In today's world, innovative manufacturing is becoming more and more important in the food industry. With the rising demand for healthier, more natural products, innovative manufacturing is the key to creating healthier, sustainable, and more enjoyable foods. Innovative manufacturing is the process of creating better products through the use of advanced technology, processes, and materials.

This article covers the following:

- Benefits of Innovative Manufacturing

- Challenges of Innovative Manufacturing

- Key Steps to Successful Innovative Manufacturing

- Applying Innovative Manufacturing to Food Production

- How to differentiate food through innovative manufacturing

- How can Deskera assist you?

Benefits of Innovative Manufacturing

In today's competitive market, food manufacturers need to differentiate their products in order to stay ahead of the competition. Innovative manufacturing can be the key to achieving this. By implementing innovative manufacturing techniques, food producers can create unique products that stand out from the crowd and appeal to their target customers. Here are a few of the benefits of innovative manufacturing:

Increased Efficiency

Innovative manufacturing techniques allow food producers to reduce production times and increase efficiency. By using automated processes and technologies, manufacturers can produce products faster, thus reducing costs and increasing profits.

Improved Quality

Innovative manufacturing processes can also help to ensure that food products are of the highest quality. By using advanced technologies and processes, manufacturers can ensure that the ingredients used in the production of the products are of the highest quality and meet safety standards.

Enhanced Branding

Innovative manufacturing processes can help food producers to create unique products that are easily recognizable. By creating unique packaging and product designs, companies can create a memorable brand identity that helps them stand out from the competition.

Cost Savings

By implementing innovative manufacturing processes, food producers can reduce their production costs. By using more efficient processes and technologies, producers can reduce their costs and increase their profits. Innovative manufacturing is an effective way for food producers to differentiate their products and stand out from the competition. By utilizing advanced technologies and processes, companies can create unique products that appeal to their target customers and increase their profits.

Challenges of Innovative Manufacturing

The process of creating new products through innovative manufacturing has become increasingly popular in the food industry. With the increasing demand for healthier options, many companies have begun to diversify their products and create innovative ways of processing and packaging food.

However, while this brings many advantages, there are also some challenges associated with this process. One of the main challenges of innovative manufacturing is the cost.

In order to create new products, companies must invest in research and development, which can be expensive. Additionally, introducing new technology to the manufacturing process can lead to additional costs.

This can be problematic for small and medium-sized businesses, as they often have limited resources and budgets. Another challenge of innovative manufacturing is the time it takes to bring a new product to market.

It can take months or even years to develop a new product, and this can be difficult for companies to manage. Additionally, the process of testing, packaging, and distributing the product can be lengthy and expensive.

Finally, there is the risk of failure. Because so much time and money is invested in the development of a new product, there is a risk that the product may not be successful. This can be financially devastating for companies and can lead to a significant loss of resources.

While innovative manufacturing can be a great way to diversify products and create healthier options, there are many challenges associated with the process. Companies must be aware of these risks and be prepared to invest the necessary resources in order to bring a new product to market.

Key Steps to Successful Innovative Manufacturing

Innovative manufacturing is an important part of the food industry. It allows companies to create products that are unique, appealing, and competitive. As a result, it’s essential for companies looking to differentiate their foods to understand the key steps to successful innovative manufacturing. Here are a few tips for getting the most out of your manufacturing process:

Research Your Target Audience

The first step in successful innovative manufacturing is understanding your target audience. Before you begin the manufacturing process, it’s important to have a clear picture of who you are creating the product for. This will help you make decisions about the ingredients, packaging, and other aspects of the product that are most likely to resonate with your target audience.

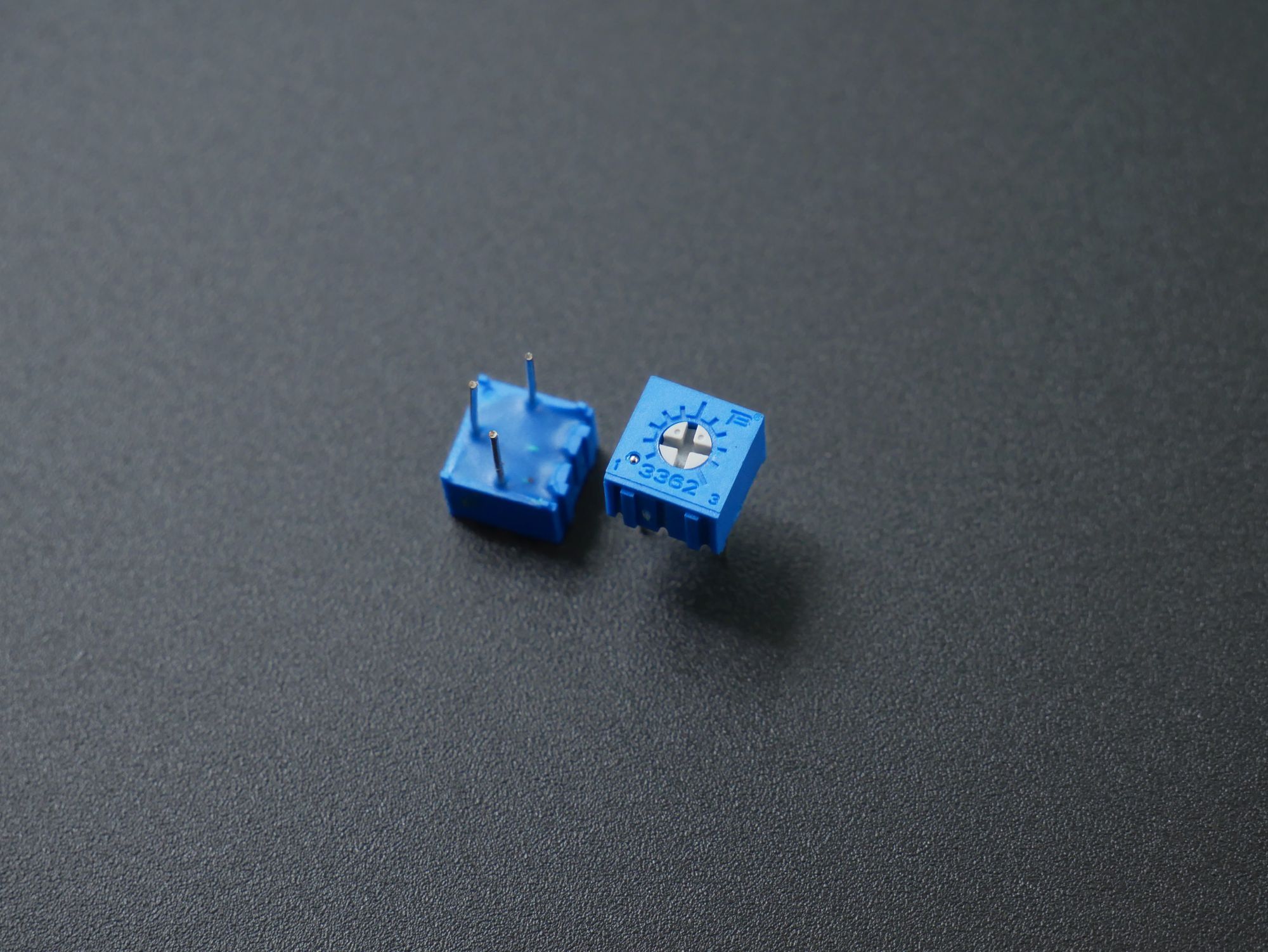

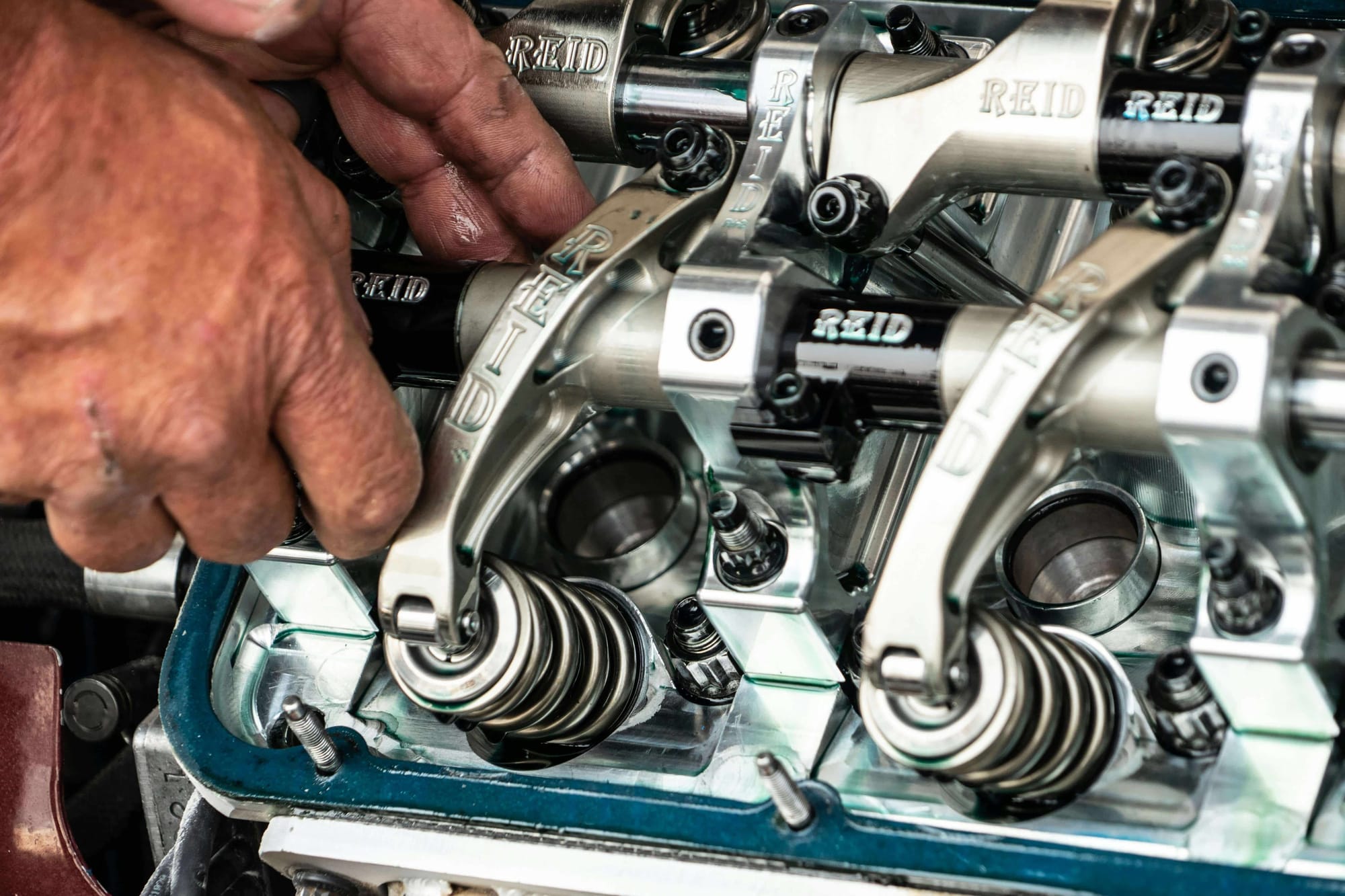

Utilize Technology

Technology has revolutionized the food industry, and innovative manufacturing is no exception. From 3D printing to automated production lines, there are a variety of tools available to help you get the most out of your production process. Investing in the right technology can help you increase efficiency and reduce costs while producing a higher-quality product.

Focus on Quality

Quality is essential in any food production process, but it’s especially important when it comes to innovative manufacturing. Make sure you are using the highest-quality ingredients, following proper safety protocols, and ensuring that your finished product meets the highest standards.

