Have you ever wondered whether keeping your supply chain in-house or outsourcing it to external partners is the smarter choice? The truth is, there’s no universal answer. The decision between insourcing vs outsourcing depends heavily on your business goals, resources, and long-term strategy. Both approaches offer distinct advantages and challenges, making it critical for businesses to evaluate what works best for their unique supply chain needs.

Insourcing allows companies to maintain complete control over operations, ensuring quality, compliance, and protection of intellectual property. On the other hand, outsourcing can deliver cost savings, flexibility, and scalability by leveraging third-party expertise. With globalization and rapidly shifting market demands, businesses today are constantly weighing these two models to find the right balance between efficiency and control.

This debate is especially important in a time when supply chain disruptions, rising costs, and shifting customer expectations have become the norm. Companies that choose the right strategy—whether insourcing, outsourcing, or even a hybrid model—are better positioned to reduce risks, improve efficiency, and stay competitive in a dynamic market.

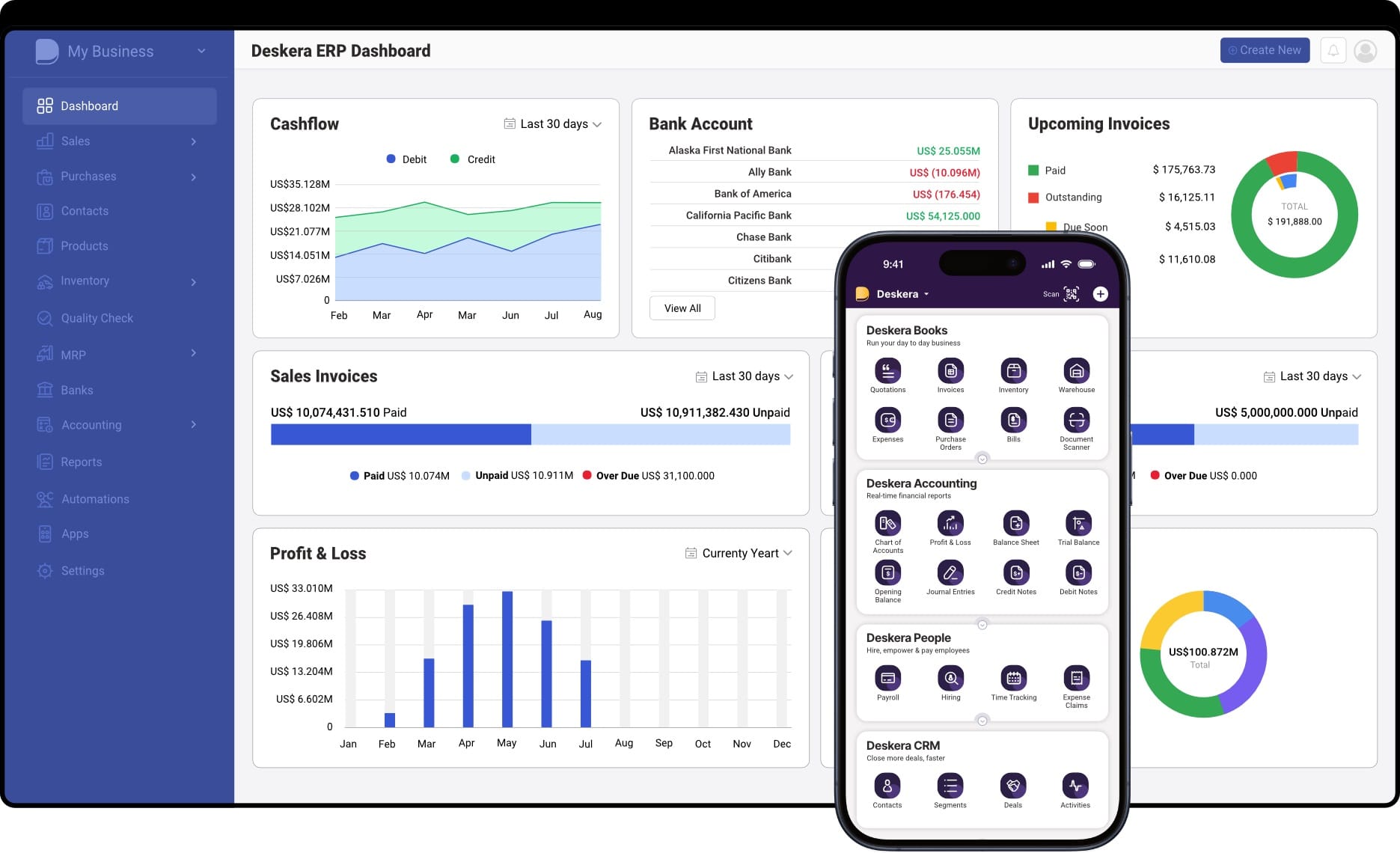

That’s where technology plays a vital role. Tools like Deskera ERP empower businesses to manage both insourced and outsourced supply chains effectively. With features like real-time tracking, demand forecasting, automated reporting, and AI-driven insights, Deskera ERP helps organizations make smarter decisions, reduce inefficiencies, and enhance overall supply chain resilience. By leveraging such technology, businesses can focus on strategy while leaving operational complexity to intelligent systems.

What is Insourcing in Supply Chains?

Insourcing in supply chains refers to the practice of handling production, logistics, or other supply chain functions within the company rather than delegating them to external partners. In simple terms, the business retains direct ownership and control over operations, relying on its own facilities, employees, and expertise to manage the supply chain from end to end.

Companies often choose insourcing when they want tighter control over quality, faster decision-making, or better protection of intellectual property. For example, manufacturers in industries like pharmaceuticals, aerospace, or luxury goods often insource because the risk of outsourcing sensitive processes may outweigh potential cost savings. Insourcing also fosters in-house expertise, enabling teams to build unique capabilities that differentiate the company from competitors.

However, insourcing comes with challenges such as higher upfront investments, ongoing maintenance costs, and the need for continuous workforce training. Despite these hurdles, businesses that prioritize quality, consistency, and long-term strategic control often find insourcing to be the most effective model for their supply chains.

What is Outsourcing in Supply Chains?

