In the manufacturing industry, customer complaints are more than just a service issue—they can directly impact brand reputation, customer loyalty, and revenue. Many businesses underestimate the silent losses they incur, with over half of customers (56%) choosing not to complain at all but simply switching to a competitor after a single bad experience. For those who do give second chances, patience is limited—73% will eventually walk away after multiple negative interactions.

Loyal customers are worth protecting, and the key often lies in how businesses respond. When a complaint is handled effectively, 83% of customers say they feel more loyal to the brand. On the other hand, negative experiences tend to spread quickly, with 95% of dissatisfied customers telling others about it. This kind of word-of-mouth can amplify the damage far beyond the initial complaint, influencing potential buyers and eroding trust.

The financial implications are just as significant. Businesses that focus on improving customer service can grow revenues between 4% and 8% above their market, proving that customer experience is directly tied to profitability. Even more telling, 81% of customers are willing to pay more for better service. For manufacturers, this means every effort to improve quality control, delivery performance, and after-sales support not only prevents complaints but can also boost long-term revenue and market share.

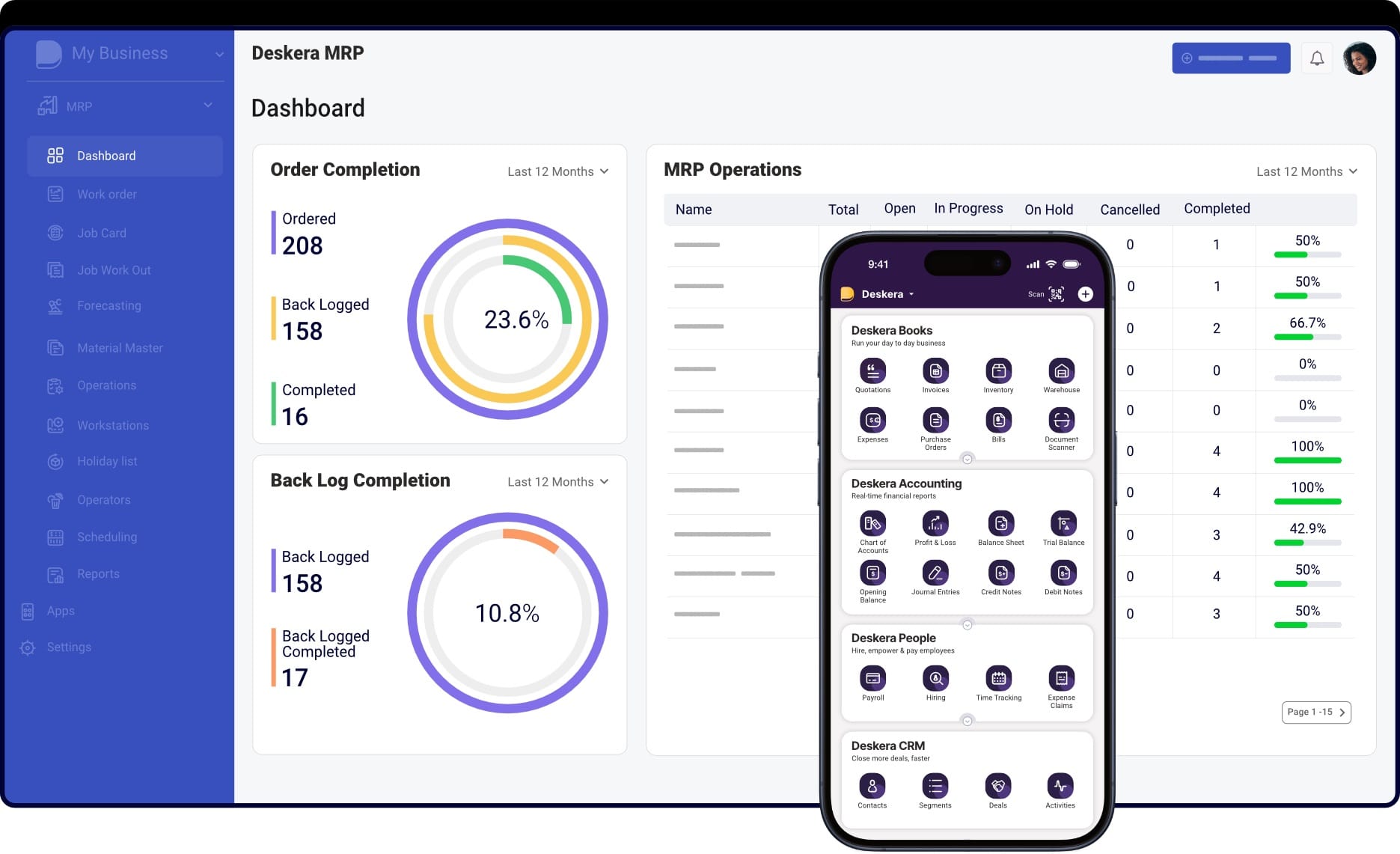

This is where technology like Deskera MRP can help turn customer satisfaction into a competitive advantage. Deskera’s cloud-based manufacturing ERP provides advanced production planning, supplier management, and AI-driven insights to detect and address potential issues before they reach the customer.

With mobile accessibility, demand forecasting, and integrated reporting, Deskera MRP empowers manufacturers to consistently deliver on time, maintain high quality, and proactively reduce customer complaints while improving operational efficiency.

What Are Customer Complaints in Manufacturing?

Customer complaints are expressions of dissatisfaction from buyers about a product, service, or overall experience. In the manufacturing industry, these complaints often arise from issues such as defective products, delayed deliveries, unclear policies, poor communication, or unmet expectations between what was promised and what was delivered. They can also stem from inadequate after-sales support or a frustrating customer service interaction.

These grievances may be communicated privately—through email, feedback forms, or direct calls—or publicly via social media, review platforms, and industry forums. While the term “complaint” often carries a negative tone, it’s important to see it as more than just a problem. When handled effectively, complaints can act as valuable feedback, revealing weaknesses in processes, highlighting areas for quality improvement, and creating opportunities to strengthen customer trust.

It’s also worth noting that, in legal contexts, a complaint is the first formal document filed in a lawsuit. This serves as a reminder that unresolved or poorly managed complaints in manufacturing can escalate from small frustrations into significant reputational harm—or even legal consequences.

Causes of Customer Complaints in Manufacturing

While even the best products can receive occasional criticism, recurring complaints in manufacturing usually point to deeper operational issues. These often involve product quality, customer service, communication, delivery, or policy-related problems.

Understanding these root causes is essential for preventing dissatisfaction, protecting brand reputation, and improving customer retention.

1. Product Quality Issues

Customers expect products that are durable, well-made, and perform exactly as promised. Complaints arise when items have defects, contain substandard materials, or fail prematurely. Inconsistent quality between batches, performance shortfalls, and safety concerns can quickly erode trust and lead to returns, replacements, or lost business.

2. Poor Customer Experience

Unhelpful or unresponsive service teams, long wait times, and inadequate follow-up can leave customers feeling undervalued. Misalignment between what customers expect and what they actually receive—whether in product features, specifications, or performance—also fuels dissatisfaction. In manufacturing, where strong relationships are vital for repeat orders, ensuring a consistently positive customer experience is as critical as product quality.

3. Poor Communication

Lack of clear updates on order status, vague or incorrect responses, and complete communication gaps can frustrate customers. When companies fail to proactively address these issues, complaints may escalate to public channels like social media, review platforms, or even legal disputes.

4. Confusing Policies

Complex or inflexible return processes, unclear warranty terms, and inconsistent pricing policies can create unnecessary friction. Customers value transparency and ease when resolving issues; anything less can quickly lead to dissatisfaction.

5. Delivery Problems

Delayed shipments, damaged goods, or incorrect orders can disrupt customer operations—especially in B2B manufacturing, where a delay may halt entire production lines. These issues are even more damaging when customers aren’t informed promptly or offered viable solutions.

6. Pricing Concerns

Unexpected price changes, discrepancies between quotes and final invoices, or a perceived mismatch between cost and value can all trigger complaints. In competitive markets, even small pricing misunderstandings can push customers toward alternative suppliers.

By identifying and addressing these triggers, manufacturers can reduce the frequency of complaints, improve customer satisfaction, and foster stronger long-term relationships.

13 Effective Ways to Reduce Customer Complaints in the Manufacturing Industry

While no manufacturer can completely eliminate complaints, proactive strategies can reduce their frequency and impact. By identifying root causes, addressing customer pain points, and fostering a culture of improvement, manufacturers can protect relationships and strengthen their brand reputation.

1. Strengthen Quality Control Standards

Quality issues remain the top driver of customer complaints in manufacturing. Implementing rigorous quality control processes—supported by measurable benchmarks—ensures that every unit meets expectations. Schedule regular inspections, maintain audit checklists, and track defect trends across product lines. Involve quality teams at multiple production stages, not only during final inspections.

When recurring defects are detected, evaluate whether they stem from supplier issues, production techniques, or environmental factors. Making targeted improvements at the source reduces repeat problems, increases customer satisfaction, and ultimately safeguards brand credibility.

2. Proactively Solicit Feedback

Not all dissatisfied customers speak up—some simply stop buying. Actively soliciting feedback through post-purchase surveys, follow-up calls, or online reviews helps uncover hidden dissatisfaction early. Gathering both positive and neutral feedback provides valuable context, revealing unmet expectations before they escalate into public complaints.

Make it easy for customers to respond by offering multiple channels, including email, SMS, and in-product QR codes. Acting on early insights not only reduces future complaints but also demonstrates a manufacturer’s commitment to listening and improving, strengthening customer trust over time.

3. Be Transparent

When problems arise, silence or vague responses only increase frustration. Transparency builds trust, even if the solution is still in progress. Explain the issue clearly—whether it’s a production delay, a defective batch, or a supply chain disruption—along with what actions are being taken to resolve it.

Share realistic timelines, and provide updates at key milestones. Customers value honesty and appreciate when companies take responsibility rather than shifting blame. This openness can turn a potentially negative experience into a loyalty-building moment, reducing the risk of escalation.

4. Monitor Complaint Data

Centralizing complaint records across all channels—phone calls, emails, online reviews, and customer service tickets—allows for comprehensive analysis. By categorizing issues, manufacturers can identify patterns, such as frequent defects in a specific product line or repeated delivery problems in certain regions.

Tracking trends over time can also reveal early warning signs, helping teams address problems before they impact more customers. Use dashboards or reporting tools to ensure every department works from the same dataset, enabling coordinated responses and long-term fixes instead of temporary patches.

5. Train Staff in Communication Skills

The outcome of a complaint often depends as much on how it is handled as on the actual resolution. Customer-facing staff should be trained in active listening, empathy, and conflict resolution. This means giving customers time to explain their concerns fully, acknowledging their frustration, and responding respectfully.

In manufacturing, where B2B relationships may involve high-value contracts, these skills are crucial for preserving trust. Equipping staff with both product knowledge and interpersonal techniques ensures that even when issues occur, the customer feels heard and respected.

6. Simplify Policies

Overly complex return processes, warranty terms, or service agreements can frustrate customers and drive unnecessary complaints. Review all policies from a customer’s perspective: Are they easy to find? Can they be understood in a single read-through? If the answer is no, simplify the language and eliminate unnecessary steps.

Provide clear instructions and examples, especially for common scenarios like exchanges or repairs. A transparent, straightforward policy reduces confusion, improves the customer experience, and shortens resolution times—freeing up service teams to focus on more complex issues.

7. Share Feedback Across Teams

Customer complaints often involve multiple touchpoints—from sales and production to logistics and after-sales support. Sharing complaint data across teams ensures a unified understanding of the problem and enables cross-departmental solutions. This might include weekly review meetings, shared dashboards, or automated reports.

Assign clear ownership for recurring issues, track progress toward resolution, and follow up to confirm improvements are effective. When all departments work collaboratively toward complaint reduction, customers experience a more consistent, reliable service, and repeat problems become far less common.

8. Leverage Technology

Modern complaint management tools can streamline responses and improve accuracy. CRM systems, help desks, and ticketing platforms centralize customer interactions, making it easier to track and resolve issues. Integrating these systems with production, supply chain, or inventory platforms provides real-time visibility, enabling quicker diagnosis of problems like stock shortages or defective batches.

Self-service customer portals can also reduce incoming complaints by allowing customers to check order status, submit support requests, or track resolutions on their own—minimizing repeated follow-ups and improving satisfaction.

9. Streamline Internal Processes

Inefficient workflows can lead to errors, delays, and inconsistent outputs—all common sources of complaints. By reviewing every stage of your manufacturing process, you can identify bottlenecks, duplication of effort, or unnecessary manual steps. Implement lean manufacturing principles, automate repetitive tasks where possible, and document standardized procedures to ensure consistency.

Training staff on these optimized workflows reduces the likelihood of mistakes, improves speed, and ensures that customers receive accurate, high-quality products on time—reducing the triggers for dissatisfaction.

10. Build a Customer-Centric Culture

A culture that prioritizes customer satisfaction across every department reduces complaints naturally. This involves instilling values of accountability, empathy, and continuous improvement at all levels—from executives to production staff. Encourage open communication with customers, reward employees for exceptional service, and integrate customer-focused KPIs into performance reviews.

When every employee understands how their role impacts the end customer, they become more invested in preventing issues rather than simply reacting to them, resulting in a more proactive and complaint-resistant organization.

11. Implement Preventive Maintenance

Equipment breakdowns can halt production, delay deliveries, and result in product defects—major sources of customer dissatisfaction. By scheduling regular preventive maintenance, manufacturers can reduce unexpected downtime and keep production lines running smoothly.

This includes routine inspections, timely part replacements, and performance monitoring. A proactive approach to maintenance not only ensures consistent output quality but also demonstrates reliability to customers, minimizing the risk of complaints related to delays or faulty products.

12. Optimize Production Planning

Poor scheduling or inefficient resource allocation often leads to late orders, production bottlenecks, and inconsistent quality—all triggers for customer complaints. Implementing advanced production planning tools and processes helps align supply chain availability, labor resources, and production capacity.

Accurate forecasting ensures that manufacturing timelines are realistic and achievable, reducing last-minute changes or missed deadlines. Effective planning keeps operations predictable, enhancing customer confidence and satisfaction.

13. Monitor Key Performance Indicators (KPIs)

Without measurable performance data, it’s difficult to know where improvements are needed. Tracking KPIs such as defect rates, on-time delivery percentages, and complaint resolution times provides valuable insight into operational health.

By reviewing these metrics regularly, manufacturers can identify problem areas early and make informed adjustments before issues escalate. A data-driven approach helps ensure consistent quality and better customer experiences, leading to fewer complaints.

How to Handle Customer Complaints in the Manufacturing Industry

Even with robust preventive measures, customer complaints are inevitable. What sets top manufacturers apart is how effectively they respond. A prompt, professional, and empathetic approach can transform a frustrated customer into a loyal advocate.

Here’s a practical, step-by-step framework for handling complaints in manufacturing:

- Acknowledge Promptly: Respond as soon as the complaint is received—even if you don’t have an immediate solution. A quick acknowledgment reassures the customer that their concern is being taken seriously.

- Listen and Understand: Give the customer space to fully explain the issue. Ask clarifying questions, review inspection records, and gather all relevant data to validate the claim and understand the root cause.

- Apologize Sincerely: Offer a genuine apology that acknowledges the inconvenience or loss caused. This builds rapport and demonstrates accountability.

- Investigate and Explain: Conduct a thorough investigation using tools like root cause analysis, Pareto charts, or the 5 Whys. Share a transparent explanation of what went wrong, and outline corrective steps with a clear timeline.

- Offer a Fair Resolution: Depending on the situation, provide a replacement, repair, partial refund, or goodwill gesture. Ensure the resolution aligns with both company policies and the customer’s expectations.

- Follow Up After Resolution: Check in with the customer after the issue is resolved to confirm satisfaction. This shows long-term commitment, not just damage control.

- Document and Share Insights: Record all complaint details, investigation results, and solutions. Share insights across departments to prevent recurrence and improve processes.

- Implement Preventive Measures: Adjust manufacturing processes, quality control steps, or supplier requirements to address the root cause. Monitor results to ensure the issue doesn’t resurface.

By combining empathy with systematic problem-solving, manufacturers can turn complaints into opportunities for strengthening relationships, improving quality, and building long-term trust.

How Can Deskera MRP Help You Manage Customer Complaints?

Deskera MRP streamlines complaint management by giving manufacturers complete visibility over their operations, enabling faster resolutions and long-term quality improvements. With its centralized platform, automation capabilities, and AI-powered insights, it ensures that issues are addressed proactively rather than reactively. Here’s how it can help:

- Centralized Complaint Tracking – Record and manage all customer complaints in one place, ensuring nothing gets missed.

- Batch and Supplier Traceability – Identify the exact batch, supplier, or production run linked to the complaint for faster root cause analysis.

- Automated Corrective Action Workflows – Assign, monitor, and complete corrective actions promptly to prevent recurrence.

- Data-Driven Insights – Use built-in analytics to spot recurring patterns in complaints and implement targeted improvements.

- Cross-Team Collaboration – Enhance coordination between production, quality assurance, and customer service teams for quicker resolutions.

- AI Assistant “David” – Get instant AI-driven recommendations for resolving recurring complaints or improving production processes.

- Mobile Accessibility – Log, track, and resolve complaints on the go, ensuring quick responses even outside the office.

- Integration with Quality Control and Inventory – Link complaint data to quality checks and inventory records for more accurate investigations.

- Demand Forecasting Impact Analysis – Assess how recurring product issues might affect demand forecasts and take corrective measures.

Key Takeaways

- Understand the Root Causes of Customer Complaints – Identifying issues at their source allows manufacturers to implement corrective measures before they impact the end customer.

- Enhance Communication Between Departments – Open communication ensures smooth handoffs across production, quality control, and customer service, preventing misunderstandings that lead to complaints.

- Implement Preventive Maintenance – Regular equipment upkeep minimizes production errors and defective products, boosting customer satisfaction.

- Standardize Quality Control Processes – Consistent inspection methods ensure that only products meeting required specifications reach customers.

- Provide Comprehensive Staff Training – Well-trained employees are more likely to follow best practices, avoid mistakes, and address issues proactively.

- Gather and Act on Customer Feedback – Collecting and analyzing customer insights helps in refining processes and enhancing the overall customer experience.

- Optimize Production Planning – Proper scheduling and resource allocation reduce delays, defects, and order fulfillment issues.

- Leverage Technology for Process Improvement – Tools like MRP systems streamline operations, enhance visibility, and ensure better decision-making.

- Monitor Key Performance Indicators (KPIs) – Tracking defect rates, returns, and resolution times enables data-driven improvements in manufacturing quality.

- Encourage a Culture of Continuous Improvement – Fostering accountability and innovation within teams drives ongoing product and service enhancements.

- Utilize Deskera MRP for Seamless Operations – Deskera MRP integrates production, inventory, and quality management, enabling proactive issue resolution and reducing customer complaints.

Related Articles