Develop a Sustainable Supply Chain

Sustainable supply chains are critical for companies looking to differentiate their foods through innovative manufacturing. Make sure you are working with suppliers that are committed to sustainability and that you are taking steps to reduce your environmental impact.

Monitor and Adapt

Finally, it’s important to monitor and adapt your process. As the industry evolves and customer tastes and preferences change, you need to be able to adjust your process accordingly.

Keep an eye on trends, pay attention to customer feedback, and be willing to make changes when necessary. By following these key steps, you can ensure that your innovative manufacturing process is successful and that you’re producing a product that truly stands out from the competition. Good luck!

Applying Innovative Manufacturing to Food Production

In recent years, the food industry has been increasingly focused on innovation and efficiency. As a result, companies have been leveraging innovative manufacturing processes to create new products and increase efficiency in their production lines.

By utilizing the latest in manufacturing technology, food producers have been able to differentiate their products and create new lines of food that appeal to a wide range of consumers.

Innovative manufacturing techniques have allowed food producers to create products that are unique and offer a wide range of benefits. For example, by utilizing 3D printing technology, food producers have been able to create custom-shaped food products that can be tailored to a specific demographic or customer base.

This has allowed companies to create products that are both visually appealing and nutritious. Additionally, 3D printing can be used to create products with intricate designs that would be difficult or impossible to create with traditional manufacturing techniques. In addition to 3D printing, there are several other innovative manufacturing techniques that can be used to create unique food products.

These include high-pressure processing, extrusion, and vacuum sealing. High-pressure processing can be used to create products that are shelf-stable and can be stored for long periods of time.

Extrusion can be used to create a wide range of products, including snacks and cereals. Lastly, vacuum sealing can be used to preserve food products while also reducing waste by minimizing the amount of air in the packaging.

By utilizing innovative manufacturing techniques, food producers can create unique products that stand out from the competition. Not only will this help to differentiate their products, but it can also help to increase efficiency in their production lines.

Additionally, these techniques can be used to create products that are healthier, more sustainable, and more cost-effective. In the end, this can lead to increased sales and profits for companies that leverage these techniques.

How to Differentiate Food Through Innovative Manufacturing?

The food industry has become increasingly competitive as food companies strive to differentiate their products from competitors. Innovative manufacturing is one of the most effective ways to stand out in the market and create a unique product that customers will be drawn to. Here are some tips on how to differentiate food through innovative manufacturing.

Focus on taste

As the saying goes, “taste is king” in the food industry. Make sure that your food products have a unique flavor profile that will draw people in and keep them coming back for more. This can be achieved through a variety of techniques, such as adding unique ingredients, using different cooking techniques, or creating interesting flavor combinations.

Embrace new technologies

Technology is playing an increasingly important role in the food industry. From advanced food processing techniques to robotics, there are a number of ways to use new technologies to create a unique product. By leveraging these new technologies, you can create products that stand out from the competition.

Utilize packaging

Packaging is often overlooked as an important factor in creating a differentiated product. Utilize creative packaging techniques, such as creative shapes or materials that will draw attention to your product. Additionally, consider the environmental impact of your packaging and look for ways to reduce your environmental footprint.

Develop targeted marketing

To reach the right customers, you must develop a targeted marketing strategy. Consider who your target consumer is and develop marketing campaigns that will resonate with them.

This may include creating unique visuals, developing engaging content, or using social media to get your message across. By following these tips, you can differentiate your food products through innovative manufacturing.

By focusing on taste, leveraging new technologies, utilizing creative packaging, and developing targeted marketing strategies, you can create a unique product that stands out from the competition.

How can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Innovative manufacturing techniques allow food producers to reduce production times and increase efficiency.

- Innovative manufacturing processes can also help to ensure that food products are of the highest quality.

- Technology is playing an increasingly important role in the food industry.

- Packaging is often overlooked as an important factor in creating a differentiated product.

- Innovative manufacturing processes can help food producers to create unique products that are easily recognizable.

Related Articles: