The United States is significantly responsible for the cosmetics industry's status as one of the most lucrative marketplaces in the world. The personal care and beauty products market is expanding rapidly as more people purchase them across the country.

A recent report suggests that each year, approximately $49.2 billion is generated by cosmetics sales in the United States. Americans spend between $244 and $313 on cosmetics every month. The global cosmetics industry is valued at $380.2 billion.

These staggering figures only suggest that the cosmetics industry is profitable, and if you are running one or planning to start one, this article might interest you. This article will cover all you need to know about the cosmetics industry and how you can improve your cosmetics business.

This article covers the following:

- What does the making of cosmetics business involve?

- How to start a cosmetics business?

- Checklist of the cosmetics manufacturing process

- Manufacturing of cosmetics include

- Challenges in manufacturing of cosmetics

- Why do you need ERP & MRP software to manage your cosmetics manufacturing business?

- How can Deskera assist you?

What does the Making of Cosmetics Business Involve?

Here is how you can run a successful cosmetics business:

Developing a Business Plan

By developing a plan, you’ll be in a better position to achieve your goals and grow your business even further. They typically start with an overview of the cosmetic manufacturing company and its products or services, with market research analyzing the cosmetic markets and the competition.

The plan then describes its strategy for growing its business and achieving profitability. Finally, a section on financials usually includes projected income and expenses.

Research and Development

Most people think of research and development (R&D) as simply developing new products or improving old ones. But in reality, R&D is a much broader term that encompasses everything from basic research to applied research to development.

Basic research is the kind of research done with pure curiosity, with no specific application. Applied research is when researchers apply basic research findings to practical problems. And cosmetic development is the actual work of bringing a product or process from idea to reality.

Formulation and Ingredients

In cosmetics formulation, it is crucial to consider the ingredients used. Some ingredients may be more harmful than others, and some may not suit certain skin types. Doing your research before selecting ingredients and carefully reading the labels is essential.

Packaging of Products

Packaging for cosmetics is important because it can impact how consumers buy and use beauty products. For example, if the packaging is attractive and eye-catching, customers might be more likely to purchase the product.

In addition, good packaging can help keep cosmetics safe and fresh, which is especially important for perishable items like lipstick or foundation. Finally, well-designed packaging can also communicate the brand’s identity and values, helping to create a connection between the customer and the product.

These factors mean that cosmetic packaging is essential for customers’ positive buying experience.

Delivery

When it comes to shipping makeup and cosmetics, there are a few things you need to take into account. The first is that different products have different requirements in terms of packaging and handling. Additionally, you’ll need to be aware of any restrictions on what can be sent overseas or locally.

How to Start a Cosmetics Business?

Here are a few steps that will help you start your cosmetics business:

Formula Purpose

The most important key to success for your cosmetic line is a well-defined purpose. You need to articulate clearly a purpose that aligns with what you are trying to produce and sell.

The key ingredients of your products should be the major selling point. Specifically, laying out the benefits of using the product will serve as a guiding framework as you move the product toward the marketing process and launch.

Market Research

Before you begin formulating your cosmetic line, you need to perform a thorough market analysis. Ask yourself: has this particular type of product been done before? How did it perform? Equipping yourself with this knowledge will help you to better meet the needs of your target audience.

Budget

Figuring out your budget can be one of the most challenging elements of any business launch, regardless of the industry. Be sure to project costs for both the start-up phase and a sustainable budget over the long term.

Production and Logistics

It is the little details that will hang you up if you are not careful. When figuring out your budget and overall business plan, you need to consider functions such as freight, product fulfillment, and other logistical elements. Developing a detailed plan will ensure that your launch is successful.

Plan and Execute Marketing

A solid marketing strategy encompasses a variety of avenues. As you launch your product, consider developing a press kit, honing your email marketing process, and planning your social media strategy. You can also try finding influencers to promote your product or use giveaways to get the word out and generate interest.

Advertising

As money will most likely be tight while you get your business off the ground, it is important that your advertising target the right audience. To achieve this goal, try buying targeted Facebook and Instagram ads, using blogs and other online publications to spread the word, or infiltrating Pinterest with your cosmetic line.

Sales Channel

In today's connected marketplace, it is no longer the standard to market your products only at brick-and-mortar outlets. There is a dizzying array of sales channels to consider for any product.

Will you be selling your products online, in physical stores, or as a combination of both? Once you decide this, you can narrow down your specific options within each category.

Checklist of Cosmetic Manufacturing Process

Budgeting

A budget is an essential tool for keeping track of one's finances that aids both individuals and families. Additionally, it empowers people to decide how best to allocate their resources.

Here is how to determine your budget:

Figuring out Product Fees

These prices will vary from one company to another, from one product to another, and from one ingredient to another. By analyzing your production costs, you may calculate these fees and ascertain whether:

- Your goods prices are excessive.

- Your vendor costs too much

- By altering your cosmetics manufacturing method, you can increase your profit margins.

Determine Production Costs

To assist you to set a fair price for yourself while providing your consumers the greatest value, you'll need to calculate production overheads. However, the cosmetics sector is heavily regulated, and these restrictions vary from country to country.

You must take this into account when figuring up your production overheads. For instance, what are the related costs of Regulations, Licensing, Permits, and Insurance

Marketing and Advertising

No business is complete without a website! A website will help you with e-commerce D2C selling and give you visibility on search engines. But what other channels are you going to utilize, and what are the costs of advertising in these spaces? From social media to writing blogs, your approach and how many marketing strategies you use are down to you – and your budget, of course.

But as a rule of thumb, here is a list of essential marketing practices:

- Developing a press kit

- Email marketing

- Social media

Sales Channel

We've already discussed how crucial it is to have a website; as an illustration, in the US, digital sales in 2018 were a staggering $258.9 million. Physical stores simply don't have the same impact they formerly had. Today, it's crucial to use multi or omnichannel sales tactics by making sales through

E-commerce

- In-person retailers

- the internet

- markets both online and offline

Manufacturing of Cosmetics Involves

Here are the essentials of cosmetics manufacturing business:

Formula for Cosmetics

In terms of manufacturing, you might think of a formula as your bill of materials.

Your formula will serve as the recipe you must adhere to when creating your cosmetic goods.

Finding a beginning place is necessary, but first things first. This could be from online formularies, your suppliers of raw materials, or even something you make yourself. Regardless of the source, your initial formula should be viewed as a beginning point rather than a finished product.

Describe your Goods

Once you have created something you are happy with, you should begin to outline the final result. What, for instance, is its purpose? It's a cleaning product, right? The moisturizer? a cleaner? a coloring agent or a mix of many elements. After then, you can observe its aesthetic qualities, such as Color\sThickness \and clarity.

It's time to redefine your cosmetics manufacturing technique and recipe if your original product doesn't live up to your expectations.

Manufacturing of Cosmetics through Internal or External Manufacture

Do you want to be actively involved in the manufacturing of your cosmetics, or would you rather send your formula to a contract manufacturer and allow them to handle the labor-intensive tasks?

There is no right or wrong response; in fact, your greatest option may be to manufacture some cosmetics goods yourself while outsourcing others.

In-House Manufacturing of Cosmetics

Steps for in-house manufacturing of cosmetics:

Internal Manufacture of Cosmetics

It's excellent if you have a manufacturing facility that allows you to make your things in your home or office. But now you have to assume all the duties involved in producing your own items. So, where should we start?

Getting your Batch Ready

Establish the number of raw materials you'll require and the number of cosmetic items you'll wish to produce. You can do this with ineffective spreadsheets or cosmetics manufacturing software, depending on your production lines and business size.

Developing your Batch

Making your first batch should be approached as a scientific experiment because, after all, it is a science. As you work through the cosmetics production process, pay close attention to your recipe and make notes.

Cosmetics Manufacturing Business by Outsourcing

A commercial arrangement known as contract manufacturing occurs when one firm contracts another to produce goods or services in accordance with the first company's requirements. It is simple to manage inventory and production at supplier facilities in addition to your own by using contract manufacturing software.

This can be done on a temporary or permanent basis and frequently entails the contractor receiving exclusive technology from the hiring cosmetics firm. Contract manufacturing firms are frequently utilized to create unique or low-volume products.

Here are some simple recommendations for discovering contract manufacturers if this is something you believe your company needs:

- visit conventions for cosmetics

- Look through reliable cosmetics databases.

- Find manufacturers of white-label and private-label products in other countries.

Quality Control of Products

Controlling quality while monitoring the production of cosmetics items. You can imagine how crucial it is to verify the quality of your products during the manufacturing process of cosmetics to prevent your customers from feeling discomfort gave that they will be spreading your goods all over their bodies, for example, skincare, body care, or hair care products.

Batch for Quality

When your batch is complete, let it rest at room temperature and start measuring things like pH and viscosity to ensure everything is in order. Since water can be lost during the heating and cooling, don't forget to weigh the batch. You can top it off if you've lost too much water during the process.

Regulations

The regulation of the cosmetics industry is dynamic and ever-changing, with new standards and constraints appearing frequently. However, there are certain laws that must be observed in every state, nation, and location.

And to further complicate matters, laws may call on you to follow specific procedures. This may involve placing limitations on the use of specific products or banning certain ingredients used in the production of cosmetics.

Regulations are typically developed and updated for public health, animal welfare, or the environment. In the end, ensuring your items and their labels adhere to national and international laws is crucial for your company's success.

Packaging of Products

Basics of packaging products:

Storage

There's a good chance that after a batch is finished, you'll need to keep the goods in your own storage space before shipping them out. To keep your carrying costs low, it's critical to maintain organization in your warehouse and storage area.

Your cosmetic products will also require specific conditions to remain fresh. Ensure that your warehouse's circumstances won't impair the quality of your products.

Shipping

Now is the time to ship your goods once you have some sales orders. Many cosmetic products are vulnerable to deterioration while in transportation. To keep it safe, you should prepare makeup in dunnage, bubble wrap, or other leak-proof packaging material. Just remember to purchase shipping insurance.

Challenges in Manufacturing of Cosmetics

Here are a few challenges in the cosmetics manufacturing process:

Stock Times

Problem When product demands increase, so too must the supply and capacity of the production facilities. There is a concern that achieving a faster speed to market will lead to complex production processes and considerable resource investment.

However, an innovative and quick-response approach to cosmetics production improves the overall cycle time, enabling brands to explore and release a high number of market-relevant items. In turn, this proactive approach presents a positive brand image and supports sales and marketing strategies.

Emulsification Process

In any given cosmetics production cycle time, there are several processing steps. The calculation of this cycle time will begin with the selection and production of the raw materials.

The main raw materials are oil and water, which need to be heated up to 80ᴼC then cooled down to 25ᴼC. And it is this cooling period that makes up the longest part of the cosmetics production process; accounting for approximately 60% of the overall cycle time.

Different Viscosity

Cosmetics products feature different levels of viscosity — the measure of a fluid's resistance to flow. Mascara and facial creams, for example, have a higher level of viscosity compared to typical shampoos, whereas nail polishes contain a low viscosity.

The production process should be designed in conjunction with this viscosity level. If over-designed, the machinery increases both capital expenditure and operating expenses unnecessarily, and if under-designed, the mixers will be unable to produce the product quality required or the total production time will be stretched

Maximum Energy Consumption

The CIP (Cleaning-In-Place) process uses a mix of chemicals, heat, and water to clean machinery, vessels, or pipework without disassembly. Typically, conventional cosmetics production units use hot water, resulting in high energy consumption.

Quality Issues

The utilization of the machine and the accuracy of ingredient dosage are a priority when transforming productivity for modern-day cosmetics production. Yet managing production parameters and planning to the necessary levels of quality and accuracy through manual processes creates risks and opens up the possibility of error.

Comprehensive and effective governance is harder to achieve due to the number of process steps, ingredients, and individual machines used in production processes.

Why do you Need an ERP & MRP System for Cosmetics Manufacturing Business?

ERP & MRP systems for Personal Care and Cosmetics are essential for every business today. It is designed and developed to make your business a breeze. An ERP software for cosmetics and personal care provides real-time visibility of all the business processes and also has specific modules which are required for smooth business processes like- formula security, lot traceability, quality assurance, physical properties change control, compliance, etc.

The unique features of cosmetic manufacturing ERP software help the manufacturers to remain competitive by getting rid of paper-based manual processes that hinder productivity and also allow them to implement current good manufacturing practices.

A best-in-class cosmetic formulation software also empowers businesses with real-time business data, and the ability to manage costs and make more informed and accurate decisions.

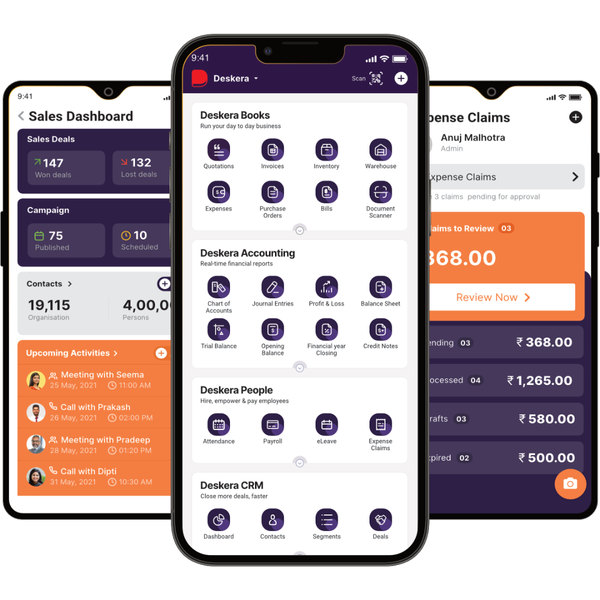

How Can Deskera Assist You?

Remember discussing best-in-class ERP software? There is no way you can find anything as well-equipped as the Deskera ERP software. Deskera MRP allows you to closely monitor the manufacturing process.

From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Key Takeaways:

- The most important key to success for your cosmetic line is a well-defined purpose.

- Before you begin formulating your cosmetic line, you need to perform a thorough market analysis.

- the cosmetics sector is heavily regulated.

- You can imagine how crucial it is to verify the quality of your products during the manufacturing process of cosmetics to prevent your customers from feeling discomfort.

- Cosmetics products feature different levels of viscosity

- The utilization of the machine and the accuracy of ingredient dosage are a priority when transforming productivity for modern-day cosmetics production.

- An ERP software for cosmetics and personal care provides real-time visibility of all business processes.

Related Articles: