Make-in-order production is an important component of the global order promising system. The global order promising system is designed to provide customers with accurate and timely information about their orders.

This information includes the estimated delivery date, product availability, and current pricing. With this information, customers can make informed decisions about their purchases.

The global order promising system also helps to improve customer satisfaction by ensuring that orders are fulfilled in a timely and accurate manner. Finally, the global order promising system helps to reduce the costs associated with order fulfillment by minimizing the need for manual processing and improving the efficiency of the process.

This article covers the following:

- What is Make-to-Order Production?

- How Does GOP Relate to Make-to-Order Production?

- Benefits of Implementing GOP in Make-to-Order Production

- Challenges of Implementing GOP in Make-to-Order Production

- Best Practices for GOP in Make-to-Order Production

- Common Mistakes in GOP for Make-to-Order Production

- Future of GOP in Make-to-Order Production

What is Make-to-Order Production?

Make-to-order (MTO) production is a type of manufacturing process in which products are made only after a customer order has been placed. This process requires careful planning, as it involves the customization of materials, parts, and components to meet a customer's specific requirements.

In MTO production, production times are longer than in make-to-stock production, and the level of inventory at any given time is usually much lower. The goal of MTO production is to ensure that customers receive exactly what they need when they need it.

In this blog, we will explore the concept of GOP (Goods-on-Process) in MTO production and how it can help reduce costs and increase efficiency for manufacturers.

How Does GOP Relate to Make-to-Order Production?

Global Order Promising (GOP) is an important concept in make-to-order production. It is a process that focuses on customer order fulfillment and the delivery of goods and services to the customer on time.

The goal of GOP is to ensure that the customer receives the goods and services they have requested in a timely manner. GOP helps make-to-order production become more efficient and reliable. It also helps reduce costs associated with late deliveries, missed orders, and other customer issues.

GOP helps companies provide better customer service, increase customer satisfaction, and increase profits. It is a critical aspect of make-to-order production and is essential for any successful business.

Benefits of Implementing Global Order Promising in Make-to-Order Production

Global order promising (GOP) has become increasingly important in today’s make-to-order production. GOP is a process that enables an organization to deliver goods and services at the right time and place to meet customer requirements.

Implementing GOP in make-to-order production can bring multiple benefits for businesses, including

Improved Customer Satisfaction

By using GOP, businesses can provide accurate information to customers about the availability of products and services, delivery times, and other important details. This helps to ensure that customers receive the goods and services they need when they need them, resulting in improved customer satisfaction.

Reduced Costs

GOP helps to reduce costs by eliminating waste and ensuring that resources are used efficiently. When businesses know exactly what is needed and when it is needed, they are better able to plan ahead and make sure they have the right amount of supplies and resources to meet customer needs.

Improved Inventory Management

GOP enables businesses to have better control over their inventory. By analyzing customer demand, businesses can ensure that they have the right amount of stock on hand to meet demand.

This helps to reduce costs associated with storing excess inventory and also helps to ensure that customers are able to get the goods and services they need when they need them.

Increased Visibility

By using GOP, businesses are able to gain better visibility into customer demand and the supply chain. This helps to ensure that customer orders are fulfilled on time and that customer expectations are met.

Overall, implementing GOP in make-to-order production can help to improve customer satisfaction, reduce costs, improve inventory management, and increase visibility. By taking advantage of these benefits, businesses can ensure that they are able to meet customer demands and remain competitive in today’s market.

Challenges of Implementing GOP in Make-to-Order Production.

The make-to-order production process is a great way to provide customers with customized products that meet their exact needs. However, implementing a Goal Oriented Planning (GOP) system can be a challenge.

GOP is a planning approach that focuses on achieving specific goals rather than making decisions based on traditional production methods. In make-to-order production, the challenge is to find a way to implement GOP while still ensuring that customer needs are met, and production is efficient.

One of the key challenges of implementing GOP in make-to-order production is to find an effective way to plan for the production of customized products. GOP requires that all resources and activities be planned in order to achieve the desired goal, but this can be difficult when dealing with products that are tailored to individual customer needs.

The key is to find a way to plan for the production process in a way that takes into account the customer’s specific requirements while still being able to efficiently produce the product.

Another challenge of implementing GOP in make-to-order production is the difficulty of creating a flexible production schedule. GOP requires that production activities be planned and scheduled in order to ensure that goals are met, but this can be difficult in a production environment where the customer’s needs are constantly changing.

The key here is to find a way to plan for production in a way that is flexible enough to accommodate any changes in customer requirements. Finally, it can be difficult to create and manage a production process that is both efficient and cost-effective when implementing GOP in make-to-order production.

GOP requires that all resources and activities be planned in order to achieve the desired goal, but this can be difficult when dealing with a production process that is constantly changing due to customer requirements. The key is to find a way to manage the production process in a way that is both efficient and cost-effective while still meeting customer needs.

Overall, implementing GOP in make-to-order production can be a challenge, but it is a challenge that can be overcome. By finding an effective way to plan for the production of customized products, creating a flexible production schedule, and managing a production process that is both efficient and cost-effective, GOP can be successfully implemented in make-to-order production.

Best Practices for GOP in Make-to-Order Production

Good inventory management is essential to ensure the success of any business, especially when it comes to make-to-order production. Properly managing inventory and materials can help reduce lead times and improve customer satisfaction.

This is where GOP (Goods on Production) comes in. GOP is the practice of managing inventory and materials in a way that optimizes the production process. When it comes to GOP in make-to-order production, there are several best practices to follow.

The most important is to keep accurate records of your inventory and materials. This includes tracking stock levels, order history, and component availability. This will help you plan ahead and ensure that you always have the necessary materials on hand when needed.

It’s also important to stay ahead of the curve when it comes to materials and components. This means having a good understanding of current and future demand for products and stocking the necessary materials and components in advance.

This will help reduce delays and keep production running smoothly. Another key component of good GOP is being able to scale up or down production quickly. This means having an efficient system in place to either increase or decrease the number of components and materials needed to make a product.

This can be done by having a flexible supply chain and a well-managed inventory system. Finally, it’s important to have a good system in place for quality control. This means testing materials and components before and after production, as well as regular inspections of the production process.

This will help ensure that only high-quality products are being produced. By following these best practices for GOP in make-to-order production, businesses can ensure that they are producing high-quality products in a timely manner. This will help increase customer satisfaction and boost profits.

Common Mistakes in GOP for Make-to-Order Production.

Goods production planning (GOP) is an essential component of successful make-to-order production. With GOP in place, manufacturers are able to efficiently manage the production of goods and keep costs low while meeting customer demands.

However, GOP can be difficult to get right, and even small mistakes can lead to costly delays and disruptions in production. In this blog, we'll discuss some of the most common mistakes made with GOP in make-to-order production and how to avoid them.

Not Planning for Flexibility

Make-to-order production can be unpredictable and require sudden changes in production plans. To avoid costly delays, it is important to plan for flexibility in production.

For example, if a customer changes their order, the GOP should have the capacity to quickly adapt to this change without having to make major changes to the production plan.

Poor Resource Allocation

Producing goods for make-to-order customers requires careful resource allocation. If resources are not allocated correctly, production may be delayed or halted altogether.

It is important to ensure that resources are available when they are needed, and that production is scheduled in such a way that resources are not over or under-utilized.

Poor Demand Forecasting

Accurately predicting customer demand is essential for a successful GOP. If demand is not accurately forecasted, production may be over- or under-produced, leading to costly delays and disruptions.

To ensure that demand is accurately forecasted, it is important to collect data from past orders, analyze trends, and use predictive analytics to get an accurate picture of customer demand.

Poor Scheduling

Poor scheduling of production tasks can cause costly delays and disruptions. The GOP should be designed to ensure that production tasks are scheduled in the most efficient manner possible.

This includes taking into account the available resources, customer deadlines, and any other constraints that may affect production. By avoiding these common mistakes in GOP for make-to-order production, manufacturers can ensure that their production process is efficient and cost-effective.

By carefully planning for flexibility, allocating resources correctly, accurately forecasting customer demand, and scheduling production tasks correctly, manufacturers can ensure that their GOP is successful and they can meet customer demands on time.

4 Stages of GOP in Make-to-Order Production

Pre-Order Planning

This is the initial stage, where the company plans out the overall process of order procurement, production, and delivery. This includes ascertaining the customer’s needs, evaluating the resources required, and setting out timelines.

Order Fulfillment

In this stage, the company takes the customer’s order and sends it to the appropriate production facility or supplier. It also includes any necessary order tracking and customer service.

Production

This is the stage where the product is actually produced. It includes everything from sourcing materials to assembly and packing.

Delivery

This is the final stage, where the finished product is shipped to the customer. It includes the coordination of logistics and customer service to ensure the product arrives in a timely manner.

How Can Deskera Assist You?

