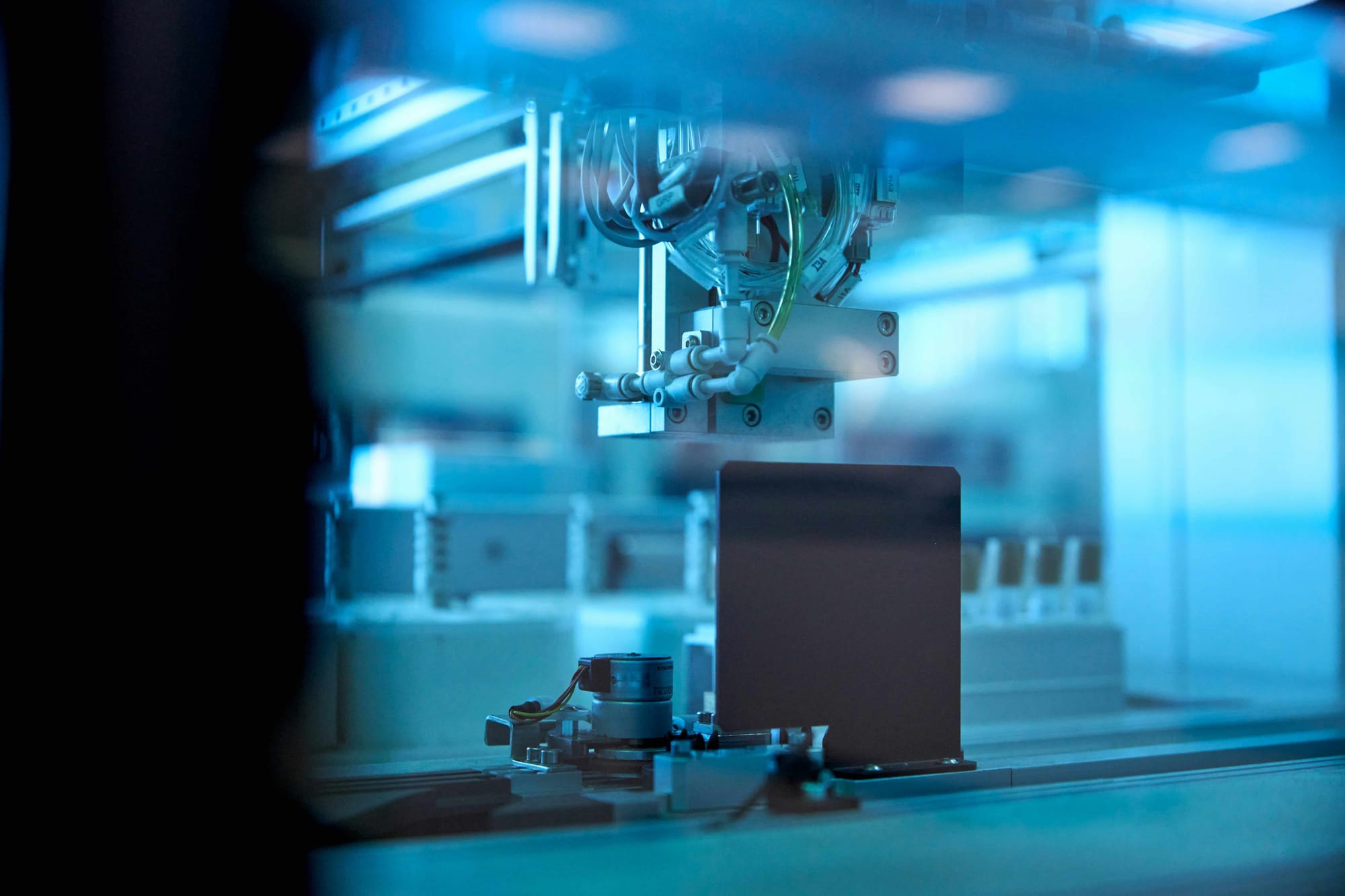

Maintenance planning plays a pivotal role in keeping industrial operations reliable, efficient, and cost-effective. In asset-intensive environments such as manufacturing, utilities, and processing industries, equipment performance directly impacts output, quality, and customer commitments. Without a structured approach to maintenance planning, organizations often fall into reactive cycles—addressing breakdowns only after they disrupt production and inflate costs.

The financial impact of maintenance further highlights why planning cannot be overlooked. On average, maintenance activities account for 20–50% of an organization’s total operating budget, making it one of the largest controllable cost areas in operations. When maintenance is poorly planned, these costs rise sharply through emergency repairs, overtime labor, excess spare parts, and extended downtime. Conversely, effective maintenance planning improves asset reliability, stabilizes maintenance spend, and strengthens overall productivity and competitiveness.

At its core, maintenance planning focuses on defining what work needs to be done, how it should be executed, and what resources are required—before the work begins. This proactive discipline ensures that technicians, tools, spare parts, and procedures are aligned in advance, reducing delays and inefficiencies during execution. Maintenance planning also lays the foundation for preventive and predictive maintenance strategies, enabling organizations to shift away from costly reactive maintenance models.

Modern manufacturing organizations increasingly rely on digital systems to support this planning process. Deskera MRP enables structured maintenance planning by centralizing asset data, maintenance schedules, work orders, and spare parts visibility within a single platform. By integrating maintenance planning with production planning, inventory management, and procurement, Deskera MRP helps manufacturers minimize downtime, control maintenance costs, and maintain uninterrupted operations while supporting long-term asset performance.

What Is Maintenance Planning?

Maintenance planning is an end-to-end, proactive process that focuses on identifying maintenance needs in advance and preparing everything required to execute maintenance work efficiently.

It involves determining what maintenance tasks need to be performed, why they are necessary, and how they should be carried out, long before the work reaches the shop floor. By defining these elements upfront, maintenance planning minimizes uncertainty, delays, and reactive decision-making during execution.

At a practical level, maintenance planning covers much more than task identification. It includes preparing detailed job instructions, estimating labor and time requirements, identifying tools and materials, and ensuring spare parts are available and staged at the right location.

This may involve handling reserve parts, ordering non-stock items, staging and illustrating parts, maintaining vendor and breakdown lists, and supporting quality assurance (QA) and quality control (QC) activities. The goal is to ensure that when a maintenance job is released, technicians can complete it without interruptions caused by missing information or materials.

Maintenance planning is often described as the backbone of an effective maintenance strategy because it directly supports asset reliability and performance. Similar to planning regular home maintenance instead of waiting for things to fail, organizations use maintenance planning to inspect, repair, and replace equipment components based on condition, criticality, and operational impact. This structured approach helps reduce unplanned downtime, extend asset life, and control maintenance costs while improving overall equipment availability.

Importantly, maintenance planning is not limited to physical assets alone. It also involves planning human resources by aligning workloads, skills, and availability to maintenance demand. By systematically organizing resources—both human and material—maintenance planning enables teams to operate efficiently without overburdening staff, while remaining prepared to respond to both routine maintenance needs and unexpected issues. In this way, maintenance planning serves as a proactive safeguard against risk, ensuring assets continue to operate at optimal performance levels.

Key Components of Maintenance Planning

Effective maintenance planning relies on a set of interrelated components that ensure maintenance work is prepared, resourced, and executed efficiently. When these components are clearly defined and consistently applied, organizations can shift from reactive repairs to a structured, reliability-focused maintenance approach.

Asset and Equipment Information

Accurate asset data forms the foundation of maintenance planning. This includes equipment hierarchies, asset criticality, maintenance history, operating conditions, and failure records. Reliable asset information allows planners to prioritize maintenance activities, define appropriate maintenance strategies, and make informed decisions that support long-term asset performance.

Maintenance Task Definition and Job Plans

Well-defined maintenance tasks and standardized job plans are essential for consistent execution. This component involves documenting the scope of work, step-by-step instructions, safety requirements, estimated labor hours, and tools needed for each task. Clear job plans reduce ambiguity, improve first-time fix rates, and help technicians complete work efficiently.

Resource and Labor Planning

Maintenance planning requires aligning the right people with the right skills at the right time. This includes estimating labor requirements, identifying required competencies, and balancing workloads across maintenance teams. Effective labor planning prevents over-allocation, reduces overtime, and ensures critical maintenance work is completed without delays.

Spare Parts and Materials Planning

Ensuring the availability of spare parts and materials is a critical aspect of maintenance planning. This component involves identifying required parts in advance, managing reserve and non-stock items, staging materials, and coordinating with inventory and procurement teams. Proper materials planning minimizes downtime caused by missing or delayed parts.

Tools, Equipment, and Worksite Preparation

Beyond labor and materials, maintenance planning also accounts for the tools, equipment, and workspace needed to perform the job safely and efficiently. This includes ensuring tools are available, calibrated, and in good condition, as well as confirming that the work area is prepared and accessible before maintenance begins.

Quality, Safety, and Compliance Considerations

Maintenance planning must incorporate quality standards, safety procedures, and regulatory requirements. This includes defining inspection checkpoints, QA/QC requirements, safety permits, and compliance documentation. Integrating these elements into the planning process helps prevent rework, accidents, and compliance issues.

Together, these components ensure that maintenance activities are not only well-organized but also aligned with broader operational and reliability goals, enabling smoother execution and better asset performance.

Maintenance Planning vs. Maintenance Scheduling

Maintenance planning and maintenance scheduling are closely related but fundamentally different activities within an effective maintenance management strategy. While they are often used interchangeably, each serves a distinct purpose and addresses different stages of the maintenance process. Understanding the difference between the two is essential for improving maintenance efficiency and asset reliability.

Maintenance planning focuses on defining what work needs to be done and how it should be executed. It involves preparing detailed job plans, identifying required tools, spare parts, materials, labor skills, and safety requirements, and documenting procedures before the work is released. Planning answers the questions what, why, and how—ensuring maintenance tasks are fully prepared and ready for execution without last-minute disruptions.

Maintenance scheduling, on the other hand, determines when the planned work will be performed and who will perform it. It involves allocating time slots, assigning technicians, coordinating with production schedules, and sequencing work based on priority and resource availability. Scheduling ensures that planned maintenance tasks fit into operational timelines with minimal impact on production.

In practice, planning should always come before scheduling. A maintenance task that is scheduled without proper planning often leads to delays, idle labor, missing parts, and incomplete work. Conversely, well-planned maintenance tasks are easier to schedule, execute faster, and deliver more predictable outcomes. Together, maintenance planning and scheduling create a structured, proactive maintenance workflow that reduces downtime, optimizes resource utilization, and supports long-term asset performance.

Types of Maintenance Planning

Maintenance planning is a strategic, top-level activity that adapts to different asset types, operating conditions, and business priorities. Rather than relying on a single approach, organizations use multiple maintenance planning strategies to balance cost, risk, and reliability.

Below are the most widely used types of maintenance planning, integrated into a comprehensive maintenance framework.

Preventive Maintenance Planning

Preventive maintenance planning focuses on performing maintenance activities at predefined intervals to reduce the likelihood of equipment failure. These plans are commonly time-based, such as scheduled inspections or servicing, or usage-based, triggered by operating hours, cycles, or meter readings.

This approach helps extend asset life, improve reliability, and reduce unplanned downtime, especially for critical equipment with predictable wear patterns.

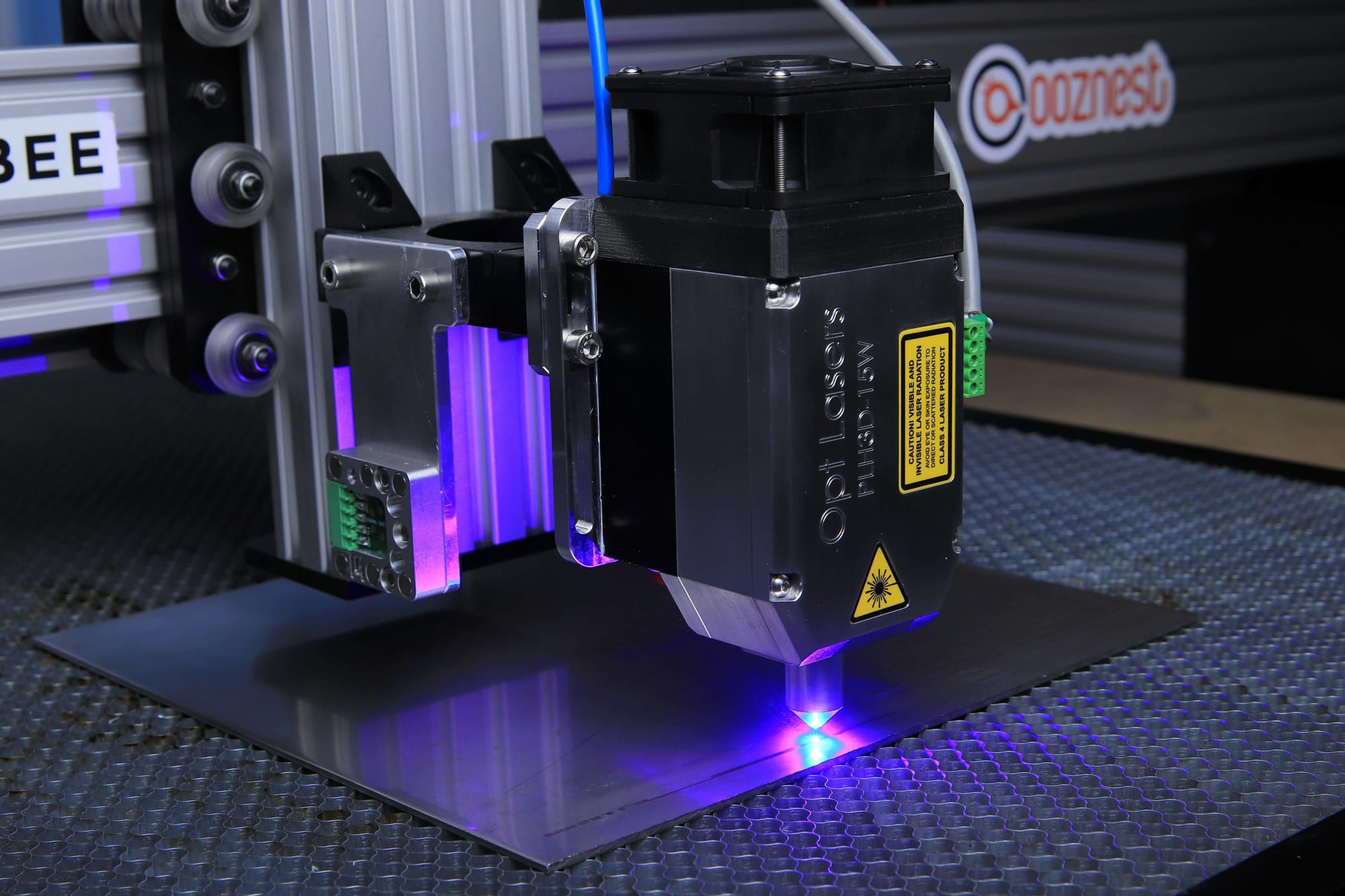

Predictive Maintenance Planning

Predictive maintenance planning uses condition monitoring and performance data to anticipate failures before they occur. It relies on inputs such as sensor readings, vibration analysis, temperature trends, and inspection data to identify early signs of degradation.

By planning maintenance only when indicators cross defined thresholds, organizations can minimize unnecessary work while preventing costly breakdowns. This strategy is most effective when supported by digital maintenance systems that continuously track asset health.

Condition-Based Maintenance Planning

Condition-based maintenance planning is closely related to predictive maintenance but typically focuses on specific condition indicators rather than advanced predictive models.

Maintenance actions are triggered when measured conditions—such as wear, pressure, or temperature—deviate from acceptable limits. This approach allows organizations to move beyond fixed schedules and plan maintenance based on actual asset condition, improving efficiency while maintaining reliability.

Corrective Maintenance Planning

Corrective maintenance planning involves organizing repair activities after a fault or abnormal condition has been identified, but before total equipment failure occurs.

While corrective maintenance is often associated with reactive work, structured planning ensures that once an issue is detected, the scope of work, required resources, spare parts, and timelines are clearly defined.

This approach is commonly used for unexpected issues or assets where preventive maintenance is not always practical.

Reactive Maintenance Planning (Run-to-Failure)

Reactive maintenance planning follows a run-to-failure strategy, where maintenance is performed only after equipment breaks down. Although it involves minimal advance planning, it still requires preparedness in terms of spare parts availability, emergency procedures, and vendor support.

This approach is typically reserved for non-critical, low-risk assets where the cost of preventive maintenance outweighs the cost of repair. Excessive reliance on reactive maintenance, however, is widely recognized as a driver of higher downtime and maintenance costs.

Shutdown and Turnaround Planning

Shutdown and turnaround planning supports large-scale, planned maintenance events that require partial or complete operational stoppages. This type of planning involves detailed coordination of labor, contractors, materials, safety procedures, and timelines to ensure complex maintenance activities are completed within a fixed window. Effective shutdown planning is critical for minimizing downtime, managing risk, and restoring assets to optimal operating condition.

Together, these maintenance planning types form a balanced, structured approach that enables organizations to apply the right maintenance strategy to the right asset—supporting reliability, cost control, and long-term operational performance.

Benefits of Effective Maintenance Planning

Effective maintenance planning delivers measurable operational, financial, and safety advantages by ensuring maintenance activities are proactive, structured, and well-coordinated.

Rather than reacting to failures, organizations that invest in maintenance planning optimize the entire maintenance process—improving reliability while controlling costs and risks.

Reduced Downtime and Fewer Unplanned Repairs

One of the most significant benefits of effective maintenance planning is reduced downtime. By identifying potential issues early and addressing them before failures occur, organizations can prevent unexpected breakdowns that disrupt operations.

Preventive and predictive maintenance planning, in particular, helps minimize unplanned repairs, ensuring equipment remains available and production schedules stay on track.

Increased Equipment Lifespan

Regular, well-planned maintenance slows equipment wear and tear and helps assets operate within optimal conditions. Industry findings indicate that aging equipment contributes to a substantial share of unscheduled breakdowns, reinforcing the importance of proactive maintenance planning. By implementing routine inspections and timely repairs, organizations can extend asset life and delay costly replacements.

Improved Maintenance Efficiency and Productivity

Maintenance planning enables better allocation of labor, tools, and materials, leading to smoother execution of maintenance work. With clear job plans, staged parts, and defined procedures, technicians spend less time waiting, searching for information, or redoing work. This results in higher maintenance productivity, lower labor costs, and a more orderly work environment.

Cost Savings and Better Budget Control

Effective maintenance planning reduces overall maintenance costs by minimizing emergency repairs, overtime labor, and production losses caused by equipment failure. It also helps control indirect costs such as energy consumption and premature asset replacement. By addressing small issues early, organizations avoid larger, more expensive failures later.

Improved Safety and Risk Reduction

Planned maintenance allows organizations to identify hazards in advance and implement appropriate safety measures. This proactive approach reduces the likelihood of accidents caused by equipment failure or rushed emergency repairs. A well-planned maintenance process contributes to a safer workplace and stronger compliance with health and safety standards.

Greater Operational Reliability and Proactive Culture

Beyond immediate cost and efficiency gains, effective maintenance planning fosters a proactive maintenance culture. Assets become more reliable, production becomes more predictable, and maintenance teams shift from firefighting to continuous improvement. Ultimately, strong maintenance planning supports higher production output, improved asset reliability, and increased profitability.

Together, these benefits demonstrate that maintenance planning is not just about keeping equipment running—it is a strategic capability that strengthens operational performance and long-term business resilience.

Common Challenges in Maintenance Planning

While maintenance planning delivers significant operational and financial benefits, many organizations struggle to implement it effectively. These challenges often stem from data gaps, process inefficiencies, and organizational constraints, making it difficult to move from reactive maintenance to a structured, proactive approach.

Incomplete or Inaccurate Asset Data

Effective maintenance planning depends on reliable asset information, including equipment specifications, maintenance history, and failure data. In many organizations, this data is incomplete, outdated, or scattered across spreadsheets and systems. Poor asset data limits visibility, leads to inaccurate job plans, and makes it harder to prioritize maintenance activities based on criticality.

Reactive Maintenance Culture

A strong reliance on reactive or run-to-failure maintenance remains one of the biggest obstacles to effective planning. When teams are constantly responding to breakdowns, there is little time to plan maintenance work properly. This firefighting mindset results in rushed repairs, higher costs, and recurring failures, reinforcing the cycle of unplanned maintenance.

Poor Coordination Between Teams

Maintenance planning often requires close coordination between maintenance, operations, inventory, and procurement teams. When these functions operate in silos, planners may schedule work without confirmed spare parts availability or production alignment. This lack of coordination leads to delays, rescheduled work orders, and inefficient use of resources.

Spare Parts Availability and Inventory Issues

Unplanned stockouts, excess inventory, or inaccurate spare parts records can significantly disrupt maintenance execution. Without clear visibility into parts availability, maintenance jobs may be delayed or completed partially, increasing downtime and labor inefficiencies. Balancing spare parts availability with inventory costs remains a persistent challenge.

Limited Resource Visibility and Skill Constraints

Maintenance planners need clear insight into workforce availability, skill levels, and workload distribution. In many cases, labor planning is done manually, making it difficult to assign the right technicians to the right jobs at the right time. Skill shortages and over-allocation further complicate planning and reduce schedule compliance.

Manual and Disconnected Planning Processes

Relying on spreadsheets, paper-based systems, or disconnected tools limits the effectiveness of maintenance planning. Manual processes increase the risk of errors, slow down planning cycles, and reduce real-time visibility into maintenance workloads and performance. This makes it harder to adapt plans when conditions change.

Difficulty Measuring Maintenance Performance

Without defined KPIs and reliable reporting, organizations struggle to assess how effective their maintenance planning efforts are. Metrics such as planned vs. unplanned work, schedule compliance, and maintenance backlog are often inconsistently tracked, limiting opportunities for continuous improvement.

Addressing these challenges requires not only better tools and data, but also a shift in mindset toward proactive maintenance planning and cross-functional collaboration.

Best Practices for Effective Maintenance Planning

Implementing maintenance planning successfully requires more than defining tasks—it demands structured processes, accurate data, and cross-functional collaboration.

The following best practices, drawn from established maintenance management principles, help organizations build a mature, efficient, and scalable maintenance planning function.

Establish a Clear Maintenance Planning Organization

Effective maintenance planning starts with clearly defined roles and responsibilities. This often includes dedicated maintenance planners, schedulers, and coordinators working together to prepare, prioritize, and sequence maintenance work.

A structured planning organization ensures accountability, improves coordination, and allows maintenance teams to focus on execution rather than last-minute decision-making.

Maintain Clean and Accurate Asset Records

Accurate asset inventory data is the foundation of effective maintenance planning. Organizations should conduct regular asset audits to ensure equipment records reflect real-world conditions, maintenance history, and criticality.

Obsolete or duplicate records should be eliminated, and updates should be made continuously. When resources are limited, prioritizing critical assets first ensures planning efforts deliver the highest operational impact.

Use Data-Driven Asset Prioritization

Not all assets carry the same risk or operational importance. Maintenance planning should prioritize critical, high-risk equipment over non-critical assets using structured asset categorization and risk assessments.

By evaluating factors such as safety impact, downtime risk, and repair costs, planners can allocate resources where they matter most and avoid over-maintaining low-risk equipment.

Standardize Work and Develop Clear Procedures

Standardized job plans and operating procedures improve consistency, safety, and efficiency. These procedures should include step-by-step instructions, safety requirements, estimated durations, tools, and materials needed.

Incorporating visual aids such as diagrams further improves clarity. Standardization also makes it easier to estimate labor and material needs accurately and ensures technicians always have the right instructions.

Define Planning Horizons

Different types of maintenance work require different planning timeframes. Emergency repairs may be planned hours in advance, while preventive work might be planned weeks ahead, and major shutdowns or overhauls planned months in advance.

Clearly defined planning horizons help balance urgency with preparedness, ensuring maintenance work is neither rushed nor delayed unnecessarily.

Refine Estimates for Labor, Materials, and Tools

Accurate estimation is a core planning responsibility. Planners should use historical data and past job performance to refine estimates for labor hours, required skills, spare parts, tools, and equipment.

Precise forecasting reduces delays, prevents resource shortages, and minimizes unnecessary costs caused by over-allocation or emergency procurement.

Ensure Spare Parts Availability Without Over-Stocking

Effective maintenance planning strikes a balance between availability and cost. Critical spare parts should be kept in stock to avoid delays, while unnecessary MRO inventory—often representing a large portion of item types—should be minimized. Regular reviews of spare parts usage help reduce excess inventory while ensuring readiness for planned work.

Leverage Maintenance Software for Planning and Insights

Maintenance planning becomes significantly more effective when supported by CMMS or ERP systems. These tools centralize asset data, standard job plans, spare parts information, and maintenance history.

They also provide analytics that help planners identify failure patterns, track KPIs such as schedule compliance, planned maintenance percentage (PMP), and MTTR, and continuously improve planning accuracy.

