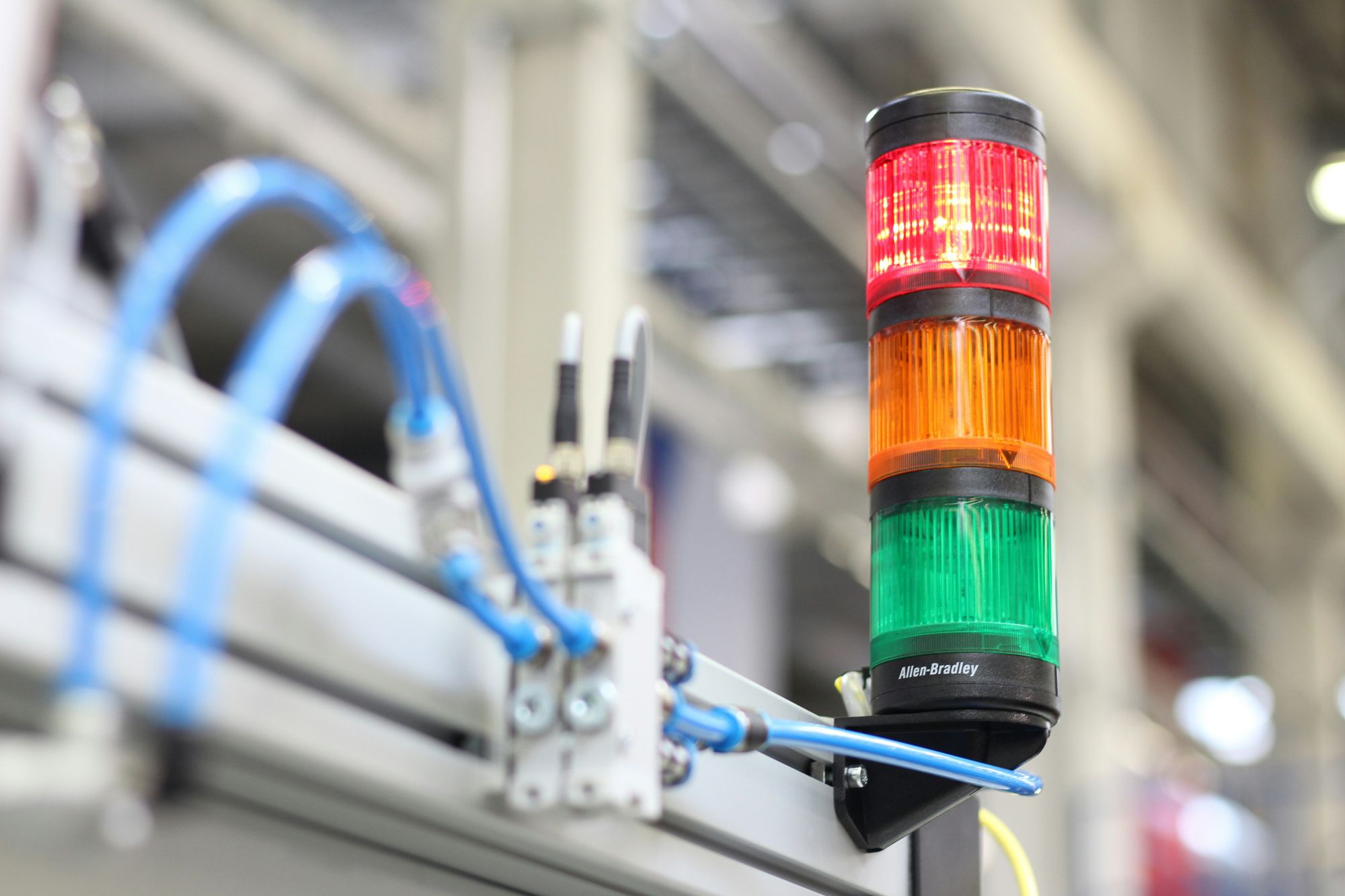

How quickly can your operations bounce back when a machine breaks down? The answer often determines whether a minor disruption stays manageable or turns into costly downtime. In fast-paced manufacturing and asset-intensive environments, the speed at which issues are diagnosed and resolved is just as important as preventing failures in the first place. This is where Mean Time to Repair (MTTR) becomes a critical metric for operational resilience.

Mean Time to Repair measures the average time required to repair a failed asset and restore it to normal working condition. It goes beyond just fixing the problem—it includes diagnosing the issue, arranging resources, completing repairs, and validating performance before the asset is back online. A lower MTTR indicates efficient maintenance processes, faster response times, and better coordination across teams, all of which directly influence uptime and productivity.

As production systems become more interconnected and customer expectations continue to rise, organizations can no longer afford prolonged equipment downtime. High MTTR not only impacts output but also increases maintenance costs, disrupts production schedules, and puts pressure on service-level commitments. This makes MTTR a vital performance indicator for maintenance, reliability, and operations teams aiming to balance efficiency with cost control.

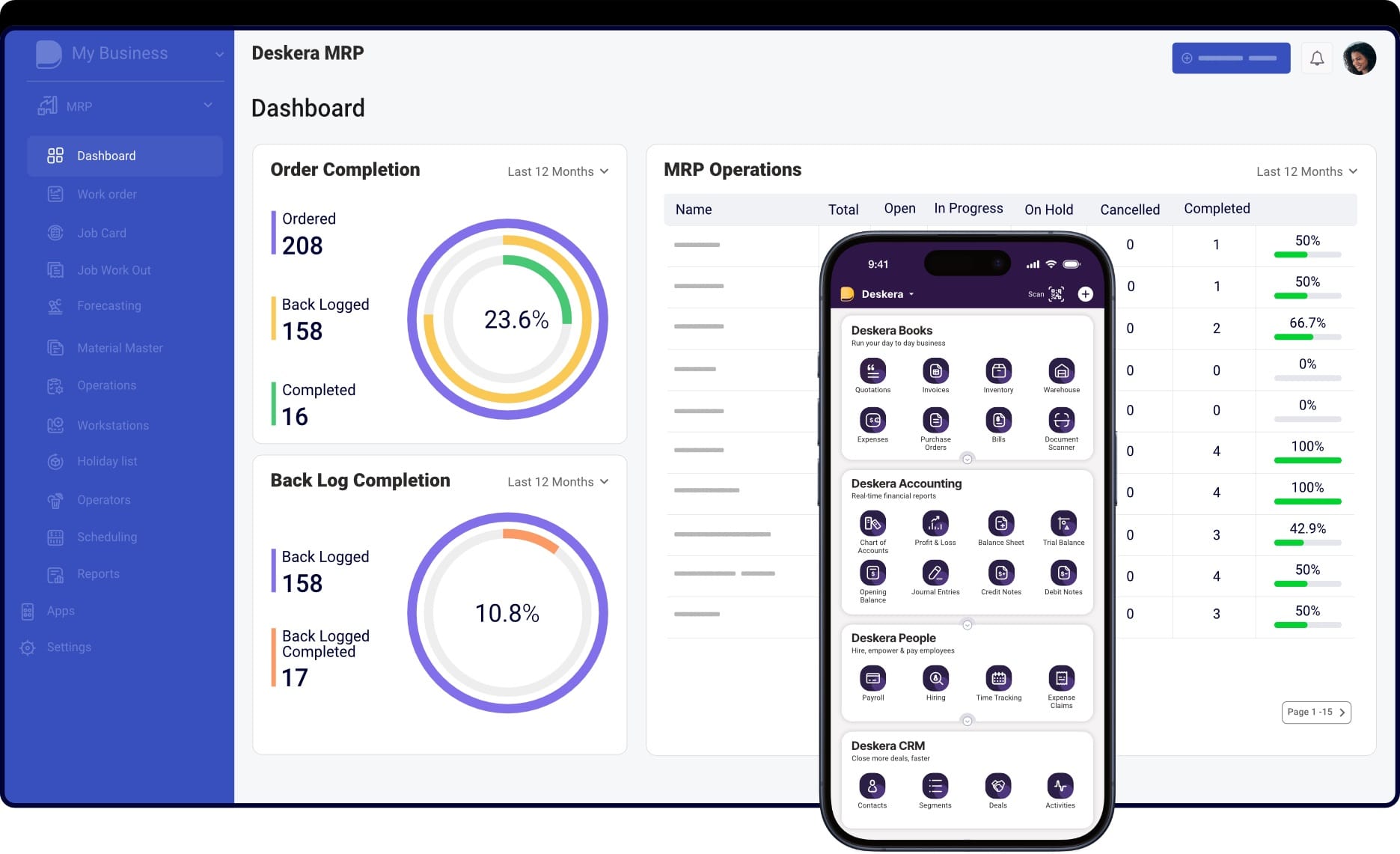

Modern manufacturing ERP solutions such as Deskera Manufacturing ERP play a key role in improving MTTR by bringing structure and visibility to maintenance operations. Deskera enables centralized work order management, real-time breakdown reporting, and easy access to asset histories and maintenance records. With better data accuracy, faster issue tracking, and streamlined coordination between maintenance and production teams, organizations can significantly reduce repair times and improve overall equipment availability.

What Is Mean Time to Repair (MTTR)?

Mean Time to Repair (MTTR) is a key maintenance and incident response metric used to measure how efficiently an organization restores a failed system, asset, or service back to normal operation. It represents the average time taken to diagnose, fix, test, and return a malfunctioning system to service after a failure has been detected. MTTR is widely applied across manufacturing, field service management, IT operations, fleet management, and software environments, making it one of the most versatile and widely tracked performance indicators.

At its core, MTTR reflects the speed and effectiveness of an organization’s response to failures. A lower MTTR indicates that teams can quickly identify issues, mobilize resources, and complete repairs with minimal disruption. Conversely, a high MTTR often signals deeper operational issues such as inefficient maintenance workflows, delayed incident response, lack of spare parts, skill gaps, or aging equipment that is harder to maintain. Because of this, MTTR is commonly used as a key performance indicator (KPI) by operations leaders, maintenance managers, and technical decision-makers.

MTTR is often analyzed alongside Mean Time Between Failures (MTBF) to assess overall system resilience. While MTBF measures how frequently failures occur, MTTR measures how long it takes to recover once they do. Together, these metrics provide a balanced view of equipment reliability, availability, and operational efficiency. Strong MTBF combined with a low MTTR indicates a resilient system that not only fails less often but also recovers quickly when issues arise—directly supporting higher uptime and profitability.

It is important to note that MTTR captures the typical or average repair time, not a guaranteed resolution window. It includes multiple phases such as failure detection, diagnosis, repair or resolution, and verification or testing before operations resume. In many organizations, MTTR is embedded into service level agreements (SLAs) to define performance expectations for maintenance and service providers. However, while MTTR is highly valuable, it does have limitations—particularly in scenarios where detection delays are significant. In such cases, organizations may also track mean time to recovery to account for the full duration of downtime from failure occurrence to complete restoration.

MTTR vs Other Maintenance Metrics

Mean Time to Repair (MTTR) is a powerful indicator of how quickly an organization can recover from failures, but it does not operate in isolation. To gain a complete picture of maintenance performance, MTTR should be analyzed alongside other key maintenance metrics that measure reliability, availability, and failure behavior. Each metric answers a different operational question, and together they provide a more balanced view of asset health and system resilience.

MTTR vs Mean Time Between Failures (MTBF)

MTTR measures how long it takes to fix a failure, while Mean Time Between Failures (MTBF) measures how often failures occur. MTBF represents the average operating time between one failure and the next, making it a reliability-focused metric.

A high MTBF indicates stable, well-performing equipment, whereas a low MTBF suggests frequent breakdowns. When paired together, MTTR and MTBF reveal whether downtime is driven by frequent failures, slow repairs, or both—helping teams prioritize preventive maintenance or process improvements accordingly.

MTTR vs Mean Time to Failure (MTTF)

Mean Time to Failure (MTTF) applies primarily to non-repairable assets or components, such as sealed electronics or consumable parts. It measures the average time an asset operates before it fails permanently.

Unlike MTTR, which focuses on restoration, MTTF is concerned with lifespan and replacement planning. While MTTR helps improve repair efficiency, MTTF supports decisions around asset replacement, redundancy, and long-term reliability planning.

MTTR vs Mean Time to Detect (MTTD)

Mean Time to Detect (MTTD) measures how long it takes to identify that a failure has occurred. MTTR typically starts once a failure is detected, meaning detection delays may not be reflected in MTTR alone.

A low MTTD ensures issues are identified quickly, allowing repair activities to begin sooner. When MTTD is high, actual downtime may be far greater than MTTR suggests, making it important to track both metrics together.

MTTR vs Mean Time to Recover (MTTR – Recovery)

The term MTTR is sometimes used to mean Mean Time to Recover, Resolve, or Restore, particularly in IT and digital operations. In these cases, MTTR includes the full duration from the onset of a failure through complete service restoration, including detection and validation. This broader definition provides a more accurate view of user-impacting downtime, especially when failures are not immediately visible.

MTTR vs Equipment Availability

Availability measures the percentage of time an asset or system is operational and ready for use. It is influenced by both how often failures occur (MTBF) and how quickly repairs are completed (MTTR).

Even highly reliable equipment can have poor availability if MTTR is high, while fast repair times can help offset occasional failures. As MTTR increases, availability typically decreases, making repair efficiency a key driver of operational uptime.

Why These Metrics Work Best Together

No single maintenance metric tells the whole story. MTTR highlights repair efficiency, MTBF and MTTF reflect reliability, MTTD exposes detection gaps, and availability captures the overall operational impact.

When analyzed together, these metrics enable organizations to identify root causes of downtime, optimize maintenance strategies, and make data-driven decisions that improve both performance and cost efficiency.

Key Factors Influencing Mean Time to Repair (MTTR)

Mean Time to Repair is shaped by far more than the moment a failure occurs. It reflects how well an organization is prepared to respond—across people, processes, technology, and operating conditions. Even with the same type of failure, MTTR can vary significantly depending on how these factors interact.

Below are the most influential elements that determine how quickly assets and systems can be restored to normal operation.

Asset Complexity and Equipment Health

The nature of the asset itself plays a major role in repair duration. Highly complex equipment with integrated electronics, embedded software, or custom-built components typically requires deeper diagnostics and specialized expertise.

In addition, older or poorly maintained assets are more prone to unexpected complications during repairs, which can further extend downtime and increase MTTR.

Spare Parts Visibility and Readiness

Repair efforts often stall when the required parts are unavailable or difficult to locate. A lack of visibility into spare parts inventory, poor storage practices, or long procurement lead times can significantly delay restoration.

Organizations with well-organized inventories and clear access to critical spares are far better positioned to keep MTTR under control.

Diagnostic Capabilities and Repair Tools

The speed of diagnosis directly affects repair time. When technicians lack the right tools or rely on manual troubleshooting, identifying the root cause can take far longer than necessary.

Access to proper diagnostic equipment, standardized toolkits, and modern repair technologies enables faster issue isolation and more accurate fixes, reducing overall MTTR.

Maintenance Team Expertise and Capacity

The skill level and availability of maintenance personnel strongly influence repair efficiency. Experienced technicians can quickly assess failures, choose the correct repair approach, and avoid unnecessary rework.

On the other hand, understaffed teams or limited expertise can create response delays, misdiagnosis, and longer recovery times—especially during simultaneous or complex breakdowns.

Documentation, Asset History, and Knowledge Sharing

Reliable documentation shortens repair cycles by eliminating guesswork. Up-to-date asset records, maintenance histories, and standardized repair instructions help technicians understand past failures and proven solutions.

When knowledge is captured and shared effectively, teams can resolve recurring issues faster and prevent the same problems from driving up MTTR repeatedly.

Maintenance Processes and Incident Response Discipline

Structured maintenance workflows and clearly defined response procedures reduce variability in repair times. Organizations that rely on consistent processes—rather than ad hoc decision-making—can initiate repairs faster, maintain safety and quality standards, and ensure predictable outcomes. Strong governance also helps align teams around priorities, especially during critical incidents.

Operating Conditions and Environmental Constraints

External conditions such as extreme temperatures, hazardous locations, or remote facilities can complicate repairs and extend downtime. Limited accessibility, safety requirements, or poor visibility can slow even well-planned maintenance activities. While these factors are often unavoidable, proper planning, protective equipment, and mobile support capabilities can help minimize their impact on MTTR.

By addressing these influencing factors holistically, organizations can move beyond reactive fixes and build a more resilient maintenance strategy—one that consistently reduces MTTR and strengthens overall operational performance.

How to Calculate Mean Time to Repair (MTTR)

Mean Time to Repair (MTTR) measures the average duration for which repair activities remain open after a failure occurs.

In simple terms, it tells you how long it typically takes to restore an asset, system, or service to normal operation once an unplanned issue is identified.

Because MTTR directly reflects downtime, it is a critical metric for understanding operational efficiency, maintenance effectiveness, and service reliability.

MTTR Formula

The standard formula for calculating MTTR is:

MTTR = Total Repair (Downtime) Time ÷ Total Number of Incidents

Here, total repair time refers to the cumulative time spent resolving unplanned failures during a defined period, while total number of incidents refers to how many breakdowns or service calls occurred in that same timeframe. MTTR is most commonly expressed in hours.

What Time Is Included in MTTR?

MTTR typically starts when a failure is detected or reported and ends when the asset or system is fully operational again. This includes:

- Time taken to detect and acknowledge the failure

- Diagnosis and troubleshooting

- Actual repair or resolution work

- Testing and verification before returning to service

In most cases, organizations exclude external lead times such as waiting for spare parts to be delivered, but they do include the time spent locating and using parts already in inventory. Because definitions can vary, it’s important to clearly define what MTTR includes—especially when it is used in service level agreements (SLAs).

Step-by-Step MTTR Calculation

- Select a time period: Choose a consistent timeframe for analysis—monthly, quarterly, or annually.

- Track total unplanned maintenance time: Record the full duration of downtime for each unplanned failure, from detection to restoration.

- Count the number of failures: Only include unexpected breakdowns or incidents that required corrective maintenance, not scheduled or preventive tasks.

- Apply the formula: Divide the total repair time by the number of incidents to calculate the average repair duration.

MTTR Calculation Example

If a manufacturing team spent 40 total hours repairing equipment failures over a quarter and addressed 25 separate incidents, the MTTR would be:

40 ÷ 25 = 1.6 hours, or 1 hour and 36 minutes

This means that, on average, each failure took about 1 hour and 36 minutes to resolve.

Interpreting MTTR Results

- Low MTTR indicates fast diagnosis, efficient repair processes, and minimal downtime.

- High MTTR suggests delays in detection, lack of resources, complex repairs, or inefficient incident response workflows.

While there is no universal “ideal” MTTR, many organizations aim for under five hours, depending on asset criticality, industry, and operating conditions. MTTR should also be analyzed alongside metrics like Mean Time Between Failures (MTBF) to understand overall availability and reliability. As MTTR increases, system availability typically declines—making continuous monitoring and improvement essential.

Benefits of Measuring Mean Time to Repair (MTTR)

Measuring Mean Time to Repair (MTTR) provides organizations with a clear, data-driven view of how effectively they respond to failures and restore operations. Because MTTR is closely tied to downtime, productivity, and service reliability, tracking it consistently delivers both operational and financial advantages across maintenance, IT, and service-driven environments.

Improved Accountability and Performance Visibility

MTTR creates a transparent benchmark for evaluating the performance of maintenance teams, field service staff, and incident response teams. By setting clear MTTR targets, organizations can hold teams accountable for response and resolution times while identifying performance gaps at the individual, team, or facility level.

Stronger Benchmarking and Competitive Comparison

MTTR enables meaningful benchmarking against internal baselines, industry standards, and competitor performance. Tracking MTTR over time helps organizations measure the impact of process improvements and demonstrate measurable gains in operational maturity, reliability, and service quality.

Higher Maintenance Efficiency

A rising MTTR often signals inefficiencies in repair workflows, diagnostics, or coordination. Measuring MTTR allows organizations to pinpoint bottlenecks, refine maintenance procedures, and standardize best practices. As processes become more streamlined, repair times shorten and overall maintenance effectiveness improves.

Smarter Resource Allocation

Consistently high MTTR can indicate shortages in skilled labor, tools, or spare parts. By analyzing MTTR at the asset or site level, organizations can make informed decisions about where to invest—whether that means adding technicians, improving spare parts availability, or upgrading diagnostic capabilities.

Increased Equipment Uptime and Availability

Lower MTTR directly translates into faster recovery and higher equipment availability. When assets return to service sooner, organizations experience fewer production delays, improved schedule adherence, and greater operational stability—especially in asset-intensive industries.

Reduced Downtime Costs and Better ROI

Downtime is expensive. Measuring and improving MTTR helps minimize lost production, missed revenue opportunities, and emergency repair costs. Faster repairs also extend asset life and improve return on investment by ensuring equipment delivers maximum value over its operational lifespan.

Improved Customer and User Experience

Extended outages negatively impact customers and internal users alike. A lower MTTR means quicker service restoration, fewer disruptions, and more reliable delivery—leading to higher customer satisfaction, stronger trust, and improved retention.

Better SLA Compliance and Risk Reduction

Many service level agreements include MTTR commitments. Tracking MTTR helps organizations stay within contractual limits, avoid penalties, and protect brand reputation. Consistent MTTR performance also reduces the risk of escalation during critical incidents.

Support for Data-Driven Decision-Making

MTTR provides actionable insights into asset reliability, failure patterns, and repair effectiveness. These insights support smarter decisions around predictive maintenance, equipment upgrades, replacement planning, and long-term reliability strategies.

Higher Employee Productivity and Morale

Frequent breakdowns and slow repairs disrupt employee workflows and create frustration. Lower MTTR ensures systems and equipment remain available, allowing teams to focus on productive, value-adding work rather than constant firefighting.

By consistently measuring and improving MTTR, organizations can reduce downtime, control costs, enhance reliability, and strengthen overall business performance—making MTTR one of the most impactful maintenance KPIs across industries.

What Does MTTR Mean for Maintenance?

Mean Time to Repair (MTTR) is more than just a technical reliability metric—it offers a practical window into how effectively a maintenance function operates on a day-to-day basis.

By analyzing MTTR, maintenance leaders can uncover delays in workflows, gaps in planning, and inefficiencies in execution that directly contribute to production downtime and higher operating costs. In essence, MTTR helps maintenance teams pinpoint where time is being lost and why.

Guiding Repair-vs-Replacement Decisions

MTTR plays a critical role in deciding whether an asset should be repaired or replaced. When repair times for aging equipment continue to increase, it often indicates diminishing returns on maintenance efforts.

In such cases, replacing the asset may be more economical than repeatedly repairing it. MTTR trends also support long-term procurement and asset design decisions by revealing the true lifecycle cost and maintainability of equipment.

Improving Preventive Maintenance Effectiveness

Although MTTR focuses on reactive maintenance, it strongly influences preventive maintenance (PM) strategies. Assets with consistently high MTTR may point to poorly defined or ineffective PM tasks.

For example, non-standardized work orders—such as lubrication tasks without clear specifications—can lead to incomplete maintenance and recurring failures. Using MTTR insights to refine PM schedules, task definitions, and standardization helps reduce breakdown frequency and shortens repair times.

Strengthening MRO Inventory Management

Extended MTTR is often a symptom of weak maintenance, repair, and operations (MRO) inventory practices. Missing, mislabeled, or poorly organized spare parts can significantly delay repairs, forcing technicians to spend valuable time searching for components instead of fixing equipment.

By correlating MTTR data with spare parts availability, maintenance teams can identify critical parts that frequently cause delays and improve forecasting, stocking, and part classification strategies.

Enhancing Maintenance Planning and Execution

At a broader level, MTTR reflects how well maintenance activities are planned, scheduled, and executed. High MTTR may signal issues such as inefficient task sequencing, limited technician availability, or lack of access to accurate asset information. Regularly tracking and reviewing MTTR enables maintenance teams to address these bottlenecks, improve coordination, and build a more responsive maintenance operation.

In summary, MTTR serves as a diagnostic metric for maintenance performance. When used correctly, it helps teams move beyond firefighting and toward smarter asset decisions, stronger preventive maintenance programs, and more efficient use of people, parts, and time.

Challenges of Measuring Mean Time to Repair (MTTR)

While Mean Time to Repair (MTTR) is a valuable indicator of repair efficiency and operational responsiveness, measuring it accurately is not always straightforward. Even small inconsistencies in how data is captured or interpreted can significantly distort results, reducing the metric’s usefulness for decision-making.

Below are some of the most common challenges organizations face when measuring MTTR.

Inconsistent Definitions of “Repair”

One of the biggest challenges is agreeing on what exactly constitutes a repair. Some teams start the MTTR clock when a failure is detected, while others begin timing only when a technician starts working on the issue.

Similarly, the end point may be defined as a temporary workaround or a permanent fix. These variations make MTTR calculations inconsistent and difficult to compare across teams, assets, or organizations.

Poor Data Quality and Limited Availability

Accurate MTTR calculations depend on complete and reliable data for every repair incident. In many organizations, data collection is manual, fragmented, or incomplete, leading to missing timestamps or inaccurate repair durations.

Limited failure data—especially for assets that rarely break down—can also make it difficult to calculate a meaningful average.

Delays in Detection and Manual Triage

When failures are not immediately detected or properly logged, the actual downtime may be far longer than what MTTR reflects.

Manual incident reporting and unclear prioritization can introduce gaps between failure occurrence and repair initiation, resulting in MTTR values that underestimate the true impact of downtime.

Multiple or Cascading Failures

Simultaneous or cascading system failures complicate MTTR measurement. When one failure triggers downstream issues, isolating repair times for individual assets or systems becomes difficult.

Dependencies between systems can blur the boundaries of where one repair ends and another begins, skewing MTTR calculations.

Variability in Repair Complexity

Not all failures are equal. Minor issues may be resolved quickly, while complex or intermittent problems can require extensive troubleshooting and testing.

This wide variation can distort MTTR averages, especially when rare but severe incidents significantly increase repair time and mask everyday performance.

Temporary Fixes vs Permanent Resolutions

In many cases, teams implement quick workarounds to restore operations before addressing the root cause. If MTTR is measured only until service is temporarily restored, it may underrepresent the true effort required to fully resolve the issue. This makes it difficult to assess long-term maintenance effectiveness.

Lack of Standardized Processes

Without standardized maintenance procedures and documentation practices, repair times can vary widely across technicians and locations.

Inconsistent workflows make it harder to establish reliable benchmarks and reduce confidence in MTTR as a performance metric.

Difficulty in Benchmarking and Comparison

Because MTTR definitions, asset criticality, and operating environments vary across organizations, comparing MTTR against industry benchmarks can be misleading. Without context, MTTR alone may not accurately reflect true performance or operational maturity.

To overcome these challenges, organizations need clear definitions, consistent data collection methods, standardized maintenance processes, and supporting systems that capture repair data accurately. When measured correctly, MTTR becomes a reliable foundation for improving uptime, efficiency, and overall maintenance performance.

Strategies for Improving Mean Time to Repair (MTTR)

Reducing Mean Time to Repair requires a deliberate, ongoing effort that addresses every stage of the repair lifecycle—from early fault detection to final verification.

Organizations that consistently improve MTTR focus not only on fixing failures faster, but also on building systems, processes, and skills that prevent delays before they occur.

The following strategies can help maintenance and operations teams achieve faster, more reliable recovery.

Strengthen Preventive and Predictive Maintenance

Routine inspections help identify wear, damage, or performance degradation before failures escalate into major breakdowns. Predictive maintenance takes this a step further by using sensors, telemetry, and condition-monitoring data to anticipate failures and schedule interventions at the right time. By reducing the severity of failures, both approaches significantly shorten repair durations.

Improve Failure Detection and Monitoring

The faster a failure is detected, the sooner repair activities can begin. Remote monitoring, real-time alerts, and automated detection systems reduce the lag between failure occurrence and response. Early detection also limits secondary damage, making repairs simpler and faster.

Standardize Repair Processes and SOPs

Clearly defined repair procedures and incident response playbooks remove uncertainty during high-pressure situations. Standard operating procedures (SOPs), checklists, and escalation guidelines ensure technicians know exactly what steps to take, reducing time lost to decision-making and rework.

Invest in Training and Skill Development

Well-trained technicians diagnose problems faster and apply the correct fix the first time. Regular technical training, cross-skilling, and access to updated troubleshooting guides improve repair accuracy and speed. Skilled teams are especially critical when dealing with complex or unfamiliar equipment.

Enhance Diagnostic Tools and Mobile Capabilities

Advanced diagnostic tools help pinpoint root causes quickly, while mobile devices give technicians instant access to asset data, manuals, and repair histories in the field. This reduces guesswork, speeds up diagnosis, and enables faster resolution—particularly for distributed or remote assets.

Optimize Spare Parts and Tool Availability

Repairs often stall due to missing parts or tools. Organizing spare parts inventory based on asset criticality, standardizing part identification, and ensuring easy access to frequently used items can dramatically reduce MTTR. The same principle applies to keeping essential tools readily available and properly maintained.

Leverage Maintenance Management Software

Computerized maintenance management systems (CMMS) or ERP-based maintenance modules centralize work orders, asset histories, and repair data. Automation streamlines task assignment, prioritization, and tracking, helping teams respond faster and analyze recurring issues that inflate MTTR.

Establish Rapid Response and Collaboration Mechanisms

For critical assets, dedicated rapid response teams can eliminate delays caused by technician availability. Instant communication platforms—such as real-time messaging or alerts—enable faster coordination among maintenance, operations, and engineering teams during complex incidents.

Conduct Root Cause Analysis and Capture Knowledge

Every failure is an opportunity to improve. Performing root cause analysis (RCA) after major incidents helps prevent recurrence and reduces future repair times. Documenting lessons learned, workarounds, and best practices builds a knowledge base that accelerates resolution when similar issues arise.

Maintain a Strong Focus on Safety and Compliance

Safe working conditions and clear compliance guidelines prevent accidents that can halt repairs or create additional downtime. When technicians have the right training, protective equipment, and safety protocols, repairs can proceed efficiently without unnecessary interruptions.

Improving MTTR is not a one-time initiative—it is a continuous process of monitoring, learning, and refining. By combining skilled teams, standardized processes, proactive maintenance, and the right technology, organizations can consistently shorten repair windows and improve overall operational resilience.

Limitations of MTTR as a Metric

While Mean Time to Repair (MTTR) is a widely used indicator of maintenance efficiency, it does not provide a complete picture of asset reliability or operational performance on its own. Relying solely on MTTR can lead to oversimplified conclusions and, in some cases, misleading decisions.

Below are the key limitations organizations should be aware of.

Focuses Only on Repair Time, Not Failure Frequency

MTTR measures how quickly equipment is restored after a failure, but it does not indicate how often failures occur. An asset with a low MTTR but frequent breakdowns may still cause significant disruption. Without pairing MTTR with metrics like Mean Time Between Failures (MTBF), organizations risk overlooking chronic reliability issues.

Heavily Dependent on Data Accuracy and Definitions

MTTR calculations are highly sensitive to how repair start and end times are defined. Inconsistent practices—such as starting the clock at failure detection versus technician arrival—can distort results. Poor documentation or manual data entry further undermines the reliability of MTTR as a performance metric.

Does Not Reflect Repair Quality or Sustainability

A short MTTR may result from temporary fixes rather than permanent solutions. While functionality may be restored quickly, unresolved root causes can lead to repeat failures. MTTR alone cannot distinguish between quick workarounds and durable repairs that improve long-term reliability.

Limited Context Around Asset Complexity and Environment

MTTR does not inherently account for differences in equipment complexity, operating conditions, or accessibility. Comparing MTTR across dissimilar assets or environments without proper normalization can produce unfair benchmarks and misrepresent maintenance performance.

Can Encourage Speed Over Safety or Accuracy

When MTTR is overemphasized as a key performance target, teams may feel pressured to prioritize speed over safety, compliance, or thorough diagnostics. This can increase the risk of errors, rework, or safety incidents, ultimately undermining maintenance effectiveness.

Not a Standalone Indicator of Maintenance Maturity

MTTR captures only one phase of the asset lifecycle—the repair process. It does not reflect preventive maintenance effectiveness, early fault detection, or overall asset health. For a balanced assessment, MTTR should be analyzed alongside complementary metrics such as MTBF, availability, downtime, and maintenance cost.

In summary, MTTR is a valuable operational metric, but its true value emerges only when used in context and combined with other reliability and maintenance performance indicators.

How to Benchmark MTTR Across Different Asset Types in Your Facility

Benchmarking MTTR across asset types requires a structured, context-aware approach. Since equipment varies in complexity, operating conditions, and business impact, effective benchmarking focuses on fair comparisons, reliable data, and realistic performance expectations.

The steps below help ensure your MTTR benchmarks are meaningful and actionable.

Group Assets by Type and Function

Begin by categorizing assets into logical groups such as pumps, compressors, conveyors, or packaging lines.

Comparing similar equipment ensures you are evaluating repair efficiency on a like-for-like basis rather than drawing misleading conclusions from vastly different asset types.

Within each group, track both individual asset MTTR and the overall group average to identify consistent underperformers or best practices.

Establish Baselines Using Sufficient Historical Data

Collect at least three months of MTTR data for each asset group to create stable and reliable baselines. Shorter periods may exaggerate anomalies, while sufficient historical data reveals recurring patterns and trends.

Reviewing both the highest and lowest MTTR values within a group helps distinguish isolated incidents from systemic issues.

Adjust MTTR for Operational and Environmental Differences

Raw MTTR figures should be normalized to account for real-world operating conditions. Factors such as equipment age, operating intensity, environmental exposure, and maintenance history significantly influence repair times.

Older assets, continuously running equipment, or machines operating in harsh environments should have adjusted expectations to ensure benchmarks remain realistic and fair.

Validate Benchmarks Against Industry Standards

Once internal benchmarks are established, compare them with industry MTTR standards for similar equipment types.

External benchmarks help validate whether your internal performance is competitive or if there is room for improvement across the entire asset category—even among your best-performing assets.

Set MTTR Targets Based on Equipment Criticality

After benchmarking by asset type, refine MTTR targets based on business impact. Critical assets that halt production should have the most aggressive targets and priority access to skilled technicians and spare parts.

Important and non-critical assets can operate with longer repair windows, enabling better resource allocation without compromising overall operational performance.

This structured approach ensures MTTR benchmarking reflects actual operating realities while providing clear direction for continuous maintenance improvement.

How Deskera Manufacturing ERP Helps Improve MTTR

Reducing Mean Time to Repair (MTTR) requires more than just faster technicians—it depends on real-time visibility, structured workflows, accurate data, and seamless coordination across maintenance, inventory, and production. Deskera Manufacturing ERP brings these elements together on a single platform, enabling maintenance teams to diagnose issues faster, execute repairs efficiently, and minimize unplanned downtime.

Centralized Maintenance and Asset Visibility

Deskera’s manufacturing solution includes machine management and maintenance planning, allowing tracking of machine performance, maintenance history, and equipment status — all foundational for diagnosing issues faster and gaining visibility into asset behavior.

Faster Issue Identification Through Real-Time Data

Deskera provides real-time inventory tracking and machine performance monitoring that help teams identify anomalies before they cause larger problems. Real-time data supports faster response and reduces downtime from delayed detection.

Streamlined Work Order Management

Deskera includes automated work order creation, assignment, progress tracking, and completion monitoring, which helps structure maintenance tasks and ensure timely execution.

Spare Parts and Inventory Readiness

Deskera’s ERP integrates inventory control with real-time tracking and automated reordering, helping ensure that spare parts are available when maintenance teams need them — a key factor in reducing MTTR.

Data-Driven Maintenance Decisions

With analytics, dashboards, and reporting, Deskera allows you to review maintenance history and performance metrics — meaning teams can analyze MTTR trends and benchmark performance over time.

Cross-Functional Coordination

Deskera ERP syncs maintenance with production planning, inventory, supply chain, and finance, ensuring maintenance schedules align with operational priorities rather than work in isolation.

Key Takeaways

- MTTR measures how quickly equipment or systems are restored after failure, making it a core indicator of repair efficiency and operational responsiveness.

- MTTR helps maintenance teams identify bottlenecks in repair workflows, improve decision-making around asset repair versus replacement, and strengthen preventive maintenance planning.

- MTTR should be evaluated alongside metrics like MTBF and availability, as repair speed alone does not reflect failure frequency or overall asset reliability.

- Tracking MTTR improves uptime, cost control, resource allocation, and customer satisfaction by minimizing downtime and strengthening maintenance accountability.

- Inconsistent definitions, poor data quality, and complex failure dependencies can distort MTTR, reducing its effectiveness unless standardized processes are in place.

- Organizations can reduce MTTR through preventive and predictive maintenance, standardized repair procedures, skilled technicians, spare-parts readiness, and digital maintenance tools.

- Meaningful MTTR benchmarking requires grouping similar assets, adjusting for operational conditions, and comparing results against both internal baselines and industry standards.

- MTTR targets must align with asset criticality, operational impact, team capabilities, and spare-parts availability rather than relying on uniform thresholds.

- MTTR does not capture failure frequency, repair quality, or asset complexity, making it insufficient as a standalone indicator of maintenance performance.

- Deskera Manufacturing ERP supports MTTR improvement through real-time asset visibility, structured work orders, integrated spare-parts management, and data-driven maintenance insights.

Related Articles