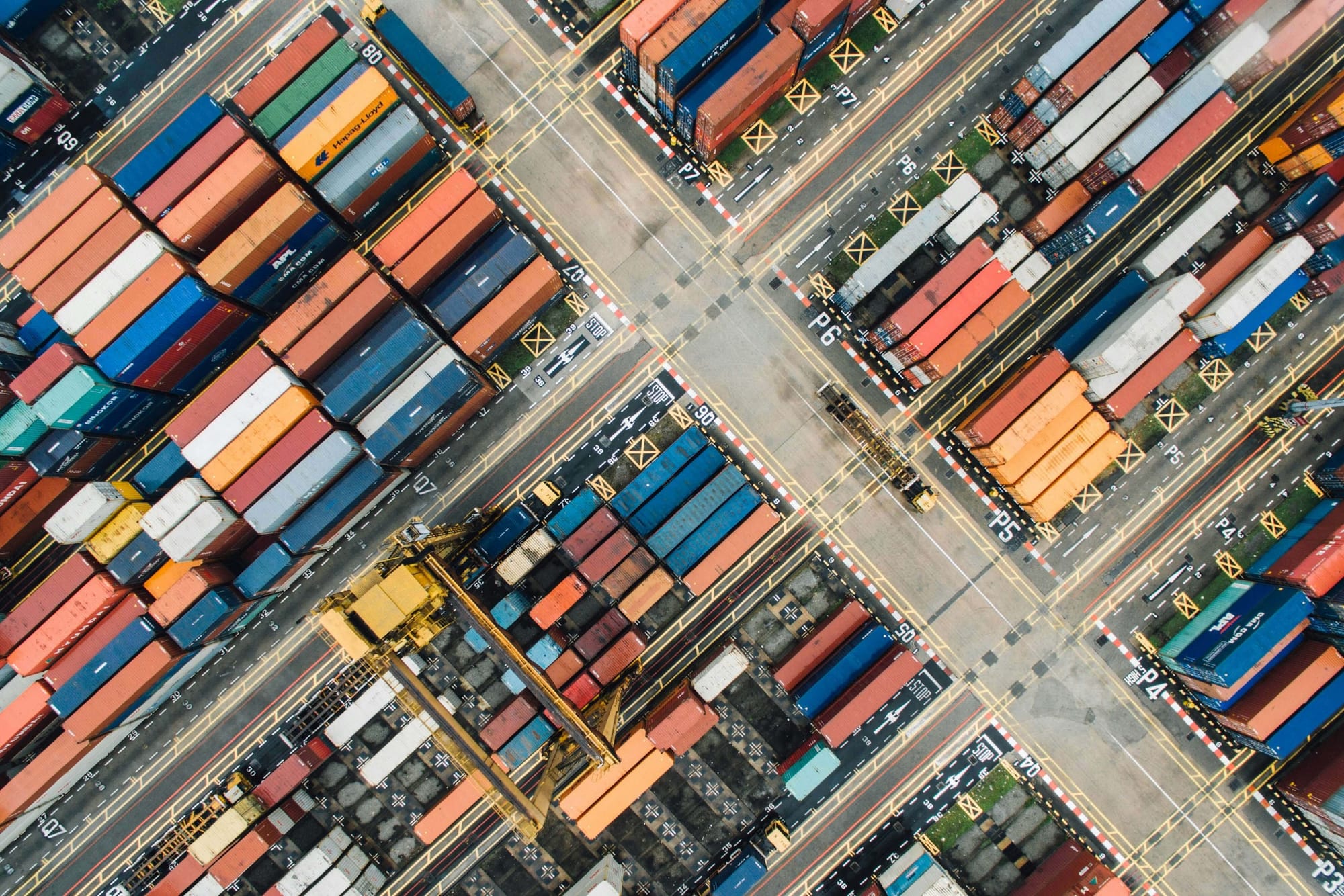

In today’s interconnected world, supply chains have become the backbone of business continuity. However, the more global and complex supply networks become, the greater the exposure to risks. Recent years have shown just how vulnerable organizations can be to supplier disruptions, whether due to financial instability, compliance failures, or operational breakdowns. What was once considered a back-end concern has now become a boardroom priority—supplier risk management is no longer optional, but essential.

The risks are not just theoretical—they are escalating at an alarming pace. Supply chain attacks surged by over 430% between 2021 and 2023, highlighting the growing threat of digital vulnerabilities. In 2024 alone, suppliers faced a sharp rise in cyber risks, with exposure increasing by more than 60%. At the same time, financial instability has also intensified, with supplier bankruptcies spiking by more than 40% in a single year. These trends reveal that risks are not isolated events but systemic challenges that businesses must actively prepare for.

Ignoring these warning signs can have severe consequences. A single supplier failure can disrupt production lines, inflate costs, damage brand reputation, and even lead to regulatory penalties. Companies that continue to treat supplier risks reactively often find themselves unprepared when crises strike. On the other hand, organizations that take a proactive, structured approach to supplier risk management build resilience, protect profitability, and secure long-term growth.

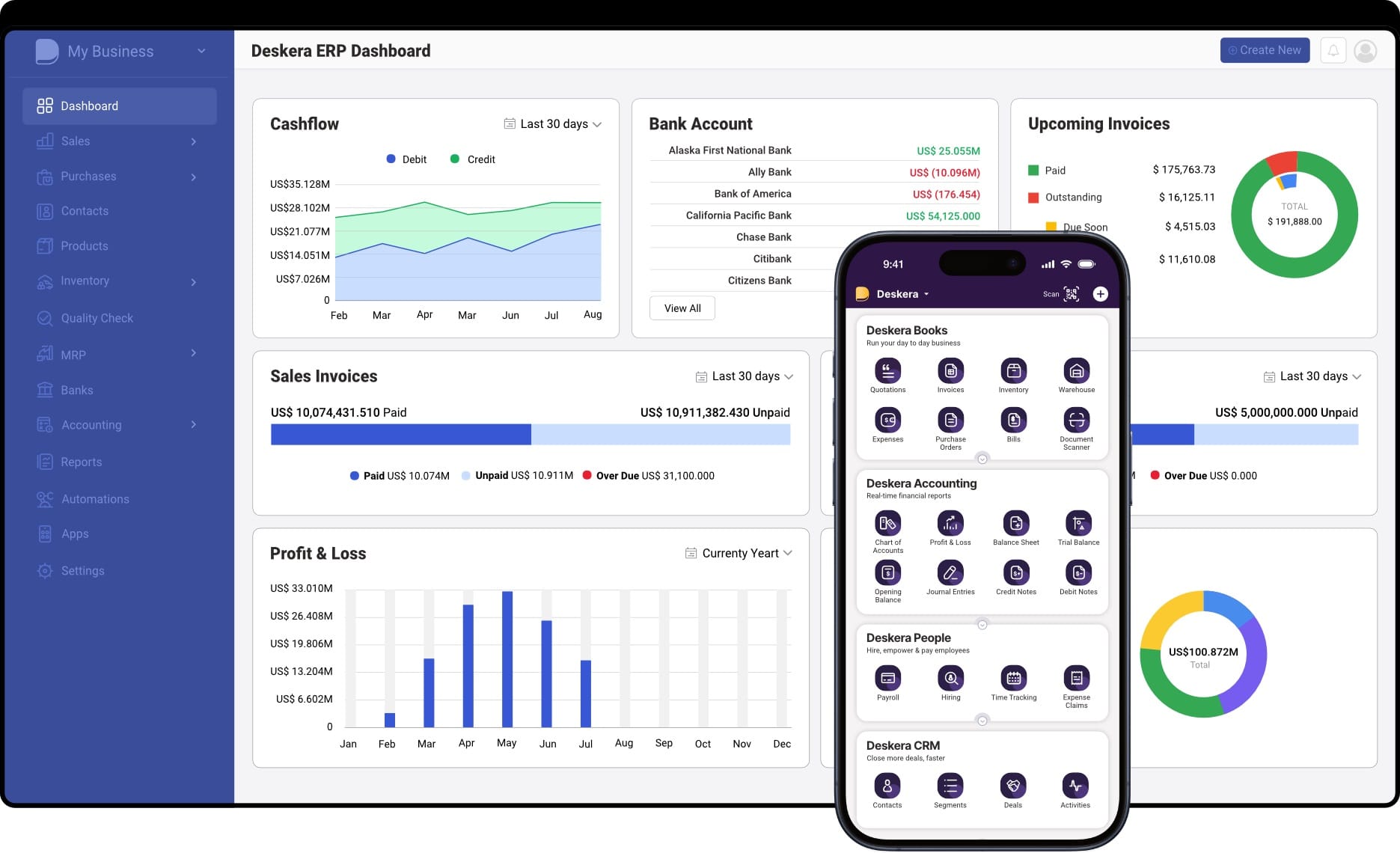

This is where technology becomes a game changer. Cloud-based solutions like Deskera ERP help businesses streamline supplier evaluation, monitor compliance, and gain real-time visibility into financial and operational risks. With powerful tools for automation, analytics, and reporting, Deskera enables organizations to move from reactive problem-solving to proactive risk prevention—ensuring that supply chains remain strong, agile, and future-ready.

What is Supplier Risk Management?

Supplier risk management is the structured process of identifying, assessing, and addressing potential threats within a company’s supplier network that could disrupt operations, inflate costs, or damage its reputation. These risks can stem from various sources—financial instability, natural disasters, geopolitical tensions, cyberattacks, or compliance failures—and can have a cascading impact on business continuity if left unmanaged.

At its core, supplier risk management ensures that organizations take a proactive approach to selecting, monitoring, and maintaining supplier relationships. Instead of reacting only when problems arise, businesses build resilience by evaluating supplier reliability upfront, continuously tracking performance, and implementing strategies that allow for quick corrective action when challenges emerge.

The importance of supplier risk management has grown significantly in recent years as supply chains have become more global, interdependent, and fragile. A supplier’s inability to deliver goods or services on time—whether due to bankruptcy, regulatory penalties, or operational breakdowns—can throw production schedules off balance, lead to financial losses, and erode customer trust. By anticipating and mitigating risks before they escalate, companies safeguard not only their operations but also their long-term profitability.

In practice, effective supplier risk management programs include supplier assessments, real-time monitoring, data-driven risk mapping, and well-defined mitigation strategies. These efforts aim to maintain supply chain continuity, improve visibility across multiple tiers, and ensure that businesses can respond swiftly to unexpected disruptions. Simply put, it’s about strengthening partnerships, leveraging data, and building the resilience needed to withstand today’s volatile business environment.

Categories of Supplier Risks

Supplier-related risks come from both internal and external sources, and each category presents unique challenges for businesses. Understanding these risks is the first step toward building a proactive supplier risk management strategy. Below are the most common categories organizations should be prepared to address:

1. Economic Risks

Shifts in the global economy—such as inflation, currency fluctuations, or trade barriers—can affect a supplier’s ability to deliver goods or services consistently. For example, recent inflationary pressures have forced many companies to renegotiate contracts, switch suppliers, or pass rising costs on to customers.

2. Performance Risks

Suppliers may struggle with production delays, quality issues, or resource shortages that compromise their ability to meet agreed timelines. A quality failure at a single supplier, such as a defective batch of semiconductors, can halt an entire automotive assembly line for days.

3. Financial Risks

When suppliers face liquidity issues, insolvency, or bankruptcy, buyers are often left scrambling for emergency replacements—usually at higher costs. Recent volatility in raw material prices, rising labor expenses, and fluctuating interest rates have made financial risks particularly widespread.

4. Event-Based Risks

Natural disasters, pandemics, or geopolitical conflicts can abruptly disrupt supply chains. Extreme weather events or armed conflicts can cut off trade routes and destabilize supplier networks, leaving businesses vulnerable to production breakdowns.

5. Regulatory and Compliance Risks

Suppliers that fail to comply with labor, environmental, or data protection standards expose buyers to legal penalties and reputational harm. Regulators are increasingly scrutinizing vendor management practices across industries like healthcare, financial services, and critical infrastructure.

6. Category and Industry-Specific Risks

Some industries face unique vulnerabilities. Electronics manufacturers, for instance, depend on rare earth metals that have limited sourcing alternatives, while agriculture companies must contend with droughts, floods, or wildfires that can wipe out crops and halt shipments overnight.

7. Ethical Risks

Unethical supplier practices—such as labor exploitation, bribery, fraud, or discrimination—can cause severe reputational damage. In a market where consumers value transparency, businesses tied to unethical suppliers risk customer backlash and loss of trust.

8. Cybersecurity Risks

Cyberattacks targeting suppliers have grown rapidly in recent years. Hackers often exploit weak supplier systems to infiltrate larger organizations, leading to data breaches, ransomware attacks, or supply chain disruptions. This is now one of the fastest-rising risk categories across global industries.

9. Geopolitical Risks

Political instability, trade wars, sanctions, or sudden regulatory changes in supplier regions can impact sourcing reliability. Companies dependent on international partners must carefully track and adapt to these risks.

10. Concentration Risks

Overreliance on a single supplier—or a small group of suppliers—for critical inputs leaves companies vulnerable if those suppliers face disruption. Diversification is often the best safeguard against this risk.

11. Strategic Risks

Sometimes a supplier’s actions or business direction no longer align with the buyer’s long-term goals. Strategic risks arise when a partnership fails to support broader objectives, creating friction instead of value.

12. Contractual Risks

Unfavorable or poorly structured contracts can expose companies to inflexible terms, hidden liabilities, or gaps in protection. Without careful drafting and monitoring, these risks may escalate into costly disputes.

13. Reputational Risks

A supplier’s misconduct—whether related to environmental issues, labor practices, or business ethics—can tarnish the buying company’s brand. In the age of social media, reputational damage spreads quickly, amplifying risk exposure.

14. Operational Risks

Internal inefficiencies, such as equipment failures, workforce shortages, or weak management processes at a supplier, can undermine delivery timelines and disrupt supply reliability.

Importance of Supplier Risk Management

In today’s volatile business landscape, companies can no longer afford to treat supplier risk management as an afterthought.

With rising supply chain complexities, global disruptions, and heightened consumer expectations, organizations must build proactive strategies that protect their operations and reputation.

Effective supplier risk management is not just about avoiding problems—it’s about building resilience, efficiency, and long-term competitiveness.

1. Reduces Disruptions and Waste

Unexpected events like natural disasters, labor strikes, or financial instability among suppliers can halt production and cause costly delays. By anticipating such vulnerabilities, businesses can establish contingency plans, such as developing alternative sourcing strategies or maintaining adequate safety stock. This proactive approach minimizes material shortages, prevents emergency procurement, and reduces waste caused by inefficient processes.

2. Improves Reliability

A strong supplier risk management framework ensures consistent supply by vetting suppliers thoroughly, diversifying sources, and continuously monitoring partner performance. By reducing reliance on a single supplier or geographic region, businesses shield themselves from bottlenecks and disruptions, maintaining steady output to meet customer demand.

3. Protects Reputation

Suppliers’ actions directly influence how customers perceive the companies they serve. Issues like labor violations, product safety scandals, or missed deliveries can harm the buyer’s brand as much as the supplier’s. Risk management ensures that suppliers comply with industry regulations and ethical standards, protecting businesses from reputational harm and preserving customer trust.

4. Lowers Costs

Proactive risk management helps companies detect underperforming suppliers early and avoid the heavy expenses of emergency sourcing, expedited shipping, or excessive buffer stock. Additionally, by building strong relationships with reliable suppliers, procurement teams can negotiate favorable terms and secure long-term cost savings.

5. Increases Efficiency

Monitoring supplier risks allows businesses to identify potential disruptions before they escalate into major problems. This foresight shortens lead times, prevents production stoppages, and streamlines operations. Ultimately, efficient supplier management enables organizations to deliver products faster, meet customer expectations, and gain a competitive edge.

6. Strengthens Compliance and Resilience

Beyond operational benefits, supplier risk management ensures adherence to evolving global standards, including environmental, labor, and data protection regulations. Companies that invest in structured risk management practices are better equipped to handle future disruptions—whether technological, economic, or geopolitical—and adapt with agility.

In short, effective supplier risk management safeguards continuity, enhances operational reliability, and positions businesses to thrive in an increasingly unpredictable marketplace.

How Supplier Risk Management Works

Supplier risk management (SRM) works by systematically identifying, assessing, and mitigating risks that could disrupt supply chains, affect operations, or damage a company’s reputation.

Rather than reacting to problems after they occur, businesses adopt a proactive approach that allows them to anticipate potential threats and implement strategies to minimize impact.

The process typically involves several key steps:

1. Define Scope and Identify Risks

The first step is to define the scope of supplier risk management, including which suppliers, regions, and categories of purchases are most critical to the business. Not all suppliers require the same level of oversight; for example, a vendor providing critical components or services that handle confidential data poses higher risks than a supplier of routine office supplies.

Once the scope is set, companies systematically identify potential risks, including financial instability, operational disruptions, regulatory non-compliance, ethical violations, cybersecurity threats, and geopolitical challenges. Techniques such as SWOT analysis, supplier audits, historical performance data, and stakeholder interviews help uncover vulnerabilities.

2. Assess and Prioritize Risks

After risks are identified, companies evaluate their likelihood and potential impact. Risk scoring models and matrices are commonly used to quantify risks, plotting them according to severity and probability.

High-likelihood, high-impact risks—such as a key supplier operating in a politically unstable region—are prioritized for mitigation, while lower-risk suppliers may require minimal monitoring. This step ensures that resources are allocated efficiently to address the threats most likely to disrupt operations.

3. Develop Mitigation Strategies

Once risks are assessed, businesses create strategies to minimize their impact. Typical approaches include diversifying the supplier base to avoid overreliance on a single vendor, establishing alternative sourcing options, maintaining safety stock, and negotiating flexible contracts that allow rapid adjustments. Contingency planning ensures that, in the event of a disruption, production schedules and customer deliveries can continue with minimal interruption.

4. Perform Due Diligence

Before finalizing supplier relationships, companies conduct thorough due diligence to verify that suppliers have the capacity, expertise, and resources to meet contractual obligations. This may involve site visits, operational audits, financial reviews, and certification checks. Proper vetting reduces the likelihood of unforeseen failures and strengthens the foundation for long-term partnerships.

5. Monitor and Manage Ongoing Risks

Supplier risk management is an ongoing effort. Continuous monitoring through audits, KPIs, performance reviews, and compliance checks helps detect emerging risks early. Technologies like ERP systems—such as Deskera ERP—enable real-time tracking of supplier performance, automated alerts for deviations, and centralized reporting for risk visibility. This proactive oversight ensures that potential issues are addressed before they escalate into full-blown disruptions.

6. Promote Governance and Risk Awareness

Finally, effective SRM relies on governance structures and a culture of risk awareness. Clear roles, responsibilities, and accountability frameworks ensure that risk management activities are integrated across procurement, operations, and compliance teams. Training programs and internal communication foster vigilance, enabling organizations to respond swiftly to changes in supplier risk profiles.

By following this structured approach, companies can proactively manage supplier risks, maintain operational continuity, reduce financial exposure, and build a resilient supply chain capable of withstanding today’s dynamic business challenges.

Supplier Risk Management Mitigation Strategies

Effectively mitigating supplier risks requires a proactive and multi-faceted approach. By implementing targeted strategies, companies can minimize disruptions, protect operational continuity, and strengthen overall supply chain resilience. Key strategies include:

1. Inventory Strategies

Maintaining safety stock is a foundational approach to mitigate supply shocks and fluctuations in demand. By keeping a buffer of essential materials, companies can continue production and fulfill customer orders even if a supplier faces delays. Determining the right level of inventory requires analyzing historical consumption patterns, lead times, and demand variability.

Additionally, adopting flexible capacity—leveraging temporary staff, third-party logistics, or contract manufacturing—allows businesses to scale operations up or down without overcommitting resources, ensuring agility during unforeseen disruptions.

2. Supplier Diversification

Relying heavily on a single supplier creates vulnerability. Diversifying the supplier base across multiple vendors and regions spreads risk, ensuring that disruptions affecting one source do not halt operations.

Many companies blend global and local sourcing to balance cost, quality, and resilience. Nearshoring and regional diversification are also gaining traction, allowing businesses to reduce exposure to political tensions, tariffs, or logistical bottlenecks.

3. Build Redundancies

Redundancies involve creating backup plans across the supply chain. This can include secondary suppliers, alternative transportation routes, and contingency production processes.

For example, a pharmaceutical company dependent on a single specialized ingredient might contract with a second supplier and multiple logistics carriers to ensure uninterrupted supply. Redundancy ensures that if one supplier or transport route is compromised, operations continue without major disruption.

4. Contract Strengthening

Strong contracts are critical to enforce expectations and safeguard against supplier failures. Contracts should clearly define quality standards, delivery timelines, compliance obligations, and consequences for non-performance, such as penalties or service credits.

Dispute resolution clauses, such as arbitration processes, help maintain supplier relationships while addressing issues efficiently. In highly regulated sectors, contracts often include requirements for ongoing compliance verification.

5. Collaboration and Communication

Fostering strong relationships and collaboration with suppliers improves visibility and responsiveness. Open communication helps anticipate potential risks, share contingency plans, and implement joint solutions to minimize disruptions. Encouraging supplier innovation and maintaining healthy competition also drives higher performance standards and operational reliability.

6. Visibility and Monitoring

Enhancing visibility across all tiers of the supply chain allows companies to detect early warning signs of risk. Continuous monitoring, performance tracking, and risk assessments provide actionable insights, enabling timely interventions before issues escalate. Tools like ERP systems, including Deskera ERP, help centralize supplier data, generate real-time alerts, and support analytics-driven decision-making.

7. Compliance and Regulatory Adherence

Ensuring suppliers meet legal, industry, and regulatory standards is a key mitigation strategy. Compliance reduces the risk of fines, operational stoppages, or reputational damage while ensuring smooth continuity of operations. Regular audits and certifications further strengthen confidence in supplier reliability.

By combining these strategies—inventory planning, supplier diversification, redundancies, contract enforcement, collaboration, monitoring, and compliance—companies can proactively reduce supplier risk, maintain operational efficiency, and secure long-term business resilience.

Key Supplier Risk Management KPIs

Measuring supplier performance through key performance indicators (KPIs) is essential for effective supplier risk management. By tracking the right KPIs, businesses can identify vulnerabilities early, monitor ongoing risks, and take corrective actions before disruptions occur. Here are the main categories and examples of KPIs to consider:

1. Process KPIs

- Order Processing / Cycle Time: Measures the efficiency of processing orders and ensures agreements are reached on time. Shorter cycle times reduce delays and help maintain smooth operations.

- Order Accuracy: Tracks the percentage of orders delivered correctly, minimizing inventory discrepancies and ensuring materials are available when needed.

2. Performance KPIs

- On-Time Delivery Rate: Monitors the reliability of suppliers in delivering goods as per agreed schedules, helping prevent production delays.

- Quality Score: Evaluates product or service quality to reduce defects, rework, or returns that can disrupt operations.

- Supplier Lead Time: Measures the time taken from placing an order to receiving goods, ensuring timely planning and inventory management.

3. Compliance KPIs

- Regulatory Compliance Rate: Tracks adherence to legal, safety, and industry-specific standards to avoid fines and operational disruptions.

- Audit Findings: Evaluates suppliers’ compliance with labor, environmental, and other regulatory requirements, highlighting areas needing corrective action.

4. Risk KPIs

- Supplier Risk Score: Aggregates multiple risk factors—financial, operational, and geopolitical—to prioritize mitigation efforts effectively.

- Financial Health Indicators: Monitors suppliers’ liquidity, solvency, and overall financial stability to anticipate potential disruptions.

5. CSR / ESG KPIs

- Sustainability Performance: Measures environmental impact and sustainability practices of suppliers to align with corporate social responsibility goals.

- Ethical Sourcing Rate: Evaluates suppliers’ adherence to ethical sourcing guidelines, fair trade practices, and labor standards, reducing reputational risks.

By continuously monitoring these KPIs, businesses can maintain visibility across their supplier network, detect early warning signs of risk, and ensure a resilient, compliant, and efficient supply chain. Tools like Deskera ERP can help automate KPI tracking, integrate supplier data, and generate real-time insights for better decision-making.

How Deskera ERP Can Help in Supplier Risk Management

Managing supplier risks effectively requires visibility, data-driven insights, and seamless collaboration across the supply chain. Deskera ERP offers a comprehensive platform to streamline these processes, enabling businesses to identify, assess, and mitigate supplier risks proactively. Here’s how it supports supplier risk management:

1. Centralized Supplier Data

Deskera ERP consolidates all supplier information in a single platform, including contracts, certifications, financial records, past performance, and compliance documents. This centralized repository allows procurement teams to quickly evaluate suppliers, track historical performance, and identify potential risks before they escalate.

2. Real-Time Monitoring and Alerts

With real-time dashboards and automated notifications, Deskera ERP helps businesses monitor key supplier KPIs such as delivery timelines, order accuracy, quality metrics, and financial health indicators. Any deviation from expected performance triggers alerts, allowing teams to act promptly and prevent disruptions.

3. Risk Scoring and Analytics

Deskera ERP enables organizations to assign risk scores to suppliers by analyzing multiple factors, including financial stability, operational performance, regulatory compliance, and past incidents. These insights help prioritize mitigation efforts and focus resources on the most critical suppliers.

4. Enhanced Compliance Management

The platform supports regulatory and ethical compliance tracking by storing documentation related to labor standards, environmental regulations, and industry certifications. This ensures that suppliers meet required standards, reducing legal and reputational risks.

5. Supplier Diversification and Contingency Planning

Deskera ERP provides visibility across the supplier base, making it easier to identify alternatives and plan for contingencies. Businesses can evaluate backup suppliers, monitor regional risks, and maintain a diversified supply chain to avoid over-reliance on a single vendor.

6. Automation and Reporting

The ERP system automates data collection, performance tracking, and reporting, saving time and reducing human error. Advanced analytics and customizable reports allow procurement managers to assess supplier risk trends, make informed decisions, and continuously improve risk management strategies.

7. Integration Across Supply Chain Functions

Deskera ERP integrates supplier management with procurement, inventory, and production planning modules. This connectivity ensures that risk management insights directly inform operational decisions, helping businesses maintain uninterrupted production and timely deliveries.

By leveraging Deskera ERP, companies gain the tools needed to proactively manage supplier risks, enhance supply chain resilience, and protect both operational continuity and brand reputation.

Key Takeaways

- Supplier risk management (SRM) is a proactive strategy for identifying, assessing, and mitigating risks within the supplier network to ensure operational continuity, reduce disruptions, and protect the company’s reputation and profitability.

- Supplier risks can be financial, operational, performance-based, regulatory, ethical, cybersecurity-related, or geopolitical. Understanding these categories helps businesses prioritize risk mitigation efforts effectively.

- Implementing SRM reduces disruptions, protects brand reputation, lowers costs, improves reliability, and increases operational efficiency, making it a critical component of a resilient supply chain.

- Effective SRM involves defining the scope, identifying and assessing risks, performing due diligence, developing mitigation strategies, continuous monitoring, and fostering a risk-aware culture across the organization.

- Mitigation strategies include maintaining safety stock, diversifying suppliers, building redundancies, strengthening contracts, collaborating with suppliers, monitoring performance, and ensuring compliance to minimize potential disruptions.

- Tracking KPIs such as on-time delivery, order accuracy, quality scores, supplier risk scores, compliance rates, and financial health indicators provides visibility into supplier performance and enables proactive risk management.

- Deskera ERP centralizes supplier data, monitors performance in real time, provides risk scoring and analytics, enhances compliance tracking, supports contingency planning, automates reporting, and integrates across supply chain functions to strengthen supplier risk management.

Related Articles