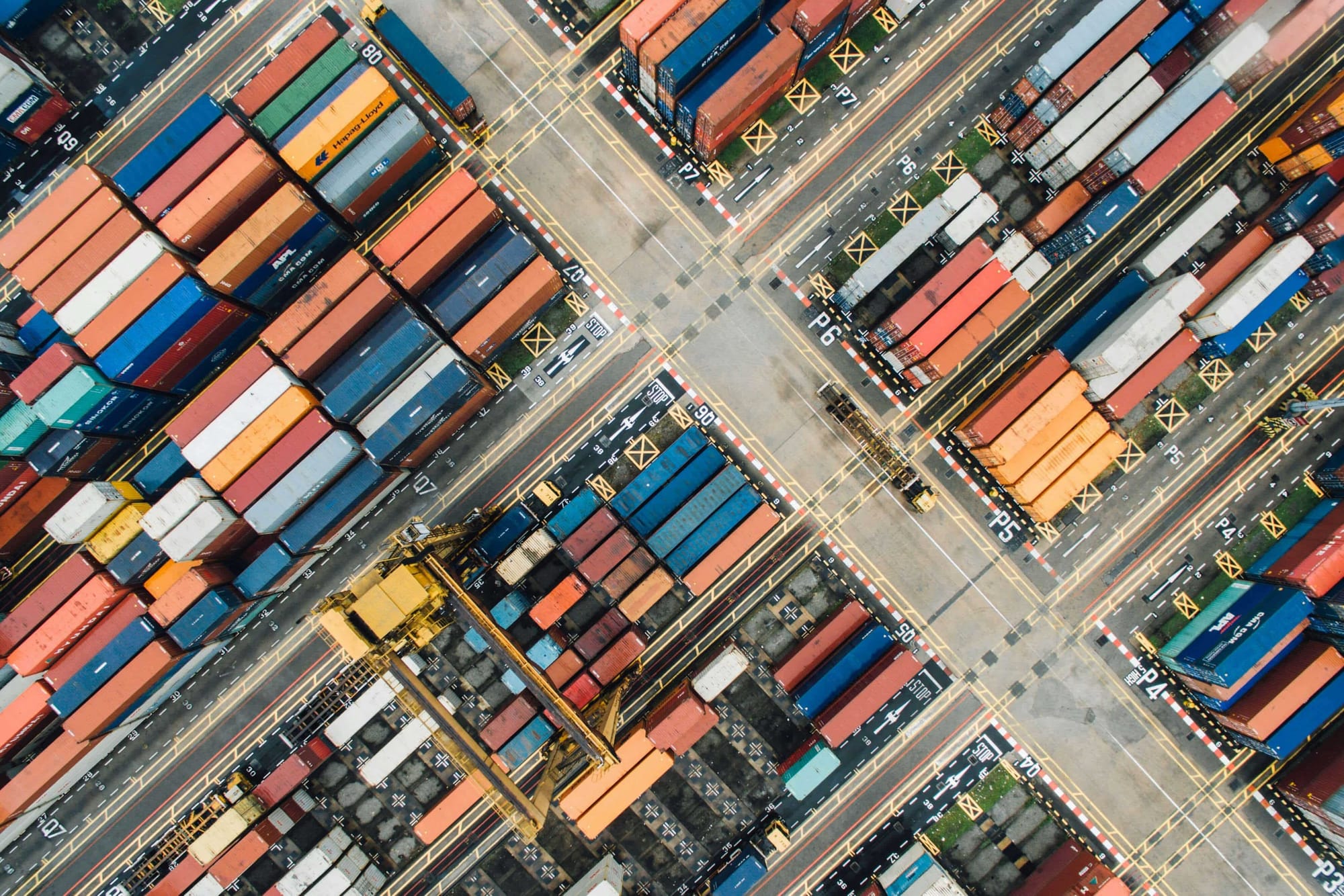

Outsourcing in supply chains is the practice of delegating specific functions—such as manufacturing, logistics, warehousing, or procurement—to third-party providers instead of managing them internally. In this model, businesses rely on external expertise and resources to handle operations, allowing them to focus on their core competencies like product development, sales, or customer service.

Organizations often choose outsourcing when they want to reduce costs, gain access to specialized skills, or expand into new markets without the burden of building infrastructure from scratch. For example, many e-commerce companies outsource warehousing and last-mile delivery to logistics partners to achieve faster fulfillment and scalability. Outsourcing also offers flexibility, as companies can quickly adjust capacity based on seasonal demand or market changes.

On the flip side, outsourcing can create challenges, including reduced control over quality, dependency on vendors, and potential risks related to compliance or supply chain disruptions. Still, when managed carefully, outsourcing becomes a strategic tool to achieve efficiency, agility, and cost savings in today’s globalized business environment.

Pros and Cons of Insourcing in Supply Chains

Insourcing can be a powerful strategy for businesses that want to maintain control and consistency across their supply chains. By keeping operations in-house, companies gain greater oversight, but this approach also comes with cost and resource challenges. Below are the key pros and cons of insourcing that businesses should consider.

Pros of Insourcing

- Greater Control Over Quality and Processes: Insourcing allows businesses to directly monitor production and logistics, ensuring standards are consistently met. This level of control minimizes errors and enhances customer satisfaction.

- Protection of Intellectual Property: Sensitive processes and proprietary knowledge remain within the organization, reducing the risk of leaks or misuse by third parties.

- Faster Decision-Making and Adaptability: With operations managed internally, businesses can quickly adapt processes, address issues, or implement improvements without relying on external partners.

- Development of In-House Expertise: Employees gain valuable skills and experience, building a strong internal knowledge base that can create long-term competitive advantages.

Cons of Insourcing

- Higher Costs and Investments: Insourcing often requires significant capital investment in infrastructure, technology, and workforce, making it a more expensive option compared to outsourcing.

- Limited Flexibility and Scalability: Expanding capacity to meet sudden demand increases can be challenging, as internal resources may not scale as quickly as outsourced options.

- Resource and Talent Constraints: Maintaining specialized expertise in-house requires continuous training and recruitment, which can strain budgets and management efforts.

- Operational Complexity: Handling end-to-end supply chain processes adds complexity, requiring businesses to manage everything from procurement to logistics internally.

Pros and Cons of Outsourcing in Supply Chains

Outsourcing has become a popular choice for companies looking to cut costs, increase flexibility, and tap into global expertise. While it offers significant advantages, outsourcing also brings certain risks that businesses must weigh carefully. Below are the key pros and cons of outsourcing in supply chains.

Pros of Outsourcing

- Cost Efficiency: Outsourcing reduces the need for heavy investments in infrastructure, labor, and technology. By leveraging third-party providers, businesses can often achieve lower operating costs.

- Access to Expertise and Technology: Specialized vendors bring advanced skills, tools, and industry knowledge that may be costly or impractical to develop in-house.

- Flexibility and Scalability: Outsourcing allows companies to quickly adjust supply chain capacity in response to seasonal peaks, market fluctuations, or global expansion.

- Focus on Core Competencies: By delegating non-core functions to external partners, businesses can focus more on strategic activities such as product innovation, marketing, and customer experience.

Cons of Outsourcing

- Reduced Control Over Operations: Entrusting processes to external partners can lead to inconsistencies in quality, timelines, or service levels.

- Dependency on Vendors: Heavy reliance on third-party providers may expose businesses to risks if vendors face disruptions, financial instability, or compliance failures.

- Communication and Coordination Challenges: Working across geographies or time zones can result in delays, miscommunication, and slower problem resolution.

- Potential Risks to Data and Compliance: Outsourcing can increase vulnerabilities related to data security, intellectual property, and regulatory compliance, especially in global supply chains.

Key Differences Between Insourcing and Outsourcing in Supply Chains

While both insourcing and outsourcing can support business growth, the two models differ significantly in terms of cost, control, scalability, and risk. The table below highlights the major differences to help you evaluate which approach aligns best with your supply chain strategy.

Factors to Consider When Choosing Between Insourcing and Outsourcing

Choosing between insourcing and outsourcing is one of the most strategic decisions a business can make for its supply chain. The decision impacts cost efficiency, operational resilience, and long-term growth.

To identify the best approach, companies must carefully weigh a variety of internal and external factors. Below are the most critical considerations to guide your decision.

1. Business Size and Growth Stage

The maturity of your business often dictates the feasibility of insourcing versus outsourcing. Startups and small businesses usually lack the capital and resources to build large-scale in-house operations.

For them, outsourcing provides an affordable and scalable way to access supply chain expertise without investing in facilities or a large workforce.

On the other hand, larger enterprises with established infrastructure may prefer insourcing, as it allows them to leverage existing assets, maintain tighter control, and invest in long-term capabilities that strengthen their competitive position.

2. Budget and Cost Efficiency Goals

Finances are a major deciding factor. Outsourcing is attractive for businesses looking to cut costs because it reduces the burden of fixed investments in warehouses, factories, or labor.

It also provides predictable cost structures through vendor contracts. However, while insourcing requires significant upfront capital, it can deliver better returns in the long term.

Companies gain control over profit margins, reduce dependency on third parties, and avoid hidden costs such as vendor markups or service delays. Businesses with strong cash flow and a long-term vision may therefore see insourcing as a strategic investment.

3. Quality Control Requirements

Quality standards can make or break a supply chain. Companies in industries such as pharmaceuticals, aerospace, or luxury manufacturing often opt for insourcing because even small errors can have serious consequences. Keeping processes internal ensures consistency and compliance with strict regulations.

Outsourcing may still work if vendors have proven quality management systems, but this requires rigorous monitoring and regular audits. If your brand reputation hinges on precision and excellence, insourcing provides greater peace of mind.

4. Access to Technology and Expertise

The availability of specialized skills and advanced technology is another important factor. Outsourcing allows companies to tap into cutting-edge capabilities, such as automated warehousing, advanced logistics systems, or industry-specific knowledge, without shouldering the cost of developing them in-house.

This is especially valuable for businesses entering new markets or industries where expertise is lacking internally. On the other hand, insourcing enables organizations to cultivate proprietary expertise and build intellectual property, turning supply chain capabilities into a strategic differentiator.

5. Risk and Compliance Factors

Every supply chain carries risks, but the type and extent differ between insourcing and outsourcing. Outsourcing may expose businesses to compliance challenges, vendor failures, or data security issues—particularly when working across international borders. Vendor dependency can also make companies vulnerable to disruptions like labor strikes, geopolitical instability, or supply shortages.

Insourcing mitigates these external risks but requires the organization to bear the full weight of compliance, certifications, and risk management internally. Companies must assess their risk tolerance and regulatory landscape before choosing.

6. Long-Term Strategic Goals

Perhaps the most critical factor is alignment with long-term business objectives. If your goal is to build a brand centered on quality, innovation, and unique processes, insourcing can help foster internal capabilities that competitors cannot easily replicate.

If your priority is rapid expansion, entering new markets, or focusing resources on product development and customer experience, outsourcing provides the agility to scale quickly without being weighed down by operational complexities. In many cases, a hybrid model—where core functions are insourced and non-core tasks outsourced—offers the best of both worlds.

Best Practices for Insourcing and Outsourcing in Supply Chains

Whether your business chooses insourcing, outsourcing, or a hybrid approach, success depends on how well the model is managed. Applying best practices ensures efficiency, reduces risks, and strengthens the overall resilience of your supply chain.

Below are the key best practices for both insourcing and outsourcing.

Best Practices for Insourcing

- Invest in Infrastructure and Technology: Build strong internal capabilities by investing in modern facilities, automation tools, and ERP systems to improve visibility and efficiency across operations.

- Develop Employee Expertise: Continuously train and upskill your workforce to ensure teams can handle evolving supply chain challenges and leverage new technologies effectively.

- Focus on Continuous Improvement: Implement lean practices and regularly review internal processes to eliminate waste, reduce costs, and maintain high-quality standards.

- Maintain Strong Risk Management: Since all responsibility lies within the organization, establish contingency plans and conduct regular risk assessments to address potential bottlenecks or failures.

- Align Supply Chain with Strategy: Ensure that insourced operations support long-term goals such as brand differentiation, innovation, and intellectual property protection.

Best Practices for Outsourcing

- Choose the Right Partners: Select vendors based on proven expertise, reliability, compliance track record, and ability to scale with your business needs. Conduct thorough due diligence before contracting.

- Define Clear Contracts and SLAs: Establish detailed agreements that outline performance metrics, responsibilities, timelines, and penalties to avoid misunderstandings and ensure accountability.

- Foster Strong Communication: Maintain transparent, frequent communication with outsourcing partners. Use collaboration tools and shared dashboards for better visibility and coordination.

- Monitor and Audit Performance: Regularly track vendor performance against KPIs such as cost efficiency, quality, delivery timelines, and compliance standards. Periodic audits help maintain trust.

- Balance Cost Savings with Value Creation: Don’t choose outsourcing partners solely on cost. Look for providers who bring innovation, advanced technology, or strategic value that contributes to long-term success.

Case Examples: When Insourcing vs Outsourcing Works Best

Real-world examples show how companies choose between insourcing and outsourcing based on their business goals, industry, and customer expectations.

Below are two contrasting cases that highlight when each model can be the right choice.

Example of Successful Insourcing: Luxury Goods Manufacturing

A leading luxury fashion brand insources most of its manufacturing to maintain complete control over quality and craftsmanship. For them, the value lies not only in the product but also in the brand reputation that comes from superior materials, precise techniques, and ethical sourcing.

By keeping production in-house, the company ensures its products meet exacting standards, safeguards its intellectual property, and sustains exclusivity—key factors that justify premium pricing. This approach demonstrates how insourcing works best when brand identity, quality, and control are non-negotiable.

Example of Successful Outsourcing: Global E-Commerce Company

A well-known global e-commerce giant relies heavily on outsourcing for warehousing, last-mile delivery, and even parts of its IT infrastructure. By partnering with logistics providers and third-party vendors, the company can handle millions of daily transactions while offering fast delivery worldwide.

Outsourcing enables scalability during peak shopping seasons, reduces overhead costs, and provides access to specialized technologies in logistics and cloud computing.

This example illustrates how outsourcing excels when speed, scalability, and efficiency are top priorities.

Hybrid Models: Combining Insourcing and Outsourcing

For many businesses, the debate isn’t simply about choosing insourcing or outsourcing—it’s about blending the two. A hybrid supply chain model allows organizations to insource critical operations while outsourcing non-core or highly specialized functions. This approach provides the best of both worlds: control and quality where it matters most, and flexibility and efficiency where external expertise adds value.

Companies often insource areas that directly impact brand reputation, customer experience, or intellectual property, such as product design, R&D, or quality control. At the same time, they outsource functions like logistics, warehousing, or IT support to trusted partners who can deliver cost savings and scalability. This balance helps businesses remain agile without sacrificing control over core competencies.

The key to making hybrid models successful lies in clear role definitions, strong communication, and the right use of technology. Tools like Deskera ERP can play a pivotal role by offering end-to-end visibility across both insourced and outsourced processes. With centralized dashboards, real-time analytics, and AI-driven insights, businesses can coordinate seamlessly with external partners while still maintaining oversight of internal operations.

In today’s volatile and globalized supply chains, hybrid models are increasingly becoming the go-to strategy for businesses that want to stay competitive, resilient, and customer-focused.

How Can Deskera ERP Help in Optimizing Both Models?

Whether a company chooses insourcing, outsourcing, or a hybrid approach, the complexity of supply chain management requires real-time visibility, seamless coordination, and data-driven decision-making.

Deskera ERP provides an integrated platform that empowers businesses to manage both insourced and outsourced supply chain processes efficiently. From production planning to vendor management, its advanced features ensure that organizations can optimize operations under either model.

1. Streamlined Operations for Insourcing

Deskera ERP helps businesses manage in-house supply chains with greater efficiency by automating tasks such as production planning, inventory tracking, and order management.

Real-time dashboards give managers full visibility into processes, making it easier to maintain quality standards and quickly respond to disruptions. This ensures tighter control over insourced operations while reducing manual errors and delays.

2. Enhanced Vendor and Outsourcing Management

For outsourcing models, Deskera ERP simplifies collaboration with external partners through centralized vendor management tools. Businesses can monitor supplier performance, track deliveries, and ensure compliance with contracts and service-level agreements (SLAs). Automated reporting and analytics allow companies to evaluate vendor efficiency, ensuring outsourced functions align with cost and quality expectations.

3. Data-Driven Decision Making

Deskera ERP’s AI-driven insights and advanced reporting tools enable businesses to analyze supply chain performance across both insourced and outsourced processes.

Predictive analytics help forecast demand, identify potential bottlenecks, and recommend optimal strategies for resource allocation. This empowers businesses to make proactive decisions that improve efficiency and resilience in either model.

4. Flexibility for Hybrid Models

Many organizations blend insourcing and outsourcing. Deskera ERP supports this hybrid model by providing a single source of truth that connects internal teams with external vendors. Its integrated platform ensures transparency across the supply chain, enabling seamless coordination between in-house operations and outsourced partners.

Key Takeaways

- Choosing between insourcing and outsourcing is a strategic decision that shapes supply chain efficiency, resilience, and long-term competitiveness. The right model depends on business goals, resources, and market conditions.

- What is Insourcing in Supply Chains?: Insourcing involves managing operations in-house, giving businesses greater control, consistency, and protection of intellectual property, though it requires higher investments and resources.

- What is Outsourcing in Supply Chains?: Outsourcing leverages third-party providers for functions like logistics or production, offering cost savings, scalability, and expertise, but it reduces direct control and introduces dependency on vendors.

- Pros and Cons of Insourcing: Insourcing builds in-house expertise and ensures quality but comes with higher costs, operational complexity, and limited scalability.

- Pros and Cons of Outsourcing: Outsourcing delivers flexibility, efficiency, and global reach, but challenges include vendor dependency, quality risks, and compliance concerns.

- Key Differences Between Insourcing and Outsourcing: The two models differ in cost structures, control, scalability, and risk management—businesses must weigh these trade-offs carefully before deciding.

- Factors to Consider When Choosing: Critical factors include business size, budget, quality requirements, access to expertise, compliance obligations, and alignment with long-term strategic goals.

- Best Practices of Insourcing and Outsourcing: Success requires investment in technology, skilled teams, and process improvements for insourcing, while outsourcing depends on choosing reliable partners, setting clear SLAs, and monitoring vendor performance.

- Case Examples: Insourcing works best in industries like luxury manufacturing where quality and control are paramount, while outsourcing shines in global e-commerce where scalability and speed are key.

- Hybrid Models: Combining insourcing and outsourcing helps businesses balance control with flexibility, ensuring agility while maintaining oversight of critical processes.

- How Deskera ERP Helps: Deskera ERP optimizes both models by offering automation, real-time visibility, vendor management, predictive analytics, and seamless integration—empowering businesses to run efficient supply chains regardless of the strategy.

- There is no single right answer; the best supply chain model depends on your business context. Using technology like Deskera ERP enables companies to confidently navigate insourcing, outsourcing, or hybrid models for long-term success.

Related Articles