Promote Cross-Functional Communication and Field Visibility

Strong maintenance planning depends on close communication with operators, production teams, and inventory managers. Planners should also regularly inspect equipment in person rather than relying solely on reports. First-hand observations help validate data, identify emerging issues, and improve the quality of maintenance plans.

Document Everything and Drive Continuous Improvement

Comprehensive documentation supports long-term planning maturity. Maintenance plans, execution feedback, and performance metrics should be recorded digitally and reviewed regularly. Establishing feedback loops, tracking KPIs, and updating plans based on real outcomes ensures maintenance planning evolves continuously and remains aligned with operational goals.

Together, these best practices help organizations move beyond reactive maintenance, creating a proactive, data-driven maintenance planning process that improves reliability, safety, and cost control over time.

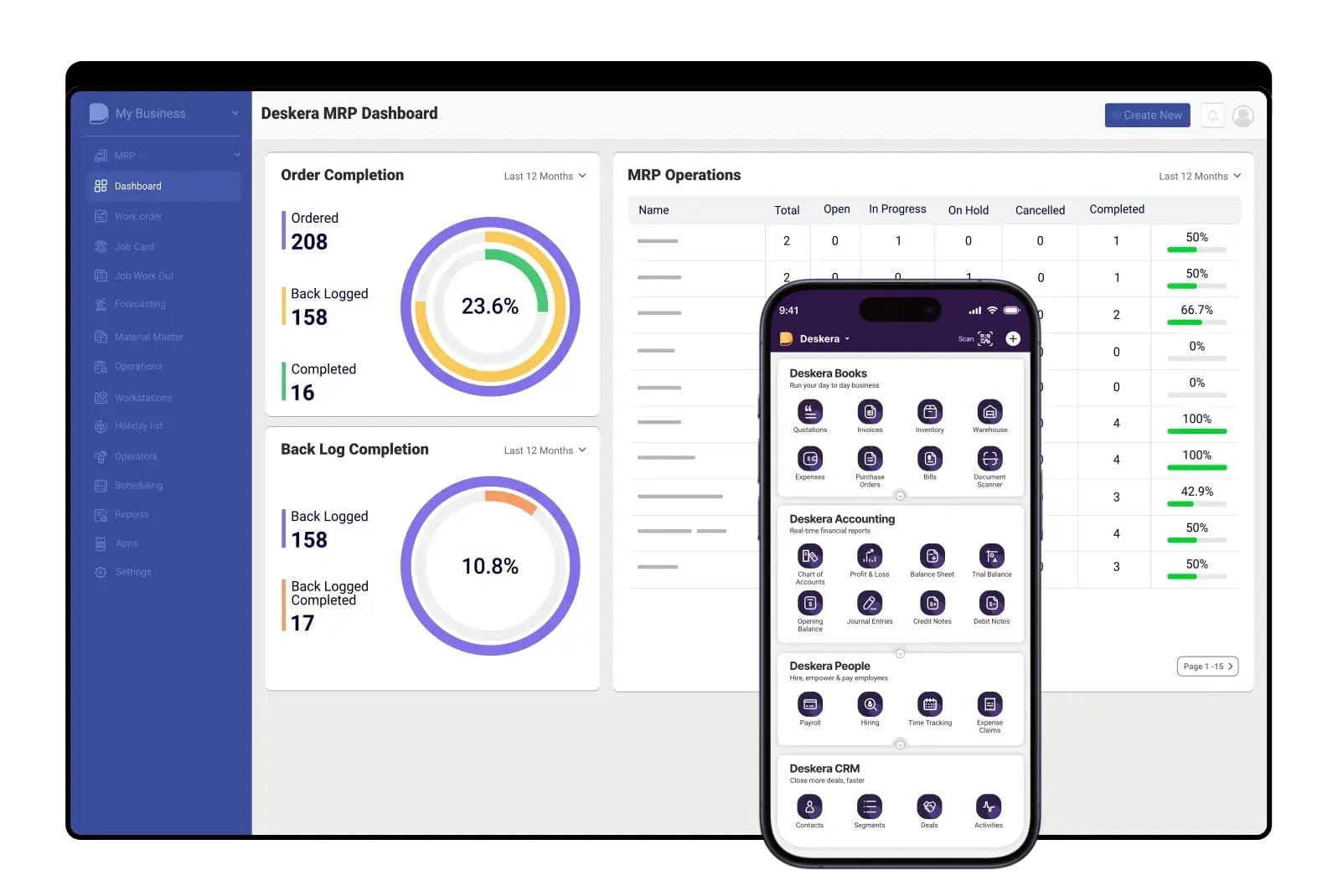

How Deskera MRP Supports Maintenance Planning

Deskera MRP supports maintenance planning primarily by enabling structured, production-aligned, and resource-aware maintenance activities, rather than acting as a full-scale CMMS or enterprise asset management system. Its strength lies in integrating maintenance-related planning with core manufacturing, inventory, and procurement processes—helping manufacturers plan maintenance more effectively within day-to-day operations.

Machine Master and Maintenance Visibility

Deskera MRP includes a Machine Master that allows manufacturers to record and manage machines used in production. This provides planners with visibility into machine details, basic maintenance schedules, and historical usage, helping them identify when inspections or routine maintenance activities are due. While not highly advanced, this visibility supports preventive maintenance planning and better coordination with production.

Work Order–Driven Maintenance Planning

Maintenance activities in Deskera MRP can be planned and executed through work orders. Planners can define maintenance-related tasks, track their status, and align them with shop-floor operations. This enables teams to document planned maintenance work, manage execution systematically, and reduce ad-hoc repair activities that disrupt production schedules.

Alignment With Production Planning

A key advantage of Deskera MRP is its integration with production planning and machine scheduling. Maintenance planners can take production loads and machine availability into account when planning maintenance activities, helping identify suitable downtime windows. This alignment minimizes production disruptions and supports smoother coordination between maintenance and manufacturing teams.

Spare Parts and MRO Inventory Support

Deskera MRP integrates maintenance planning with inventory management, allowing planners to check the availability of spare parts and MRO items before releasing maintenance work orders. This helps reduce delays caused by missing materials and supports better control over maintenance-related inventory without excessive overstocking.

Procurement Support for Maintenance Needs

For non-stock or long-lead-time maintenance parts, Deskera MRP enables planners to initiate purchase requests linked to planned work. This integration with procurement reduces last-minute emergency purchases, improves vendor coordination, and supports more predictable maintenance execution.

Maintenance History and Basic Reporting

Deskera MRP captures maintenance-related work order history and material usage, providing basic insights that planners can use to refine future maintenance plans. While it does not offer advanced maintenance KPIs or predictive analytics, this historical data still supports continuous improvement by helping teams identify recurring issues and improve planning accuracy over time.

In practice, Deskera MRP works best as a maintenance planning enabler within manufacturing operations, rather than a replacement for specialized CMMS or EAM platforms. It supports preventive and corrective maintenance planning at an operational level, particularly for small to mid-sized manufacturers who want maintenance to stay closely aligned with production, inventory, and procurement workflows.

By embedding maintenance planning into the broader manufacturing ecosystem, Deskera MRP helps organizations reduce unplanned disruptions, improve coordination, and maintain consistent production performance—without adding the complexity of a standalone maintenance system.

Key Takeaways

- Maintenance planning is a proactive, structured approach to ensuring equipment reliability and operational efficiency, helping organizations reduce downtime and optimize resources.

- Effective maintenance planning relies on defining tasks, identifying required resources, scheduling work, and tracking completion to ensure consistency, safety, and reliability.

- Maintenance planning establishes what, why, and how work should be done, while maintenance scheduling focuses on when it should be executed, linking planning to actionable timelines.

- Organizations can adopt multiple strategies such as preventive, predictive, corrective, condition-based, reactive, and shutdown/turnaround planning to balance cost, risk, and asset reliability.

- Proper maintenance planning reduces downtime, extends equipment lifespan, improves safety, increases operational efficiency, and generates cost savings.

- Challenges include incomplete asset data, reactive maintenance culture, poor coordination, spare parts issues, limited workforce visibility, and manual processes, which can hinder planning effectiveness.

- Establish a dedicated planning team, maintain accurate asset records, prioritize critical assets, standardize work procedures, refine resource estimates, leverage maintenance software, and continuously document and improve processes.

- Deskera MRP enables maintenance planning through machine records, work order management, integration with production and inventory, spare parts visibility, procurement support, and basic reporting, helping organizations plan maintenance effectively within manufacturing operations.

Related Articles