive, especially for small and medium-sized enterprises.

Limited infrastructure: Circular practices require the development of infrastructure and systems to support the collection, sorting, and processing of materials, which can be a challenge in some regions.

Regulatory barriers: Some regulations may not support circular practices, making it difficult for businesses to implement circular solutions.

Consumer behavior: Circular practices rely on consumers to embrace sustainable behaviors, such as recycling and waste reduction, which may not always be easy to achieve.

Overall, circular practices offer numerous benefits, but they require significant investments and systemic changes to be implemented effectively.

D. Examples of companies implementing circular practices

There are several companies that have implemented circular practices in their operations. Here are some examples:

- IKEA: The Swedish furniture giant has implemented several circular practices, including product take-back programs, where customers can return used furniture for resale or recycling. IKEA also uses renewable energy and has committed to becoming a circular and climate-positive business by 2030.

- H&M: The fashion retailer has implemented a recycling program where customers can bring their used clothes to H&M stores for recycling. H&M also uses sustainable materials in its products and has committed to becoming a circular and climate-positive business by 2030.

- Interface: The carpet manufacturer has implemented a closed-loop system where it recycles its old carpet tiles into new ones. Interface also uses renewable energy and has committed to becoming a carbon-neutral and restorative company by 2040.

- Patagonia: The outdoor clothing brand has implemented a product repair program, where customers can send in their old and damaged clothing for repair. Patagonia also uses recycled materials in its products and has committed to becoming a circular and carbon-neutral company.

Frequently Asked Questions (FAQs) Associated with Advancements in Sustainable Leather Manufacturing

Following, we’ve discussed some crucial frequently asked questions (FAQs) associated with advancements in sustainable leather manufacturing. Let’s discuss:

Que 1: How do these advancements benefit the environment?

Ans: These advancements benefit the environment in several ways:

Reduced water consumption: The use of closed-loop systems and alternative processes that require less water help to conserve water resources and reduce the amount of wastewater produced during leather production.

Reduced chemical use: Eco-friendly tanning methods and other chemical reduction technologies help to minimize the use of harmful chemicals that can pollute the environment.

Waste reduction and recycling: By finding ways to repurpose and recycle waste generated during the leather production process, sustainable leather manufacturers can help to reduce the amount of waste that ends up in landfills or pollutes the environment.

Reduced carbon footprint: By adopting sustainable practices throughout the supply chain, including using renewable energy sources and reducing the use of fossil fuels, sustainable leather manufacturing can help to reduce the industry's overall carbon footprint.

Overall, these advancements help to create a more responsible and environmentally friendly leather industry that is better equipped to address the environmental challenges of the future.

Que 2: Do sustainable leather manufacturing practices have any economic or social benefits?

Ans: Yes, sustainable leather manufacturing practices can have economic and social benefits as well.

Economically, sustainable leather manufacturing practices can:

Create new business opportunities: The development of innovative technologies and processes in sustainable leather manufacturing can create new business opportunities for manufacturers, suppliers, and other stakeholders in the industry.

Reduce costs: Some sustainable practices, such as reducing water and chemical use, can help to reduce the cost of production over time.

Improve marketability: As consumers become more environmentally and socially conscious, sustainable leather products may become more attractive to buyers, potentially leading to increased demand and higher prices.

Socially, sustainable leather manufacturing practices can:

Improve working conditions: By prioritizing fair labor practices, sustainable leather manufacturers can help to improve working conditions for workers in the industry.

Support local communities: Sustainable leather manufacturing can create economic opportunities and support local communities where leather production is a significant industry.

Promote animal welfare: Sustainable leather manufacturing can prioritize the humane treatment of animals, promoting responsible and ethical animal husbandry.

Overall, sustainable leather manufacturing practices can have a positive impact on both the economy and society, in addition to their environmental benefits.

Que 3: Is sustainable leather more expensive than traditionally produced leather?

Ans: Sustainable leather can be more expensive than traditionally produced leather because of the additional costs associated with using eco-friendly technologies and responsible production practices. However, as sustainable leather production becomes more common, prices may become more competitive.

Que 4: Are there any drawbacks or limitations to sustainable leather manufacturing?

Ans: One limitation of sustainable leather manufacturing is that not all manufacturers may be willing or able to invest in the necessary technologies and practices to produce sustainable leather.

Additionally, some sustainable leather alternatives, such as vegan leather made from synthetic materials, may not be biodegradable or recyclable.

Que 5: What can consumers do to support sustainable leather manufacturing practices?

Ans: Consumers can support sustainable leather manufacturing practices by choosing products made from sustainably produced leather and asking companies about their production practices. They can also look for third-party certifications that indicate whether a product is sustainably produced.

Que 6: What role do government regulations play in promoting sustainable leather manufacturing?

Ans: Government regulations can play a role in promoting sustainable leather manufacturing by setting standards and guidelines for sustainable production practices. For example, some governments have implemented regulations around water usage and chemical waste in leather production.

Que 7: Are there any certifications or standards that indicate whether leather is sustainably produced?

Ans: Yes, there are several certifications and standards that indicate whether leather is sustainably produced. These include the Leather Working Group certification, which assesses the environmental compliance and performance of leather manufacturers, and the Global Recycled Standard, which certifies products made from recycled materials.

Wrapping Up

In conclusion, advancements in sustainable leather manufacturing are a promising development in the industry's efforts to reduce its environmental impact. Through the use of innovative and eco-friendly technologies, leather producers are finding ways to reduce water consumption, minimize chemical use, and recycle waste.

These efforts not only benefit the environment, but also create economic opportunities and improved working conditions for workers in the industry. While there is still much work to be done, the progress made so far is a positive step towards a more sustainable and responsible industry.

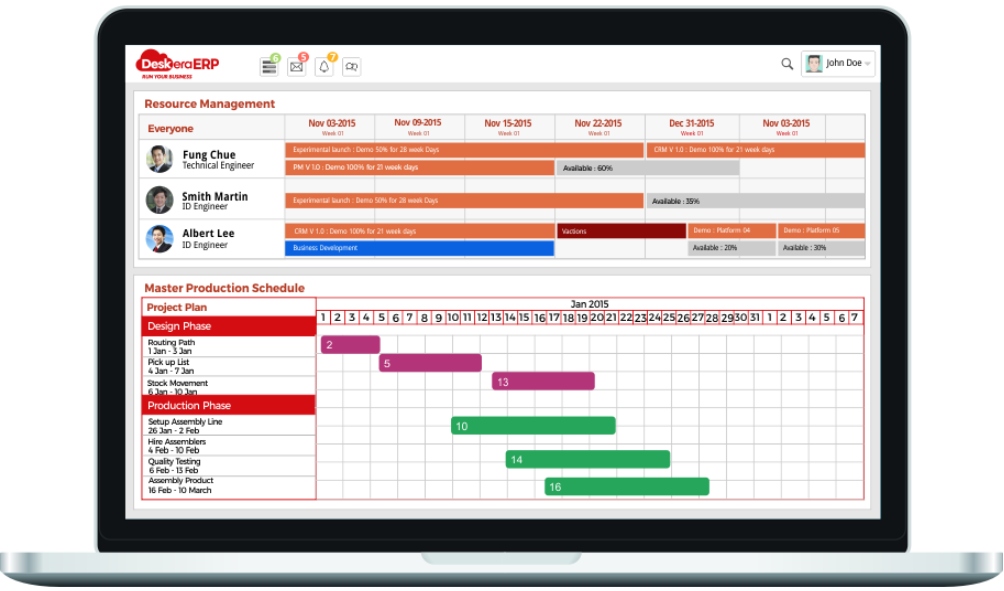

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Sustainable leather manufacturing refers to the production of leather using methods that minimize negative impacts on the environment and prioritize ethical and social responsibility. This can include reducing water consumption, minimizing the use of harmful chemicals, and recycling or repurposing waste.

- One of the key benefits of sustainable leather manufacturing is the reduction of pollution. Eco-friendly leather manufacturing processes involve using natural and biodegradable materials, such as vegetable tanning, which reduces the use of harmful chemicals that can pollute the environment.

- Plant-based leather is made from plant materials, such as pineapple leaves, apple peels, and cactus. The production process involves extracting cellulose fibers from the plants and combining them with natural resins to create a leather-like material.

- Alternative materials such as plant-based leather and mushroom leather offer a more sustainable and eco-friendly option compared to traditional leather. While they may have some drawbacks, they provide companies with the opportunity to create innovative and sustainable products that benefit both the environment and society.

- Chromium is a known carcinogen and can cause respiratory problems, skin irritation, and other health issues. The use of chromium and other hazardous chemicals in leather tanning has led to pollution of water sources and soil, and poses a significant risk to the health of workers in the industry.

- Circular Economy is an economic model that aims to minimize waste and promote the sustainable use of resources by keeping them in the system for as long as possible. In this model, products are designed to be reused, repaired, and recycled, rather than disposed of after a single use. This approach not only reduces the environmental impact of our economic activities but also creates new economic opportunities.

- Recycling is the process of converting waste materials into new products or materials. This can be done through a variety of methods, including mechanical recycling, chemical recycling, and thermal recycling.

Related Articles