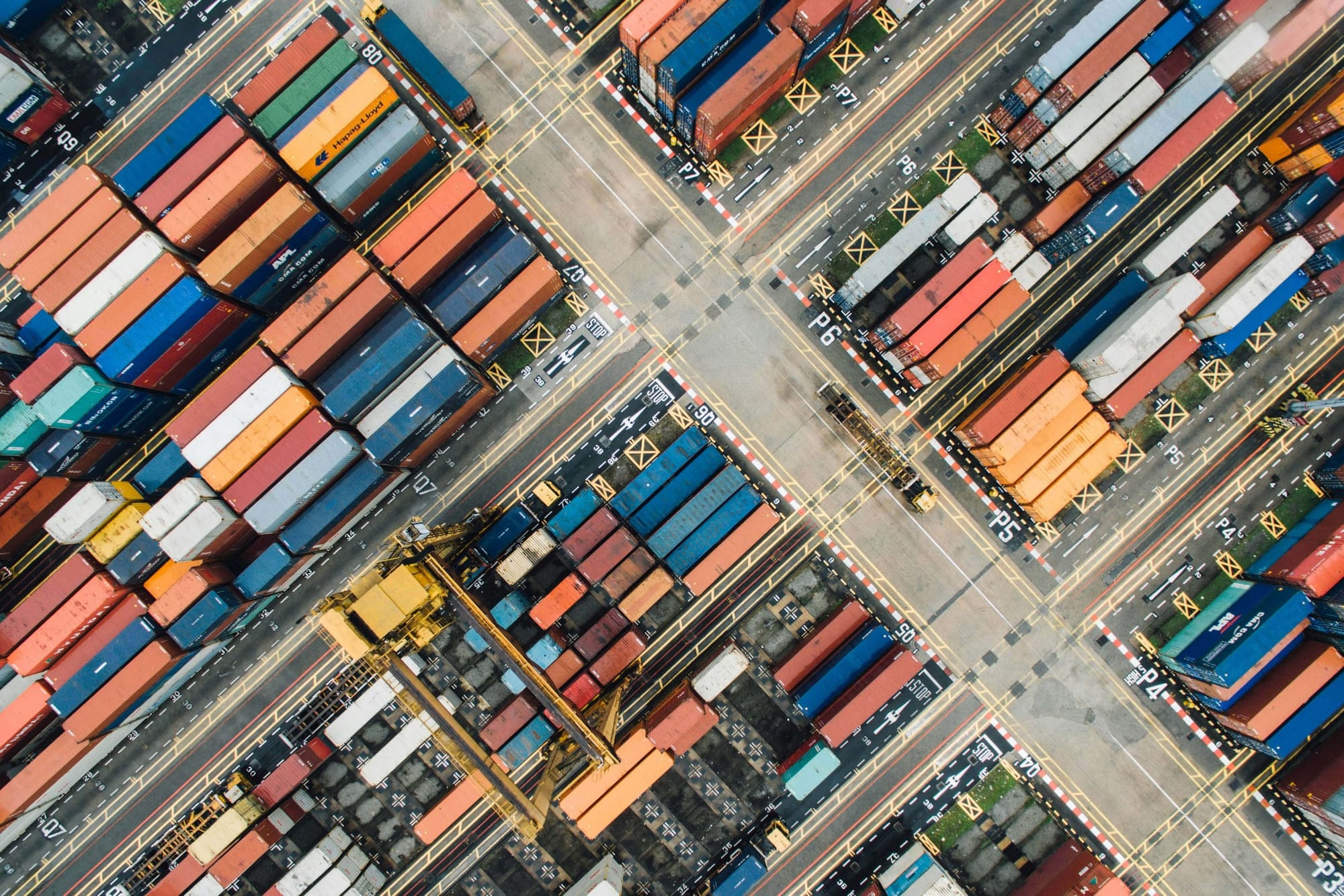

In today’s fast-paced business environment, supply chains face unprecedented challenges. Statistics reveal that supply chain disruptions are frequent, with 80% of organizations experiencing at least one disruption in the past year, and many lasting over a month. These interruptions can significantly impact production schedules, increase costs, and strain relationships with suppliers and customers. As a result, businesses are increasingly recognizing the critical role that strategic sourcing plays in maintaining continuity and resilience.

Sourcing strategies are no longer just about finding the cheapest supplier. Companies must carefully evaluate risk, quality, delivery timelines, and supplier reliability. From single sourcing to multi-sourcing and global procurement, each approach carries unique benefits and challenges. Making informed sourcing decisions can help organizations reduce vulnerability to supply chain shocks while optimizing costs and ensuring product quality.

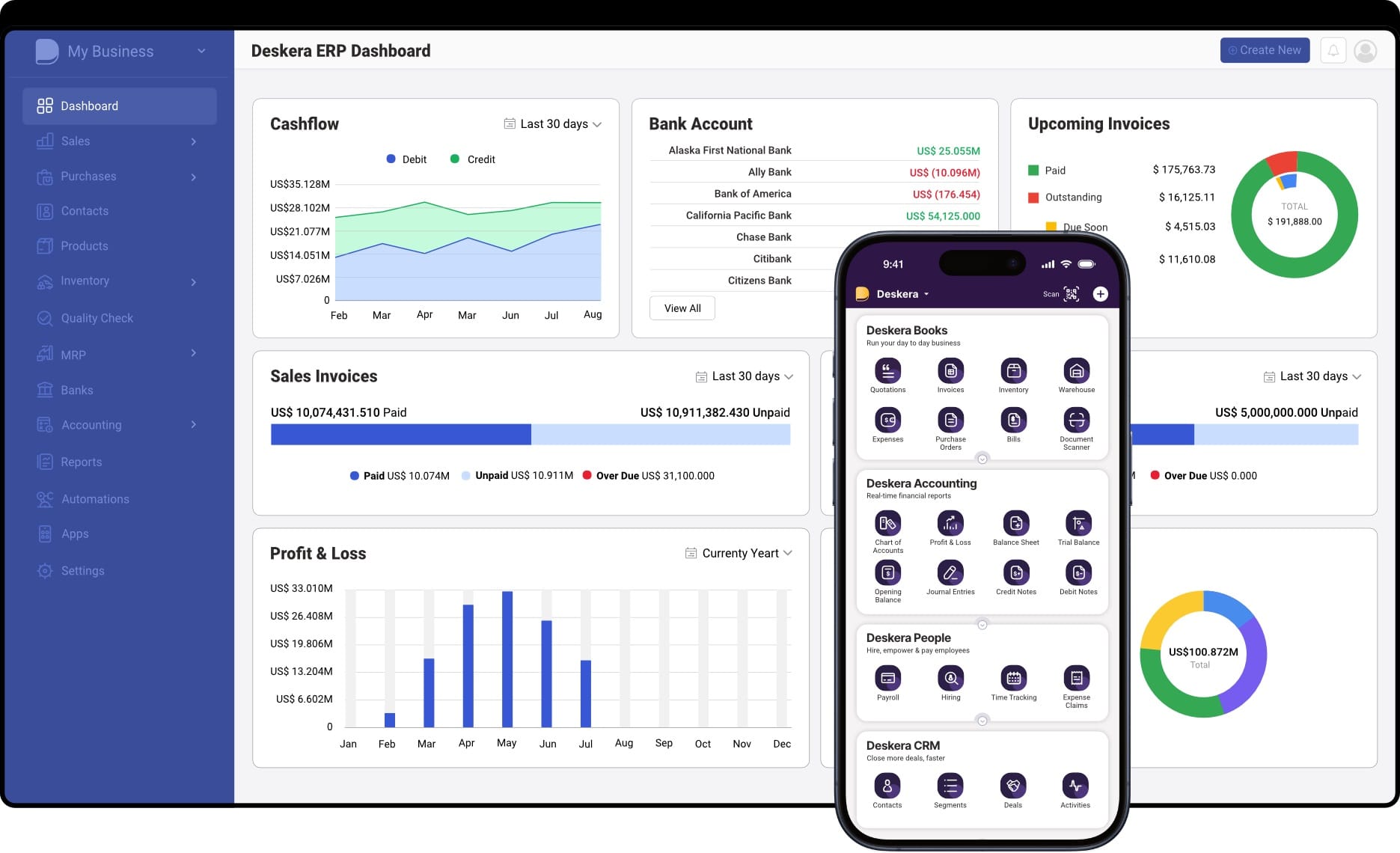

In addition to selecting the right sourcing strategy, leveraging the right technology has become essential. Deskera ERP offers businesses a comprehensive platform to manage procurement, supplier relationships, and inventory efficiently. Its AI-driven tools provide real-time insights, automate workflows, and forecast demand, enabling businesses to make data-backed decisions and respond swiftly to supply chain disruptions.

This guide will explore the top 10 sourcing strategies that organizations can adopt to build a resilient supply chain in 2025. By understanding each strategy’s advantages, risks, and applications, businesses can tailor their approach to suit their unique needs. Whether you are aiming to minimize risk, optimize costs, or enhance operational efficiency, implementing the right sourcing strategies—supported by tools like Deskera ERP—can ensure long-term success and supply chain resilience.

What Is a Sourcing Strategy?

A sourcing strategy is a plan that outlines how a business selects, evaluates, and manages suppliers to procure goods or services effectively. It is a critical component of supply chain management because it directly impacts cost, quality, delivery, and risk management. A well-defined sourcing strategy helps organizations optimize procurement decisions and build a resilient supply chain.

Key aspects of a sourcing strategy include:

- Supplier Selection: Identifying suppliers that align with business goals, quality standards, and risk tolerance.

- Cost Management: Evaluating total cost of ownership, not just the purchase price.

- Risk Mitigation: Assessing supplier reliability, geopolitical factors, and potential disruptions.

- Quality Assurance: Ensuring products or services meet predefined standards consistently.

- Delivery & Lead Time Optimization: Choosing suppliers who can meet timelines without delays.

- Strategic Alignment: Ensuring sourcing decisions support long-term business objectives.

- Sustainability & Compliance: Considering environmental, social, and regulatory factors in procurement.

By integrating these elements, companies can choose the right sourcing strategy—be it single, dual, multi, or global sourcing—that balances cost, risk, and operational efficiency.

Supplier-Focused Sourcing Strategies

Supplier-focused sourcing strategies are centered around managing relationships and procurement processes with individual suppliers. These strategies are crucial for businesses that want to optimize supplier performance, reduce risks, and ensure consistent quality.

By carefully choosing how many suppliers to engage and how to distribute orders, companies can achieve the right balance between reliability, flexibility, and cost-effectiveness.

1. Single Sourcing

Single sourcing involves relying on one supplier for a particular product or service. This strategy focuses on building a strong, long-term relationship with a trusted supplier, often for critical components or high-quality items.

Benefits:

- Stronger Supplier Relationships: A focused partnership allows for better collaboration, negotiation, and mutual understanding.

- Consistent Quality: Relying on one supplier ensures standardized processes and uniform product quality.

- Streamlined Procurement: Simplifies purchasing, reduces administrative overhead, and makes communication easier.

- Cost Negotiation Opportunities: High-volume orders with a single supplier often lead to better pricing or terms.

Risks:

- High Dependency: If the supplier faces disruptions, the entire supply chain can be affected.

- Limited Flexibility: Switching suppliers or scaling production quickly can be challenging.

- Potential for Supply Interruptions: Natural disasters, strikes, or geopolitical events can halt supply completely.

Best Practices:

- Maintain strong contractual agreements and performance metrics.

- Regularly assess supplier performance and financial stability.

- Develop contingency plans for potential disruptions.

2. Dual Sourcing

Dual sourcing splits procurement between two suppliers for the same product. This approach balances risk reduction with the benefits of supplier relationships, offering a middle ground between single and multi-sourcing.

Benefits:

- Reduced Dependency: Having a second supplier mitigates the risk of complete supply chain disruption.

- Supply Stability: Provides flexibility if one supplier faces delays or capacity issues.

- Competitive Advantage: Encourages healthy competition between suppliers, potentially improving quality and pricing.

Risks:

- Coordination Complexity: Managing two suppliers requires careful planning to avoid overlaps or conflicts.

- Supplier Rivalry: Suppliers may compete aggressively, which could impact collaboration.

- Slightly Higher Management Costs: Requires additional monitoring and communication efforts compared to single sourcing.

Best Practices:

- Clearly define order volumes, quality standards, and delivery schedules for each supplier.

- Maintain transparent communication to prevent conflicts or misunderstandings.

- Monitor supplier performance and adjust allocation as needed.

3. Multi-Sourcing

Multi-sourcing involves working with multiple suppliers for the same product or component. This strategy spreads risk and provides high flexibility, making it ideal for large-scale operations or industries with volatile demand.

Benefits:

- Diversified Risk: Distributes supply risk across several suppliers, reducing the impact of disruptions.

- Handles Large Demand: Multiple suppliers ensure sufficient capacity to meet production requirements.

- Improved Flexibility: Easier to adjust sourcing in response to market changes or supplier issues.

- Innovation Opportunities: Exposure to multiple suppliers can lead to new ideas, better materials, or improved processes.

Risks:

- Complex Supplier Management: Requires careful coordination, monitoring, and integration across all suppliers.

- Quality Inconsistency: Different suppliers may have varying quality standards or processes.

- Higher Administrative Costs: More time and resources are needed for supplier evaluation, contracts, and logistics.

Best Practices:

- Implement a supplier performance management system to monitor quality, delivery, and compliance.

- Standardize processes and specifications to minimize variability.

- Use technology tools like ERP systems to streamline communication, orders, and tracking.

Geographic-Focused Sourcing Strategies

Geographic-focused sourcing strategies prioritize the location of suppliers to optimize cost, delivery times, and risk management. By strategically selecting suppliers based on their proximity or global reach, businesses can improve supply chain efficiency, reduce lead times, and mitigate risks associated with international trade, logistics, and geopolitical factors.

1. Global Sourcing

Global sourcing involves procuring goods or services from suppliers located in different countries, often to take advantage of lower costs, specialized expertise, or access to innovative technologies.

Benefits:

- Cost Efficiency: Access to suppliers in low-cost regions can significantly reduce production expenses.

- Access to Innovation: Global suppliers may offer advanced technology, materials, or processes unavailable locally.

- Diverse Supply Base: Reduces over-reliance on domestic suppliers and spreads risk across regions.

Risks:

- Long Lead Times: Shipping products internationally can increase delivery times.

- Geopolitical & Currency Risks: Tariffs, trade restrictions, and currency fluctuations can impact costs.

- Complex Logistics: Managing customs, compliance, and transportation across borders can be challenging.

Best Practices:

- Conduct thorough supplier due diligence and risk assessments.

- Maintain contingency plans, including backup suppliers closer to home.

- Leverage technology to track international shipments and supplier performance.

2. Local Sourcing

Local sourcing involves procuring products or services from suppliers within the same region or country. This strategy emphasizes speed, convenience, and supply reliability.

Benefits:

- Faster Delivery: Reduced transportation distances lead to shorter lead times.

- Lower Shipping Costs: Less dependency on international logistics reduces expenses.

- Simpler Compliance: Local suppliers are more likely to follow domestic regulations and standards.

- Support for Local Economy: Strengthens regional business networks and sustainability initiatives.

Risks:

- Limited Supplier Options: Fewer local suppliers may be available, limiting flexibility.

- Higher Costs: Domestic production costs may be higher than international alternatives.

Best Practices:

- Establish strong relationships with reliable local suppliers.

- Use local sourcing strategically for critical or time-sensitive components.

- Monitor supplier performance regularly to ensure consistent quality.

3. Nearshoring

Nearshoring refers to sourcing from neighboring or nearby countries, striking a balance between global sourcing advantages and local sourcing convenience.

Benefits:

- Shorter Lead Times than Global Sourcing: Proximity reduces transportation and delivery delays.

- Lower Costs than Local Sourcing: Labor and production costs can be more competitive than domestic suppliers.

- Easier Communication & Collaboration: Similar time zones and cultural similarities improve coordination.

Risks:

- Higher Costs than Offshoring to Low-Cost Countries: May not achieve the same cost savings as global sourcing in distant regions.

- Limited Supplier Options: Nearby countries may not have the same breadth of supplier capabilities as global markets.

Best Practices:

- Identify nearby countries with stable political and economic conditions.

- Use nearshoring for products that require flexibility, faster turnaround, or frequent adjustments.

- Incorporate risk monitoring to quickly respond to regional disruptions.

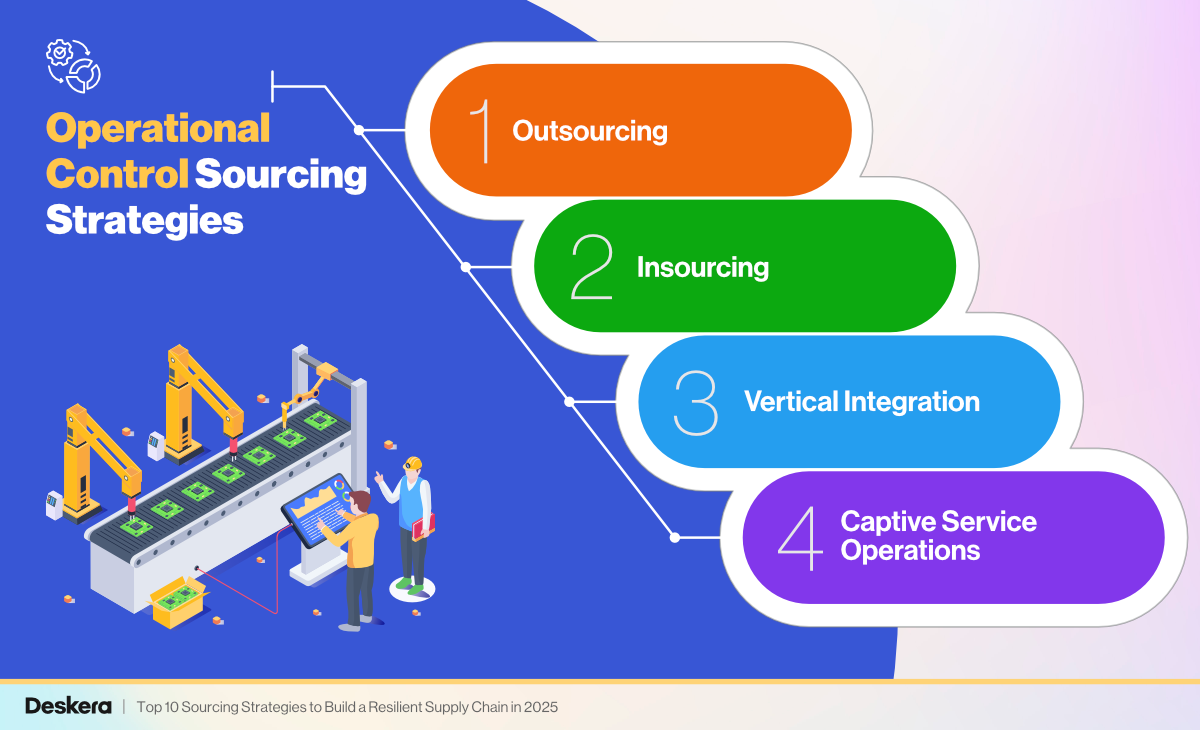

Operational Control Sourcing Strategies

Operational control strategies focus on how much control a business maintains over its supply chain operations. These strategies help companies manage quality, costs, and timelines by determining whether activities should be handled internally or delegated to external partners. Implementing the right operational control strategy allows businesses to balance efficiency, flexibility, and risk management.

1. Outsourcing

Outsourcing involves delegating certain tasks, processes, or production activities to external suppliers or service providers who specialize in those areas.

Benefits:

- Focus on Core Competencies: Allows the business to concentrate on strategic areas while external partners handle specialized tasks.

- Cost Savings: Leveraging external expertise can reduce operational and labor costs.

- Access to Specialized Skills: Outsourced providers often bring advanced technology and industry expertise.

Risks:

- Reduced Control: Limited oversight can affect quality, timelines, or confidentiality.

- Dependency on External Providers: Disruptions or performance issues from the supplier can impact your operations.

- Communication Challenges: Managing outsourced operations may require additional coordination.

Best Practices:

- Clearly define scope, KPIs, and service level agreements (SLAs).

- Maintain regular communication and performance monitoring.

- Have contingency plans or backup providers in case of disruptions.

2. Insourcing

Insourcing means bringing previously outsourced tasks or production back in-house, allowing the company to regain full control over operations.

Benefits:

- Greater Control: Complete oversight of processes, quality, and timelines.

- Better Alignment: Ensures operations are closely aligned with business objectives.

- Improved Quality Assurance: Direct management of production can lead to more consistent standards.

Risks:

- Higher Operational Costs: In-house operations may require more investment in infrastructure, labor, and technology.

- Capacity Limitations: Scaling production may be more challenging internally.

- Resource Requirements: Requires sufficient expertise, management, and workforce.

Best Practices:

- Invest in employee training and advanced technology.

- Assess the cost-benefit of insourcing vs. outsourcing regularly.

- Use insourcing for critical or high-value operations where control is essential.

3. Vertical Integration

Vertical integration involves controlling multiple stages of the supply chain, from raw material sourcing to production and distribution.

Benefits:

- Supply Stability: Reduces reliance on external suppliers, ensuring consistent availability of key inputs.

- Cost Control: Helps manage costs across the supply chain by internalizing key processes.

- Enhanced Operational Efficiency: Streamlines processes and reduces bottlenecks.

Risks:

- High Capital Investment: Requires significant resources to acquire or manage multiple supply chain stages.

- Reduced Flexibility: May be difficult to adapt quickly to market changes or disruptions.

- Complex Management: Integrating multiple operations increases managerial complexity.

Best Practices:

- Implement vertical integration gradually, starting with critical components.

- Use technology and ERP systems to track performance across all stages.

- Continuously evaluate ROI and operational efficiency improvements.

4. Captive Service Operations

Captive service operations involve establishing your own production or service operations in a foreign country, rather than relying on third-party providers.

Benefits:

- Full Control Over Foreign Operations: Ensures quality, compliance, and process alignment with corporate standards.

- Protection of Intellectual Property: Reduces risks compared to outsourcing to third parties.

- Consistency and Reliability: Maintains stable operations in international markets.

Risks:

- High Setup Costs: Initial investment in infrastructure, staffing, and legal compliance can be substantial.

- Cultural and Regulatory Challenges: Requires navigating local laws, labor practices, and business culture.

- Operational Complexity: Managing overseas operations adds logistical and managerial demands.

Best Practices:

- Conduct thorough feasibility and risk assessments before establishing operations.

- Hire local expertise to navigate regulations and cultural nuances.

- Monitor performance regularly and integrate with central management systems.

Holistic & Strategic Sourcing

While individual sourcing strategies—supplier-focused, geographic-focused, and operational control—offer specific advantages, businesses also need a holistic approach to ensure long-term resilience and alignment with organizational goals. Strategic sourcing is a comprehensive framework that evaluates the full supply chain, supplier market, and business objectives to make informed procurement decisions.

Strategic sourcing goes beyond just choosing suppliers; it involves analyzing total cost of ownership, risk factors, and supplier performance to select the most appropriate sourcing strategy for each category of goods or services. This approach enables businesses to balance cost, quality, flexibility, and sustainability while ensuring supply chain continuity.

Key Elements of Strategic Sourcing

- Sourcing Objectives: Define clear goals, such as cost reduction, risk mitigation, or sustainability.

- Supplier Evaluation: Assess suppliers based on reliability, quality, financial stability, and compliance.

- Market Analysis: Monitor global and local supply markets to identify opportunities and potential risks.

- Risk Management: Identify vulnerabilities across the supply chain and implement contingency plans.

- Continuous Improvement: Regularly review sourcing decisions, supplier performance, and market conditions.

Benefits of Strategic Sourcing

- Optimized Costs: Reduces unnecessary expenses while maintaining quality.

- Risk Mitigation: Anticipates and minimizes disruptions in the supply chain.

- Enhanced Supplier Relationships: Encourages collaboration, innovation, and long-term partnerships.

- Sustainability Compliance: Integrates ESG principles into procurement practices.

Risks of Strategic Sourcing

- Implementation Complexity: Comprehensive analysis and planning can be challenging.

- High Initial Investment: Costs of technology, training, and market research may be significant.

- Over-Reliance on Historical Data: Past data may not fully predict sudden market changes.

- Supplier Resistance: Long-term contracts or stringent requirements may create tension.

- Time-Consuming Process: Evaluation and monitoring can be resource-intensive.

- Potential Misalignment: Sourcing objectives not aligned with broader business goals may cause inefficiency.

Best Practices for Implementing Strategic Sourcing

- Leverage ERP systems like Deskera ERP to centralize supplier data, track performance, and forecast demand.

- Ensure cross-functional collaboration between procurement, finance, and operations teams.

- Continuously monitor supplier performance and market conditions to adjust sourcing strategies.

- Start with pilot projects before fully scaling strategic sourcing initiatives.

- Align sourcing strategies closely with overall business objectives to ensure efficiency and long-term value.

By combining individual sourcing strategies within a strategic sourcing framework, businesses can make informed, flexible, and resilient procurement decisions. This balanced approach ensures supply chains remain robust, cost-efficient, and capable of adapting to changing market conditions.

Choosing the Right Sourcing Strategy for Your Business

Selecting the right sourcing strategy is crucial for building a resilient and efficient supply chain. There is no one-size-fits-all approach—each strategy comes with its own benefits, risks, and suitability depending on factors such as product criticality, demand variability, supplier reliability, and geographic considerations.

Businesses must carefully evaluate these factors to ensure their sourcing decisions align with overall objectives, including cost optimization, risk mitigation, and operational efficiency.

A structured approach helps organizations balance cost, risk, and flexibility while enabling them to respond quickly to market changes and disruptions. Below are key considerations and steps to guide businesses in choosing the most effective sourcing strategy.

1. Assess Product Criticality and Complexity

- Identify which products or components are mission-critical to your operations.

- High-value or specialized products may benefit from single sourcing or strategic partnerships to ensure quality and reliability.

- Less critical, high-volume items may be suitable for dual, multi, or low-cost country sourcing to optimize costs.

- Consider lead times, production complexity, and quality requirements when deciding supplier strategy.

2. Evaluate Supplier Reliability and Performance

- Assess historical performance, financial stability, and capacity of potential suppliers.

- Reliable suppliers reduce risk and may allow for single or dual sourcing.

- For volatile markets or uncertain supplier performance, multi-sourcing or nearshoring can provide greater resilience.

- Monitor suppliers continuously using KPIs such as on-time delivery, defect rates, and responsiveness.

3. Consider Cost Implications

- Total cost of ownership should guide sourcing decisions—not just the purchase price.

- Global or low-cost country sourcing can reduce direct costs but may increase logistics and risk expenses.

- Balance cost savings with potential risks to ensure sourcing decisions are financially sustainable.

- Factor in hidden costs like tariffs, shipping, quality control, and supplier management.

4. Factor in Risk and Disruption Management

- Analyze the potential risks in the supply chain, including natural disasters, geopolitical issues, and supplier failures.

- For high-risk environments, strategies such as dual sourcing, multi-sourcing, or nearshoring help diversify and mitigate exposure.

- Develop contingency plans and maintain backup suppliers to ensure continuity.

- Use risk assessment tools and ERP systems to track vulnerabilities in real time.

5. Align with Business Goals and Operational Priorities

- Ensure the chosen sourcing strategy supports long-term objectives like growth, sustainability, or innovation.

- Strategies like strategic sourcing or vertical integration may align with goals of efficiency, control, and sustainability.

- Evaluate whether sourcing decisions complement other supply chain functions such as production, logistics, and inventory management.

- Leverage technology like Deskera ERP to centralize data, forecast demand, and align sourcing with operational priorities.

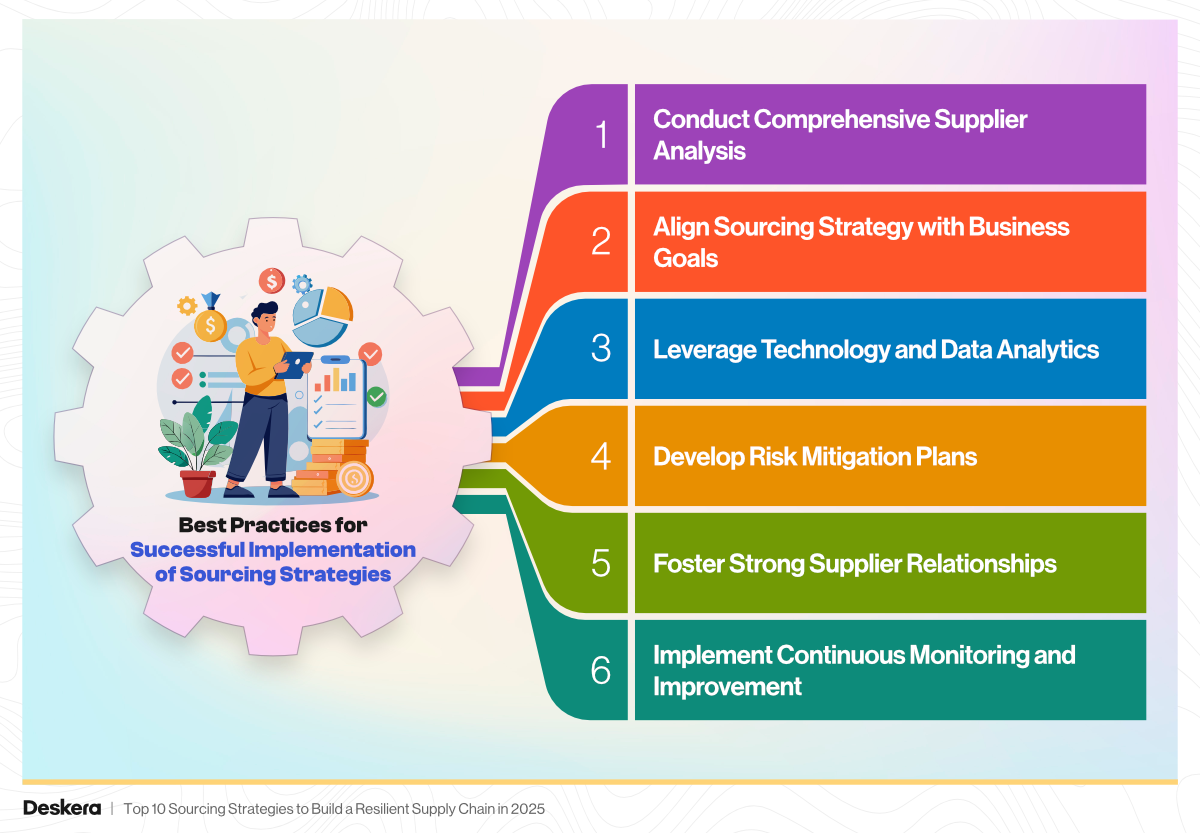

Best Practices for Successful Implementation of Sourcing Strategies

Implementing sourcing strategies effectively requires more than selecting the right approach—it demands careful planning, coordination, and continuous improvement.

Businesses that follow best practices can optimize costs, mitigate risks, and ensure long-term supply chain resilience. The following are key practices for successful sourcing strategy implementation:

1. Conduct Comprehensive Supplier Analysis

- Evaluate potential suppliers based on financial stability, capacity, quality, compliance, and past performance.

- Use structured assessment tools and scoring matrices to compare suppliers objectively.

- Maintain a mix of suppliers where necessary to balance risk and flexibility.

- Include both quantitative (cost, delivery time) and qualitative (trust, innovation capability) criteria.

2. Align Sourcing Strategy with Business Goals

- Ensure that sourcing decisions support long-term objectives such as cost optimization, sustainability, innovation, and growth.

- Tailor strategies for different product categories based on criticality, demand, and strategic importance.

- Integrate sourcing decisions with overall supply chain, production, and financial planning.

3. Leverage Technology and Data Analytics

- Use ERP systems like Deskera ERP to centralize supplier data, monitor performance, and track key metrics.

- Implement analytics tools to forecast demand, model risks, and evaluate sourcing scenarios.

- Automate procurement workflows to reduce errors and improve efficiency.

- Maintain real-time dashboards to support data-driven decisions.

4. Develop Risk Mitigation Plans

- Identify potential risks, including supplier failure, geopolitical instability, natural disasters, and logistics disruptions.

- Establish contingency plans, such as backup suppliers, buffer inventory, or alternative transportation routes.

- Monitor supplier risk continuously using scorecards and early-warning systems.

- Conduct periodic stress testing to evaluate supply chain resilience under adverse conditions.

5. Foster Strong Supplier Relationships

- Build long-term partnerships with key suppliers based on trust, transparency, and collaboration.

- Encourage joint problem-solving, innovation, and continuous improvement initiatives.

- Negotiate mutually beneficial contracts that balance risk, cost, and performance expectations.

- Engage suppliers in strategic planning discussions to align on goals and priorities.

6. Implement Continuous Monitoring and Improvement

- Regularly evaluate sourcing strategy performance using KPIs such as delivery reliability, cost savings, quality compliance, and risk reduction.

- Adjust sourcing strategies based on changing market conditions, supplier performance, or business needs.

- Encourage cross-functional collaboration to identify improvement opportunities across procurement, production, and logistics.

- Document lessons learned to inform future sourcing decisions and enhance organizational knowledge.

Future Trends in Sourcing (2025 and Beyond)

As we approach 2025, sourcing strategies are evolving rapidly, influenced by technological advancements, shifting global dynamics, and changing consumer expectations. Businesses must adapt to these trends to maintain competitiveness and resilience in their supply chains.

1. AI and Automation Integration

- Predictive Analytics: Leveraging AI to forecast demand fluctuations and identify potential supply chain disruptions before they occur.

- Robotic Process Automation (RPA): Automating repetitive tasks such as invoice processing and order management to increase efficiency and reduce human error.

- Enhanced Decision-Making: Utilizing machine learning algorithms to analyze vast amounts of data, enabling more informed and timely sourcing decisions.

2. Blockchain for Transparency and Security

- Supply Chain Traceability: Implementing blockchain to provide an immutable record of product journeys, enhancing transparency and trust with consumers.

- Smart Contracts: Using blockchain-based contracts to automate and secure transactions, reducing the risk of fraud and disputes.

- Regulatory Compliance: Ensuring adherence to international standards and regulations through transparent and verifiable sourcing practices.

3. Sustainability and Ethical Sourcing

- Environmental Impact: Prioritizing suppliers that adhere to sustainable practices, such as reducing carbon footprints and minimizing waste.

- Social Responsibility: Engaging with suppliers who uphold fair labor practices and contribute positively to their communities.

- Circular Economy: Embracing models that promote recycling, reuse, and the reduction of resource consumption throughout the product lifecycle.

4. Nearshoring and Regional Sourcing

- Supply Chain Resilience: Reducing dependency on distant suppliers to mitigate risks associated with geopolitical tensions, tariffs, and natural disasters.

- Cost Considerations: Balancing the potential for higher labor costs with savings in transportation and reduced lead times.

- Agility: Enhancing the ability to respond quickly to market changes and consumer demands by sourcing closer to end markets.

5. Digital Procurement Platforms

- E-Procurement Systems: Adopting cloud-based platforms to streamline procurement processes, improve collaboration, and provide real-time data analytics.

- Supplier Portals: Creating digital interfaces for suppliers to submit bids, track orders, and manage invoices, improving communication and efficiency.

- Data-Driven Insights: Utilizing integrated systems to gain actionable insights into spending patterns, supplier performance, and market trends.

6. Talent Transformation in Procurement

- Skill Development: Investing in training programs to equip procurement professionals with skills in data analysis, digital tools, and strategic sourcing.

- Collaborative Culture: Fostering a culture of collaboration between procurement teams and other departments to align sourcing strategies with overall business objectives.

- Leadership Evolution: Recognizing procurement leaders as strategic partners who contribute to innovation, risk management, and value creation within the organization.

7. Geopolitical and Economic Influences

- Trade Policies: Navigating the complexities of changing tariffs, trade agreements, and import/export regulations that impact sourcing decisions.

- Currency Fluctuations: Managing risks associated with exchange rate volatility, especially when dealing with international suppliers.

- Economic Shifts: Adapting to global economic changes that affect supply and demand dynamics, such as inflation rates and consumer spending behaviors.

The sourcing landscape in 2025 and beyond is characterized by technological innovation, a focus on sustainability, and a need for agility in response to global challenges. By embracing these trends, businesses can build more resilient, efficient, and ethical supply chains that meet the demands of the modern marketplace.

How Deskera ERP Can Help You With Sourcing

Managing sourcing strategies effectively requires real-time data, supplier insights, and streamlined processes. Deskera ERP offers a comprehensive solution to help businesses optimize sourcing, mitigate risks, and build resilient supply chains.

1. Centralized Supplier Management

- Maintain a single repository for all supplier data, including contact details, performance history, certifications, and compliance records.

- Evaluate suppliers consistently using KPIs such as on-time delivery, defect rates, and lead times.

- Easily identify high-performing suppliers for strategic sourcing decisions.

2. Demand Forecasting and Inventory Planning

- Utilize AI-driven forecasting tools to predict demand fluctuations and plan sourcing accordingly.

- Ensure the right inventory levels are maintained to prevent overstocking or stockouts.

- Align sourcing strategies with production requirements to improve efficiency and reduce costs.

3. Streamlined Procurement Workflows

- Automate purchase orders, approvals, and supplier communications to reduce manual errors and save time.

- Track procurement stages in real time, from requisition to payment.

- Improve collaboration between procurement teams and suppliers through integrated supplier portals.

4. Cost Optimization and Total Cost of Ownership

- Analyze spending patterns across suppliers and product categories to identify cost-saving opportunities.

- Evaluate the total cost of ownership (including logistics, tariffs, and quality costs) for informed sourcing decisions.

- Generate actionable reports to support negotiation and supplier selection.

5. Risk Management and Compliance

- Monitor supplier performance and compliance in real time to reduce operational risks.

- Identify potential disruptions and develop contingency plans proactively.

- Ensure sourcing practices meet regulatory requirements and sustainability standards.

6. Data-Driven Insights for Strategic Decisions

- Leverage dashboards and analytics to gain actionable insights into supplier performance, procurement trends, and market conditions.

- Make informed decisions about single, dual, multi, or global sourcing strategies.

- Continuously optimize sourcing strategies based on real-time data and historical trends.

With Deskera ERP, businesses can streamline sourcing operations, gain visibility across the supply chain, and make data-driven decisions that balance cost, risk, and efficiency. By centralizing supplier data, automating procurement workflows, and leveraging AI insights, Deskera ERP empowers organizations to implement robust sourcing strategies and maintain a resilient, agile supply chain.

Key Takeaways

- Supply chain disruptions are frequent and often prolonged, with 80% of organizations experiencing at least one in the past year; implementing effective sourcing strategies is critical for resilience.

- A sourcing strategy defines how a business selects, evaluates, and manages suppliers to optimize cost, quality, risk, and operational efficiency.

- Single Sourcing: Builds strong supplier relationships and ensures consistent quality but increases dependency risk.

- Dual Sourcing: Balances reliability and flexibility while requiring careful coordination.

- Multi-Sourcing: Diversifies risk and supports large demand but adds complexity in management and quality control.

- Global Sourcing: Reduces costs and provides access to innovation but requires managing long lead times and geopolitical risks.

- Local Sourcing: Offers faster delivery and lower shipping costs while potentially limiting supplier options.

- Nearshoring: Combines proximity and cost efficiency, enhancing supply chain agility while maintaining moderate risk.

- Outsourcing: Improves efficiency and access to expertise but reduces operational control.

- Insourcing: Provides full control and quality assurance but may increase costs and require capacity investment.

- Vertical Integration: Enhances supply stability and cost management but demands high capital and operational complexity.

- Captive Service Operations: Ensures reliable foreign operations and IP protection but requires significant setup investment.

- Strategic sourcing aligns procurement with business goals, optimizing cost, risk, and supplier performance while requiring careful planning to mitigate complexity and implementation risks.

- Selecting a sourcing strategy should consider product criticality, supplier reliability, costs, risk factors, and alignment with overall business objectives.

- Implementing sourcing strategies successfully requires comprehensive supplier analysis, alignment with business goals, technology adoption, risk mitigation, supplier collaboration, and continuous monitoring.

- Sourcing is increasingly driven by AI, automation, blockchain, sustainability, nearshoring, digital procurement platforms, talent transformation, and geopolitical awareness, requiring businesses to adopt agile, data-driven strategies.

- Deskera ERP centralizes supplier data, automates procurement workflows, provides demand forecasts, and delivers actionable insights, enabling businesses to implement resilient, efficient, and strategic sourcing strategies.

Related Articles