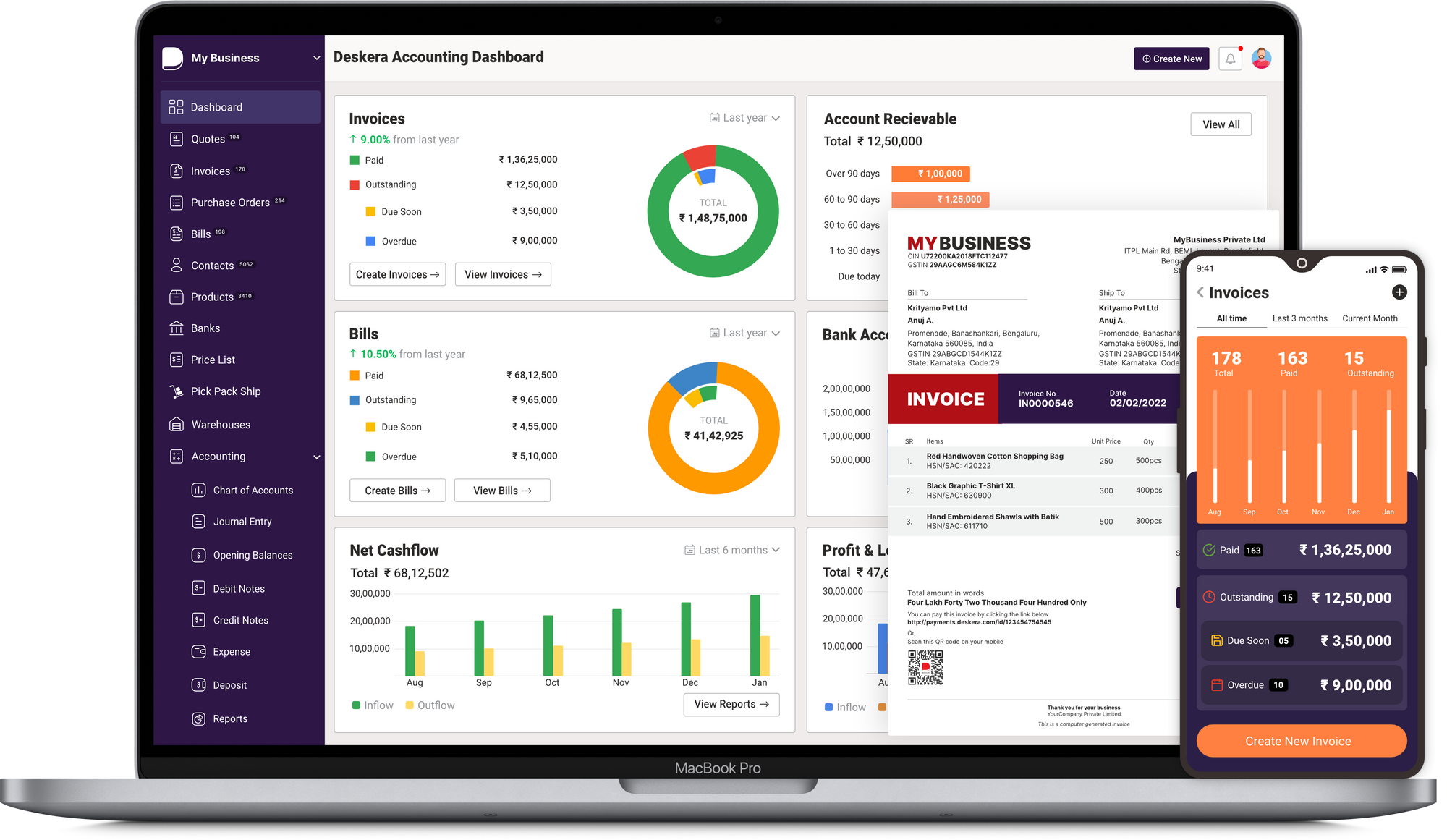

Deskera offers a comprehensive inventory management solution that can help businesses manage their inventory more efficiently. It provides features such as stock tracking, stock alerts, order fulfillment, supplier management, and more.

It also provides useful insights into inventory levels, helping businesses make informed decisions about purchasing and stocking.

Key Takeaways

- Make-to-order (MTO) production is a type of manufacturing process in which products are made only after a customer order has been placed.

- Global Order Promising (GOP) is an important concept in make-to-order production. It is a process that focuses on customer order fulfillment and the delivery of goods and services to the customer on time.

- By using GOP, businesses can provide accurate information to customers about the availability of products and services, delivery times, and other important details.

- GOP helps to reduce costs by eliminating waste and ensuring that resources are used efficiently.

- The most important is to keep accurate records of your inventory and materials.

Related Articles: