Paper manufacturing has come a long way in the past few decades with technological, process, and material innovations. According to a report by Research and Markets, the global market for digital printing in the paper industry is expected to grow at a CAGR of 6.5% between 2020 and 2025. According to a report by Allied Market Research, the global market for biodegradable paper products is expected to reach $3.4 billion by 2026. The market for synthetic paper is expected to grow at a CAGR of 6.4% between 2020 and 2025.

Let us look at some of the latest innovations in paper manufacturing below:

- Sustainable Manufacturing

- Digital Printing

- Biodegradable Paper

- Nanotechnology

- Waterless Printing

- Synthetic Paper

- 3D Paper Printing

- Micro-Fibrillated Cellulose (MFC)

- Digital Watermarks

- Recyclable Barrier Coatings

- Smart Paper

- Pulp Molding

- Paper Made from Agricultural Waste

- Lightweight Corrugated Board

- Energy-Efficient Dryers

- Conclusion

Sustainable Manufacturing

Sustainable manufacturing is a process that seeks to minimize the negative environmental impacts of manufacturing while maintaining economic viability. It involves the use of sustainable materials, the reduction of waste and pollution, and the efficient use of energy and resources.

In the paper manufacturing industry, sustainable manufacturing involves using recycled paper and reducing the consumption of natural resources such as water and wood fiber. The industry has implemented a range of sustainable practices, including:

- Using renewable energy sources such as hydroelectric, wind, and solar power to reduce reliance on non-renewable sources.

- Implementing efficient manufacturing processes that reduce water usage and waste, such as closed-loop water systems that recycle water in the production process.

- Using sustainable materials, such as wood fiber certified by organizations such as the Forest Stewardship Council (FSC), and sourcing paper pulp from responsibly managed forests.

- Developing new products and applications that use recycled paper, such as tissue and packaging products.

Sustainable manufacturing not only benefits the environment but can also improve a company's bottom line by reducing costs, improving brand reputation, and attracting environmentally conscious consumers.

Digital Printing

Digital printing is a printing technique that involves the use of digital technology to produce high-quality printed images on a variety of surfaces, including paper. This technology has transformed the printing industry, enabling faster turnaround times, lower costs, and greater flexibility in design and customization.

In the paper manufacturing industry, digital printing has numerous advantages over traditional printing methods, including:

- Cost-Effective: Digital printing eliminates the need for printing plates and setup costs, resulting in lower costs for short print runs and on-demand printing.

- Customization: Digital printing enables variable data printing, allowing for the customization of each printed piece, such as personalized marketing materials or packaging.

- Quality: Digital printing produces high-quality images with fine details and vibrant colors, making it suitable for printing photographic images and artwork.

- Speed: Digital printing is faster than traditional printing methods, enabling shorter turnaround times and quicker delivery of printed materials.

- Environmental Benefits: Digital printing produces less waste than traditional printing methods, as there is no need for prepress setup, and it allows for the use of recycled paper.

The advancements in digital printing technology have also enabled the development of new applications and products, such as digitally printed wallpaper, textiles, and packaging.

Biodegradable Paper

Biodegradable paper is paper that is made from plant fibers and other natural materials that decompose quickly and completely, reducing waste and the environmental impact of paper manufacturing. Biodegradable paper can be made from a variety of sources, including bamboo, bagasse, cotton, and hemp.

The development of biodegradable paper has several benefits for the environment, including:

- Reduced Waste: Biodegradable paper decomposes quickly and completely, reducing the amount of waste in landfills.

- Reduced Environmental Impact: Biodegradable paper is made from natural materials that require less energy and fewer chemicals to produce, reducing the environmental impact of paper manufacturing.

- Renewable Resources: Biodegradable paper can be made from renewable resources such as bamboo and hemp, reducing the reliance on non-renewable resources such as wood fiber.

- Sustainable Manufacturing: The production of biodegradable paper often involves sustainable manufacturing practices, such as using recycled water and reducing emissions.

- Versatility: Biodegradable paper can be used for a wide range of applications, including packaging, printing, and tissue products.

While biodegradable paper offers many benefits, it is important to note that not all biodegradable paper is created equal. Some biodegradable paper may contain chemicals that can be harmful to the environment, or may not break down as quickly as advertised. It is important to do research and choose products that are certified by reputable organizations to ensure that they meet environmental standards.

Nanotechnology

Nanotechnology involves the manipulation and control of matter on an atomic, molecular, and supramolecular scale. In the paper manufacturing industry, nanotechnology has the potential to improve the properties of paper and paper-based products, such as strength, durability, and water resistance.

Some of the potential applications of nanotechnology in the paper manufacturing industry include:

- Nanocellulose: Nanocellulose is a material derived from wood fibers that has unique properties, including high strength and low weight. It can be used to reinforce paper products, improving their strength and durability.

- Nanocoatings: Nanocoatings can be applied to paper products to make them more water-resistant and durable. These coatings can also be used to create anti-bacterial and anti-fungal properties.

- Nanoparticles: Nanoparticles can be added to paper products to provide a range of functional properties, including UV protection, color enhancement, and increased strength.

- Nanoinks: Nanoinks can be used in digital printing, enabling high-quality printing on a range of surfaces, including paper.

While nanotechnology offers many potential benefits for the paper manufacturing industry, there are also concerns about the potential environmental and health risks associated with the use of nanoparticles. It is important for manufacturers to take a cautious and responsible approach to the use of nanotechnology, ensuring that products are safe for both consumers and the environment.

Waterless Printing

Waterless printing is a printing technique that eliminates the need for water in the printing process. Instead of using water to dampen the printing plate and transfer ink to the paper, waterless printing uses silicone-coated plates that repel ink in non-image areas, allowing for greater precision and consistency in the printing process.

In the paper manufacturing industry, waterless printing has several advantages over traditional offset printing, including:

- Improved Print Quality: Waterless printing produces sharper and more vibrant colors than traditional offset printing, with no dot gain or ink spread.

- Reduced Waste: Waterless printing eliminates the need for water, reducing waste and making it a more environmentally friendly option.

- Shorter Setup Times: Waterless printing does not require dampening systems, reducing setup times and allowing for faster printing speeds.

- Greater Flexibility: Waterless printing enables the use of a wide range of paper stocks, including coated and uncoated papers, and is compatible with a range of inks.

- Improved Productivity: Waterless printing reduces the need for maintenance and cleaning, improving productivity and reducing downtime.

While waterless printing offers many benefits, it can be more expensive than traditional offset printing due to the cost of the silicone-coated plates. However, the reduced waste and improved print quality may make it a cost-effective option for some applications.

Synthetic Paper

Synthetic paper is a type of paper-like material made from synthetic materials, such as plastic or resin, rather than from natural fibers. It is commonly used in applications where traditional paper is not suitable due to its properties, such as water resistance, durability, and tear resistance.

Some of the benefits of synthetic paper in the paper manufacturing industry include:

- Water Resistance: Synthetic paper is highly water-resistant, making it ideal for use in applications where traditional paper would be damaged by water, such as outdoor signage or labels.

- Durability: Synthetic paper is much more durable than traditional paper, making it suitable for use in applications where the printed material will be subjected to frequent handling or harsh environments.

- Tear Resistance: Synthetic paper is tear-resistant, which makes it a great option for products that need to withstand frequent handling, such as menus or ID cards.

- Versatility: Synthetic paper can be produced in a range of thicknesses and finishes, making it suitable for a wide variety of applications.

- Sustainability: Synthetic paper can be recycled and reused, making it a more sustainable option than traditional paper in some cases.

While synthetic paper has many benefits, it can be more expensive than traditional paper, which may limit its use in some applications. Additionally, some synthetic papers may not be compatible with certain printing processes, so it is important to choose the right type of synthetic paper for the intended application.

3D Paper Printing

3D paper printing is a technique that uses paper as the primary material to create three-dimensional objects using a printer. This technology is similar to traditional 3D printing, but instead of using plastic or metal, it uses paper as the building material.

The process of 3D paper printing typically involves the following steps:

- Design: A 3D model is designed using computer-aided design (CAD) software.

- Slicing: The 3D model is sliced into thin layers, which are sent to the printer.

- Printing: The printer uses a heated roller to apply a layer of adhesive to a sheet of paper. The sheet is then cut into the shape of the first layer of the 3D model. The process is repeated for each layer of the model, with the adhesive and paper layers building up to form the final object.

3D paper printing offers several advantages over traditional 3D printing, including:

- Cost-Effective: Paper is a relatively inexpensive material, making 3D paper printing a more cost-effective option than other 3D printing methods.

- Sustainability: Paper is a renewable resource and can be recycled, making 3D paper printing a more sustainable option than other 3D printing methods.

- Lightweight: Paper is a lightweight material, making 3D paper printed objects ideal for applications where weight is a concern, such as in the aerospace industry.

- High Resolution: 3D paper printing can achieve high resolution and fine detail, making it suitable for applications that require precise and intricate designs.

Some potential applications of 3D paper printing include creating paper models, prototypes, and artistic objects. However, the technology is still in the early stages of development, and there are limitations to the types of objects that can be created using this method.

Micro-Fibrillated Cellulose (MFC)

Micro-fibrillated cellulose (MFC) is a type of cellulose-based material that is made from the mechanical treatment of plant fibers, such as wood or cotton. During the production process, the fibers are separated into individual micro-fibrils, which are then dispersed in water to create a suspension.

MFC has several properties that make it a popular material in the paper manufacturing industry, including:

- High Strength: MFC has excellent tensile strength, making it ideal for use in products that require strength and durability, such as packaging materials.

- Improved Barrier Properties: MFC can be used as a barrier material to prevent the penetration of gases, liquids, and other materials. This makes it a useful material for packaging applications.

- Low Environmental Impact: MFC is made from renewable sources and can be produced using a relatively low amount of energy and water, making it a more sustainable option than some other materials.

- Compatibility with Other Materials: MFC can be easily combined with other materials, such as plastic or paper, to create composite materials with enhanced properties.

Some potential applications of MFC in the paper manufacturing industry include packaging materials, paper coatings, and printing inks. MFC can also be used in a range of other industries, such as food, cosmetics, and healthcare. However, MFC is still a relatively new material, and there are ongoing efforts to further optimize its production and use in various applications.

Digital Watermarks

Digital watermarks are a type of security feature that can be embedded into digital documents, images, or videos to identify and authenticate them. A digital watermark is a unique identifier that is embedded into the content itself and is difficult to remove or alter without damaging the content.

Digital watermarks can be used for a variety of purposes, including:

- Copyright Protection: Digital watermarks can be used to protect copyrighted content by identifying the owner and the source of the content.

- Brand Protection: Digital watermarks can be used to protect brand identity by embedding a unique identifier into product images or videos.

- Anti-Counterfeiting: Digital watermarks can be used to prevent counterfeiting by embedding a unique identifier into product images or videos that can be used to verify the authenticity of the product.

- Authentication: Digital watermarks can be used to authenticate documents or images by embedding a unique identifier into the content itself.

Digital watermarks can be visible or invisible. Visible watermarks are typically logos, text, or symbols that are overlaid on top of the content, while invisible watermarks are embedded into the content itself and are not visible to the naked eye.

The use of digital watermarks has become increasingly important in the digital age as the distribution of digital content has become more widespread. They are used by various industries, including the entertainment industry, the publishing industry, and the financial industry, to protect their digital assets and intellectual property.

Recyclable Barrier Coatings

Recyclable barrier coatings are a type of coating material that is applied to packaging materials, such as paper and cardboard, to improve their barrier properties. These coatings help to protect the contents of the package from moisture, oxygen, and other external factors that can affect the quality of the product.

Traditional barrier coatings, such as those made from plastic, are not recyclable and can contribute to environmental pollution. Recyclable barrier coatings, on the other hand, are made from sustainable and biodegradable materials, making them a more eco-friendly alternative.

One type of recyclable barrier coating that is gaining popularity is made from cellulose nanocrystals (CNC). CNC is a type of nanomaterial that is derived from renewable resources, such as wood pulp, and can be used to create a transparent and strong barrier coating. This coating can be applied to paper and cardboard packaging materials to make them more resistant to water and oil while still being recyclable.

Another type of recyclable barrier coating is made from polyhydroxyalkanoates (PHA), a type of biodegradable polymer that can be produced from renewable resources, such as plant starch. PHA coatings can be applied to paper and cardboard packaging materials to improve their barrier properties while still being biodegradable and compostable.

Recyclable barrier coatings offer several benefits, including:

- Sustainability: Recyclable barrier coatings are made from sustainable and biodegradable materials, reducing the environmental impact of packaging materials.

- Barrier Properties: Recyclable barrier coatings can provide excellent barrier properties, protecting the contents of the package from external factors that can affect the quality of the product.

- Versatility: Recyclable barrier coatings can be applied to a range of packaging materials, including paper and cardboard.

- Recyclability: Recyclable barrier coatings can be easily separated from the packaging material during the recycling process, making them a more sustainable alternative to traditional barrier coatings.

Overall, the use of recyclable barrier coatings is a promising development in the packaging industry, offering a more sustainable and eco-friendly alternative to traditional barrier coatings.

Smart Paper

Smart paper, also known as interactive paper, is a type of paper that is designed to have interactive features, such as the ability to display digital content, record data, or communicate wirelessly with other devices. Smart paper incorporates various technologies, such as printed electronics, RFID, and near-field communication (NFC), to create new functionalities and applications.

Some examples of smart paper include:

- Electronic Paper Displays: Electronic paper displays (EPDs) are thin, flexible displays that use electronic ink to display text and images. EPDs are commonly used in e-readers, but they can also be used in other applications, such as electronic shelf labels, digital signage, and smart packaging.

- Printed Sensors: Printed sensors are sensors that are printed on paper or other flexible substrates. These sensors can be used for a variety of applications, such as monitoring temperature, humidity, and gas levels.

- RFID-enabled Paper: RFID-enabled paper contains a small radio frequency identification (RFID) chip that can store information and communicate wirelessly with other devices. RFID-enabled paper is commonly used in security applications, such as access control and asset tracking.

- Conductive Ink: Conductive ink is a type of ink that contains conductive particles, such as silver or copper. This ink can be printed on paper or other substrates to create conductive traces that can be used for electronic circuits and other applications.

Smart paper has many potential applications in various industries, including packaging, printing, and security. For example, smart packaging could enable consumers to access additional product information or track the location of their packages, while smart printing could enable printed materials to be interactive and dynamic. However, there are still challenges to be addressed in terms of cost, scalability, and compatibility with existing infrastructure.

Pulp Molding

Pulp molding is a manufacturing process that uses recycled paper or pulp to create products and packaging materials. In the pulp molding process, paper or pulp is first mixed with water to create a slurry. The slurry is then poured into a mold, which is typically made from metal, plastic, or wood, and shaped into the desired product.

The mold is then placed into a machine that applies pressure and heat to the slurry, causing it to solidify and take on the shape of the mold. Once the product has hardened, it is removed from the mold and can be trimmed or finished as needed.

Pulp molding is a sustainable and eco-friendly manufacturing process, as it uses recycled materials and produces minimal waste. Some common products that are made using pulp molding include egg cartons, fruit trays, and disposable food containers.

Pulp molding has several advantages over traditional manufacturing processes, including:

- Sustainability: Pulp molding uses recycled materials, reducing waste and environmental impact.

- Cost-effectiveness: Pulp molding is a cost-effective manufacturing process, as it uses low-cost raw materials and requires minimal energy and resources.

- Customizability: Pulp molding allows for the creation of custom shapes and sizes, making it a versatile process for a variety of applications.

- Durability: Pulp molding products are durable and can be designed to provide protection and cushioning for fragile items.

Overall, pulp molding is a sustainable and efficient manufacturing process that has many applications in packaging and product manufacturing.

Paper Made from Agricultural Waste

Paper made from agricultural waste is a type of sustainable paper that is produced using agricultural residues such as wheat straw, rice straw, bagasse, and corn husk. These residues are by-products of the agricultural industry and are often burned or discarded, leading to environmental pollution. By using these residues to produce paper, the waste is minimized, and a valuable resource is created.

The process of making paper from agricultural waste is similar to traditional papermaking, but it requires less energy and fewer chemicals. The process involves converting the agricultural waste into pulp, which is then processed and formed into paper sheets. The resulting paper is eco-friendly and biodegradable, making it a sustainable alternative to conventional paper.

Some benefits of using agricultural waste to produce paper include:

- Sustainability: Using agricultural waste to produce paper reduces waste and minimizes the environmental impact of the agricultural industry.

- Cost-effectiveness: Agricultural waste is often available at low cost or for free, making it a cost-effective raw material for paper production.

- Reduced energy consumption: The production of paper from agricultural waste requires less energy and fewer chemicals than traditional papermaking processes.

- Durability: Paper made from agricultural waste can be designed to be durable and resistant to tearing, making it suitable for a variety of applications.

Overall, paper made from agricultural waste is a sustainable and eco-friendly alternative to traditional paper, with many potential applications in packaging, printing, and other industries.

Lightweight Corrugated Board

Lightweight corrugated board is a type of paperboard that has been specifically engineered to be lightweight, while still retaining the strength and durability of traditional corrugated board. It is made using a combination of recycled fibers and virgin wood fibers, which are processed and bonded together to create a sturdy, lightweight material.

There are several benefits to using lightweight corrugated board, including:

- Reduced shipping costs: Since lightweight corrugated board weighs less than traditional corrugated board, it can significantly reduce shipping costs for businesses that rely on packaging for their products.

- Environmental sustainability: Lightweight corrugated board is made using a combination of recycled fibers and virgin wood fibers, which makes it an environmentally sustainable packaging option.

- Increased design flexibility: Lightweight corrugated board can be customized to fit a wide range of shapes and sizes, making it ideal for packaging a variety of different products.

- Improved product protection: Despite its lightweight nature, lightweight corrugated board still provides excellent product protection during shipping and handling.

Overall, lightweight corrugated board is a versatile and cost-effective packaging option that is well-suited for a wide range of applications. Its lightweight nature makes it an ideal choice for companies that are looking to reduce their shipping costs, while its durability and strength make it a reliable option for protecting products during transit.

Energy-Efficient Dryers

Energy-efficient dryers are an important innovation in the paper manufacturing industry, as they help to reduce energy consumption and improve sustainability. Traditional paper drying processes typically rely on high-temperature drying methods, which can be energy-intensive and expensive. Energy-efficient dryers, on the other hand, use advanced technology and design to reduce energy consumption and improve efficiency.

There are several types of energy-efficient dryers used in the paper industry, including:

- Heat pump dryers: These dryers use a heat pump to extract heat from the air, which is then used to dry the paper. They are highly energy-efficient, as they can use up to 50% less energy than traditional drying methods.

- Impingement dryers: These dryers use a series of high-velocity air jets to remove moisture from the paper, which reduces drying time and energy consumption.

- Infrared dryers: These dryers use infrared radiation to transfer heat directly to the paper, which is more energy-efficient than traditional drying methods.

- Vacuum dryers: These dryers use a vacuum to lower the boiling point of water, which allows the paper to be dried at lower temperatures and reduces energy consumption.

Energy-efficient dryers have several benefits, including:

- Reduced energy consumption: Energy-efficient dryers use less energy than traditional drying methods, which helps to reduce costs and improve sustainability.

- Improved product quality: Energy-efficient drying methods can help to reduce paper shrinkage, curling, and other defects, resulting in higher-quality paper products.

- Increased production capacity: Energy-efficient drying methods can help to reduce drying time, which can increase production capacity and improve efficiency.

Overall, energy-efficient dryers are an important innovation in the paper manufacturing industry, as they help to reduce energy consumption, improve sustainability, and increase production efficiency.

How Deskera Can Assist You?

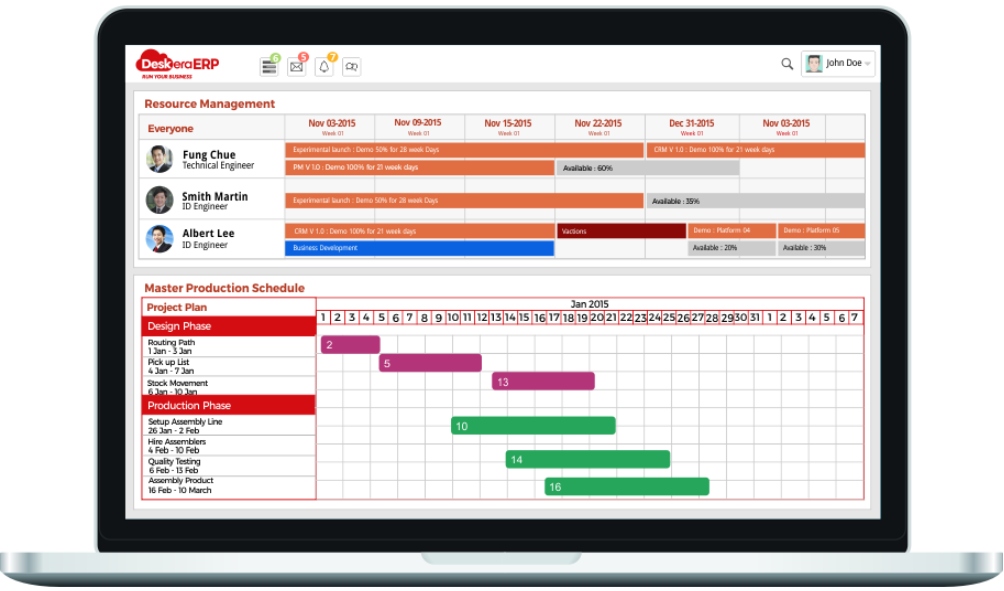

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

The latest innovations in paper manufacturing are transforming the industry in many ways. They are making paper production more sustainable, efficient, and cost-effective, while also improving the quality and functionality of paper products. These innovations are using advanced technologies such as digital printing, nanotechnology, and smart paper, and are exploring new materials and production methods such as biodegradable paper, lightweight corrugated board, and pulp molding. Overall, these innovations are helping the paper industry to adapt to changing market demands and consumer preferences, while also addressing environmental concerns and contributing to a more sustainable future.

Related Articles