Quality control is an important part of furniture manufacturing. Without it, furniture can easily become damaged, and customers may not be satisfied with their purchase. Furniture manufacturers must ensure that their products meet the highest standards of quality before they are shipped off to stores and homes.

This article covers the following:

- What is Furniture Manufacturing?

- Quality Control in Furniture Manufacturing

- Benefits of Quality Control in Furniture Manufacturing

- Types of Quality Control in Furniture Manufacturing

- Automation in Furniture Manufacturing Quality Control

- Common Issues in Furniture Manufacturing Quality Control

- Benefits of Automation in Furniture Manufacturing Quality Control

- Challenges of Automation in Furniture Manufacturing Quality Control

- Best Practices for Furniture Manufacturing Quality Control

- Tips for Optimizing Furniture Manufacturing Quality Control

What is Furniture Manufacturing?

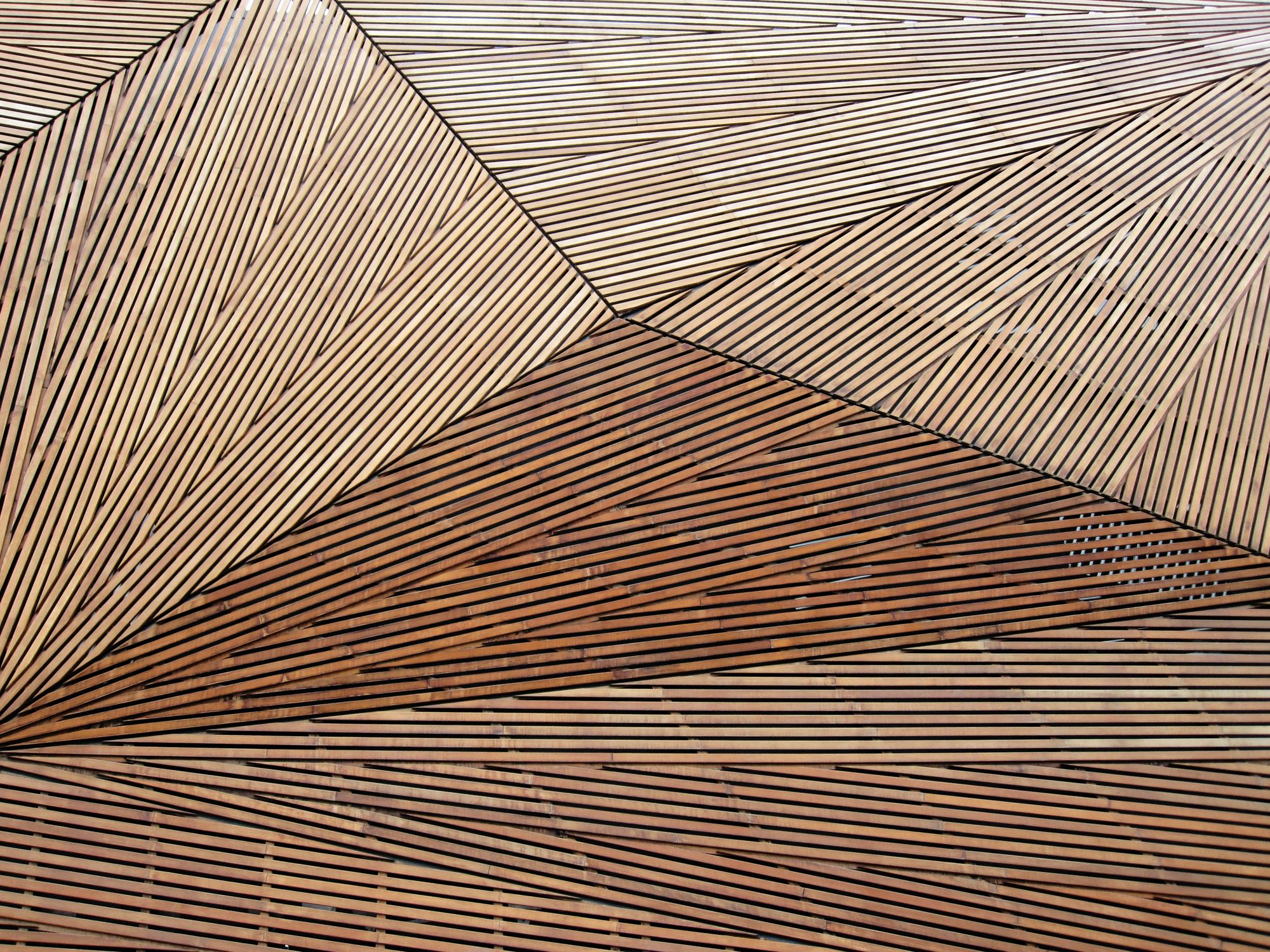

Furniture manufacturing is the process of creating and constructing furniture for everyday use. Furniture is made from a variety of materials, including wood, metal, plastic, and fabric, and the manufacturing process varies depending on the type of material used.

The first step in furniture manufacturing is material selection. The type of material used will depend on the kind of furniture being made. For example, if the furniture is made from wood, the type of wood used must be carefully chosen based on the desired look and durability of the furniture.

Once the material is selected, it is cut into the required shapes and sizes. This is followed by the joining of the pieces to create the structure. The next step in furniture manufacturing is finishing.

This includes sanding, staining, painting, and varnishing the pieces to create a smooth surface. This step is very important in ensuring the furniture looks attractive and is also durable.

The last step in furniture manufacturing is assembly. This involves putting all the pieces together to create the furniture. In some cases, the furniture may require additional pieces such as hinges and screws.

Assembling the furniture correctly is essential in creating a safe and stable product. Furniture manufacturing is a complex and time-consuming process. However, the end result is furniture that is both attractive and durable. With the right materials and techniques, furniture manufacturers can create stunning pieces of furniture that will last for years to come.

Quality Control in Furniture Manufacturing

Quality control is an integral part of any furniture manufacturing process. It ensures that the end product meets all the necessary standards of quality and durability.

Quality control is especially important for furniture because it is an item that is expected to last for many years, and poor quality control can lead to customer dissatisfaction and potential litigation.

The quality control process begins with the selection of raw materials. Furniture manufacturers should use only the highest quality materials available. This includes hardwoods, leather, fabrics, and finishes.

All of these components must be of the highest quality so that they can stand up to the daily wear and tear of use. Once the materials have been selected, the next step is to ensure that all pieces are properly constructed.

This includes using the right tools and techniques to create the desired shape, finish, and strength. Furniture manufacturers should also pay attention to the finishing touches, such as ensuring that all of the joints are properly aligned and that all of the hardware is properly installed.

The final step in quality control is testing. This includes testing the furniture for durability and strength. This should be done by a third-party testing agency, as it will provide an unbiased opinion of the product.

Quality control is essential to ensure that customers are satisfied with the furniture they purchase. By following these steps, furniture manufacturers can ensure that their products are of the highest quality. This will help to ensure customer satisfaction and help to protect the company from potential litigation.

Benefits of Quality Control in Furniture Manufacturing

When it comes to furniture manufacturing, quality control should always be a top priority. Quality control is a process that includes checking and testing products to ensure that they meet certain standards of quality.

Quality control can be especially important in the furniture manufacturing industry, as customers often have high expectations when it comes to the quality of their furniture. Benefits of Quality Control in Furniture Manufacturing

Improved Customer Satisfaction

Quality control helps to ensure that the furniture you manufacture is of the highest quality, which in turn leads to improved customer satisfaction. When customers know that the furniture they purchase is made to a high standard, they will be more likely to purchase from you again in the future.

Reduced Product Returns

Quality control helps to reduce the number of product returns. By ensuring that the furniture you manufacture meets certain standards of quality, you can reduce the number of customers who are unhappy with their purchase and want to return the product. This can save you time and money, as you don’t have to spend as much time and resources dealing with product returns.

Improved Brand Reputation

Quality control can help to improve your brand’s reputation. If your furniture is consistently made to a high standard, customers will be more likely to trust your brand and recommend it to others.

Cost Savings

Quality control can help to reduce costs associated with the manufacturing process. By catching potential defects and flaws early in the process, you can save money by avoiding costly rework or repairs.

Additionally, by ensuring that your furniture meets certain standards of quality, you can avoid having to deal with product returns, which can also save you time and money.

Overall, quality control is a key component of successful furniture manufacturing. Quality control helps to ensure that the furniture you manufacture meets certain standards of quality, which can lead to improved customer satisfaction, reduced product returns, improved brand reputation, and cost savings. By implementing a robust quality control process, you can rest assured that your furniture will be made to the highest standards.

Types of Quality Control in Furniture Manufacturing

Quality control has become increasingly important in the furniture manufacturing industry, as it helps to ensure that products are produced to meet customer expectations and industry standards.

Quality control also helps to identify potential problems during the manufacturing process and prevent them from becoming costly mistakes. There are many different types of quality control used in the furniture manufacturing industry, each with its own purpose and benefits.

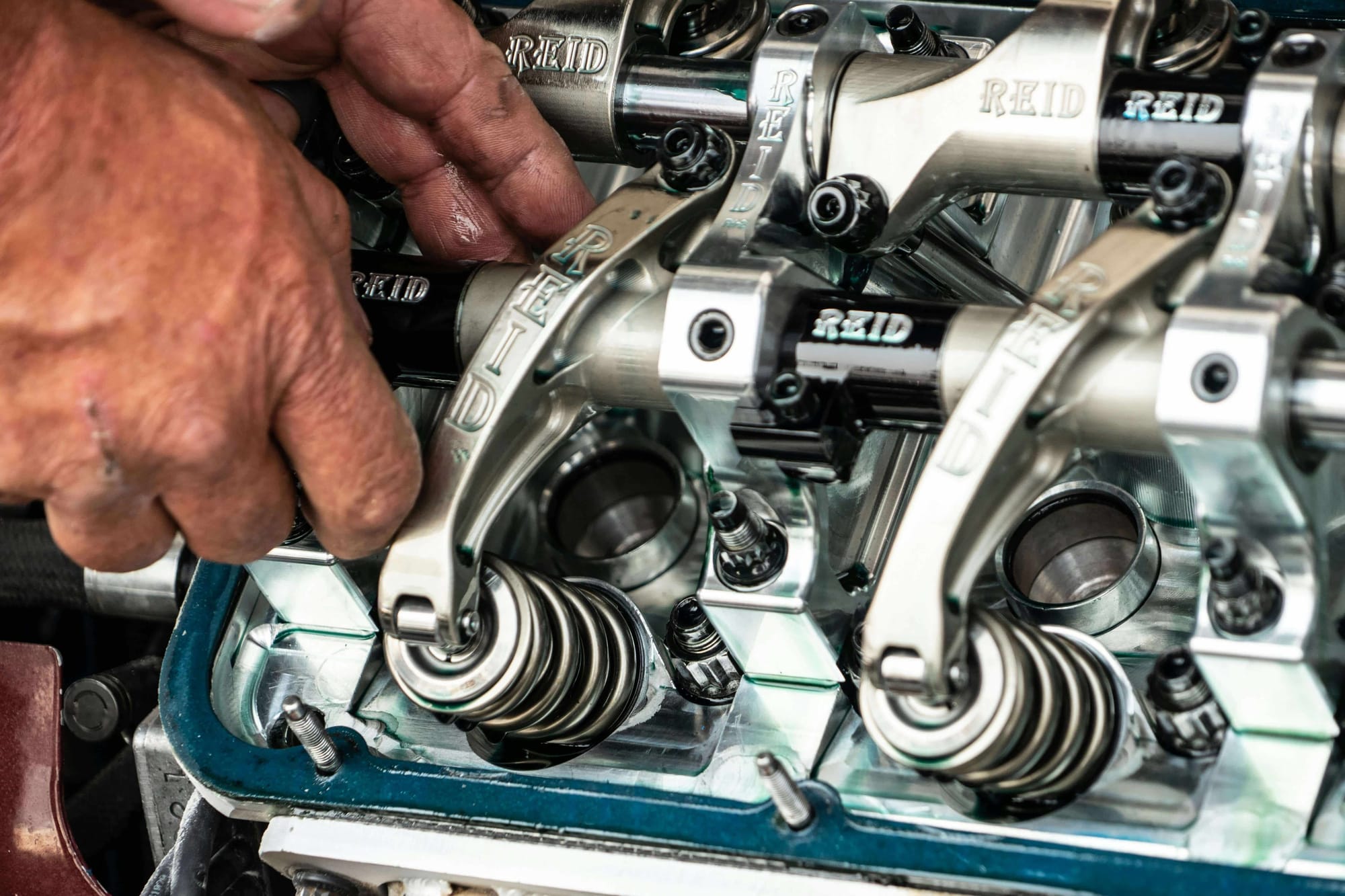

First and foremost, furniture manufacturers must use visual inspections to ensure that all products meet their quality standards. During these inspections, trained technicians carefully inspect each piece to check for any defects or discrepancies in the wood or other materials used.

These inspections are conducted in accordance with industry standards and are usually conducted by a third-party inspector. Another type of quality control used in the furniture manufacturing industry is measurement testing.

This type of testing helps to ensure that all components of furniture are the correct size and dimensions. Measurement testing is often done with the use of a caliper, which is a precision measuring instrument.

This type of testing helps to ensure that all parts of the furniture are the correct size and fit together properly. In addition to visual inspections and measurement tests, furniture manufacturers also use destructive testing.

This type of testing is used to test the strength and durability of furniture materials. For example, furniture manufacturers may use destructive testing to check the strength of glue joints, the strength of nails, and the strength of screws.

This type of testing helps to ensure that all furniture pieces are built to last and can stand up to everyday use. Finally, furniture manufacturers also use non-destructive testing to test the safety of their products.

This type of testing is used to check for issues such as flammability, toxicity, and any other potential hazards. Non-destructive testing is often conducted in accordance with industry standards and is sometimes done by a third-party inspector.

These are just a few of the different types of quality control used in the furniture manufacturing industry. Quality control plays an important role in the production of furniture, as it helps to ensure that products are produced to meet customer expectations and industry standards. By using quality control methods, furniture manufacturers can rest assured that their products will be of the highest quality.

Automation in Furniture Manufacturing Quality Control

In the furniture manufacturing industry, automation and quality control have become increasingly important in recent years. Automation in the furniture manufacturing process has been growing at a rapid rate, and it has become essential for furniture makers to stay competitive in the market.

Automation has been shown to improve product quality, increase efficiency, and reduce costs. Automation in furniture manufacturing can be broadly divided into two categories: automated production and automated quality control.

Automated production processes involve the use of machinery and robotics to perform tasks such as wood cutting, drilling, sanding, and assembly. Automated production allows for a higher level of precision and accuracy than manual processes, which in turn results in a better-quality product.

Automated production also increases speed and efficiency, resulting in cost savings. Automated quality control is the second category of automation in furniture manufacturing. Quality control is essential to ensure that the finished product meets customer expectations and safety standards.

Automated quality control involves the use of sensors and computer vision to detect flaws and defects in furniture pieces. The sensors and computer vision can detect flaws such as splinters, warps, and other imperfections that would have been difficult to detect through manual inspection.

Automated quality control systems can also provide data on the performance of different parts, making it easier to identify potential problems before they become expensive repairs.

Automation in furniture manufacturing has revolutionized the industry and has allowed furniture makers to produce higher-quality products at a lower cost. Automated production and quality control systems have made it easier to produce furniture that meets customer expectations and safety standards.

Automation has also allowed furniture makers to reduce waste and improve efficiency, resulting in cost savings. Automation has revolutionized the furniture industry and is sure to continue to do so in the future.

Common Issues in Furniture Manufacturing Quality Control

When it comes to furniture manufacturing, quality control is of utmost importance. Poorly designed or constructed furniture can lead to not only customer dissatisfaction but also product recalls and safety hazards.

As such, manufacturers must have stringent quality control processes in place to ensure that all furniture produced meets the highest standards. However, despite best efforts, there are often some common issues that can arise during the production process.

One of the most common issues in furniture manufacturing quality control is poor material selection. Choosing the wrong materials can lead to a piece of furniture being weak and prone to breakage.

It is important that manufacturers carefully consider the materials they use and select those that are strong enough to withstand the intended use of the furniture. Another issue that can arise in furniture manufacturing is poor craftsmanship.

While advances in automated production have made it easier and faster to produce furniture, there are still some elements of craftsmanship that cannot be automated. These include joinery, carving, and finishing.

If these steps are not done properly, the furniture may not last as long as it should or may not perform as intended. The third common issue in furniture manufacturing quality control is the use of inferior hardware.

While the furniture itself may be properly designed and constructed, if the hardware used is not up to par, it can weaken the overall structure of the piece. This can lead to furniture breaking down prematurely or becoming loose over time.

Lastly, a fourth common issue in furniture manufacturing quality control is the lack of a thorough testing process. Many manufacturers are so eager to get their furniture to market that they do not take the time to properly test their products before release.

This can lead to furniture that does not perform as expected or that is not safe to use. As such, it is important that manufacturers have a thorough testing process in place to ensure that all furniture they produce is of the highest quality.

By understanding these common issues in furniture manufacturing quality control, manufacturers can better equip themselves to produce furniture that meets the highest standards.

By taking the time to properly select materials, hire skilled craftspeople, use high-quality hardware, and implement a thorough testing process, manufacturers can ensure that their furniture will be of the highest quality and will last for many years to come.

Benefits of Automation in Furniture Manufacturing Quality Control

The furniture industry is an ever-evolving one, with manufacturers constantly looking for ways to increase production while maintaining quality standards. Automation is one of the best ways to do this, as it increases production and quality control while reducing costs.

Automation not only helps with the production of furniture, but it can also be used to improve quality control. Here are some of the benefits of automation in furniture manufacturing quality control.

Improved Efficiency

Automation can dramatically increase the speed and accuracy of quality control in furniture manufacturing. Machines can inspect items much faster than humans and with greater precision, allowing manufacturers to spot any potential defects and address them before they become a problem. This increases efficiency and helps to ensure that only the highest-quality furniture is produced.

Reduced Waste

Automation can reduce the amount of waste generated during the furniture manufacturing process. By using automated quality control systems, manufacturers can quickly identify any defects and address them, rather than having to dispose of a large amount of material due to a fault. This helps to reduce costs and improve the efficiency of the production process.

Increased Productivity

Automation can also help to increase productivity. As automation takes over some of the more labor-intensive tasks, such as quality control, manufacturers can free up personnel to focus on other tasks. This can help to reduce production times and increase overall productivity.

Reduced Risk of Human Error

One of the main benefits of automation in furniture manufacturing quality control is that it reduces the risk of human error. Automated quality control systems can be programmed to detect any potential defects and address them before they become a problem, reducing the risk of faulty furniture being produced.

This can help to reduce costs and improve customer satisfaction. The furniture industry is constantly evolving, and automation can help manufacturers stay ahead of the curve.

Automation can improve quality control, reduce waste, increase productivity and reduce the risk of human error. By investing in automated quality control systems, furniture manufacturers can ensure that only the highest-quality furniture is produced.

Challenges of Automation in Furniture Manufacturing Quality Control

The furniture industry is one of the oldest and most diverse industries in the world. As technology advances, the need for automation in furniture manufacturing and quality control has become more and more important.

Automation can help to improve the efficiency and accuracy of the production process, reduce costs, and improve product quality. However, automation in furniture manufacturing and quality control is not without its challenges.

Automated systems can be complex and require a great deal of expertise to implement and maintain. Additionally, automated systems require a significant upfront investment of time and money.

Furthermore, automated systems may not be suitable for all types of furniture manufacturing and quality control. For example, a manufacturer of custom furniture may find it difficult to automate certain processes due to the unique characteristics of each individual piece of furniture.

Finally, automated systems can be prone to errors and malfunctions. This can lead to mistakes in the production process, resulting in poor quality control, and costly rework. To overcome these challenges, furniture manufacturers must invest in the right automation technologies and processes.

These technologies should be tailored to the specific needs of the business and should be regularly monitored and maintained to ensure they are functioning properly. Additionally, a well-trained and qualified workforce is essential to ensure that any automated system is properly implemented and used.

By investing in automation and quality control processes, furniture manufacturers can increase the efficiency and accuracy of their production process, reduce costs, and improve product quality. This will help ensure that the finished product is of the highest quality and meets customer expectations.

Best Practices for Furniture Manufacturing Quality Control

Quality control is a critical part of any furniture manufacturing process. From ensuring the materials that are used are of the highest quality to making sure that the finished product meets the customer's expectations, furniture manufacturers need to take a variety of steps to ensure that their furniture is of the highest quality. Below are some of the best practices for furniture manufacturing quality control.

Source Quality Materials

Quality furniture starts with quality materials. Choose suppliers that provide high-grade materials and have a good reputation. It is also important to inspect the materials upon arrival to ensure that they meet your standards.

Establish a Quality Control Plan

Having a well-defined quality control plan is essential for any furniture manufacturing process. This plan should include the steps that need to be taken to ensure that the furniture meets your standards. This should include testing the materials, inspecting each piece of furniture, and ensuring that all of the parts are working correctly.

Have a Robust Testing Process

Once you have sourced the materials and established the quality control plan, it is important to have a robust testing process. This should include testing the materials for any defects and ensuring that the finished product meets all of the customer's expectations.

Regularly Inspect the Manufacturing Process

Regularly inspecting the manufacturing process is essential to ensuring that the furniture is of the highest quality. This can include inspecting each piece of furniture for any defects, as well as checking that all of the parts are properly installed.

Have a Quality Assurance Team

Having a quality assurance team is important for any furniture manufacturing process. This team should be responsible for regularly inspecting the furniture and ensuring that all of the quality control procedures are being followed.

By following these best practices for furniture manufacturing quality control, you can ensure that all of the furniture you produce is of the highest quality and meets the customer's expectations.

Quality control is essential for any furniture manufacturing process, and following these practices will help to ensure that the furniture you produce is of the highest quality.

Tips for Optimizing Furniture Manufacturing Quality Control

When it comes to furniture manufacturing, quality control is essential. Poor quality control can lead to issues with customer satisfaction, safety concerns, and even costly product recalls.

Fortunately, there are ways to optimize your furniture manufacturing quality control to ensure that your products are up to the highest standards. Here are a few tips to help you get started.

Set Quality Standards

Make sure that your furniture is manufactured to a certain set of standards. This could include everything from the type of materials used to the level of craftsmanship expected in each piece of furniture. Setting these standards will ensure that your furniture is consistently produced to a high quality.

Use Automation

Automation can be a great way to improve the accuracy and efficiency of your furniture manufacturing process. Investing in automated machines and processes can help to reduce the time it takes to produce furniture and ensure that each piece is produced to the highest standard.

Establish a Quality Assurance Team

Having a dedicated quality assurance team is essential for furniture manufacturers. This team should be responsible for inspecting each piece of furniture for defects and ensuring that it meets the set standards. They should also be on the lookout for any potential areas of improvement for the manufacturing process.

Invest in Testing Equipment

Investing in testing equipment can help to ensure that your furniture is of the highest quality. Testing equipment can help to identify any issues with the furniture before they become a problem. This can help to save time, money, and potential customer dissatisfaction.

Monitor Quality at All Stages

Make sure that you are monitoring quality at all stages of the manufacturing process. This can include inspecting raw materials, monitoring the production process, and testing finished furniture.

Doing this will help to identify any potential issues before they become a problem. By following these tips, you can optimize your furniture manufacturing quality control and ensure that your products are always of the highest quality.

Investing in the right equipment, setting standards, and having a dedicated quality assurance team are all essential for ensuring that your furniture is up to par. By taking the time to optimize your furniture manufacturing quality control, you can ensure that your customers are satisfied and that your furniture is safe and reliable.

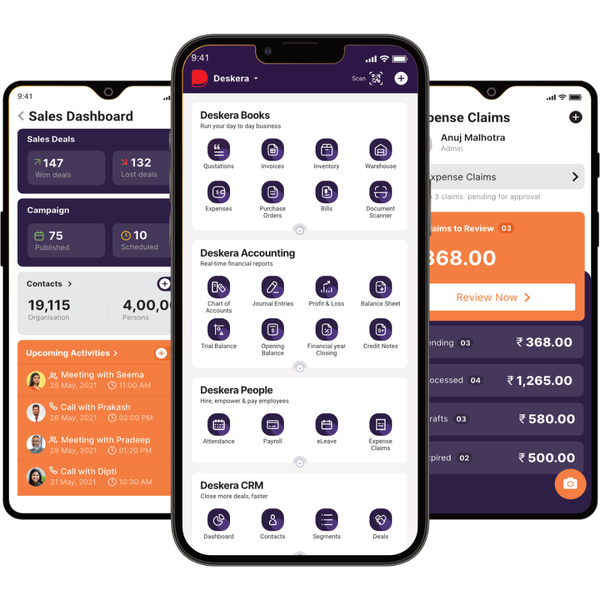

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Sustainable wood is becoming increasingly popular as people become more conscious of the environment and their impact on it.

- Sustainable wood is a great choice for furniture and home décor, as it helps reduce our impact on the environment.

- When it comes to sustainability, wood is one of the most abundant and renewable resources available to us.

- With the increasing concern about global warming and deforestation, it's important to make sure the wood we buy is sourced from sustainable sources.

- Many companies are now labeling their wood with labels that indicate where the wood was sourced and how it was harvested. Look for labels that say FSC-certified, SFI-certified, or PEFC-certified.

Related Articles: