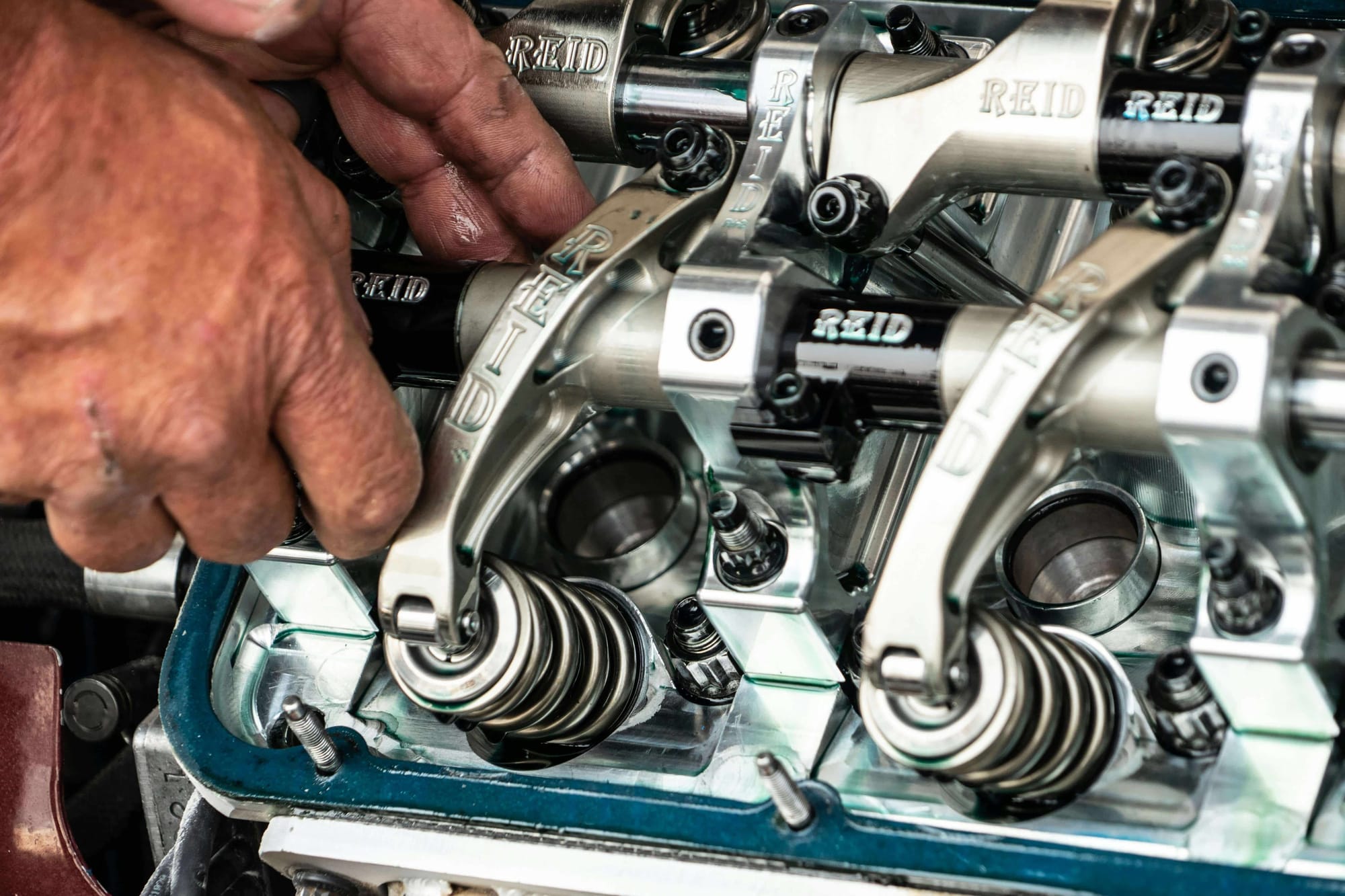

Why do equipment failures still disrupt operations even when maintenance is being performed regularly? Because maintenance without a structured schedule is often reactive, inconsistent, and poorly aligned with asset priorities. A well-defined maintenance schedule brings order to maintenance activities by clearly outlining what needs to be done, when it needs to be done, and by whom—ensuring that critical assets receive timely attention before small issues escalate into costly breakdowns.

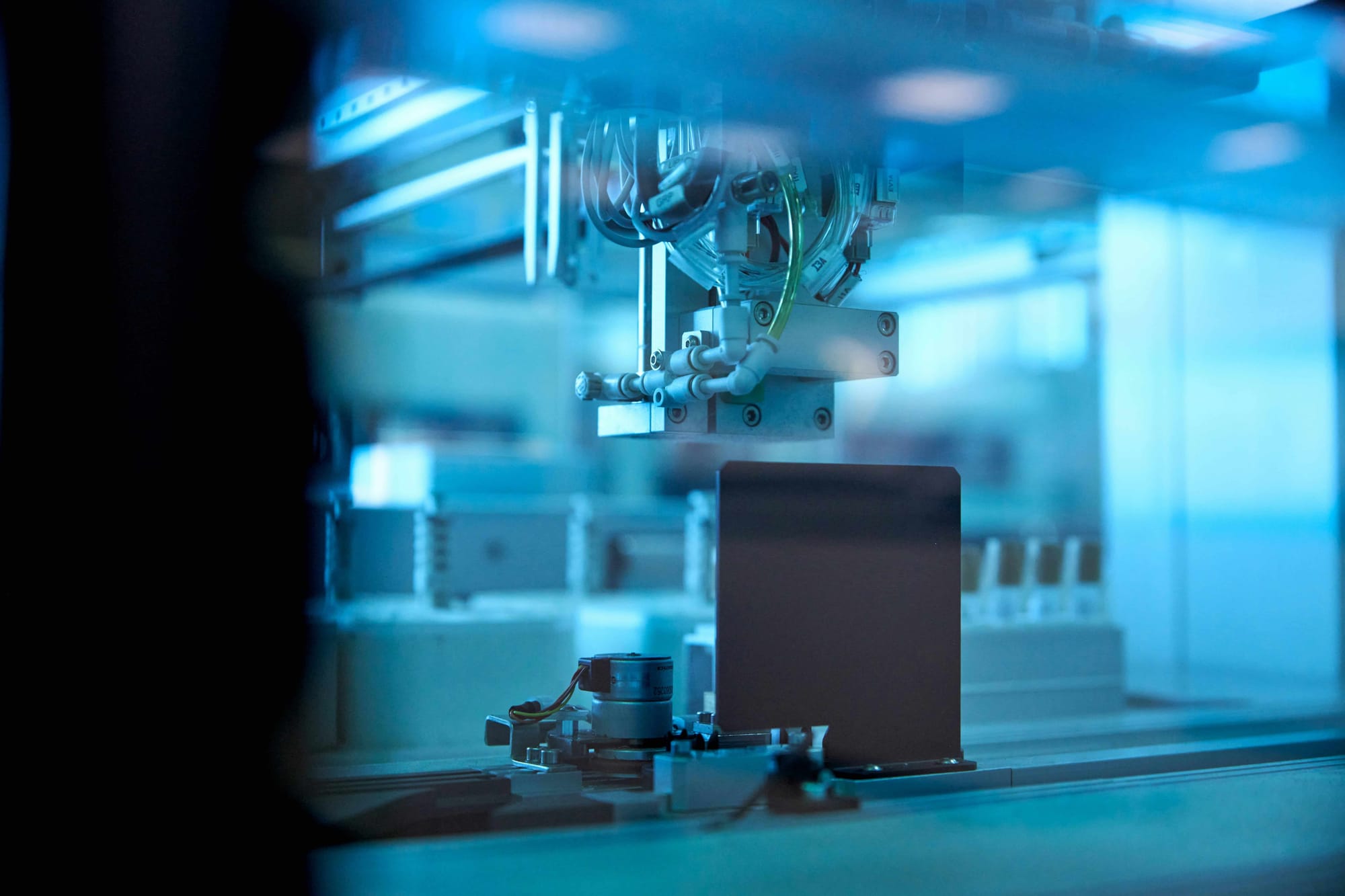

In today’s fast-paced, asset-intensive environments, maintenance schedules are no longer just operational checklists—they are strategic tools. From manufacturing plants and warehouses to facilities management and utilities, structured maintenance scheduling helps organizations reduce downtime, control maintenance costs, improve safety, and extend equipment life. As businesses move away from firefighting failures toward proactive and predictive maintenance, maintenance schedules form the backbone of effective maintenance management.

This blog breaks down maintenance schedules in a practical and easy-to-understand manner. It explains what a maintenance schedule is, explores the different types of maintenance schedules, highlights their key benefits, shares best practices for effective implementation, and walks through a step-by-step process to create a maintenance schedule that actually works in real-world operations.

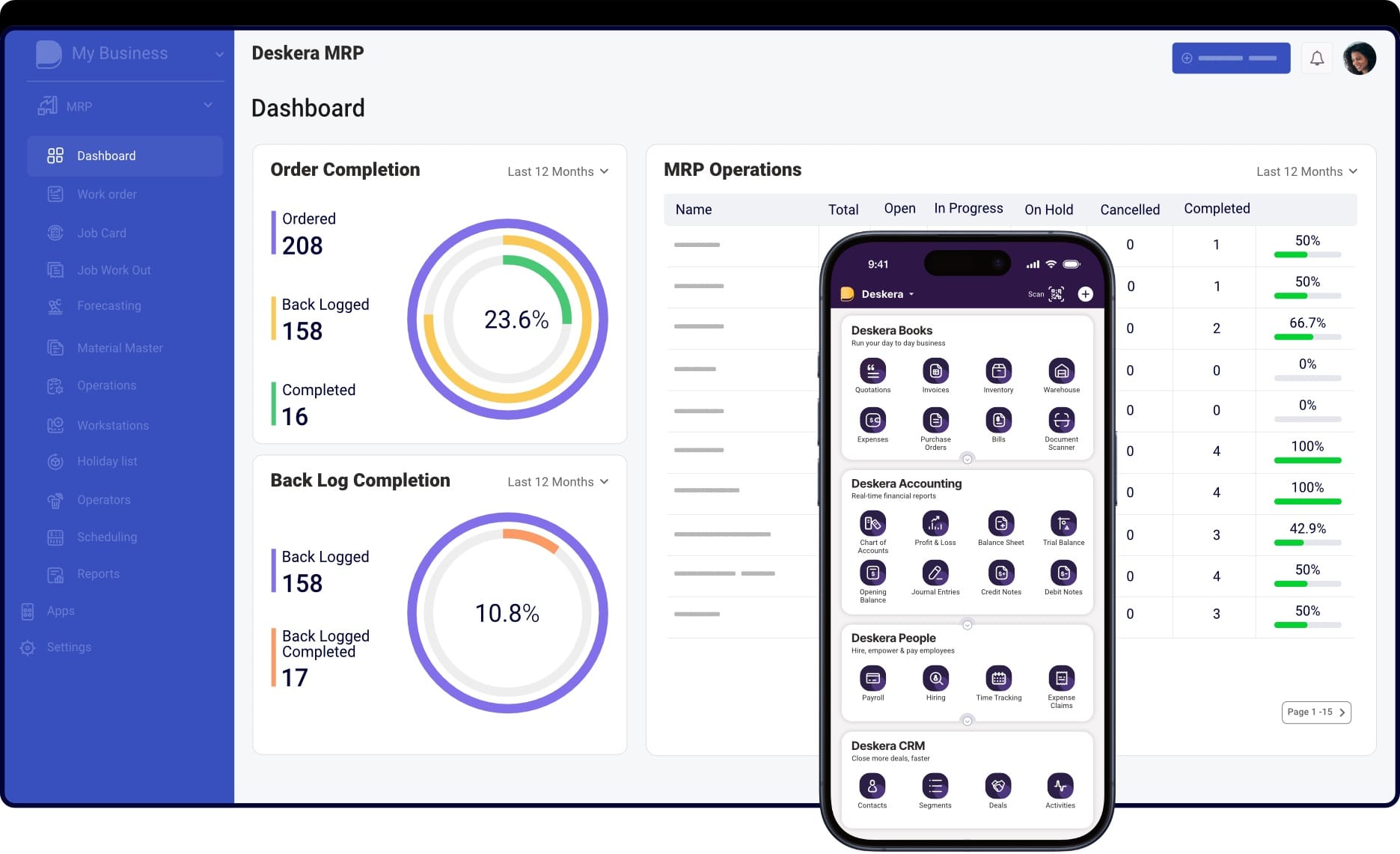

Modern maintenance scheduling is also increasingly supported by digital tools like Deskera MRP, which helps organizations plan, track, and optimize maintenance activities alongside production and resource planning. With centralized asset data, automated maintenance alerts, and real-time visibility into maintenance tasks, Deskera MRP enables businesses to move from manual, error-prone scheduling to streamlined, data-driven maintenance operations that support long-term operational efficiency.

What Is a Maintenance Schedule?

A maintenance schedule is a structured plan that defines when, how often, and how maintenance activities should be performed on equipment, machinery, and facilities within an organization. Its primary purpose is to keep assets in optimal working condition by ensuring maintenance tasks are carried out at the right time and with the right resources—reducing unexpected failures and minimizing operational disruptions.

A well-designed maintenance schedule typically includes a complete asset inventory, clearly defined maintenance activities, task frequency, assigned personnel, required resources, and proper documentation. By outlining responsibilities and resource needs in advance, maintenance teams can work more efficiently, avoid last-minute firefighting, and ensure consistency across all maintenance operations.

Having a structured maintenance schedule significantly reduces unscheduled downtime by enabling proactive planning and better resource allocation. Instead of reacting to breakdowns, organizations can anticipate maintenance needs, address issues early, and prevent minor faults from escalating into major equipment failures.

More importantly, implementing a maintenance schedule helps organizations protect production continuity and control costs. By solving potential problems before they lead to breakdowns, maintenance schedules extend equipment lifespan, improve asset reliability, and enhance overall operational efficiency—making them a critical component of effective maintenance management.

Types of Maintenance Schedules

Maintenance schedules can be designed in different ways depending on asset criticality, operating conditions, and business objectives. Choosing the right type of maintenance schedule helps organizations balance cost, reliability, and performance while minimizing unexpected failures.

Preventive Maintenance Schedule

This type of maintenance schedule is based on predefined time or usage intervals. Maintenance tasks are performed regularly—such as weekly inspections or monthly servicing—to prevent equipment failure before it occurs. Preventive maintenance schedules are widely used for critical assets where downtime can significantly impact operations.

Predictive Maintenance Schedule

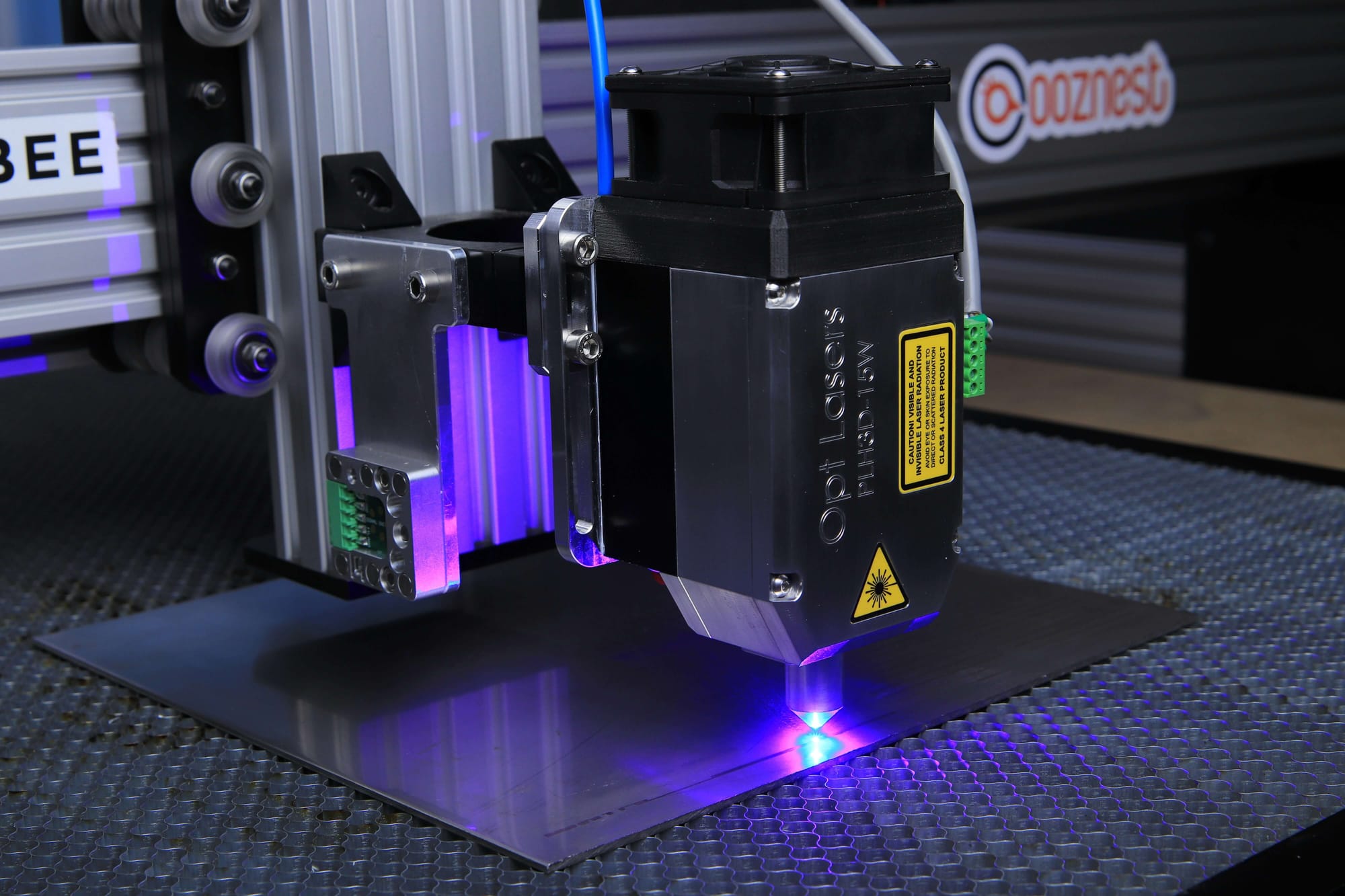

Predictive maintenance schedules rely on equipment data, performance trends, and condition-monitoring tools to determine when maintenance is required. Instead of fixed intervals, maintenance is scheduled based on actual asset condition, helping organizations reduce unnecessary maintenance while preventing unexpected breakdowns.

Condition-Based Maintenance Schedule

In condition-based maintenance schedules, maintenance activities are triggered when equipment performance crosses specific thresholds, such as temperature, vibration, or pressure limits. This approach ensures maintenance is carried out only when needed, making it more efficient than purely time-based scheduling.

Corrective Maintenance Schedule

Corrective maintenance schedules focus on fixing known issues that have already been identified but are not yet critical. These tasks are planned and scheduled in advance to prevent minor faults from developing into major failures, offering a balance between reactive and preventive maintenance.

Reactive Maintenance Schedule

Reactive maintenance schedules are executed only after equipment fails. While this approach may be suitable for non-critical or low-cost assets, relying heavily on reactive maintenance can lead to higher downtime, increased repair costs, and operational inefficiencies.

Time-Based vs. Usage-Based Maintenance Scheduling

Time-based schedules trigger maintenance at regular calendar intervals, while usage-based schedules depend on operating hours, cycles, or production output. Selecting the right approach depends on how equipment is used and the impact of potential failures on operations.

By understanding these types of maintenance schedules, organizations can design a maintenance strategy that aligns with asset criticality, operational demands, and long-term reliability goals.

Key Benefits of Maintenance Schedules

A well-planned maintenance schedule delivers far more than routine upkeep—it directly impacts operational reliability, cost efficiency, safety, and long-term business performance.

By systematically planning and executing maintenance activities, organizations can move from reactive firefighting to proactive asset management, ensuring equipment performs consistently and reliably over time.

Prevent Equipment Breakdowns

Maintenance schedules help identify and resolve potential issues before they escalate into equipment failures. Regular inspections, servicing, and timely interventions reduce the likelihood of sudden breakdowns that can disrupt operations and impact productivity.

Extend Equipment Lifespan

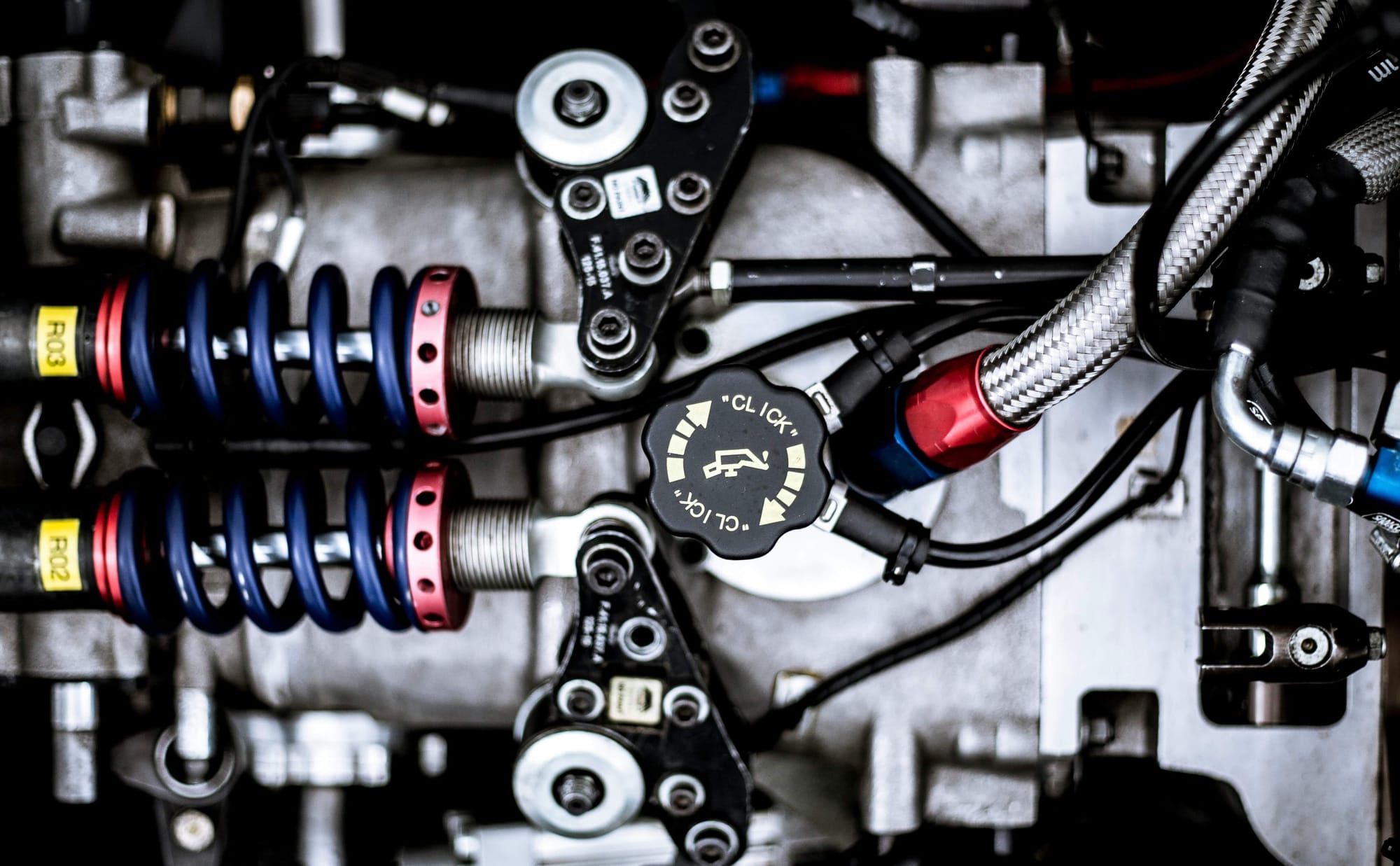

Consistent maintenance performed at scheduled intervals reduces excessive wear and tear on equipment. Well-maintained assets operate more smoothly, last longer, and allow organizations to maximize return on investment while delaying costly replacements.

Reduce Repair and Emergency Costs

By addressing minor issues early, maintenance schedules prevent small problems from turning into expensive repairs. This proactive approach minimizes the need for emergency maintenance, which is often more disruptive and costly.

Optimize Equipment Performance

Scheduled maintenance ensures equipment operates at peak efficiency through regular calibration, cleaning, and adjustments. This leads to improved productivity, better output quality, and enhanced energy efficiency across operations.

Minimize Unplanned Downtime

Unscheduled downtime can severely impact production timelines and profitability. Maintenance schedules reduce the risk of unexpected failures, helping ensure uninterrupted operations and improved delivery reliability.

Ensure Safety and Regulatory Compliance

Routine maintenance inspections and safety checks help organizations meet regulatory requirements and maintain a safe working environment. This reduces workplace accidents, legal liabilities, and the risk of non-compliance penalties.

Improve Energy Efficiency and Sustainability

Well-maintained equipment consumes less energy and operates more efficiently. Maintenance schedules help reduce energy waste, lower operating costs, and support environmental sustainability initiatives.

Enable Early Problem Detection

Regular maintenance allows teams to identify potential faults at an early stage. Early detection enables timely corrective actions, preventing operational disruptions and extending equipment reliability.

Enhance Equipment Reliability and Consistency

By systematically addressing wear, deterioration, and performance deviations, maintenance schedules improve overall equipment reliability. Reliable assets contribute to smoother workflows and fewer production interruptions.

Maintain Product Quality Standards

Equipment operating within optimal parameters produces consistent, high-quality output. Maintenance schedules help ensure accuracy, precision, and consistency, reducing defects and rework.

Support Documentation and Asset History Tracking

Maintenance schedules provide a structured framework for documenting maintenance activities. These records are valuable for audits, compliance checks, warranty claims, and data-driven maintenance decisions.

Protect Equipment Warranties and Insurance Coverage

Many manufacturers and insurers require adherence to maintenance schedules. Following documented maintenance plans helps keep warranties valid and ensures compliance with insurance requirements.

Optimize Maintenance Resource Allocation

Planned scheduling allows organizations to allocate time, labor, and spare parts more efficiently. This improves workforce productivity and ensures maintenance budgets are used effectively.

Improve Employee Productivity and Morale

Reliable equipment reduces disruptions and frustrations for employees. A stable operating environment enables teams to work more efficiently, boosting overall productivity and job satisfaction.

Support Business Continuity and Organizational Reputation

Proactive maintenance scheduling reduces operational risk and supports business continuity planning. It also reflects a commitment to operational excellence, strengthening trust among customers, partners, and stakeholders.

Best Practices for Effective Maintenance Scheduling

Effective maintenance scheduling goes beyond assigning tasks to a calendar. It requires clear communication, smart prioritization, flexibility, and the right processes to balance planned maintenance with inevitable unplanned work.

By following proven best practices, organizations can improve schedule compliance, reduce disruptions, and move away from reactive “firefighting” maintenance.

Prioritize Clear and Continuous Communication

Communication is the foundation of successful maintenance scheduling. Schedulers must ensure that supervisors, technicians, and operations teams clearly understand what tasks need to be completed, when they are due, and what resources are required.

Frequent check-ins—such as daily coordination meetings—help align priorities, communicate changes, and ensure everyone is working from the same schedule. Without consistent communication, even the most well-planned schedule can quickly fall apart.

Build a Dynamic and Flexible Schedule

Maintenance priorities can change daily due to production demands, asset conditions, or unexpected failures. Static schedules maintained on paper or spreadsheets quickly become outdated and reduce visibility for technicians.

A dynamic scheduling approach ensures that updates are reflected in real time, allowing teams to adapt quickly while maintaining alignment with overall maintenance goals.

Prioritize Jobs Based on Asset Criticality

Not all maintenance tasks carry the same level of risk or impact. Effective scheduling requires prioritizing work based on equipment criticality, safety risks, operational impact, and cost.

High-priority assets should receive preventive maintenance at predefined intervals, while lower-priority tasks can be scheduled with more flexibility. This structured prioritization reduces workflow disruptions and ensures resources are focused where they matter most.

Plan for Break-Ins and Unplanned Work

Unplanned maintenance, or “break-ins,” is inevitable in most facilities. Best-in-class maintenance schedules account for this by leaving capacity buffers—often scheduling only 80–85% of available resources—or by dedicating specific teams to handle emergency work. This prevents constant reshuffling of the schedule and allows planned maintenance to proceed without interruption.

Use Dedicated Teams for Reactive Maintenance

Assigning separate teams or work centers to manage break-in work helps protect the integrity of the planned maintenance schedule. When emergency repairs arise, dedicated teams can respond without forcing other technicians to abandon scheduled tasks. This approach improves focus, reduces schedule disruption, and increases overall productivity.

Avoid the Firefighting Maintenance Cycle

Organizations that consistently drop preventive maintenance tasks to address emergencies often fall into a reactive maintenance loop. Skipped preventive work eventually leads to more breakdowns, creating even more unplanned work. Breaking this cycle requires disciplined scheduling, strong prioritization, and a commitment to completing preventive maintenance as planned.

Align Scheduling with Reliability and Operations Teams

Schedulers should work closely with reliability and operations teams to identify critical assets, define preventive maintenance intervals, and anticipate risks. This collaboration ensures maintenance schedules support production goals while reducing the likelihood of unexpected failures.

Leverage Digital Tools for Visibility and Control

Modern maintenance scheduling benefits greatly from digital solutions that provide real-time visibility, mobile access, and quick schedule adjustments. Digital scheduling tools allow schedulers to update priorities, reassign work, and communicate changes instantly—helping teams stay aligned even in fast-changing operational environments.

By following these best practices, organizations can create maintenance schedules that are realistic, resilient, and aligned with operational priorities—enabling a shift from reactive maintenance to proactive, reliability-driven asset management.

How to Create a Maintenance Schedule: Step-by-Step

Creating an effective maintenance schedule requires a structured, methodical approach that ensures no asset is overlooked and every maintenance activity is planned with purpose.

By following these steps, organizations can build a maintenance schedule that supports reliability, minimizes downtime, and aligns maintenance efforts with operational priorities.

Step 1: List and Inventory All Equipment

The first step in creating a maintenance schedule is developing a complete inventory of all equipment, machinery, and facilities that require maintenance.

This involves conducting a thorough inspection to ensure no assets are missed, including backup systems and less frequently used equipment.

A comprehensive asset inventory forms the foundation of effective maintenance scheduling and ensures consistent coverage across all assets.

Step 2: Identify Required Maintenance Activities

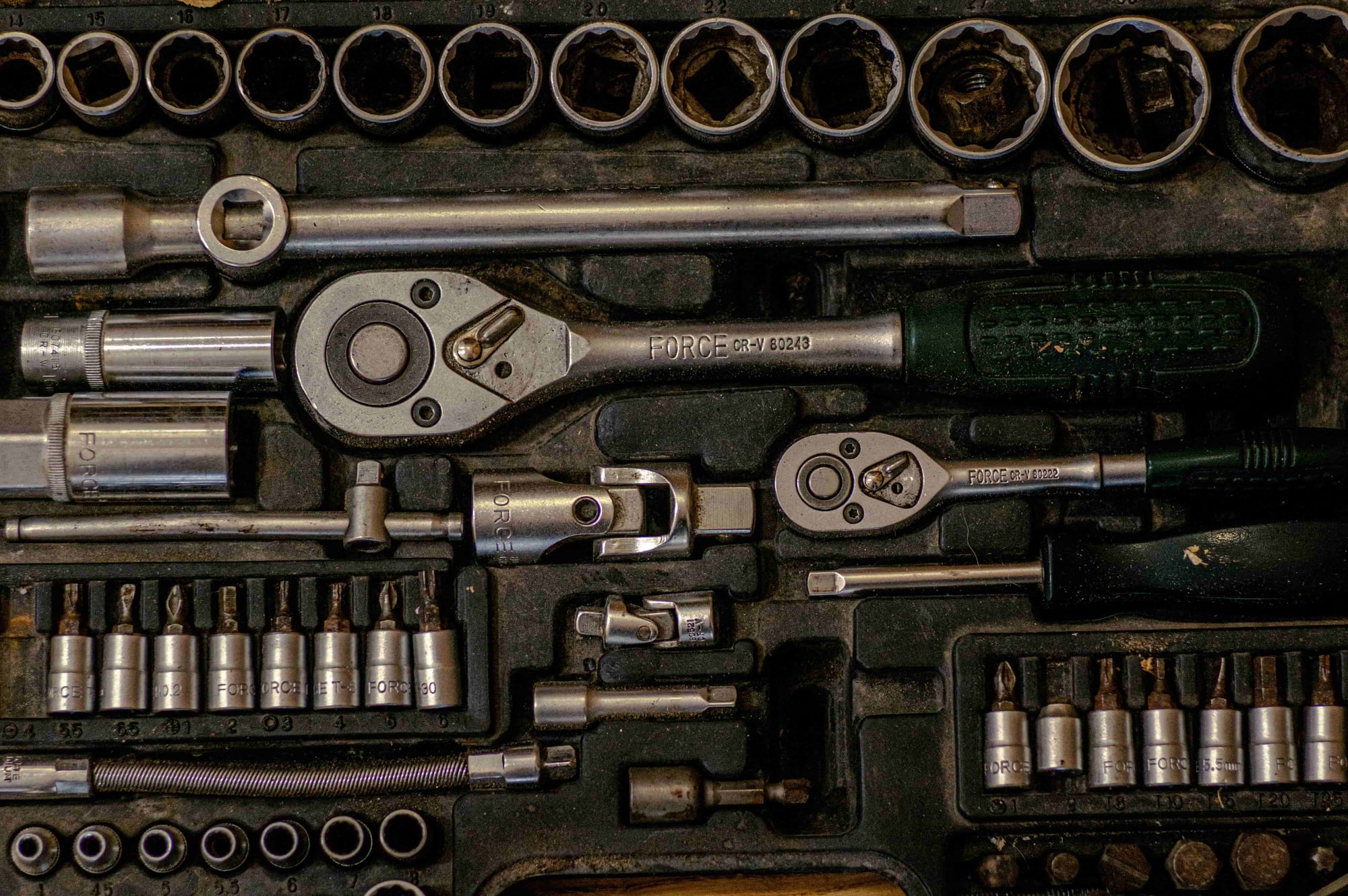

Once all equipment is documented, the next step is to identify the specific maintenance activities required for each asset. Different equipment has different maintenance needs, which may include inspections, lubrication, calibration, part replacements, or safety checks.

Manufacturer recommendations, historical maintenance data, and equipment usage patterns should be considered when defining these activities. Creating standardized maintenance checklists helps streamline execution and ensures consistency.

Step 3: Determine Maintenance Frequency

After defining maintenance activities, establish how often each task needs to be performed. Some activities may be required daily, while others may be weekly, monthly, or based on usage or condition.

Maintenance frequency should reflect asset criticality, operating environment, usage intensity, and potential failure impact. Clearly defining frequency helps prevent both over-maintenance and neglected assets.

Step 4: Assign Responsibilities and Resources

For a maintenance schedule to be effective, roles and responsibilities must be clearly defined. Assign technicians, supervisors, and support staff to each task, and identify the tools, spare parts, and time required for execution. Proper resource planning ensures tasks are completed on time without disrupting operations.

Step 5: Define Maintenance Dates and Build the Schedule

With all inputs in place, convert maintenance tasks into a structured calendar. Schedule maintenance activities in a way that aligns with production cycles and operational constraints. Maintenance dates should be realistic and allow flexibility for unplanned work while ensuring critical tasks are completed as planned.

Step 6: Track Execution and Document Outcomes

Once the maintenance schedule is active, track task completion and document results. Recording completed activities, observations, and corrective actions creates a valuable maintenance history that supports audits, warranty claims, and future decision-making.

Step 7: Review, Adjust, and Improve Continuously

A maintenance schedule should not remain static. Regularly review performance metrics such as downtime, breakdown frequency, and schedule compliance to identify improvement areas. Adjust maintenance activities, frequencies, or priorities as equipment conditions, operational demands, or business goals change.

By following this step-by-step approach, organizations can build maintenance schedules that are proactive, adaptable, and aligned with long-term asset performance and operational efficiency.

How Can Deskera MRP Help You with Maintenance Scheduling?

Manual maintenance scheduling often results in missed tasks, poor coordination with production, and limited visibility. Deskera MRP supports maintenance scheduling by bringing together asset information, work orders, inventory, and production planning on a single platform—helping organizations plan maintenance more systematically and reduce operational disruptions.

Centralized Asset and Maintenance Records

Deskera MRP allows businesses to maintain structured records of equipment, related work orders, and maintenance history. Having this information in one place improves visibility, helps teams track what maintenance has been performed, and supports more consistent scheduling decisions.

Planned and Preventive Maintenance Support

Maintenance activities can be planned in advance using work orders linked to specific assets. This makes it easier to follow preventive maintenance routines instead of relying on reactive repairs, helping reduce unexpected breakdowns and extend equipment life.

Alignment with Production and Operations

Because Deskera MRP is built around manufacturing and production planning, maintenance activities can be scheduled in coordination with production timelines. This helps minimize disruptions by planning maintenance during low-load periods or planned stoppages.

Better Spare Parts and Inventory Planning

Maintenance tasks often fail or get delayed due to unavailable spare parts. Deskera MRP connects maintenance work orders with inventory management, ensuring required materials and spares are visible and available when maintenance is scheduled.

Improved Task Assignment and Accountability

Maintenance tasks can be assigned through work orders, making responsibilities clear across teams. This improves accountability, ensures better follow-through, and helps supervisors track task status more effectively.

Scalable, System-Driven Maintenance Planning

By moving maintenance scheduling out of spreadsheets and into an ERP-driven system, organizations gain better structure, consistency, and scalability. As operations grow, maintenance schedules can be managed more efficiently without increasing manual effort.

Overall, Deskera MRP helps organizations bring discipline and visibility to maintenance scheduling by integrating it with core manufacturing and operational processes—supporting smoother operations and more reliable asset performance.

Key Takeaways

- A maintenance schedule is a structured plan that defines what maintenance tasks need to be performed, when they should occur, and who is responsible, helping organizations keep equipment in optimal working condition.

- Different types of maintenance schedules—such as preventive, predictive, condition-based, corrective, and reactive—allow businesses to choose the right approach based on asset criticality and operational needs.

- Maintenance schedules play a vital role in reducing equipment breakdowns, extending asset lifespan, controlling repair costs, improving safety, and ensuring consistent operational performance.

- Following best practices like clear communication, smart job prioritization, planning for unplanned work, and avoiding reactive “firefighting” helps improve schedule compliance and maintenance effectiveness.

- Creating a maintenance schedule requires a step-by-step approach that starts with asset inventory, defines maintenance activities and frequency, assigns responsibilities, and continuously reviews performance.

- Using a system like Deskera MRP helps bring structure to maintenance scheduling by centralizing asset data, linking maintenance with production and inventory, and improving visibility and accountability across teams.

Related Articles