What keeps machines running smoothly, costs under control, and operations on track—often without being noticed? The answer is effective maintenance management. Behind every efficient production line or well-functioning facility lies a structured approach to maintaining assets, preventing breakdowns, and ensuring reliability. Without it, even the most advanced equipment can quickly become a source of downtime and unexpected expenses.

Maintenance management goes far beyond fixing equipment when it fails. It involves planning, scheduling, monitoring, and optimizing maintenance activities to extend asset life and improve operational performance. As businesses scale and systems become more complex, a well-defined maintenance management strategy becomes essential to balancing productivity, safety, and cost efficiency.

In today’s competitive environment, unplanned downtime can directly impact revenue, customer satisfaction, and brand reputation. Organizations are increasingly shifting from reactive maintenance to preventive and predictive approaches that rely on data, technology, and standardized processes. This shift allows maintenance teams to act before failures occur, reducing disruptions and enabling more informed decision-making.

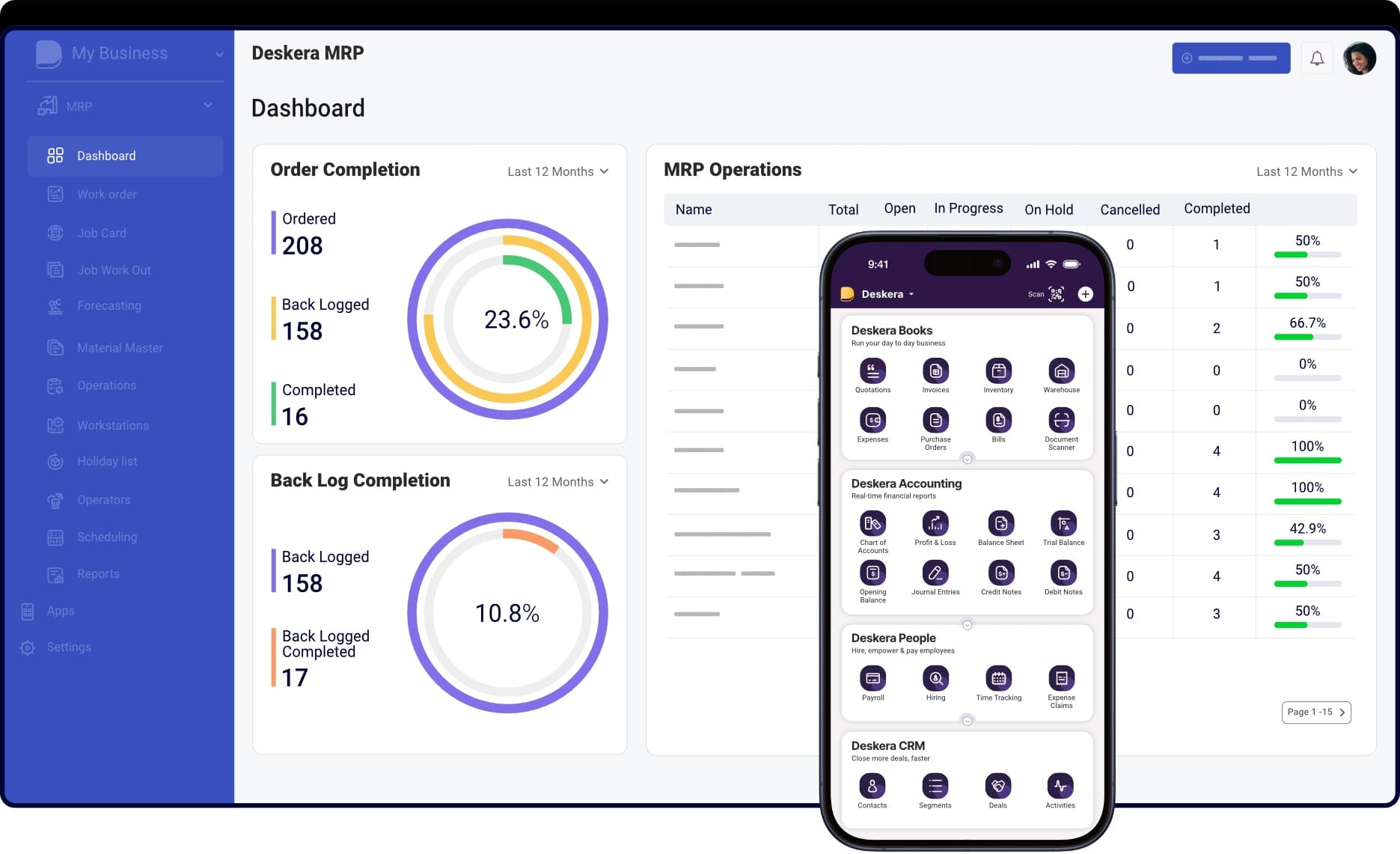

This is where solutions like Deskera MRP play a critical role in modern maintenance management. Deskera MRP helps businesses centralize maintenance data, track asset performance, and plan maintenance activities alongside production schedules. With real-time visibility, automated workflows, and integrated inventory management, it enables organizations to minimize downtime, optimize resource usage, and align maintenance efforts with overall operational goals.

What Is Maintenance Management?

Maintenance management is the structured and strategic process of maintaining an organization’s assets, equipment, and facilities to ensure they operate reliably, efficiently, and cost-effectively. Its primary goal is to maximize asset uptime while controlling time, labor, and maintenance costs—especially in environments where uninterrupted operations are critical, such as manufacturing, utilities, and facilities management.

At its core, maintenance management integrates planning, scheduling, tracking, and execution of maintenance activities. This includes preventive maintenance to avoid failures, timely corrective repairs when issues arise, and efficient allocation of resources such as labor, spare parts, and tools. By optimizing maintenance schedules and reducing unexpected equipment breakdowns, organizations can significantly lower operational costs and improve productivity.

While maintenance management is often associated with manufacturing plants and industrial facilities, its relevance extends to any asset-intensive business where reliability directly impacts performance. From production machinery and utilities to physical infrastructure, maintenance management ensures that resources are used effectively and that production or service delivery continues without disruption. In this sense, it plays a crucial role in achieving operational excellence.

Maintenance management is closely related to Enterprise Asset Management (EAM) but differs in scope. EAM focuses on the entire asset lifecycle—from acquisition to disposal—whereas maintenance management primarily concentrates on the later stages of an asset’s life, emphasizing upkeep, performance optimization, and longevity. Today, what was once a manual, reactive process has evolved into a technology-driven discipline, supported by CMMS and modern best practices that combine software, skilled personnel, and continuous improvement to keep operations running smoothly.

Objectives of Maintenance Management

Maintenance management is a critical function within operations management, aimed at ensuring that assets remain reliable, efficient, and cost-effective throughout their usable life. To achieve this, organizations design maintenance programs around clearly defined objectives that balance performance, cost, safety, and compliance while supporting uninterrupted operations.

Maximizing Asset Reliability

The primary objective of maintenance management is to ensure that equipment and facilities operate consistently with minimal unexpected failures. Reliable assets reduce unplanned downtime, stabilize production schedules, and help organizations meet operational and delivery targets without disruption.

Cost Control and Budget Optimization

Maintenance management focuses on controlling maintenance-related expenses by planning activities in advance and avoiding costly emergency repairs. Through effective budgeting and informed decision-making—such as choosing between short-term savings and long-term durability—organizations can maximize returns on maintenance investments.

Extending Asset Lifecycle

By adopting proactive maintenance practices, organizations can preserve asset health and extend the useful life of machinery and infrastructure. This helps defer expensive replacements, optimize capital utilization, and reduce the total cost of ownership over time.

Minimizing Downtime and Productivity Loss

Well-planned maintenance schedules are designed to minimize asset downtime and keep operations running smoothly. By aligning maintenance activities with production plans, organizations reduce interruptions, maintain workflow continuity, and protect revenue streams.

Improving Operational Efficiency

Maintenance management aims to streamline workflows by optimizing work orders, labor allocation, and resource usage. Well-maintained equipment performs more efficiently, which in turn enhances employee productivity and overall operational effectiveness.

Ensuring Safety and Regulatory Compliance

Another key objective is to maintain assets in line with safety regulations and industry standards. Regular inspections, documented maintenance, and timely repairs help minimize workplace hazards, reduce legal risks, and foster a strong culture of safety.

Effective Work Scheduling and Resource Allocation

Scheduling maintenance tasks at the right time is a delicate balance between asset availability and operational needs. Maintenance management ensures that work is planned with minimal disruption while making optimal use of skilled personnel, tools, and spare parts.

Training and Skill Development

Maintenance programs often include training objectives to ensure employees are equipped to operate and maintain equipment safely and efficiently. Continuous training improves maintenance quality, reduces human error, and supports long-term operational resilience.

Continuous Improvement Through Data and Insights

Modern maintenance management emphasizes analyzing historical data and performance reports to uncover trends, recurring failures, and improvement opportunities. Insights from CMMS reports enable better planning, smarter scheduling, and ongoing optimization of maintenance strategies.

Types of Maintenance Management

Maintenance management is not a one-size-fits-all practice. Organizations adopt different types of maintenance approaches based on asset criticality, cost considerations, operational risk, and available technology. Understanding these types helps businesses design a balanced maintenance strategy that minimizes downtime while optimizing cost and performance.

Reactive (Run-to-Failure) Maintenance

Reactive maintenance, also known as run-to-failure maintenance, involves repairing or replacing equipment only after it breaks down. This approach is typically suitable for low-cost, non-critical assets where downtime does not significantly impact operations or safety. While it requires minimal planning and upfront cost, overreliance on reactive maintenance can lead to unexpected failures, higher repair costs, and operational disruptions for critical assets.

Preventive Maintenance

Preventive maintenance is a proactive approach where maintenance tasks are scheduled at regular intervals based on time, usage, or manufacturer recommendations. The goal is to prevent equipment failures before they occur by addressing wear and tear early. This type of maintenance improves asset reliability, extends equipment life, and supports regulatory compliance, though it can sometimes result in over-maintenance if not optimized properly.

Predictive Maintenance

Predictive maintenance uses data, sensors, and analytics to predict when equipment is likely to fail. By monitoring parameters such as vibration, temperature, or pressure, maintenance teams can intervene only when indicators suggest an impending issue. This just-in-time approach reduces unnecessary maintenance, minimizes unplanned downtime, and improves overall maintenance efficiency, though it requires higher upfront investment and technical expertise.

Condition-Based Maintenance

Condition-based maintenance relies on real-time monitoring of asset conditions to trigger maintenance actions when predefined thresholds are reached. Unlike time-based schedules, maintenance decisions are driven by the actual health of the equipment. This targeted approach ensures resources are used efficiently, avoids premature servicing, and helps prevent failures caused by deteriorating conditions.

Reliability-Centered Maintenance (RCM)

Reliability-centered maintenance focuses on identifying the most effective maintenance strategy for each asset based on its function, failure modes, and operational risk. Rather than applying the same approach across all equipment, RCM prioritizes assets that have the greatest impact on safety, production, and cost. This method helps organizations allocate maintenance resources where they deliver the highest value.

Total Productive Maintenance (TPM)

Total Productive Maintenance emphasizes shared responsibility for equipment maintenance across the entire organization. Operators, technicians, and management all play a role in maintaining asset health through routine checks, preventive actions, and continuous improvement initiatives. TPM fosters a culture of ownership, improves equipment effectiveness, enhances safety, and drives long-term operational efficiency.

CMMS-Driven Maintenance Management

CMMS-driven maintenance management leverages software to centralize maintenance data, automate scheduling, manage work orders, and track asset performance. By providing real-time visibility and historical insights, a CMMS enables better planning, cost control, compliance tracking, and continuous improvement. This technology-driven approach transforms maintenance from a reactive function into a strategic contributor to operational excellence.

Key Components of an Effective Maintenance Management System

An effective maintenance management system brings structure, visibility, and control to maintenance operations. Rather than functioning as isolated activities, maintenance processes are integrated to ensure asset reliability, cost efficiency, and operational continuity. The following components form the foundation of a robust maintenance management system.

Asset and Equipment Management

This component focuses on maintaining a centralized record of all assets, including their specifications, usage history, maintenance requirements, and lifecycle status. Accurate asset tracking enables better planning, improves accountability, and supports informed decisions related to repairs, upgrades, or replacements.

Work Order Management

Work order management streamlines how maintenance tasks are created, assigned, executed, and tracked. It ensures that maintenance requests are clearly documented, prioritized, and completed on time, improving coordination between maintenance teams and reducing response times.

Maintenance Planning and Scheduling

Effective planning and scheduling ensure that maintenance activities are carried out at the right time with minimal disruption to operations. This component balances asset availability, workforce capacity, and production schedules to reduce downtime and avoid last-minute, reactive repairs.

Spare Parts and Inventory Control

Managing spare parts and maintenance inventory is critical to avoiding delays and excess costs. An effective system tracks stock levels, usage patterns, and reorder points to ensure that the right parts are available when needed—without tying up capital in excess inventory.

Preventive and Predictive Maintenance Programs

A strong maintenance management system supports both preventive and predictive maintenance approaches. Preventive maintenance reduces the likelihood of failures through scheduled tasks, while predictive maintenance uses data and condition monitoring to intervene before breakdowns occur.

Performance Monitoring and Reporting

Tracking maintenance metrics such as downtime, mean time between failures (MTBF), and maintenance costs provides valuable insights into system performance. Regular reporting helps identify inefficiencies, uncover trends, and drive continuous improvement in maintenance strategies.

Safety, Compliance, and Documentation

This component ensures that maintenance activities adhere to safety standards, regulatory requirements, and internal policies. Proper documentation of inspections, repairs, and compliance checks reduces risk, supports audits, and promotes a safe working environment.

Technology and System Integration

Modern maintenance management systems rely on digital tools such as CMMS and ERP platforms to centralize data and automate workflows. Integration with other business systems improves data accuracy, enhances visibility across departments, and enables more strategic decision-making.

Maintenance Management Process Explained

The maintenance management process provides a structured framework for keeping assets reliable, safe, and cost-effective throughout their operational life. Rather than reacting to breakdowns, an effective process ensures maintenance activities are planned, executed, monitored, and continuously improved to support uninterrupted operations.

Identifying Maintenance Requirements

The process begins with identifying what assets require maintenance and why. This includes assessing equipment criticality, understanding failure patterns, reviewing manufacturer recommendations, and analyzing historical performance data. Clear identification helps prioritize maintenance tasks based on operational risk and business impact.

Planning Maintenance Activities

Once requirements are identified, maintenance tasks are planned in detail. This involves defining the scope of work, estimating labor and material needs, preparing tools and spare parts, and establishing standard procedures. Proper planning minimizes delays, avoids resource shortages, and improves execution efficiency.

Scheduling and Resource Allocation

Scheduling determines when maintenance activities will be performed and who will carry them out. Maintenance managers balance asset availability, production demands, and workforce capacity to minimize disruption. Effective scheduling ensures that the right people and resources are available at the right time.

Executing Maintenance Tasks

This stage involves carrying out the planned maintenance work, whether preventive, predictive, or corrective. Technicians follow defined procedures, complete inspections or repairs, and document all actions taken. Accurate execution and documentation are essential for quality control and future analysis.

Monitoring and Performance Tracking

After execution, maintenance performance is monitored using key metrics such as downtime, maintenance costs, and equipment reliability. Tracking performance provides visibility into how well assets are functioning and whether maintenance objectives are being met.

Reviewing and Analyzing Results

Data collected during maintenance activities is analyzed to identify trends, recurring issues, and improvement opportunities. Root cause analysis helps uncover underlying problems, enabling teams to prevent repeated failures rather than treating symptoms.

Continuous Improvement and Optimization

The final step focuses on refining the maintenance process over time. Insights from performance analysis are used to optimize maintenance schedules, update strategies, improve workflows, and adopt better technologies. Continuous improvement ensures the maintenance management process evolves alongside business needs and operational complexity.

Benefits of Maintenance Management

Effective maintenance management delivers far-reaching benefits that go beyond keeping equipment operational. By shifting from reactive fixes to a structured, data-driven approach, organizations can improve productivity, reduce costs, enhance safety, and make better long-term decisions. In fact, a significant portion of unplanned downtime is caused by aging equipment and mechanical failure—risks that can be substantially reduced with the right maintenance practices in place.

Improved Asset and Workforce Productivity

Well-maintained equipment operates more reliably, allowing employees to work without frequent interruptions or safety concerns. In industrial environments, this means smoother production flows and fewer disruptions, while in offices and facilities, it ensures comfortable, safe working conditions. Proactive maintenance helps both people and machines perform at their best.

Reduced Maintenance and Repair Costs

Planned maintenance is far more cost-effective than emergency repairs. Reactive, run-to-failure scenarios often involve expedited spare parts, higher labor costs, and extended downtime. Maintenance management helps control expenses by preventing breakdowns, optimizing spare parts usage, and avoiding costly last-minute interventions.

Increased Asset Uptime and Longer Lifespan

Regular inspections and timely maintenance improve asset reliability and availability. By tracking metrics such as MTBF, MTTR, and remaining useful life, organizations ensure assets operate as intended, deliver maximum ROI, and reach their full lifecycle—reducing the need for premature replacements.

Enhanced Safety and Regulatory Compliance

Maintenance management plays a critical role in maintaining a safe working environment. Regularly serviced equipment is less likely to malfunction, reducing the risk of workplace accidents and injuries. At the same time, documented maintenance activities help organizations meet regulatory requirements and avoid penalties or legal issues.

Data-Driven Decision-Making

A mature maintenance management program relies on accurate, historical data collected through inspections, work orders, and performance tracking. This data uncovers recurring issues, failure patterns, and cost trends, enabling informed decisions around repair-versus-replace, budgeting, and capital investments.

Improved Operational Efficiency

By minimizing downtime and eliminating unplanned disruptions, maintenance management helps operations run more efficiently. Equipment availability improves, workflows stabilize, and organizations can meet production targets without constant firefighting.

Time Savings for Maintenance Teams

Clear maintenance plans ensure technicians arrive prepared—with the right tools, spare parts, and instructions—to complete tasks efficiently. This reduces repeat visits, saves time, and allows teams to focus on higher-value activities instead of emergency repairs.

Reduced Human Error and Process Gaps

Standardized procedures, automation, and digital tracking reduce the likelihood of missed tasks or inconsistent maintenance practices. Well-maintained facilities and automated alerts help minimize human error and improve overall reliability.

Identification of Maintenance Trends and Improvement Opportunities

Maintenance management systems provide visibility into daily operations and long-term performance trends. If an asset or component consistently underperforms, teams can quickly identify the issue and take corrective action—driving continuous improvement across maintenance and operations.

Energy and Sustainability Benefits

Properly maintained equipment operates more efficiently and consumes less energy. Over time, this leads to lower energy costs, reduced environmental impact, and more sustainable operations—an increasingly important consideration for modern organizations.

Together, these benefits position maintenance management as a strategic enabler of operational excellence rather than just a support function.

Challenges in Maintenance Management

Maintenance management is essential for keeping assets reliable and operations running smoothly, but it comes with a unique set of challenges. As organizations grow, assets age, and operations become more complex, maintenance teams must navigate financial, operational, and organizational constraints that can limit effectiveness if not addressed proactively.

Budget Constraints and Cost Pressures

Limited maintenance budgets are one of the most common challenges organizations face. When funds are tight, maintenance activities are often deferred to reduce short-term costs. However, postponed maintenance can lead to equipment failures, safety risks, higher repair expenses, and shortened asset lifespans. Budget constraints also restrict investments in modern tools, training, and technologies that could improve long-term efficiency.

Balancing Preventive and Reactive Maintenance

Finding the right balance between preventive and reactive maintenance is difficult. Over-maintenance increases costs and resource usage, while under-maintenance leads to frequent breakdowns and downtime. Unpredictable equipment failures and limited resources make it challenging to design maintenance schedules that are both cost-effective and operationally sound.

Managing Spare Parts and Inventory

Ensuring the availability of the right spare parts at the right time is a complex task. Maintenance teams often manage large inventories with hundreds or thousands of parts, each with different suppliers, lead times, and usage patterns. Poor inventory visibility can lead to stockouts, emergency purchases, excess inventory, or obsolete parts—each of which impacts uptime and costs.

Aging Assets and Infrastructure

As equipment and facilities age, they require more frequent maintenance and repairs. Older assets are more prone to breakdowns, harder to service, and may rely on obsolete components that are difficult to source. Aging infrastructure also increases safety risks and puts additional strain on maintenance budgets and skilled labor availability.

Maintenance Planning and Scheduling Complexity

Effective maintenance requires careful coordination to minimize operational disruptions. Unexpected breakdowns often force teams to reprioritize work, pushing planned maintenance aside. Limited manpower, tight production schedules, and regulatory requirements further complicate planning and scheduling efforts.

Compliance and Regulatory Requirements

Many industries are subject to strict safety, environmental, and operational regulations. Keeping up with inspections, documentation, audits, and compliance timelines adds administrative burden and increases the complexity of maintenance management—especially when managed manually.

Lack of Skilled Maintenance Workforce

A shortage of skilled technicians and experienced maintenance professionals is an increasing challenge. Retiring workforces, limited training opportunities, and evolving technology make it difficult for organizations to maintain the required skill levels, leading to longer repair times and reduced maintenance quality.

Poor Data Visibility and Fragmented Information

When maintenance data is spread across spreadsheets, paper logs, and disconnected systems, teams lack real-time visibility into asset health and maintenance performance. This fragmentation hinders analysis, slows decision-making, and prevents teams from identifying recurring issues or optimization opportunities.

Coordination Across Teams and Departments

Maintenance activities often require collaboration between operations, procurement, safety, and finance teams. Siloed departments, misaligned priorities, and poor communication can delay approvals, disrupt schedules, and lead to inefficient use of shared resources.

Unplanned Downtime and Emergency Repairs

Unexpected equipment failures can derail maintenance plans and divert resources from strategic initiatives. Emergency repairs are typically more expensive, disruptive, and stressful for maintenance teams, making it difficult to maintain long-term improvement programs.

Adapting to New Technologies

While digital tools and automation offer significant benefits, adopting new maintenance technologies can be challenging. High upfront costs, integration issues, resistance to change, and the need for employee training often slow down digital transformation efforts.

Managing Maintenance in Multi-Site Operations

For organizations operating across multiple locations, maintaining consistent standards and visibility is difficult. Differences in processes, asset types, and local regulations can lead to uneven maintenance performance and higher operational risk.

Together, these challenges highlight why maintenance management requires a structured, data-driven, and continuously evolving approach to remain effective in modern operations.

Maintenance Management Best Practices

Effective maintenance management is built on clarity, consistency, and continuous improvement. By following proven best practices, organizations can reduce downtime, control costs, improve asset reliability, and create a safer, more efficient operating environment.

Establish Clear Objectives and Goals

Begin by defining what success looks like for your maintenance program. Objectives may include reducing unplanned downtime, extending equipment lifespan, improving safety, or lowering maintenance costs. Clear goals provide direction, align teams, and make it easier to measure performance and ROI.

Conduct a Maintenance Audit and Asset Assessment

Before improving maintenance processes, assess the current state of equipment and facilities. Reviewing maintenance logs, inspecting assets, and analyzing historical costs helps identify weaknesses, recurring failures, and improvement opportunities. This baseline assessment ensures maintenance efforts are targeted and effective.

Implement the Right Maintenance Strategy Mix

No single maintenance strategy fits all assets. Combine approaches such as reactive, preventive, predictive, condition-based, reliability-centered, and total productive maintenance based on asset criticality and operational needs. A balanced strategy maximizes reliability while controlling costs.

Tag and Standardize Asset Identification

Tagging equipment with asset IDs, barcodes, or labels creates the foundation for accurate tracking and reporting. Clear asset identification improves work order accuracy, simplifies inspections, supports inventory control, and ensures maintenance activities are properly logged against the right equipment.

Allocate Resources Effectively

A strong maintenance program requires the right balance of skilled personnel, tools, spare parts, and budget. Resource allocation should reflect asset criticality and operational risk. Investing appropriately in maintenance prevents larger costs caused by failures and emergency repairs.

Deploy a CMMS or Maintenance Management Software

Centralized maintenance software improves visibility, coordination, and control. A CMMS helps schedule tasks, track work orders, manage assets and inventory, capture performance data, and support data-driven decisions—transforming maintenance into a strategic function.

Develop and Maintain Preventive Maintenance Schedules

Create detailed inspection and routine maintenance schedules based on asset usage, manufacturer recommendations, and performance history. Well-structured preventive maintenance reduces breakdowns, stabilizes operations, and improves long-term asset health.

Train and Educate Employees

Maintenance effectiveness depends on people as much as processes. Ensure technicians and equipment users understand their roles, follow standard procedures, and adhere to safety protocols. Regular training improves maintenance quality, reduces human error, and enhances workplace safety.

Maintain Strong Safety and Compliance Practices

Integrate safety and regulatory requirements into all maintenance activities. Regularly review and update procedures to align with industry standards, audits, and inspections. Consistent compliance reduces legal risk and protects employees and assets.

Monitor Performance Using KPIs

Track key performance indicators such as downtime, MTBF, MTTR, maintenance costs, and asset utilization. Continuous monitoring helps evaluate whether maintenance objectives are being met and highlights areas for improvement.

Commit to Continuous Improvement

Maintenance management is not static. Encourage feedback from technicians and operations teams, analyze performance trends, and refine strategies over time. Continuous improvement ensures the maintenance program evolves with changing assets, technologies, and business needs.

Maintain Thorough Documentation

Accurate documentation supports compliance, audits, performance analysis, and future planning. Recording maintenance activities, costs, outcomes, and improvements ensures transparency and provides valuable insights for long-term decision-making.

Together, these best practices help organizations build a structured, proactive, and resilient maintenance management program that delivers sustained operational value.

Maintenance Management Metrics and KPIs

Maintenance management metrics and key performance indicators (KPIs) play a critical role in evaluating how effective, efficient, and reliable your maintenance operations truly are. These measurements help organizations move beyond reactive decision-making and instead rely on data to improve asset performance, reduce downtime, optimize costs, and extend equipment lifespan. When tracked consistently, they provide clear visibility into what’s working, what’s not, and where corrective action is needed.

Before diving into individual KPIs, it’s important to distinguish between maintenance metrics and maintenance KPIs. Maintenance metrics are operational, activity-based measurements—such as the number of work orders completed, total downtime hours, or maintenance costs incurred. KPIs, on the other hand, are higher-level performance indicators aligned with strategic objectives. They reflect the overall health of your maintenance program and its impact on productivity, reliability, safety, and profitability. While the distinction may blur in practice, together they form the foundation of a data-driven maintenance strategy.

Mean Time to Repair (MTTR)

Mean Time to Repair measures the average time required to restore an asset to operational condition after a failure. It reflects how quickly maintenance teams can diagnose issues, mobilize resources, and complete repairs.

Formula: MTTR = Total Downtime / Total Number of Repairs

A lower MTTR indicates efficient troubleshooting and repair processes, while a higher MTTR may signal skill gaps, spare part delays, or procedural inefficiencies.

Mean Time Between Failures (MTBF)

MTBF is a key reliability metric that measures the average operating time between equipment failures. It helps identify assets that are prone to breakdowns and supports better maintenance planning.

Formula: MTBF = (Total Operating Time – Unplanned Downtime) / Number of Failures

An increasing MTBF over time generally indicates that preventive and predictive maintenance strategies are working effectively.

Preventive Maintenance Compliance (PMC)

Preventive Maintenance Compliance measures how well scheduled preventive tasks are executed on time. It reflects discipline in maintenance planning and execution.

Formula: PMC = (Number of Executed Tasks / Number of Planned Tasks) × 100

Most organizations target a PMC of 90% or higher to minimize unexpected failures and downtime.

Maintenance Backlog

The maintenance backlog represents all identified but incomplete maintenance work, including preventive, corrective, and predictive tasks. It is often expressed in total hours, number of work orders, or weeks of work.

Tracking backlog helps maintenance leaders balance workloads, allocate resources effectively, and prevent critical work from being delayed excessively.

Unplanned Machine Downtime

Unplanned downtime measures the time equipment is unexpectedly unavailable due to failures or breakdowns. This metric directly impacts productivity, revenue, and customer commitments.

It is calculated by logging all unexpected stoppages and summing their durations over a defined period. Many organizations also translate downtime into lost production or revenue to quantify its financial impact.

Maintenance Cost as a Percentage of Replacement Value (MC/ERV)

This metric compares maintenance spending against the estimated replacement value of an asset, helping assess whether maintenance costs are economically justified.

Formula: Maintenance Cost % = (Total Maintenance Costs / Estimated Replacement Value) × 100

A very high ratio may indicate aging or inefficient equipment, while a very low ratio could suggest under-maintenance and increased failure risk.

Cost to Repair vs. Cost to Replace

This comparison helps determine whether it is more economical to continue maintaining an asset or replace it altogether. It considers annual maintenance costs versus the annualized cost of replacement plus expected maintenance.

While cost is a key factor, decisions should also account for reliability, efficiency improvements, energy savings, and operational risk.

Overall Equipment Effectiveness (OEE)

OEE is a comprehensive metric that measures how effectively equipment is utilized during planned production time. It combines three factors: Availability, Performance, and Quality.

Formula: OEE = Availability × Performance × Quality

An OEE score of 85% is generally considered world-class, while 100% indicates perfect production with no downtime, speed losses, or quality defects.

Scheduled Maintenance Critical Percent (SMCP)

SMCP indicates the proportion of scheduled maintenance tasks that are critical to safety, operations, or business continuity.

Formula: SMCP = (Number of Critical Tasks / Total Scheduled Tasks) × 100

A high SMCP highlights strong dependency on critical assets and helps prioritize resources and risk mitigation efforts.

Asset Utilization Rate

Asset Utilization Rate measures how effectively assets are used relative to their available operating time.

Formula: Asset Utilization Rate = (Actual Operating Time / Available Operating Time) × 100

Low utilization may indicate capacity imbalances, planning inefficiencies, or equipment redundancy.

Safety Incidents Rate

This KPI tracks the frequency of safety incidents relative to hours worked, offering insight into workplace safety performance.

Formula: Safety Incidents Rate = (Number of Incidents / Total Hours Worked) × 100,000

Monitoring this metric helps identify safety risks associated with maintenance activities and supports continuous improvement in safety practices.

Maintenance Cost per Unit

Maintenance Cost per Unit evaluates maintenance spending relative to production output, linking maintenance efficiency directly to operational costs.

Formula: Maintenance Cost per Unit = Total Maintenance Costs / Total Units Produced

A rising cost per unit may signal inefficiencies, excessive breakdowns, or poor asset performance.

Distribution by Types of Maintenance Performed

This metric analyzes how maintenance activities are distributed across preventive, predictive, corrective, and condition-based maintenance.

Formula: Percent of Maintenance Type = (Number of Specific Maintenance Activities / Total Maintenance Activities) × 100

A healthy maintenance program typically shows a higher share of preventive and predictive maintenance compared to reactive work.

Work Order Cycle Time

Work Order Cycle Time measures how long it takes to complete a maintenance request from creation to closure.

Formula: Work Order Cycle Time = End Time – Start Time

Shorter cycle times indicate responsive and efficient maintenance operations, while longer cycles may reveal bottlenecks or resource constraints.

Inventory Turnover Ratio (MRO Inventory)

This KPI measures how efficiently maintenance inventory, such as spare parts and consumables, is used and replenished.

Formula: Inventory Turnover Ratio = MRO Expenditure / Average Maintenance Inventory

An optimal turnover ratio balances availability with reduced carrying and obsolescence costs.

Overtime

Overtime tracks the number of hours worked beyond standard schedules and serves as an indicator of workforce efficiency and maintenance planning effectiveness.

Formula: Overtime Hours = Actual Hours Worked – Standard Hours

Consistently high overtime may point to staffing shortages, frequent breakdowns, or inadequate preventive maintenance.

Together, these maintenance management metrics and KPIs provide a comprehensive framework for evaluating performance, improving reliability, controlling costs, and aligning maintenance efforts with broader business goals. When supported by the right systems and processes, they enable maintenance teams to shift from firefighting mode to proactive, strategic asset management.

How Deskera MRP Helps You Streamline Maintenance Management

Deskera MRP supports maintenance management by bringing structure, visibility, and data-driven control to how organizations manage assets, schedules, and resources. Instead of relying on disconnected tools or manual tracking, Deskera MRP enables teams to plan, execute, and monitor maintenance activities within a unified manufacturing and operations ecosystem.

Centralized Asset and Maintenance Data

Deskera MRP allows businesses to maintain a single source of truth for machines, equipment, and production assets. Maintenance histories, usage patterns, and operational data are stored centrally, making it easier to identify recurring issues, assess asset health, and make informed maintenance decisions. This visibility reduces guesswork and supports long-term asset reliability.

Preventive Maintenance Planning Aligned with Production

With Deskera MRP, maintenance schedules can be aligned with production plans. Teams can plan preventive maintenance during low-production periods, minimizing disruption and avoiding costly unplanned downtime. This alignment helps improve preventive maintenance compliance while ensuring that production targets remain on track.

Work Order Tracking and Execution

Deskera MRP streamlines the creation, assignment, and tracking of maintenance-related work orders. Maintenance teams can monitor task status, prioritize critical repairs, and reduce work order cycle times. This structured workflow improves accountability and ensures that maintenance activities are completed efficiently and on time.

Inventory Control for Maintenance Spare Parts

Maintenance often suffers from spare part shortages or excess inventory. Deskera MRP integrates maintenance needs with inventory management, ensuring critical spare parts and MRO items are available when required. This helps reduce maintenance delays, optimize inventory turnover, and control carrying costs.

Real-Time Reporting and Maintenance Insights

Deskera MRP provides real-time dashboards and reports that help track maintenance KPIs such as downtime, maintenance costs, and asset utilization. These insights allow maintenance managers to identify trends, evaluate performance, and continuously improve maintenance strategies based on actual data.

Improved Cost Control and Resource Utilization

By linking maintenance activities with labor, inventory, and production data, Deskera MRP enables better control over maintenance costs. Organizations can track maintenance cost per unit, analyze repair versus replacement decisions, and allocate resources more effectively to maximize asset lifespan and ROI.

Scalable Support for Growing Operations

As operations grow in size or complexity, Deskera MRP scales with the business. It supports multi-location manufacturing environments and evolving maintenance requirements, making it suitable for organizations transitioning from reactive maintenance to more structured, preventive, and reliability-focused maintenance management.

Overall, Deskera MRP helps transform maintenance management from a reactive, siloed function into a strategic, well-coordinated process that improves equipment reliability, reduces downtime, and supports long-term operational efficiency.

Key Takeaways

- Maintenance management is a strategic function that ensures asset reliability, reduces operational disruptions, and supports long-term cost control across the equipment lifecycle.

- Using the right mix of reactive, preventive, predictive, condition-based, reliability-centered, TPM, and CMMS-driven maintenance helps organizations balance risk, cost, and performance.

- Reactive (run-to-failure) maintenance may seem cost-effective initially but often results in higher downtime and repair expenses when applied to critical assets.

- Preventive maintenance minimizes unexpected breakdowns by addressing issues early, improving equipment lifespan and operational consistency.

- Predictive maintenance leverages data and monitoring tools to forecast failures, enabling timely interventions and reducing unnecessary maintenance work.

- Condition-based maintenance ensures maintenance actions are taken only when asset conditions indicate a need, optimizing resource utilization.

- Reliability-centered maintenance prioritizes maintenance efforts based on asset criticality, improving safety, reliability, and cost efficiency.

- Total productive maintenance builds a culture of shared ownership by involving operators in routine maintenance, boosting productivity and equipment availability.

- CMMS-driven maintenance centralizes work orders, asset data, and performance tracking, enabling better visibility and informed decision-making.

- An effective maintenance management system depends on clear objectives, accurate asset data, skilled personnel, standardized workflows, and reliable performance reporting.

- A structured maintenance management process—from assessment and planning to execution and continuous improvement—ensures maintenance efforts align with business goals.

- Maintenance management best practices such as regular audits, preventive scheduling, workforce training, safety compliance, and performance monitoring drive sustained operational excellence.

- Maintenance management metrics and KPIs like MTTR, MTBF, OEE, downtime, backlog, and maintenance costs provide actionable insights into efficiency, reliability, and ROI.

- The benefits of maintenance management include reduced downtime, extended asset life, improved safety, better resource utilization, and stronger alignment between maintenance and production goals.

- Common challenges in maintenance management include budget constraints, aging infrastructure, spare parts complexity, unplanned downtime, scheduling conflicts, data silos, and difficulty balancing preventive and reactive maintenance.

- Deskera MRP supports maintenance management by integrating maintenance planning with production, inventory, and analytics, helping organizations shift from reactive fixes to proactive, data-driven maintenance strategies.